Method for assessing nonuniform humidity degrees of oil-paper insulation components

A technology of insulating components and oil-impregnated paper, which is applied in the field of evaluating the uneven moisture content of oil-impregnated paper insulating components, which can solve the problems of low measurement accuracy, low measurement accuracy, and damage to equipment insulation, so as to improve accuracy and precision , the effect of non-destructive testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be illustrated below with reference to the accompanying drawings.

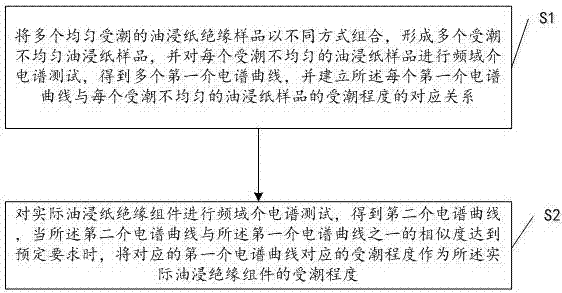

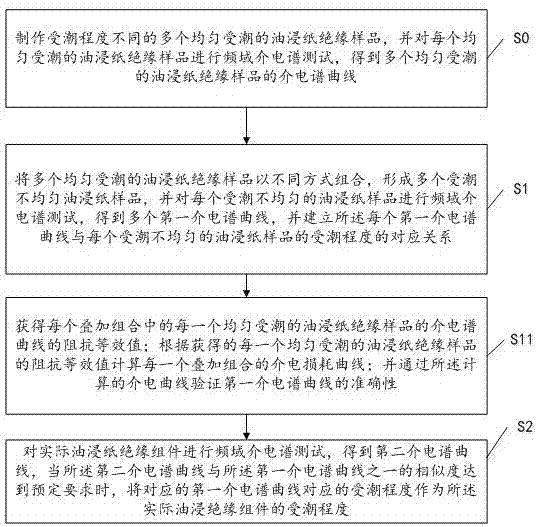

[0028] figure 1 It is a schematic flowchart of an embodiment of a method for evaluating the degree of uneven damping of an oil-impregnated paper insulation assembly according to the present invention. The applicable object of the invention is the insulation system of equipment such as oil-immersed transformer, oil-paper bushing and oil-immersed capacitor.

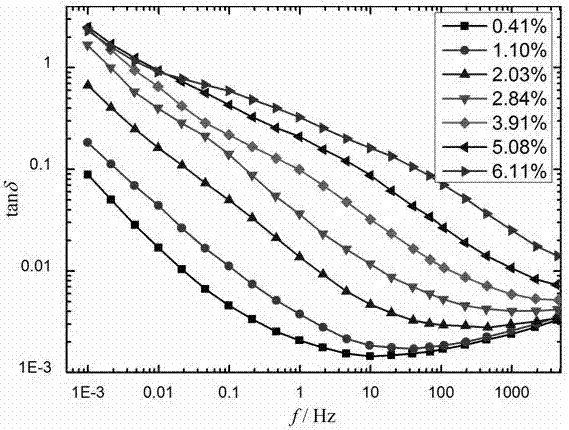

[0029] Step S1, combining the plurality of uniformly damp oil-soaked paper insulation samples in different ways to form a plurality of non-uniformly damp oil-soaked paper samples, and performing frequency-domain dielectric spectroscopy on each non-uniformly damp oil-soaked paper sample Test to obtain a plurality of first dielectric spectrum curves, and establish a corresponding relationship between each of the first dielectric spectrum curves and the moisture content of each non-uniform oil-impregnated paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com