Waste box for collecting metal chips

A technology for metal chips and waste bins, which is used in metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as non-compliance with emission standards, and achieve the effect of meeting emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

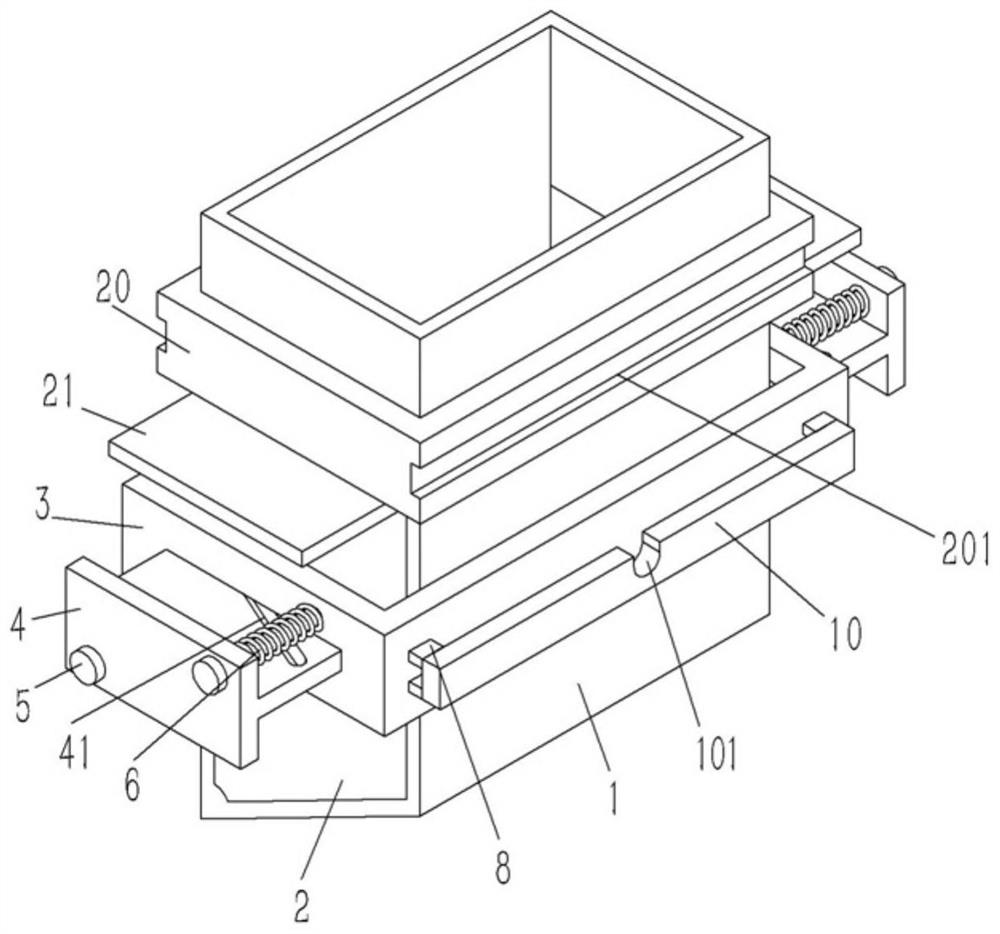

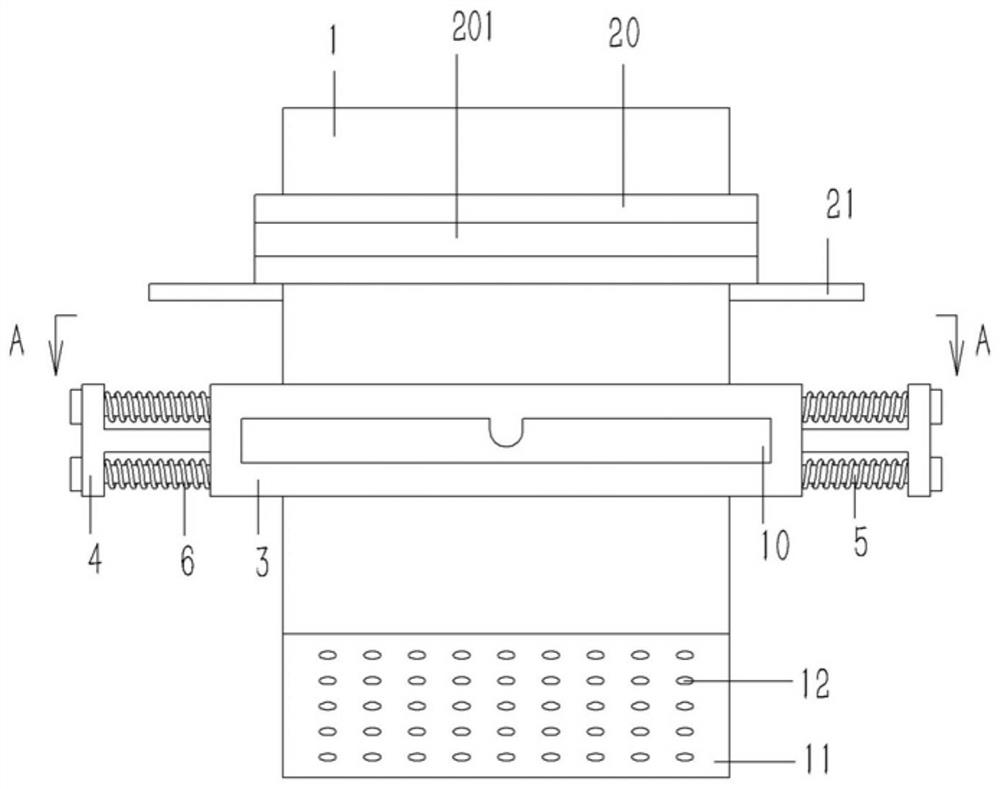

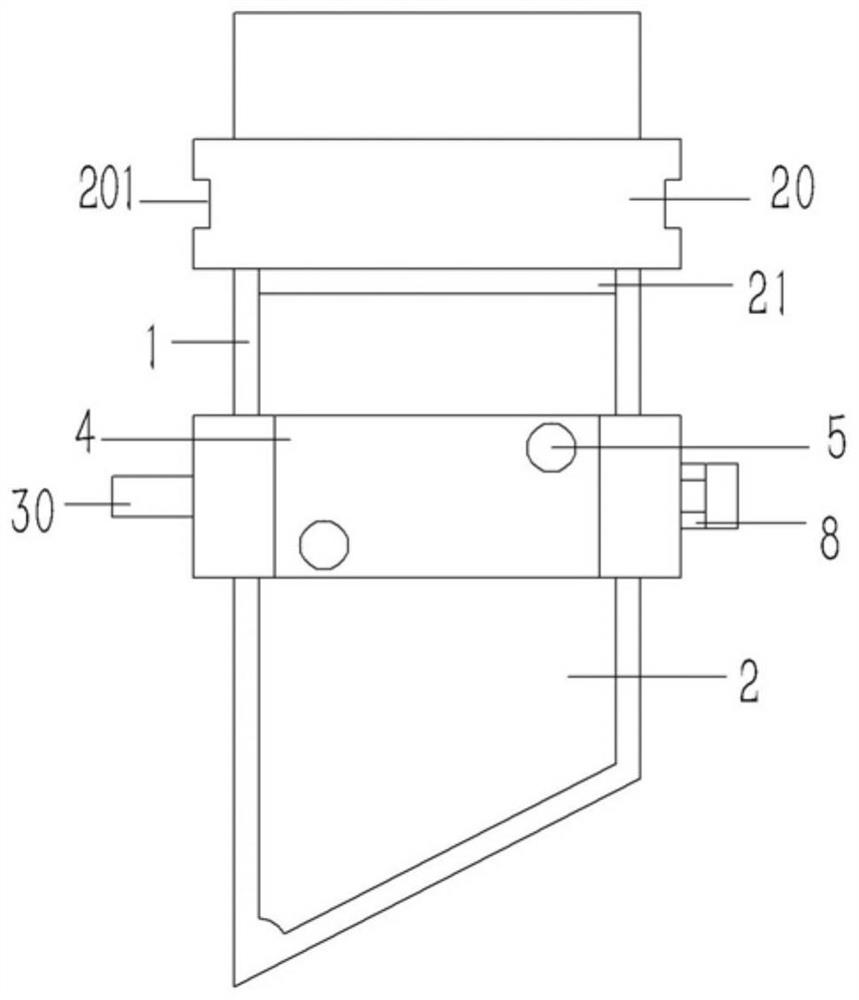

[0020] Example: see Figures 1 to 4 As shown, a waste box for collecting metal chips includes a rectangular box body 1. The lower end of the box body 1 is formed with a slanted bottom 11, and several water filter holes 12 are formed on the slanted bottom 11. The left and right sides of the box body 1 are opposite to each other. A splint 2 is plugged into the side wall, and the upper end of the splint 2 is bent to form a horizontal baffle plate 21, which is distributed on both sides of the box body 1; Support frame 3, there is a gap between the left and right frames of the lower support frame 3 and the left and right side walls of the box body 1; the left and right frames of the lower support frame 3 are plugged with a T-shaped drive plate 4, The inner side of the drive plate 4 is fixed on the splint 2, the drive plate 4 is composed of a horizontal part and a vertical part, an inclined guide groove 41 is formed on the horizontal part of the drive plate 4, and a guide groove 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com