Reinforced concrete hollow brick and preparation method thereof

A technology for concrete and hollow bricks is applied in the field of brick body manufacturing to achieve the effects of increased compressive strength, low manufacturing cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

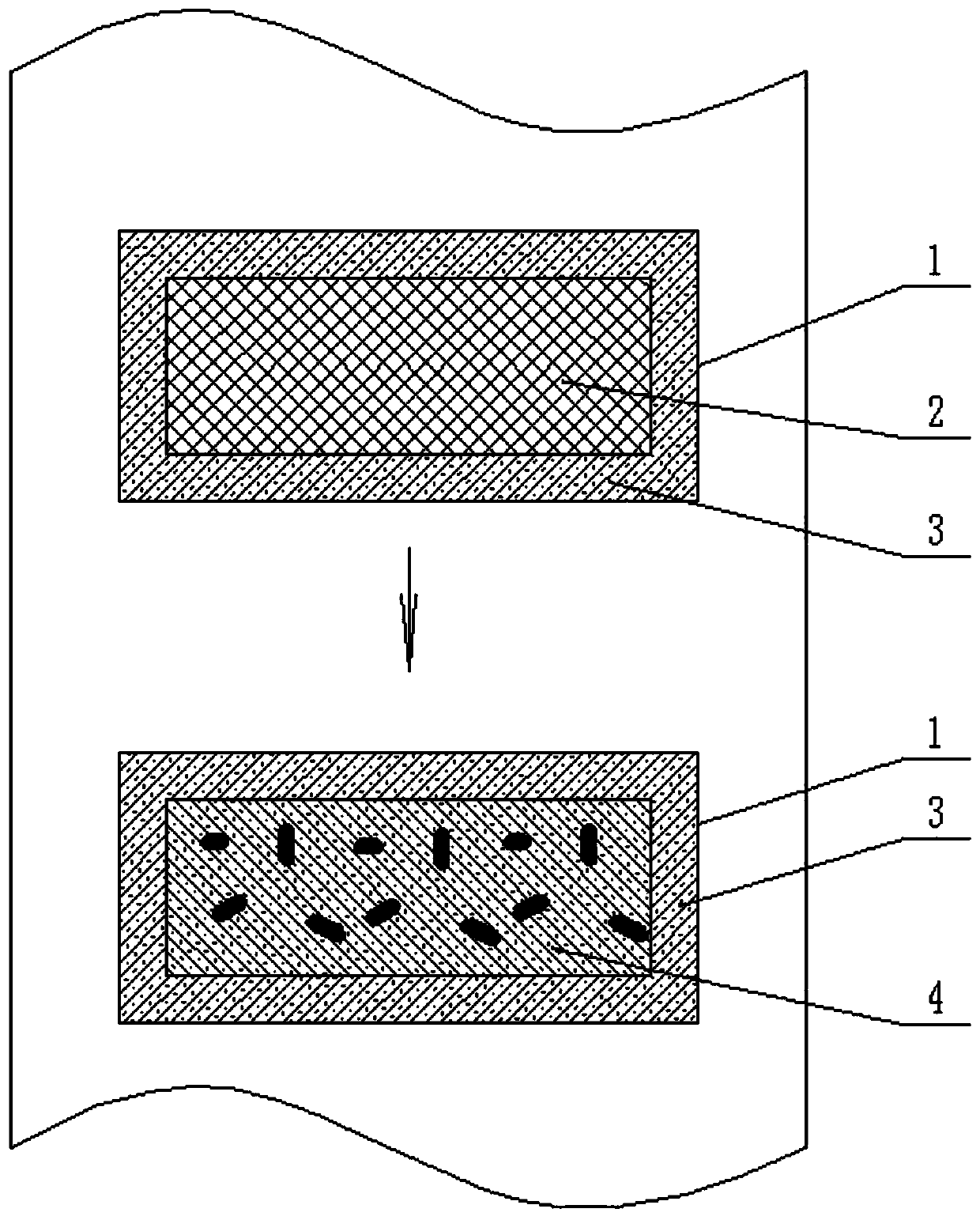

Method used

Image

Examples

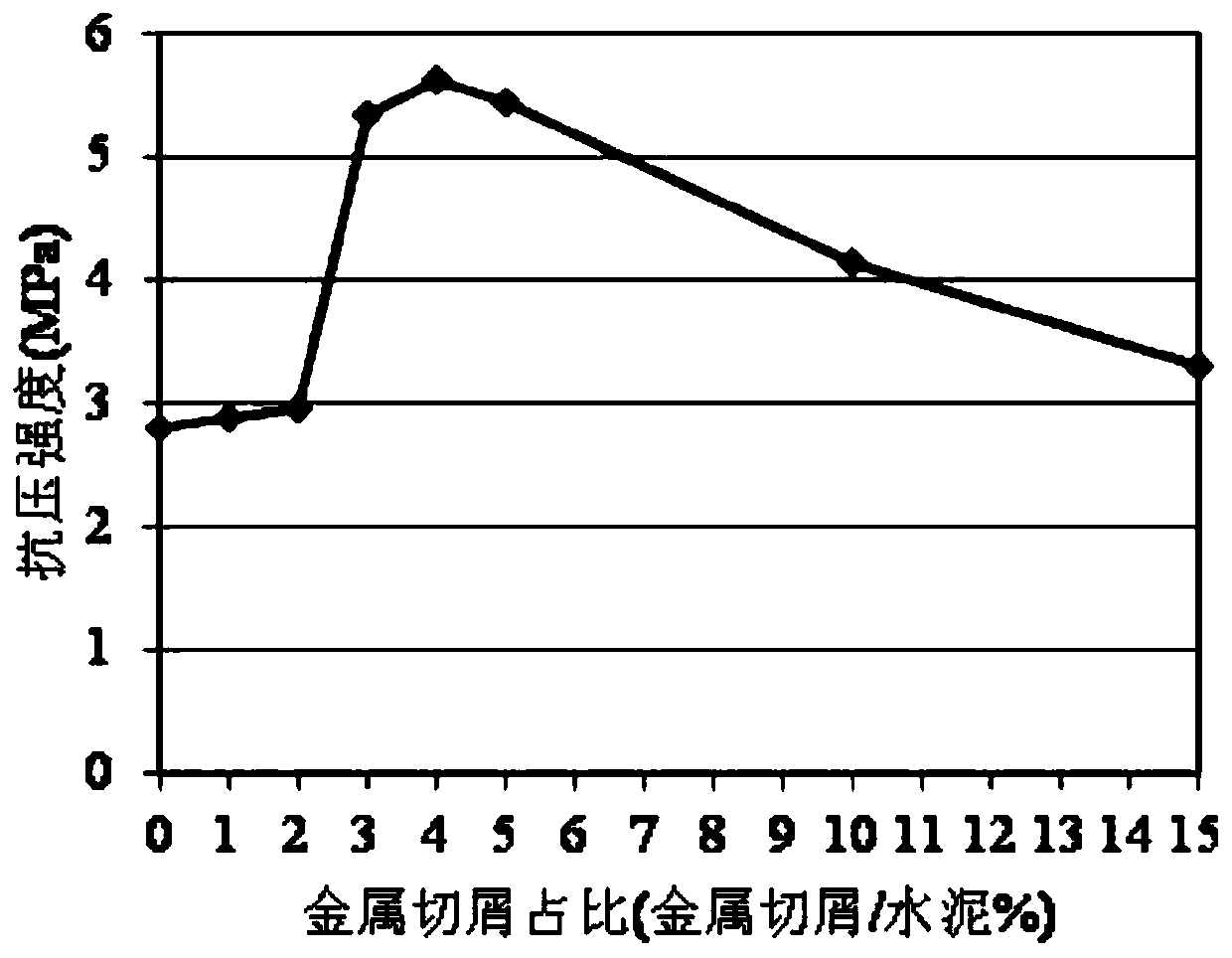

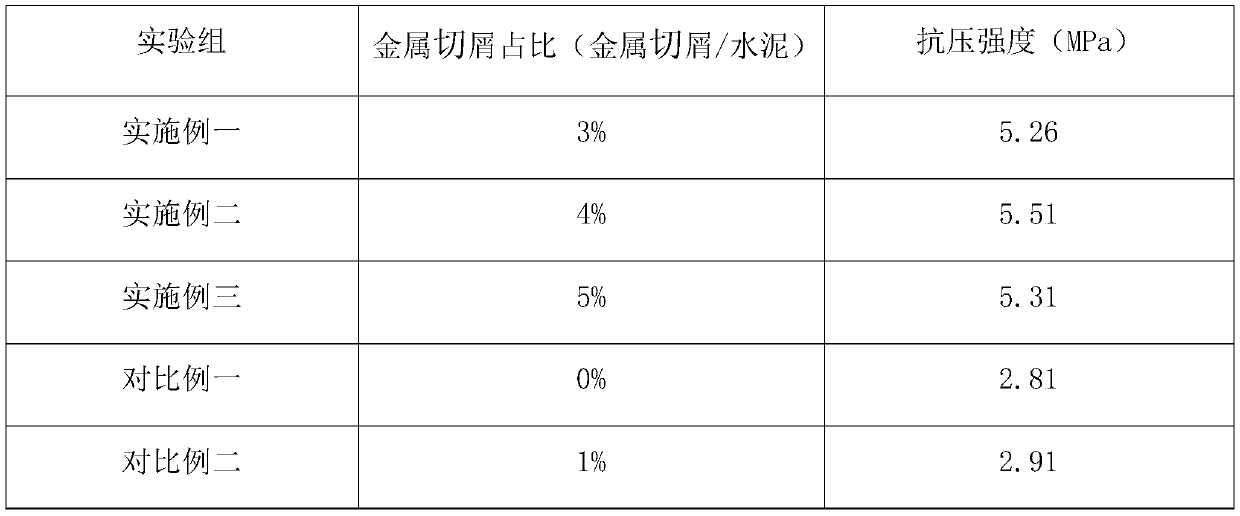

Embodiment 1

[0042] The strengthened hollow brick of the present embodiment comprises the raw material of following mass fraction: Prepare the raw material of following mass: described cement is 25 parts, and sand is 150 parts, and water is 20 parts, and metal chip is 0.8 part, and wherein: cement can adopt No. 325 ordinary Portland cement, the sand is medium sand, medium sand refers to the sand whose particle size is greater than 0.25mm and the mass of the particles exceeds 50% of the total mass, and the mud content in the sand does not exceed 5%. The amount of mortar is low, and the strength of the mortar configured is higher. The length of the metal chips is 5-20mm. Steel is the most commonly used material in the processing and manufacturing industry. Therefore, the metal chips in this embodiment mainly include iron filings. Of course, not all iron chips Chips can be used. Due to the high carbon content and high brittleness of cast iron, the chips produced by turning, milling, planing, g...

Embodiment 2

[0053] The strengthened hollow brick of the present embodiment comprises the raw material of following mass fraction: Prepare the raw material of following quality: described cement is 25 parts, and sand is 150 parts, and water is 20 parts, and metal chip is 1 part, and wherein: cement can adopt No. 325 ordinary Portland cement, the sand is medium sand, medium sand refers to the sand whose particle size is greater than 0.25mm and the mass of the particles exceeds 50% of the total mass, and the mud content in the sand does not exceed 5%. The metal cuttings The length is 5-20mm, steel is the most commonly used material in the processing and manufacturing industry, so the metal chips in this embodiment mainly include iron filings, of course not all iron filings can be used, because cast iron has a high carbon content Chips produced during processing such as cutting, milling, planing, and grinding are broken chips, which are not within the scope of use.

[0054] The preparation me...

Embodiment 3

[0064] The reinforced hollow brick of the present embodiment comprises the following mass fractions of raw materials: prepare the following mass of raw materials: 25 parts of the cement, 150 parts of the sand, 20 parts of the water, and 1.2 parts of the metal swarf, wherein: the cement can be No. 325 ordinary Portland cement, the sand is medium sand, medium sand refers to the sand whose particle size is greater than 0.25mm and the mass of the particles exceeds 50% of the total mass, and the mud content in the sand does not exceed 5%. The metal cuttings The length is 5-20mm, steel is the most commonly used material in the processing and manufacturing industry, so the metal chips in this embodiment mainly include iron filings, of course not all iron filings can be used, because cast iron has a high carbon content Chips produced in processes such as cutting, milling, planing, and grinding are broken chips, which are not within the scope of use.

[0065] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com