Abrasion detection device of mixed type rotary cutter

A technology of rotary tool and detection device, applied in manufacturing tools, measuring/indicating equipment, metal processing mechanical parts, etc., can solve the problems of large error and complicated operation, and achieve the effect of convenient and quick acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the invention will be further described below in conjunction with the accompanying drawings and embodiments.

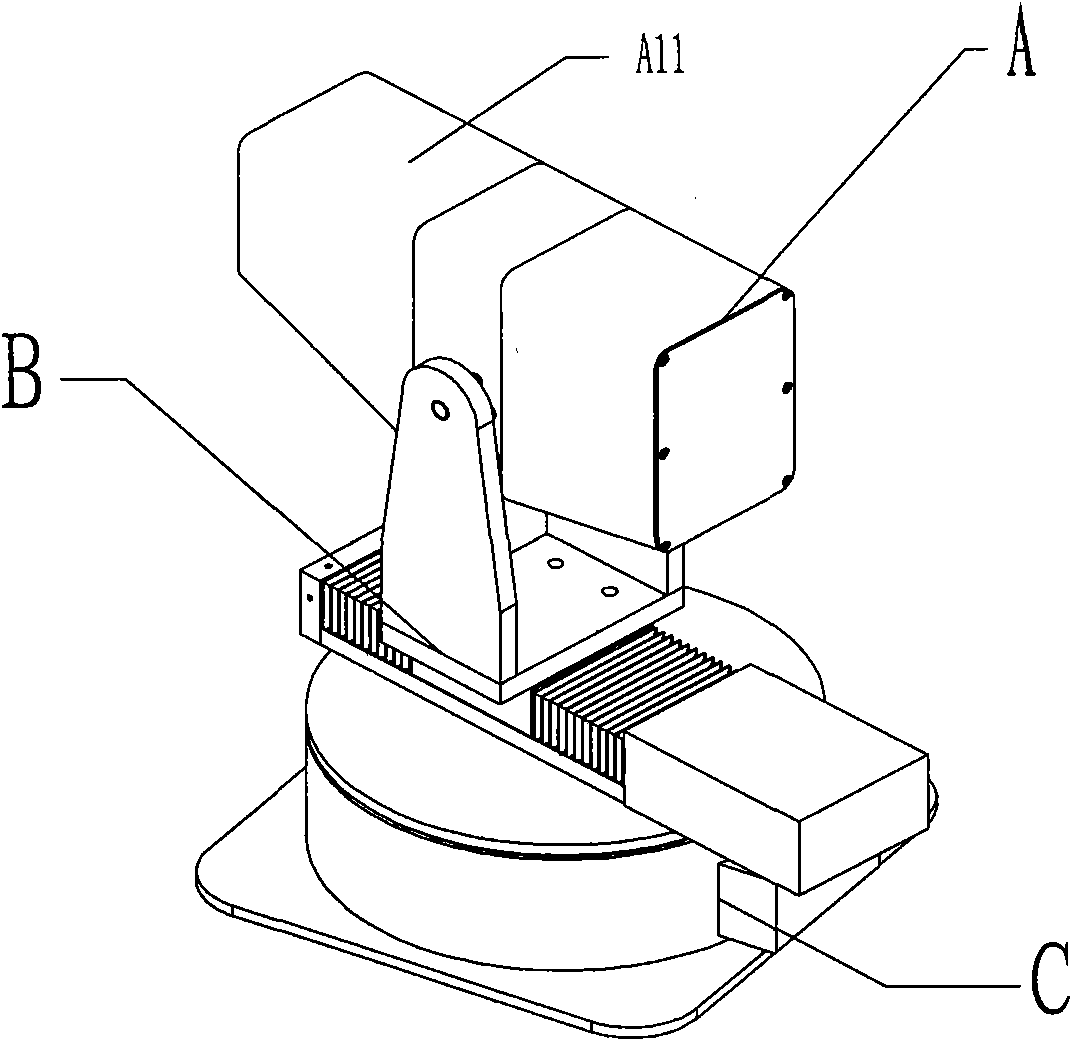

[0024] The invention is a hybrid rotary tool wear detection device, which adopts an online direct measurement method, that is, a camera is mounted on a machine tool workbench. The device is designed with three degrees of freedom in order to realize multi-angle photography of the cutting tool. Such as figure 1 It is composed of three parts: electronically controlled tilting platform A, electronically controlled translation platform B, and electronically controlled rotating platform C. The electronic control tilting platform A realizes the camera shooting different angles of the tool; the electronically controlled translation platform B realizes the focusing between the camera and the tool under test; the electronically controlled rotating platform C realizes the camera shooting different orientations of the tool.

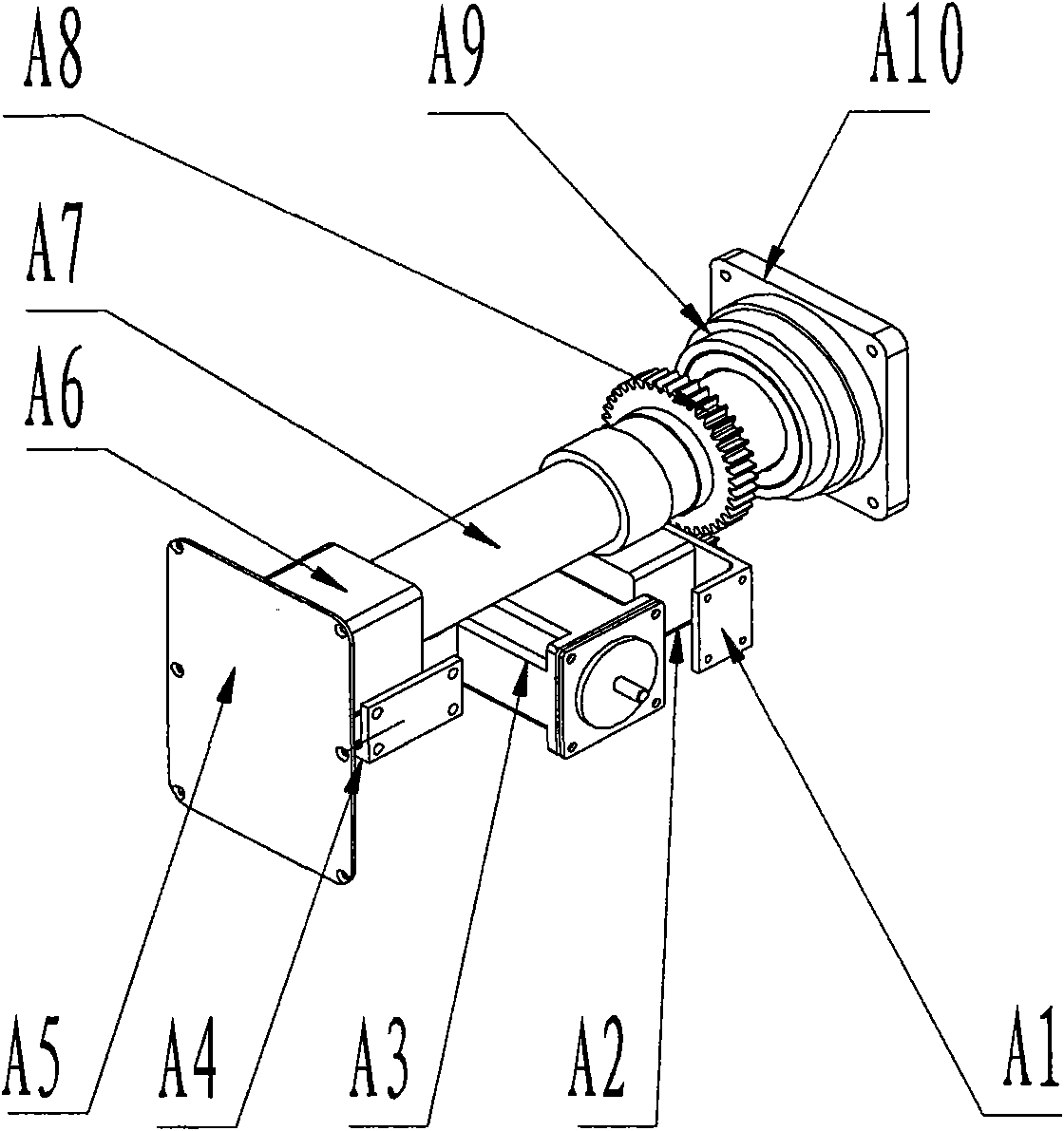

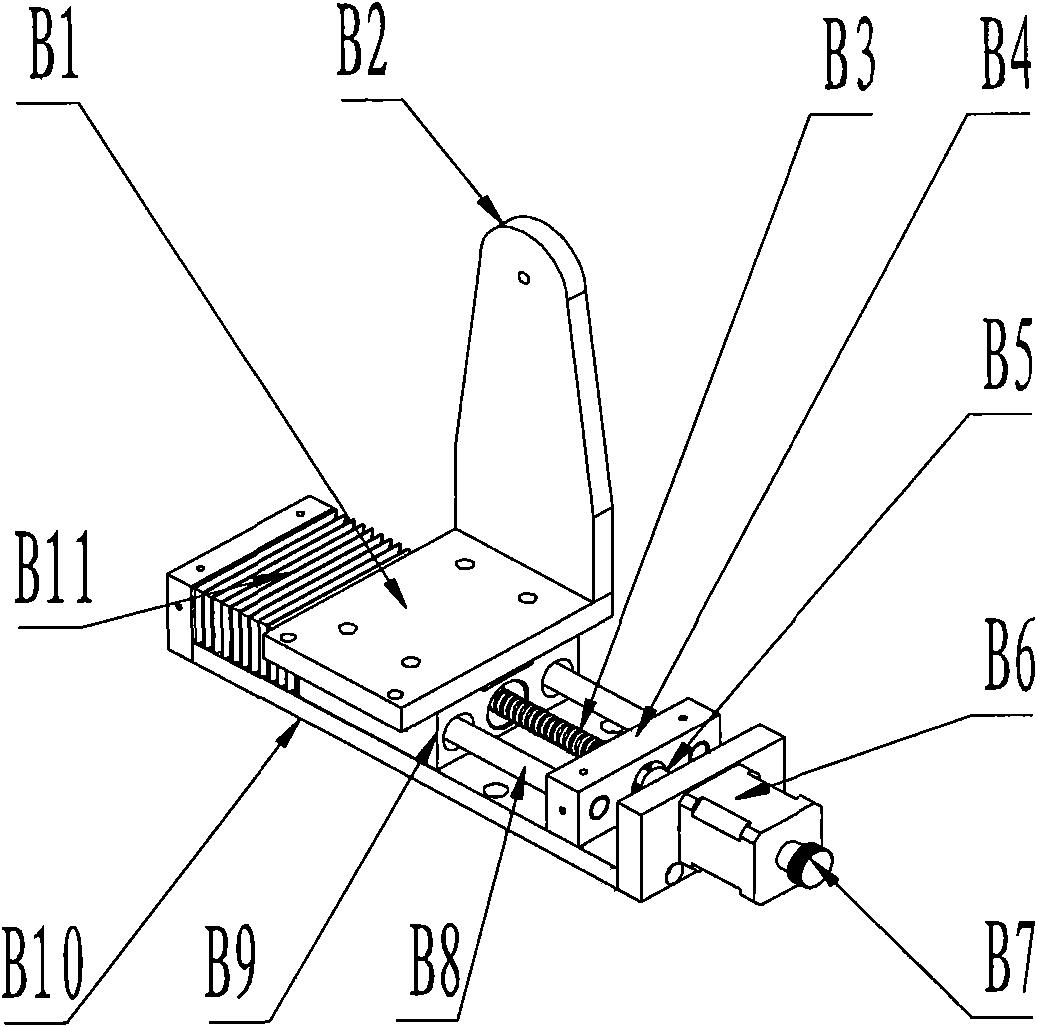

[0025] The electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com