Hot-rolled chrome molybdenum low-alloy steel antirust production method

A chromium-molybdenum low-alloy and low-alloy steel technology, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, can solve problems such as easy rusting on the surface, and achieve easy rusting and good social benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The composition of a hot rolled chromium molybdenum low alloy steel is C: 0.1, Mn: 0.45, P: 0.003, S: 0.030, Si: 0.6, Cr: 1.2, Mo: 0.55.

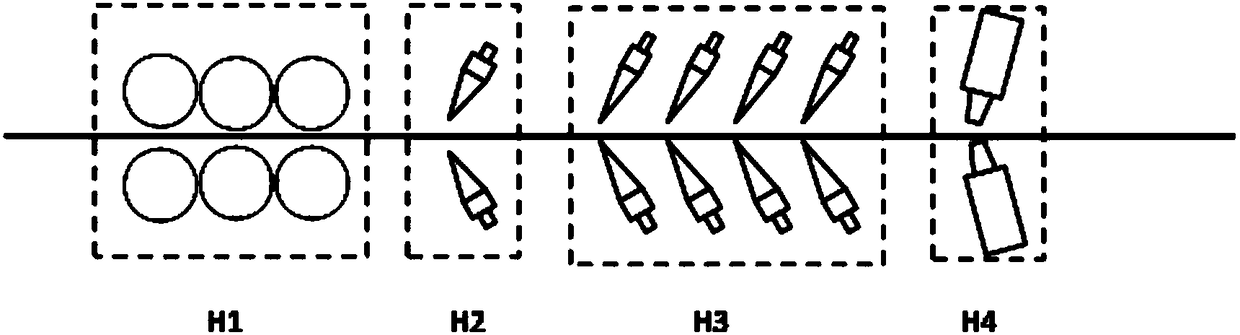

[0041] The process steps of the present invention mainly include a roller brushing process section, a surface cleaning process section, an antirust agent spraying process section and a heating and purging process section.

[0042] The annealed hot-rolled chromium-molybdenum low-alloy steel plate enters the roller brush process section through the pinch roller on the roller table. The diameter of the upper and lower brush rollers is 350mm and the length is 2450mm. The material of the roller shaft of the brush roller is 40Cr (tempered heat treatment). The material is nylon + alumina abrasive, and the abrasive content gradually decreases from front to back. The upper and lower brush rollers are active rollers, which are installed in a closed brush roller frame, and a pneumatic blowing device and a dust removal system are arranged in the...

Embodiment 2

[0048] The composition of hot-rolled chromium-molybdenum low-alloy steel is C: 0.15, Mn: 0.75, P: 0.004, S: 0.036, Si: 0.7, Cr: 1.5, Mo: 0.65.

[0049] The process steps of the present invention include a roller brushing process section, a surface cleaning process section, an antirust agent spraying process section and a heating and purging process section.

[0050]The annealed hot-rolled chromium-molybdenum low-alloy steel plate enters the roller brush process section through the pinch roller on the roller table. The diameter of the upper and lower brush rollers is 450mm and the length is 2500mm. The material of the roller shaft of the brush roller is 35CrMo (tempered heat treatment). The material is nylon + silicon carbide abrasive, and the abrasive content gradually decreases from front to back. The upper and lower brush rollers are active rollers, which are installed in a closed brush roller frame, and a pneumatic blowing device and a dust removal system are arranged in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com