Application of inner chill in investment casting process

A technology of investment casting and inner cooling iron, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of inner cooling iron rust, high cost, and affect the application effect of inner cooling iron, so as to improve the yield , the effect of reducing the number and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

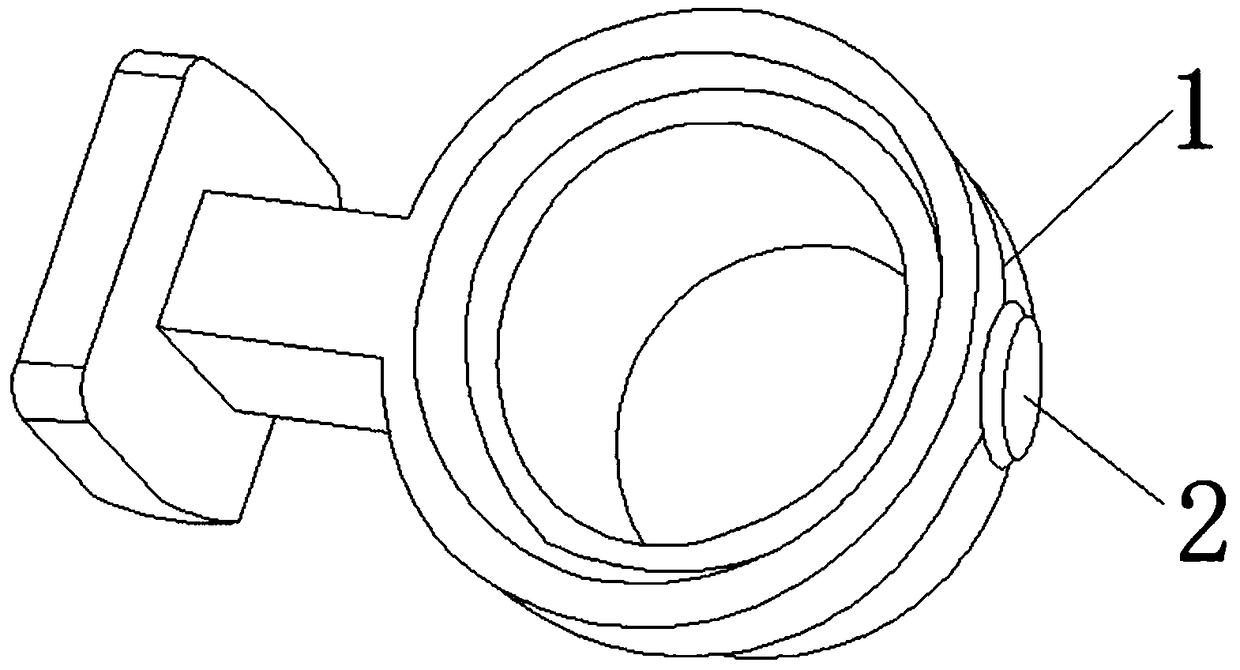

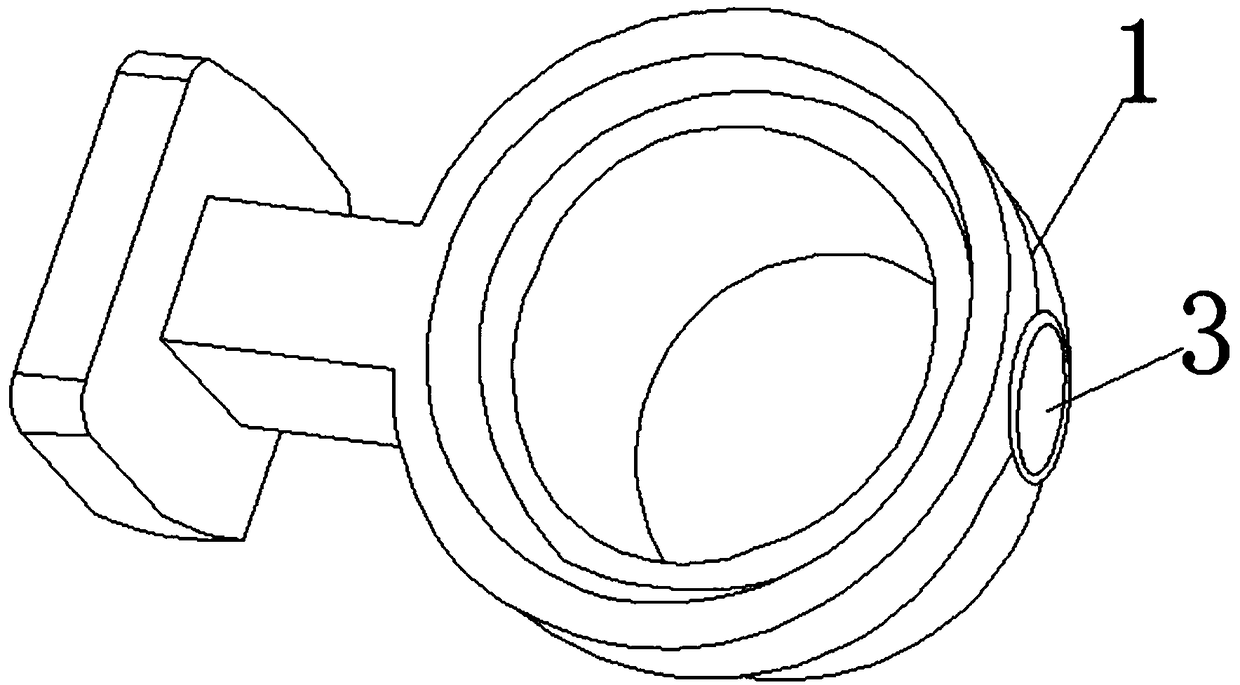

[0023] Such as Figure 1-3 As shown, the application of the inner cooling iron proposed by the present invention in the investment casting process includes opening holes at the hot joint, preparation of the inner cooling iron, oil stain treatment on the surface of the inner cooling iron, derusting treatment on the surface of the inner cooling iron, and Installation and formwork baking and pouring steel;

[0024] 1) A hole is opened at the hot joint, and a small hole is opened at the independent hot joint of the casting, and the small hole is a circular structure;

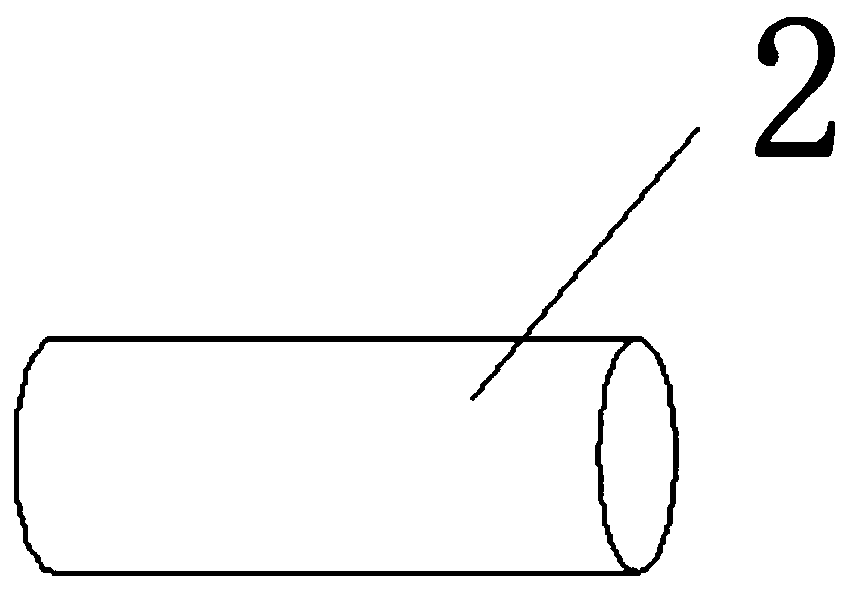

[0025] 2) Preparation of inner cooling iron, the inner cooling iron material is selected from the same material as the casting, and the inner cooling iron with a cylindrical structure is machined by machining, and the diameter of the inner cooling iron is less than the diameter of the small hole by 2mm;

[0026] 3) Oil stain treatment on the surface of the inner cooling iron. Place the inner cooling iron in a sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com