Atomizer

An atomizer and atomizing core technology, applied in the field of atomizers, can solve problems such as inconvenient replacement, easy oil leakage, and affecting the physical and mental health of smokers, and achieve the effect of convenient replacement and easy rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

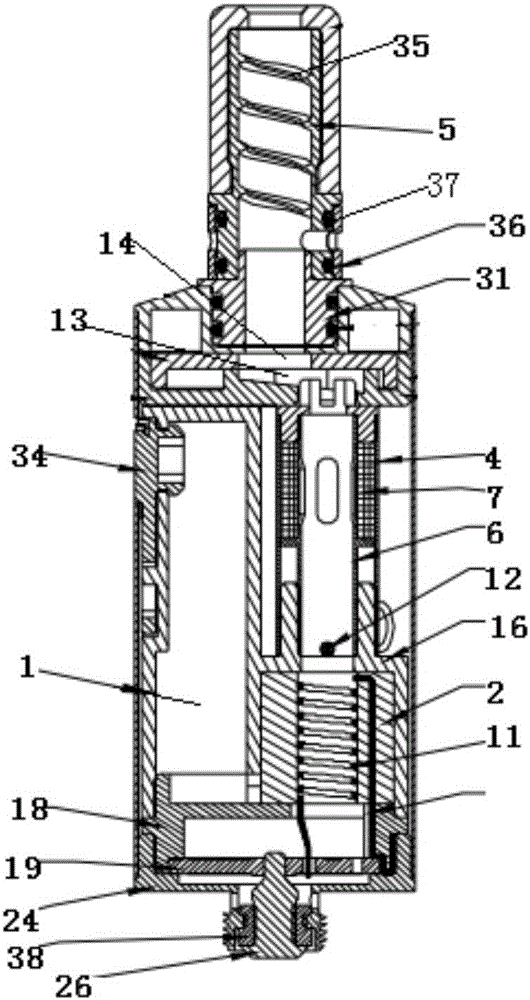

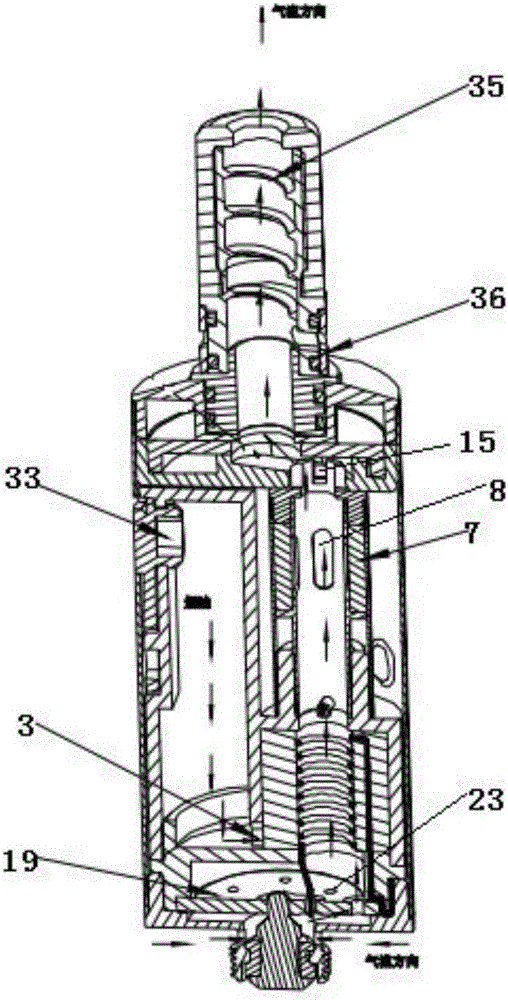

[0039] In Embodiment 2, the top end of the trachea 4 is connected to the suction nozzle 5 through a nozzle holder 31; The connection between the suction nozzle 5 and the suction nozzle seat 31 is sealed by a sealing ring 37 .

[0040] Such as figure 1 and Figure 6 As shown, in Embodiment 1 and Embodiment 2, an air inlet 43 is formed at the bottom of the suction nozzle 5, and the air inlet 43 is provided with an air flow conversion ring 36 for adjusting the air flow of the air inlet 43. The air flow conversion ring 36 can rotate. When the air flow hole on the air flow conversion ring 36 is aligned with the air inlet 43, the air flow entering the suction nozzle is maximum. When the air flow hole on the air flow conversion ring 36 deviates from the air inlet, the air flow becomes Small even closed air intake.

[0041] Such as Figure 6 As shown, an isolation net 32 is fixed on the top of the atomizing core 2, and the isolation net 32 abuts on the atomizing core 2 to bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com