Tire nut deep blind hole plating and coating process

A deep blind hole and nut technology, applied in the direction of metal material coating process, etc., can solve the problems of iron slag residue, inability to completely remove blind hole oil and oxide scale, etc., and achieve the effect of preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] It should be noted that this embodiment is only used to explain the present invention, and is not used to limit the present invention.

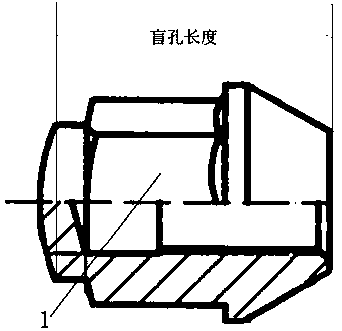

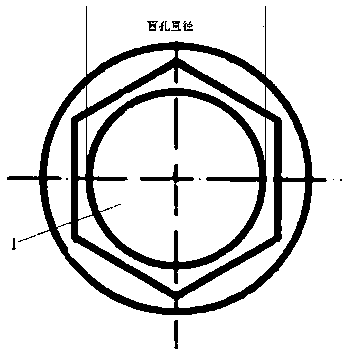

[0022] Such as figure 1 For the tire nut parts shown, firstly, the parts are subjected to pretreatment in sequence: hot alkali degreasing, hot alkali degreasing, electrolytic degreasing, pickling, electrolytic degreasing, activation, pre-plating, deplating, electroplating; two hot alkali Degreasing to ensure that the oil in the blind hole 1 is completely removed; deplating after pre-plating, and peeling off the oxide skin in the blind hole 1.

[0023] Electroplating natural color nickel complex alloy, adding additives to electroplating potion during electroplating.

[0024] Use the rotation of the production line drum and the feeding centrifugal dryer to shake off the excess water in the blind hole 1 after electroplating.

[0025] Then, dehydrogenation baking is used to evaporate excess water in the blind hole by high temperature bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com