Mattress with nonmetal elastic members

An elastic part, non-metal technology, applied in the field of mattresses with non-metal elastic parts, can solve problems such as rust, abnormal noise, deformation, etc., achieve comprehensive functions, reduce service life, and relieve fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing:

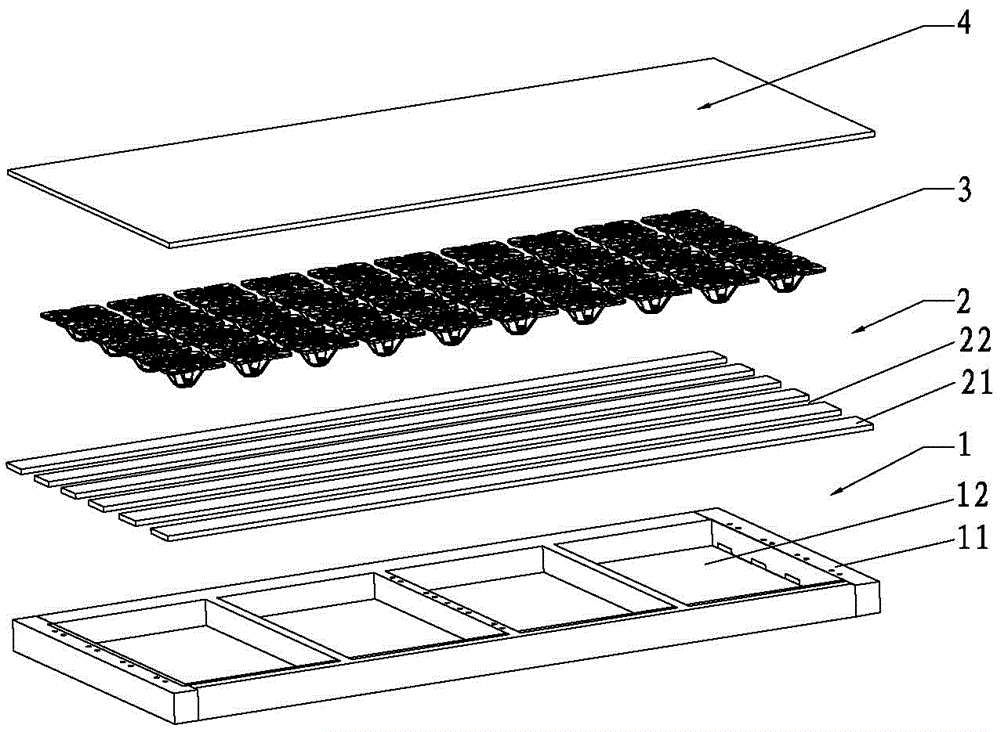

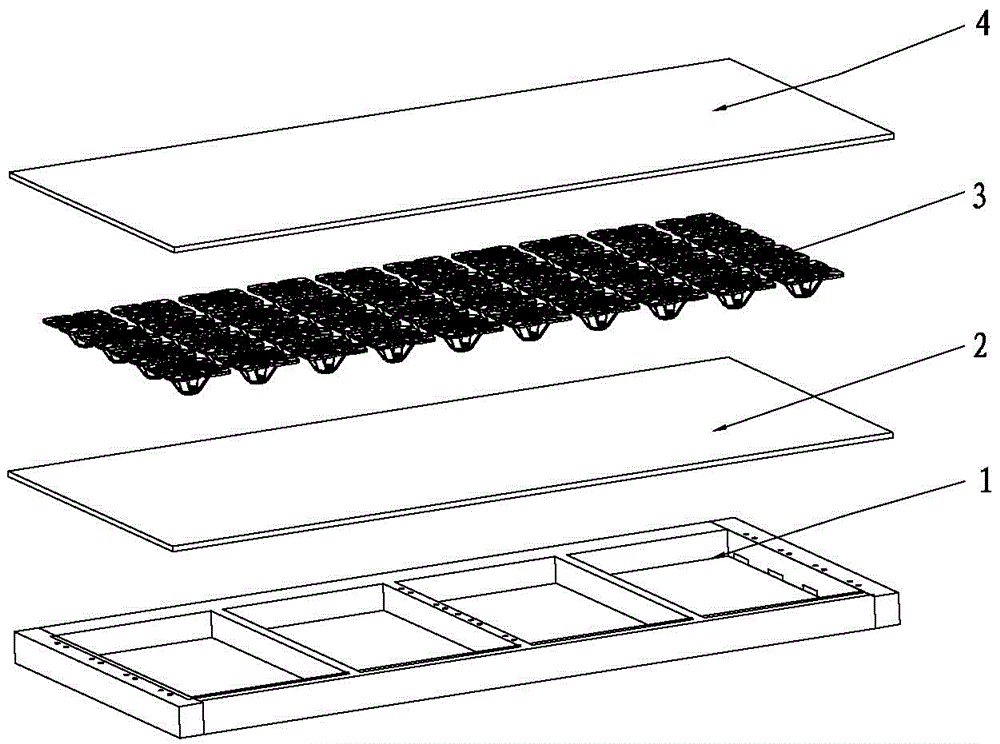

[0027] figure 1 , image 3 , Figure 4 , Figure 5 A first embodiment of the invention is shown.

[0028] see figure 1 , image 3 As shown, the mattress with non-metal elastic parts is composed of a base 1, an elastic part fixing part 2 embedded in the base 1, and an elastic layer composed of 3 sets of non-metal elastic parts fixed by the elastic part fixing part 2.

[0029] In this embodiment, the elastic member fixing part 2 is composed of a plurality of strip plates 21 arranged parallel to each other; the plurality of non-metal elastic members 3 are respectively fixed in the gaps of the elastic member strip plates 21 .

[0030] In this embodiment, the top of the non-metallic elastic member 3 is provided with a pressure divider 4 that can be changed in hardness and is used to decompose and buffer the pressure from above. The pressure divider 4 is selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com