Surface silanization regenerated cellulose microsphere filling and preparation method and use thereof

A technology of regenerated cellulose and microsphere fillers, which is applied in the fields of chromatography and polymer chemistry, can solve the problems of expensive cellulose solvent system, abnormal chromatographic behavior, complicated preparation process, etc., and achieves high alkali resistance, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

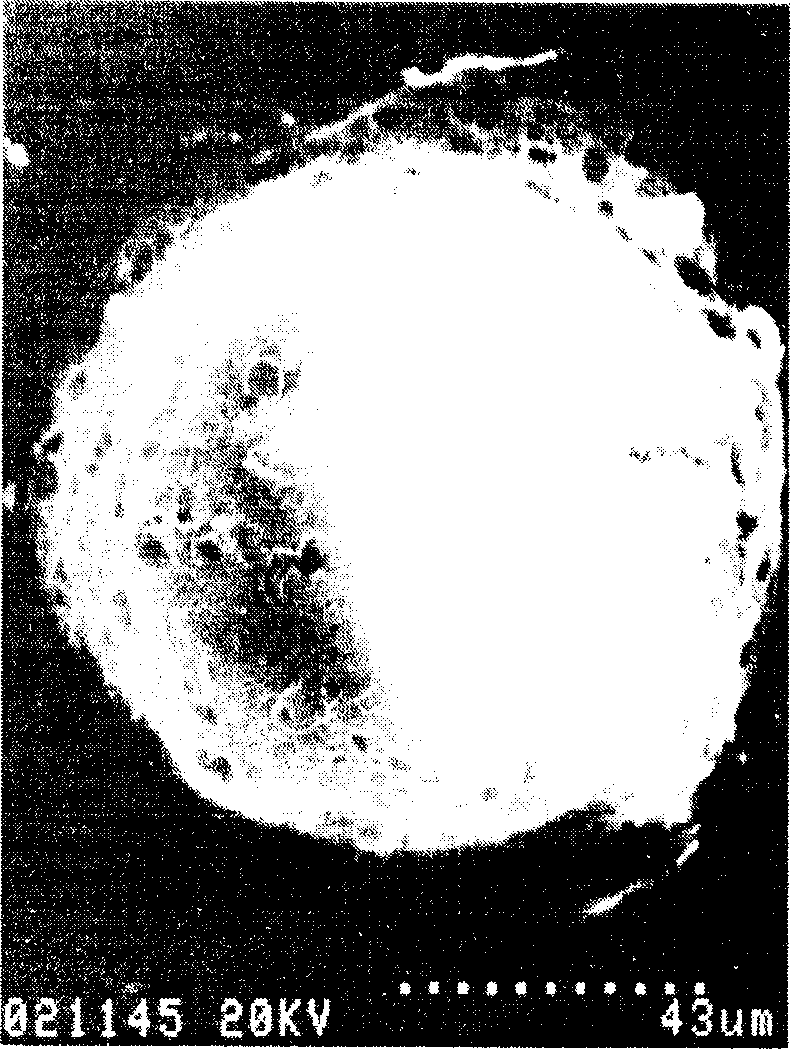

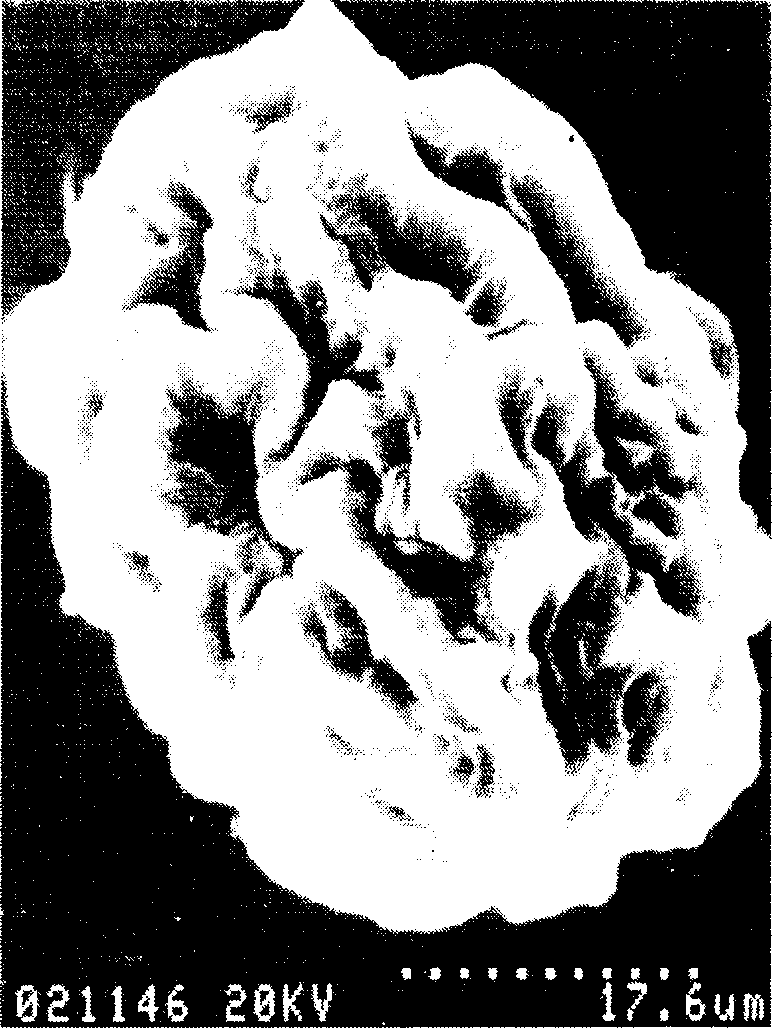

[0015] Mix 3% cellulose and 2% konjac glucomannan NaOH / thiourea aqueous solution according to the ratio of cellulose: konjac glucomannan is 6:4 and defoam, take 40 grams and put it into a 250mL three-port bottle, add 40 mL of 2% Span80 liquid paraffin solution into the system, stir at 200 rpm for 2 hours, and then add 5% CaCl 2 50 mL of aqueous solution was stirred for 1 hour, and then 100 mL of 2% aqueous HCl was added and stirred for half an hour. Stirring was stopped, filtered, and the obtained solid was washed with acetone, absolute ethanol and distilled water, and the product was lyophilized. Take 4 grams of the dried above product and put it into a 100 mL three-necked flask, add 30 mL of N,N dimethylacetamide and 10 mL of pyridine, blow nitrogen at 20°C and stir at a speed of 100 rpm for 1 hour, then add 4 grams of Chlorotrimethylsilane, stirred for 2 hours. The resulting product is filtered with toluene, washed with acetone and absolute ethanol to obtain the desired f...

Embodiment 2

[0017] 4% cellulose and 2% konjac glucomannan NaOH / thiourea aqueous solution are mixed by cellulose: konjac glucomannan is a ratio of 7:3 and defoamed, and 40 grams are put into 250mL three mouthfuls bottle, add 50 mL of 4% Span80 liquid paraffin solution into the system, stir at 200 rpm for 1 hour, and then add 5% CaCl 2 80 mL of aqueous solution was stirred for 1 hour, and then 80 mL of 5% aqueous HCl was added and stirred for half an hour. Stirring was stopped, filtered, and the resulting solid was washed with acetone, absolute ethanol and distilled water, and the product was freeze-dried. Take 4 grams of dried product and put it into a 100mL three-necked flask, add 30mL N, N dimethylacetamide and 10mL pyridine, blow nitrogen at 40C and stir at a speed of 100 rpm for 1 hour, then add 8 grams of triethyl Chlorosilane, stirred for 2 hours. The resulting product is filtered with toluene, acetone and absolute ethanol to wash the desired filler, its particle size is 30 to 50 μ...

Embodiment 3

[0018] Example 3: The surface silanized regenerated cellulose microsphere filler prepared in Example 1 was packed into a glass tube of 550×20 mm to form a gel bed of 500×20 mm, thereby preparing a preparative gel permeation chromatography column. The theoretical pedal number of this preparative gel permeation chromatography column is 2730. The column is used to fractionate the weight average molecular weight M w 8.31×10 4 , a tetrahydrofuran solution of polycaprolactone with a dispersion index d of 1.55, the mobile phase is tetrahydrofuran, and the flow rate is 1.2 mL min-1. This polymkeric substance is divided into 6 fractions, obtains the fraction product of different molecular weight, and its molecular weight is respectively 18.4 * 10 4 , 13.4×10 4 , 11.0×10 4 , 8.48×10 4 , 6.10×10 4 and 1.17×10 4 , and the dispersion index is 1.2. The weight of each fraction accounts for 10-15% of the injection volume, and the total yield reaches 96.2%. It is indicated that the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com