Anti-aging PE water supply pipe

An anti-aging technology for water supply pipes, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of aging of PE water supply pipes, poor environment of PE water supply pipes, poor performance of PE water supply pipes, etc., and achieve service life Increase, increase mechanical properties, increase the effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

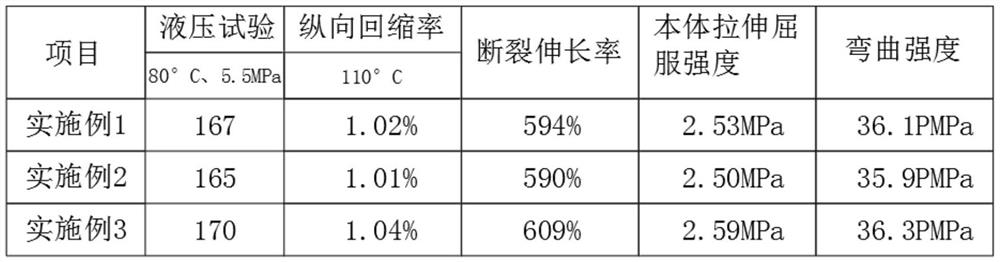

Examples

Embodiment 1

[0019] An anti-aging PE water supply pipe, comprising the following raw materials in parts by weight:

[0020] 90 parts of low-density polyethylene, 6 parts of bentonite, 0.1 part of tribasic lead sulfate, 2 parts of stearamide, 2 parts of sodium polyacrylate, isopropyl dioleate (dioctyl phosphate acyloxy) titanium 0.1 part of ester, 0.1 part of N-isopropyl-N'-phenyl-p-phenylenediamine, 0.1 part of 2-mercaptobenzimidazole, 1 part of glycerol triacetate, 10 parts of filler, 3 parts of modification additive, The filler is one of glass fiber, diatomite, asbestos and carbon black, and the modification aid is one of silane coupling agent, titanate coupling agent or aluminate coupling agent.

[0021] The preparation method of the anti-aging PE water supply pipe includes the following steps: heating the polyphthalamide to 120-130°C, adding aluminum nitride, keeping the temperature and stirring for 10-15 minutes, cooling to normal temperature to obtain a premix; Mix low-density polye...

Embodiment 2

[0023] An anti-aging PE water supply pipe, comprising the following raw materials in parts by weight:

[0024] 95 parts of low-density polyethylene, 7 parts of bentonite, 0.2 parts of tribasic lead sulfate, 3 parts of stearamide, 3 parts of sodium polyacrylate, isopropyl dioleate (dioctyl phosphate acyloxy) titanium 0.2 parts of acid ester, 0.2 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 0.2 parts of 2-mercaptobenzimidazole, 2 parts of glycerol triacetate, 13 parts of fillers, 4 parts of modification additives, The filler is one of glass fiber, diatomite, asbestos and carbon black, and the modification aid is one of silane coupling agent, titanate coupling agent or aluminate coupling agent.

[0025] The preparation method of the anti-aging PE water supply pipe includes the following steps: heating the polyphthalamide to 120-130°C, adding aluminum nitride, keeping the temperature and stirring for 10-15 minutes, cooling to normal temperature to obtain a premix; Mix low-d...

Embodiment 3

[0027] An anti-aging PE water supply pipe, comprising the following raw materials in parts by weight:

[0028] 100 parts of low-density polyethylene, 8 parts of bentonite, 0.3 parts of tribasic lead sulfate, 4 parts of stearamide, 4 parts of sodium polyacrylate, isopropyl dioleate (dioctyl phosphate acyloxy) titanium 0.3 parts of acid ester, 0.3 parts of N-isopropyl-N'-phenyl-p-phenylenediamine, 0.3 parts of 2-mercaptobenzimidazole, 3 parts of glycerol triacetate, 15 parts of fillers, 5 parts of modification additives, The filler is one of glass fiber, diatomite, asbestos and carbon black, and the modification aid is one of silane coupling agent, titanate coupling agent or aluminate coupling agent.

[0029] The preparation method of the anti-aging PE water supply pipe includes the following steps: heating the polyphthalamide to 120-130°C, adding aluminum nitride, keeping the temperature and stirring for 10-15 minutes, cooling to normal temperature to obtain a premix; Mix low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com