Low-loss high-efficiency dephenolizing extractant for treating low-rank coal quality-divided conversion phenol-containing wastewater

A technology for dephenolizing extractant and phenol wastewater, which is applied in solvent extraction, extraction water/sewage treatment, liquid solution solvent extraction, etc., can solve the problems of unsatisfactory dephenolization effect of extractant, complex extraction process, secondary pollution, etc. To achieve the effect of shortening the phase equilibrium time, high extraction efficiency and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

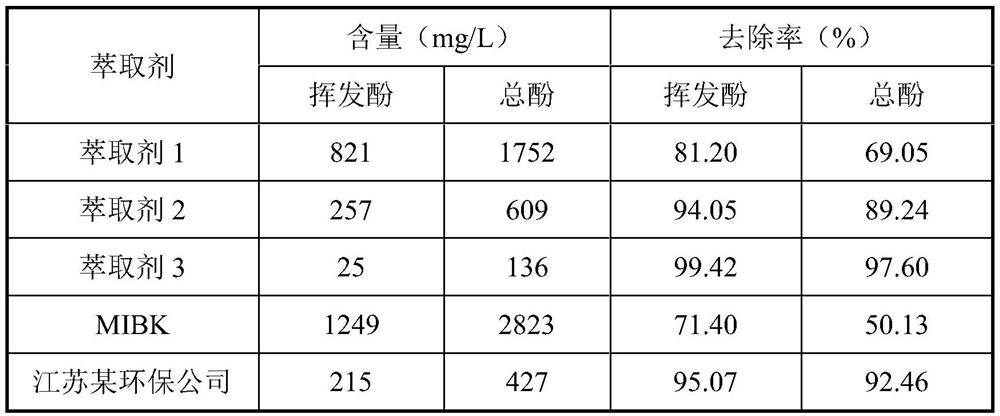

Embodiment 1

[0039] Extractant 1 is composed of dioctyl phosphate and kerosene, wherein the volume ratio of dioctyl phosphate to kerosene is 1:3.

Embodiment 2

[0041] The extractant 2 is composed of dioctyl phosphate, kerosene, and trialkylamine, wherein the volume ratio of dioctyl phosphate to kerosene is 1:3.5, the volume ratio of dioctyl phosphate to trialkylamine is 1:0.3, and the volume ratio of kerosene to kerosene is 1:0.3. The volume ratio of trialkylamine is 1:0.06.

Embodiment 3

[0043] The extractant 3 is composed of dioctyl phosphate, kerosene, trialkylamine and isomeric β-branched primary alcohol, wherein the volume ratio of dioctyl phosphate to isomeric β-branched primary alcohol is 1:0.1, diphosphoric acid The volume ratio of octyl ester to kerosene is 1:3.5, the volume ratio of dioctyl phosphate to trialkylamine is 1:0.4, the volume ratio of kerosene to trialkylamine is 1:0.1, and the volume ratio of kerosene to isomerized β-branched primary alcohol The volume ratio is 1:0.03, and the volume ratio of trialkylamine and isomeric β-branched primary alcohol is 1:0.25.

[0044] (2) Use of extractant

[0045] 1) Wastewater pretreatment

[0046] Use concentrated sulfuric acid to adjust the pH of low-rank coal fractionation to phenol-containing wastewater to 1.5, break the emulsion to remove oil and suspended matter, and take the supernatant after static precipitation.

[0047] The concentrations of volatile phenols, total phenols, and TOC in the pretr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com