Method for removing lead in water body by using magnetic pig manure biochar

A technology for biochar and pig manure, which is applied in separation methods, chemical instruments and methods, water pollutants, etc. Quickly realize problems such as solid-liquid separation, and achieve the effects of controlling heavy metal pollution, reducing bioavailability, and strong alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of method utilizing magnetic pig manure biochar of the present invention to remove lead in water body comprises the following steps:

[0043] S1: First prepare magnetic pig manure biochar by the following method:

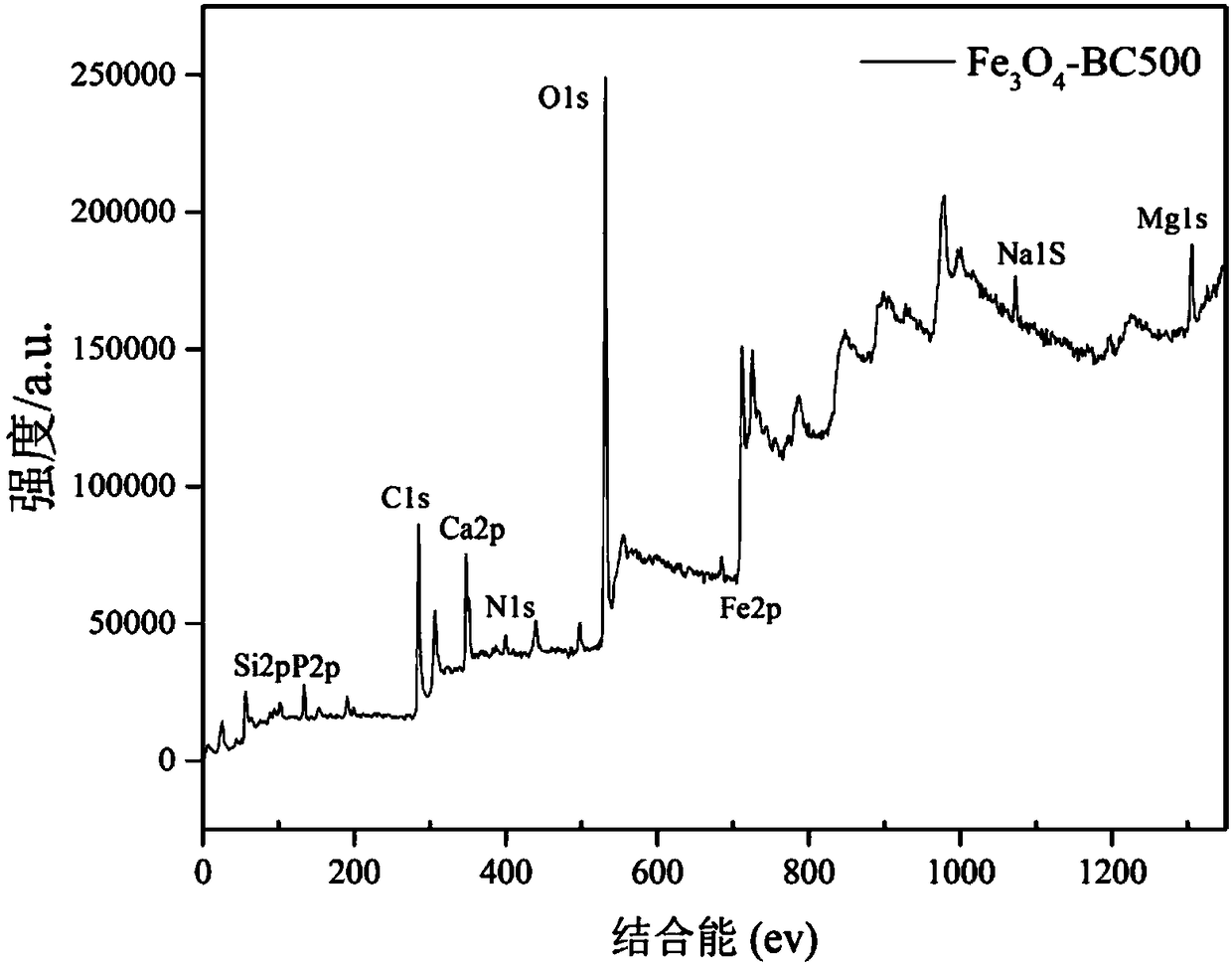

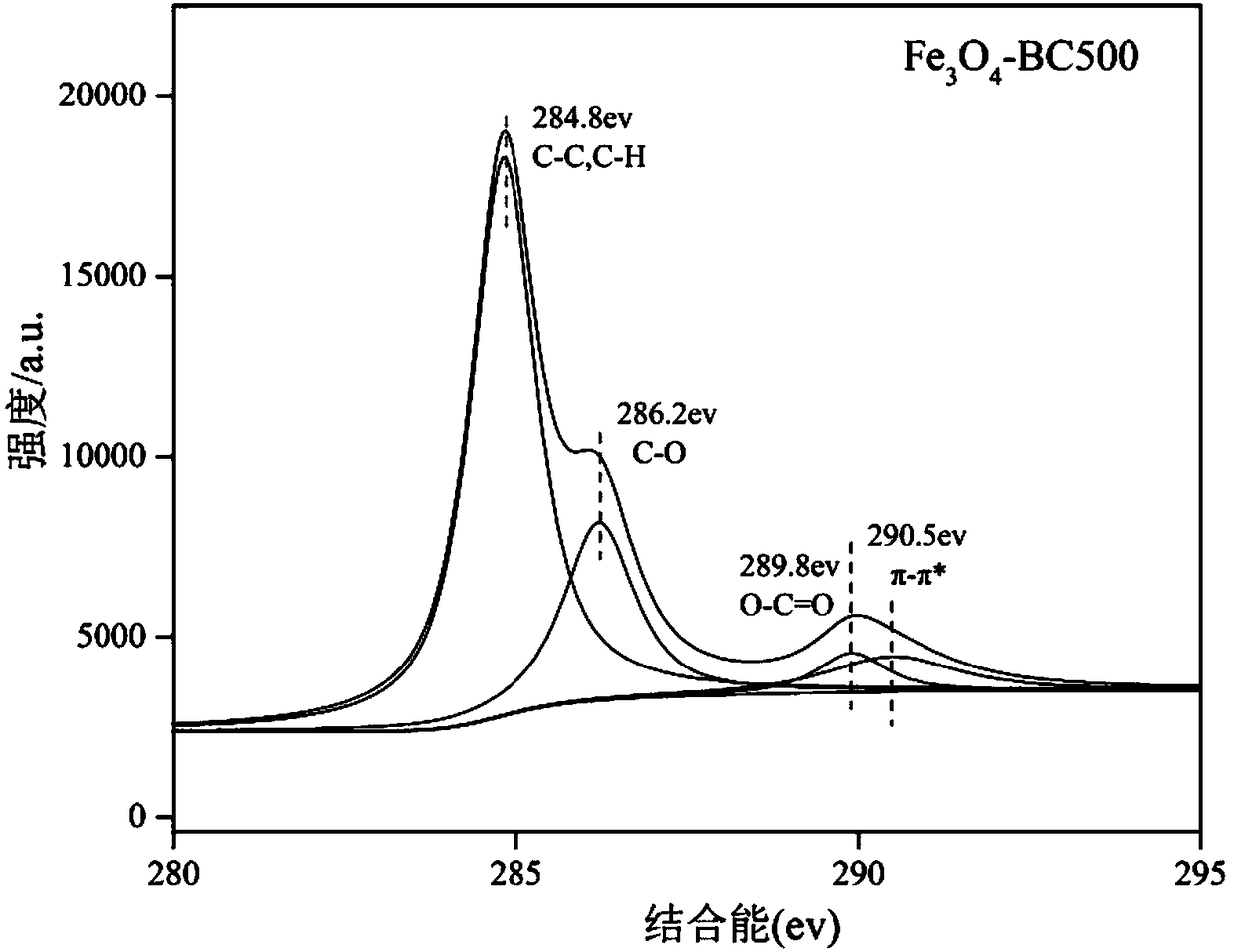

[0044] (1) Preparation of pig manure biochar: collect fresh pig manure, dry at 60°C to 10%-15%, pulverize, pass through a 100-mesh sieve, and seal and store for later use. Put the crushed and sieved pig manure into a tube furnace, feed in nitrogen, and pyrolyze at a high temperature. The heating rate is 8°C / min, the pyrolysis temperature is 500°C, and the pyrolysis residence time is 2h. Crushed and passed through a 100-mesh sieve to obtain pig manure biochar (BC).

[0045] (2) Preparation of pig manure biochar dispersion: Weigh 5g of pig manure biochar and add it to a beaker, add 50mL of ultrapure water to stir and disperse, the stirring speed is 800r / min, and the stirring time is 30min to obtain pig manure biochar Dispersions.

[0046] FeSO 4 ·7H ...

Embodiment 2

[0059] A method for removing lead in water using magnetic pig manure biochar of the present invention uses the magnetic pig manure biochar prepared in Example 1. This example investigates the effect of pH on the efficiency of magnetic pig manure biochar on lead treatment.

[0060] Take 0.01g of magnetic pig manure biochar in 10mL of 50mg / L lead-containing solution, and adjust the pH of the solution to 2, 3, 4, 5, 6, and 7 with 1M HCl and NaOH solutions. At 25°C and 180rpm, shake at constant temperature for 24h (5min or more than 4min is acceptable, as long as the adsorption equilibrium is reached). The treated solution is separated from solid and liquid under the action of an external magnetic field, and the supernatant is filtered through a filter with a pore size of 0.48 μm to obtain a filtrate. The untreated lead in the filtrate was measured with a flame atomic absorption spectrometer, and the treatment efficiency of the magnetic swine manure biochar under pH conditions was...

Embodiment 3

[0065] A method of using magnetic pig manure biochar to remove lead in water according to the present invention adopts the magnetic pig manure biochar prepared in Example 1. This example investigates the effect of the initial concentration of lead on the magnetic pig manure biochar on the lead treatment efficiency .

[0066]0.01g of magnetic pig manure biochar was added to 10mL of lead-containing aqueous solutions with concentrations of 5, 10, 20, 30, 50, 100, 200, 300, and 500mg / L, and the pH value of the solution was adjusted to 5 with 1M HCl and NaOH solutions. . Shake at a constant temperature of 25°C and 180rpm for 24h (5min or more than 4min is acceptable, as long as the adsorption equilibrium is reached). The treated solution is separated from solid and liquid under the action of an external magnetic field, and the supernatant is filtered through a filter with a pore size of 0.48 μm to obtain a filtrate. The untreated lead in the filtrate was measured with a flame ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com