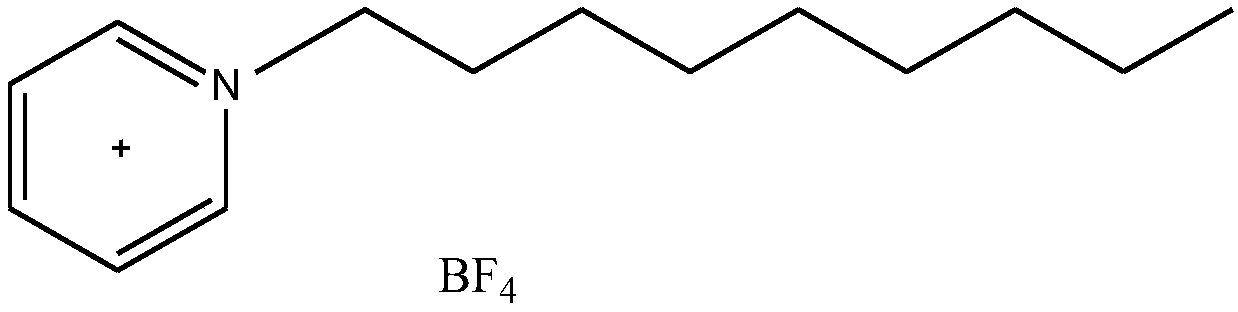

Method for extracting rare earth element with N-octylpyridinium tetrafluoroborate

A technology of octylpyridine tetrafluoroborate and rare earth elements, which is applied in the field of extracting rare earth elements with N-octylpyridine tetrafluoroborate, can solve the problems of large acid-base consumption and environmental impact, and achieve equilibrium in a short time , cost saving, simple extraction operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the method for extracting rare earth elements using N-octylpyridine tetrafluoroborate is carried out according to the following steps:

[0031] (1) to contain La 3+ The rare earth chloride solution is the raw material solution, and the La in the raw material solution 3+ The concentration is 0.01mol / L, and the acidity is 0.3mol / L;

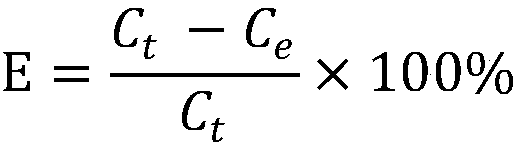

[0032] (2) Mix and extract the raw material solution and N-octylpyridine tetrafluoroborate in a shaker, the mixing ratio O / A is 2:1, the rotation speed during the extraction process is 500r / min, and the extraction time is 5min. The extraction temperature is 25°C. After the extraction is completed, the mixed solution is centrifuged to obtain the rare earth-loaded organic phase and raffinate. The centrifugal speed of centrifugation is 1000r / min, and the centrifugation time is 8min. La in the raffinate is measured. 3+ concentration, the extraction rate was 85.2%;

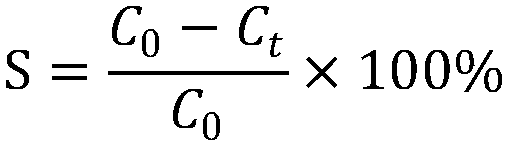

[0033] (3) Use a stripping agent to strip the loaded rare ...

Embodiment 2

[0035] The present embodiment adopts the method for extracting rare earth elements by N-octylpyridine tetrafluoroborate to carry out according to the following steps:

[0036] (1) to contain Ce 3+ The rare earth chloride solution is the raw material solution, and Ce in the raw material solution 3+ The concentration is 0.01mol / L, and the acidity is 0.4mol / L;

[0037] (2) The raw material liquid and N-octylpyridine tetrafluoroborate are mixed and extracted in a shaker, the mixing ratio O / A is 1:2, the rotation speed during the extraction process is 800r / min, and the extraction time is 20min. The extraction temperature is 25°C. After the extraction is completed, the mixed solution is centrifuged to obtain the rare earth-loaded organic phase and raffinate. The centrifugal speed of centrifugation is 2000r / min, the centrifugation time is 10min, and the Ce in the raffinate is determined. 3+ concentration, the extraction rate was 82.7%;

[0038] (3) Use a stripping agent to carry o...

Embodiment 3

[0040] In this embodiment, the method for extracting rare earth elements using N-octylpyridine tetrafluoroborate is carried out according to the following steps:

[0041] (1) to contain Pr 3+ The rare earth nitrate solution is the raw material solution, and the Pr in the raw material solution 3+ The concentration is 0.05mol / L, and the acidity is 0.5mol / L;

[0042](2)) Mix and extract the raw material liquid and N-octylpyridine tetrafluoroborate in a shaker, the mixing ratio O / A is 1:1, the rotation speed during the extraction process is 1000r / min, and the extraction time is 30min , the extraction temperature is 35°C, the mixed solution after the extraction is centrifuged to obtain the rare earth-loaded organic phase and the raffinate, the centrifugation speed is 1500r / min, the centrifugation time is 15min, and the Pr 3+ concentration, the extraction rate was 88.1%;

[0043] (3) Use a stripping agent to strip the loaded rare earth organic phase. The stripping agent is 0.09mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com