Method for producing doubly labelled water by water distillation and distillation equipment for enrichment production of doubly labelled water

A rectification and enrichment technology, which is applied in the field of rectification devices for the production of double-standard water by water rectification and its enrichment and production of double-standard water, can solve the problems of difficult realization of pumps, mechanical failures, unstable performance, etc. The effect of shortening the balancing time and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

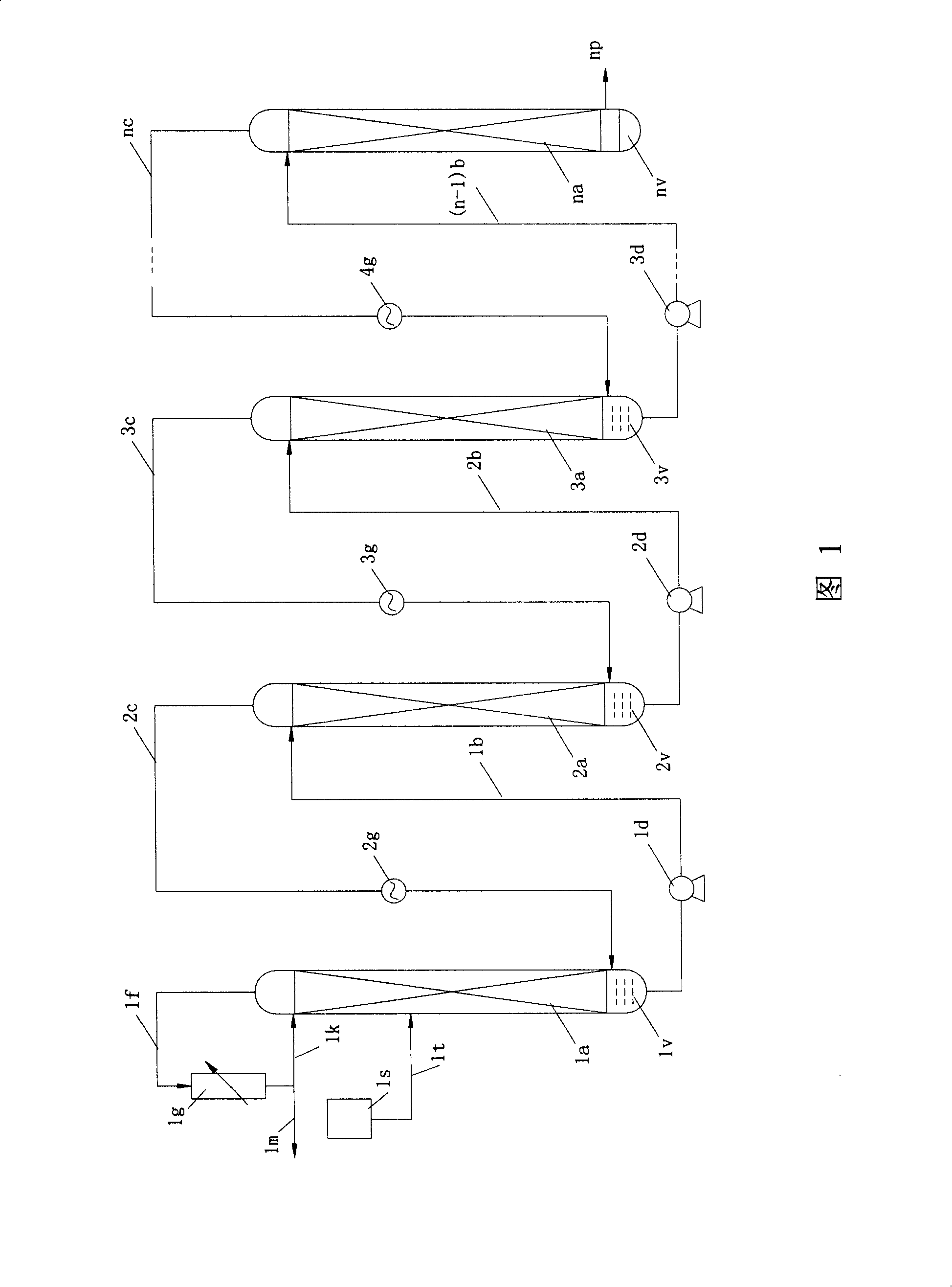

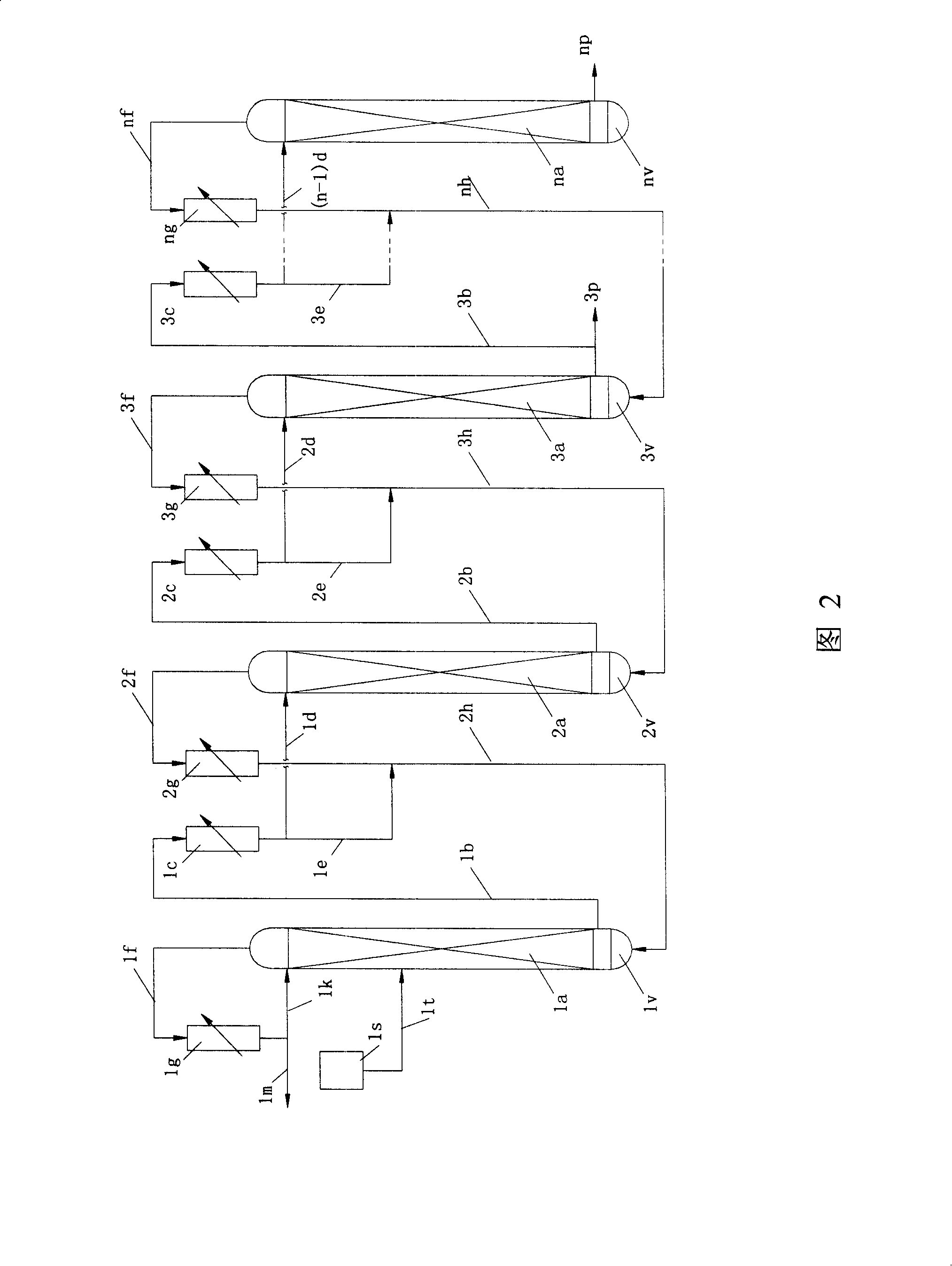

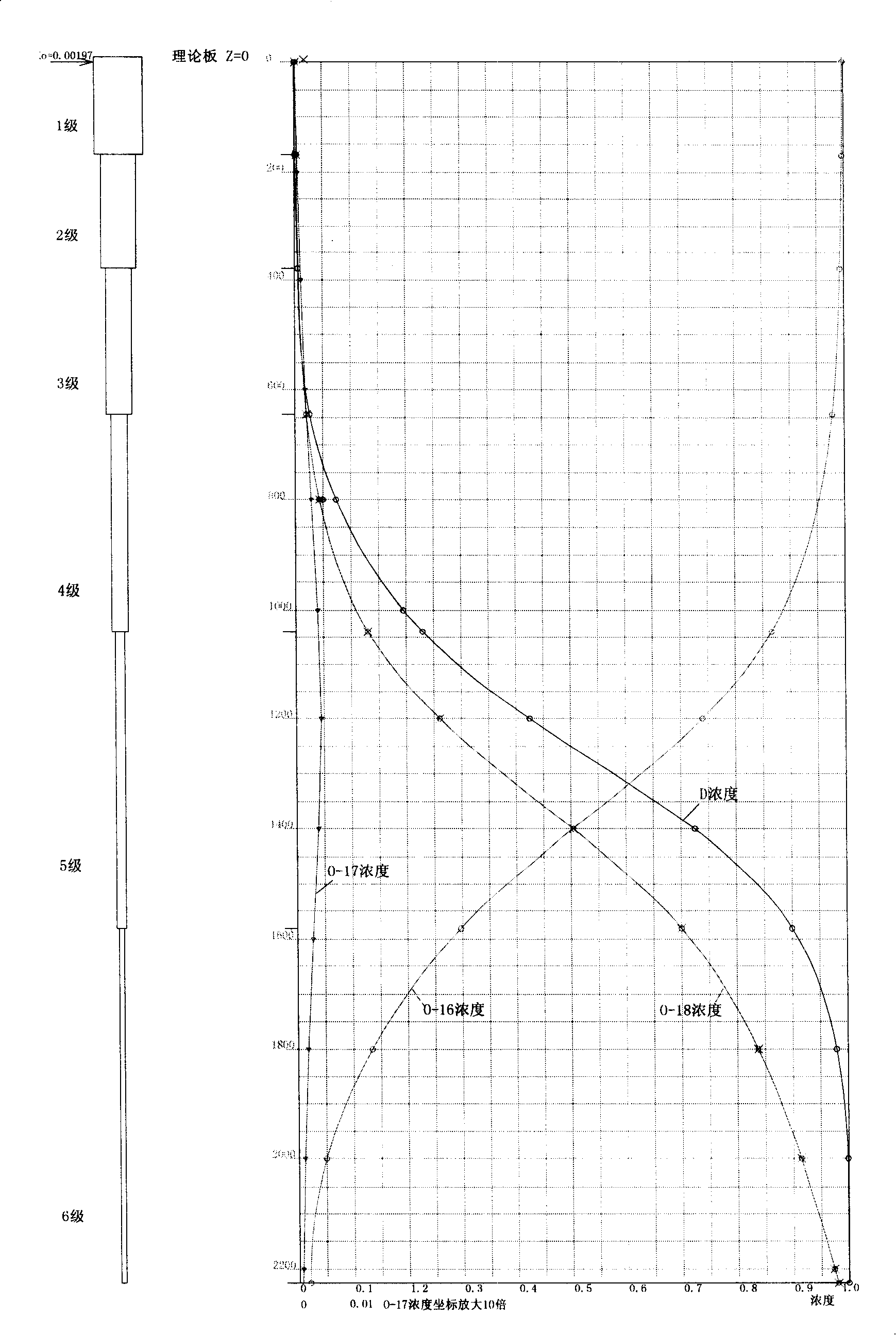

[0071] A cascade device consisting of six towers adopts the process shown in Figure 2, and the raw material is natural water containing 0.015% deuterium and O 18 0.2%. The raw material water is pumped into the raw material high level tank by the raw material pump, and enters the middle part of the first-stage rectification tower 1a at a speed of 800 grams per minute. After the water vapor from the top of the first tower 1a is condensed, part of it enters the first tower as reflux the top of 1a, and the rest of the O 18 Stripped "waste water" discharge system. Column and tube falling film evaporators are used for tower kettle 1v~6v. Table 1 shows the inner diameters, packing types, packing heights, operating conditions and concentration of bottom products of the rectification towers 1a to 6a at all levels. After the isotope accumulation of the continuous operation system reaches equilibrium, low-concentration double-labeled water is obtained from the bottom of the fourth-sta...

Embodiment 2

[0076] A cascade device consisting of four towers adopts the process shown in Figure 2. The raw material is heavy water, which contains 99.8% deuterium and O 18 0.5%. The raw material heavy water is pumped into the raw material high level tank by the raw material pump, and enters the middle part of the first-stage rectification tower 1a at a speed of 430 grams per hour, and part of the water vapor from the top of the first tower 1a is condensed and enters the first tower 1a as reflux The rest of the "wastewater" that is almost equal to the raw material is discharged from the system. Column and tube falling film evaporators are used for tower kettle 1v~4v. Table 2 shows the inner diameters, packing types, packing heights, operating conditions, and column bottom product concentrations of the rectification towers 1a to 4a at all levels. After 580 days of continuous operation, the accumulation of isotopes in the system reached equilibrium, and the product double water was obtain...

Embodiment 3

[0080] In precision distillation, the smaller the diameter of the column, the higher the separation efficiency. In order to improve the separation efficiency and reduce the number of stages, several towers with smaller diameters are often connected in parallel in the front stage. This embodiment is 5 stages composed of 9 towers in series / parallel. The cascading method is shown in Figure 4: four towers T11, T12, T13, and T14 are connected in parallel to form the first stage, and these four towers adopt the same specification and operating conditions; two towers T21 and T22 are connected in parallel to form the second stage . The two towers adopt the same specifications and the same operating conditions; T3, T4, and T5 are respectively the 3rd, 4th, and 5th grades. The connection between stages still adopts the process shown in Figure 2, except that the steam from the bottom of T11 and T12 is mixed and then condensed and enters T21 together. (It can also be condensed separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com