UV-cured conductive silver paste and preparation method thereof

A technology of conductive silver paste and solidification solution, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve the problems of silver paste adhesion, bending resistance, and cost pressure. Problems, achieve the effect of enhancing the conductive effect, reducing the dosage, and contacting closely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment shows a preparation method of a UV-cured conductive silver paste, which specifically includes the following steps:

[0027] Step 1: Weigh 0.5 parts of 1-hydroxycyclohexyl phenyl ketone, 0.25 parts of isopropylthioxanthone, 1 part of acrylic acid, 4 parts of 1,4-hexanediol diacrylate and add them to the reaction kettle, heat When the temperature reaches 50°C, the initiator is fully dissolved by high-speed stirring, and then cooled to room temperature to obtain a photo-initiated curing solution;

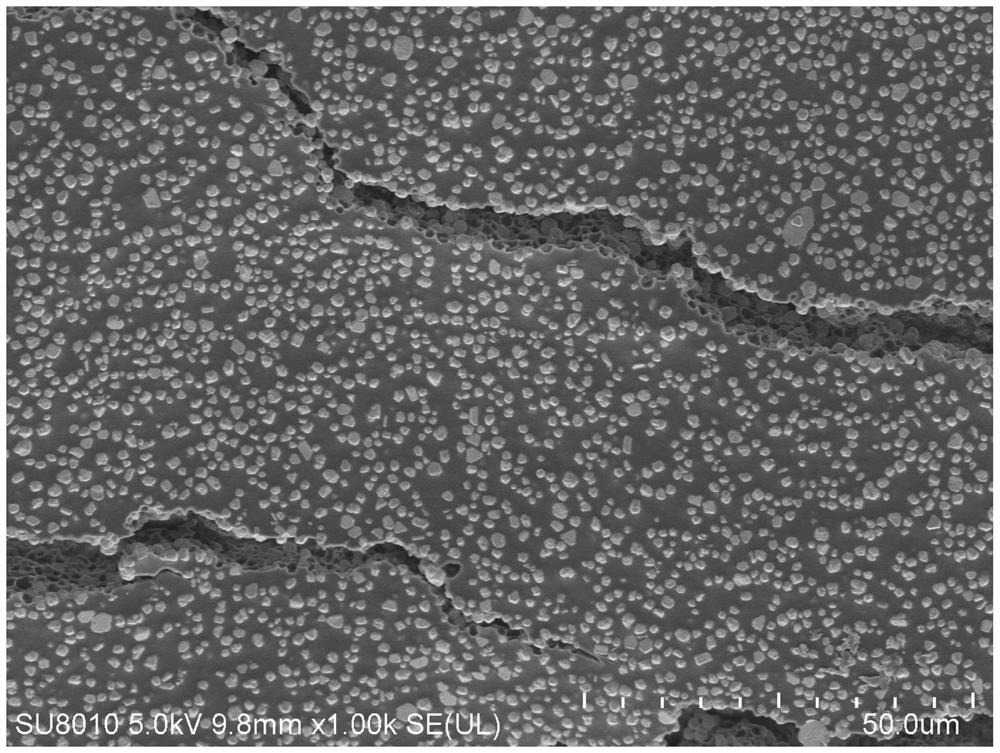

[0028] Step 2: Weigh 8 parts of polyester acrylate, 10 parts of urethane acrylate, 0.25 parts of tetraneoalkoxy bis(didecyl phosphite acyloxy) titanate and 76 parts of 500nm spherical silver powder into step 1 In the initiating curing solution of , use a three-roll mill to grind the conductive adhesive with a fineness of less than 5 μm;

[0029] Step 3: Print the conductive adhesive on the PET film with 300 mesh screen, and then use 1500mW / cm 2 The cured...

Embodiment 2

[0032] The present embodiment shows a preparation method of a UV-cured conductive silver paste, which specifically includes the following steps:

[0033] Step 1: Weigh 0.5 parts of 1-hydroxycyclohexyl phenyl ketone, 0.25 parts of isopropylthioxanthone, 1 part of acrylic acid, and 5 parts of 1,4-hexanediol diacrylate and add them to the reaction kettle, heat When the temperature reaches 55 °C, the initiator is fully dissolved by high-speed stirring, and then cooled to room temperature to obtain a photo-initiated curing liquid;

[0034] Step 2: Weigh 13 parts of polyester acrylate, 10 parts of urethane acrylate, 0.25 parts of tetraneoalkoxy bis(didecyl phosphite acyloxy) titanate and 70 parts of 500nm spherical silver powder and add them to step 1 In the initiating curing solution of , use a three-roll mill to grind the conductive adhesive with a fineness of less than 5 μm;

[0035] Step 3: Print the conductive adhesive on the PE film with 400 mesh screen, and then use 1500mW / c...

Embodiment 3

[0038] The present embodiment shows a preparation method of a UV-cured conductive silver paste, which specifically includes the following steps:

[0039]Step 1: Weigh 0.5 parts of 1-hydroxycyclohexyl phenyl ketone, 0.25 parts of isopropylthioxanthone, 1.5 parts of acrylic acid, and 5 parts of 1,4-hexanediol diacrylate and add them to the reaction kettle, heat At 45°C, stir at a high speed to fully dissolve the initiator, and then cool to room temperature to obtain a photoinitiated solidification solution;

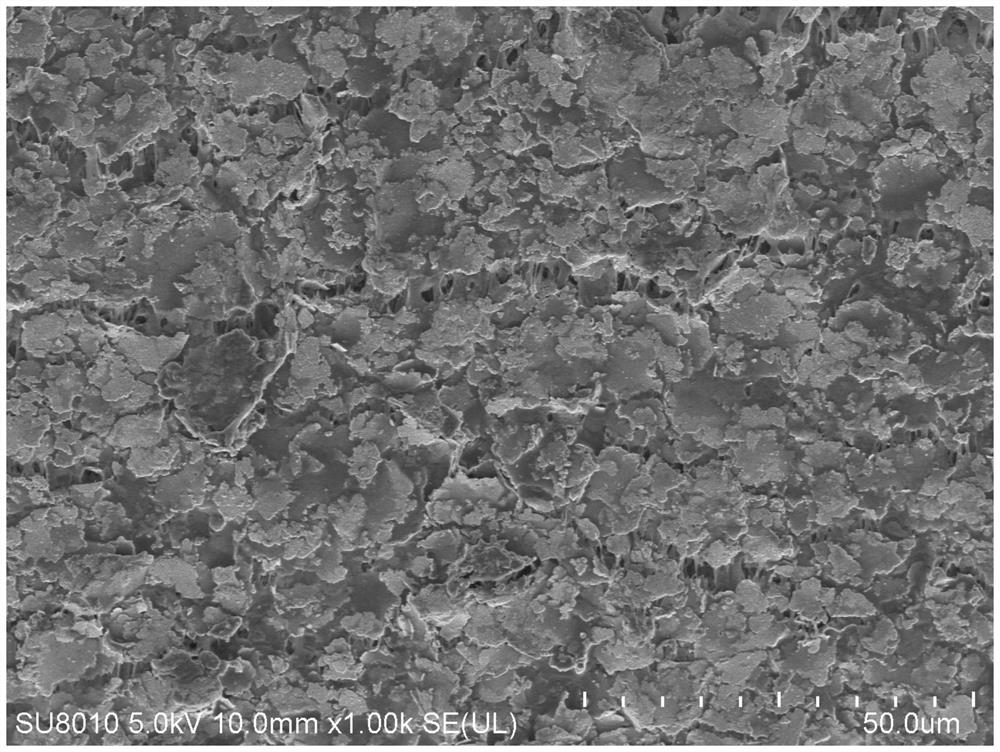

[0040] Step 2: Weigh 10 parts of polyester acrylate, 10 parts of polyurethane acrylate, 0.75 parts of tetraneoalkoxy bis(didecyl phosphite acyloxy) titanate and 72 parts of 200nm flake silver powder and add to step 1 In the initiating solidification solution in , use a three-roll mill to grind the conductive adhesive with a fineness of less than 5 μm;

[0041] Step 3: Print the conductive adhesive on the PC film with 500 mesh screen, and then use 2500mW / cm 2 The cured sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com