Preparation method of high-purity dioctyl phosphate

A dioctyl phosphate and high-purity technology, applied in the field of preparing high-purity dioctyl phosphate, can solve the problems of long production cycle and high production energy consumption, and achieve the effects of short reaction cycle, improved purity and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

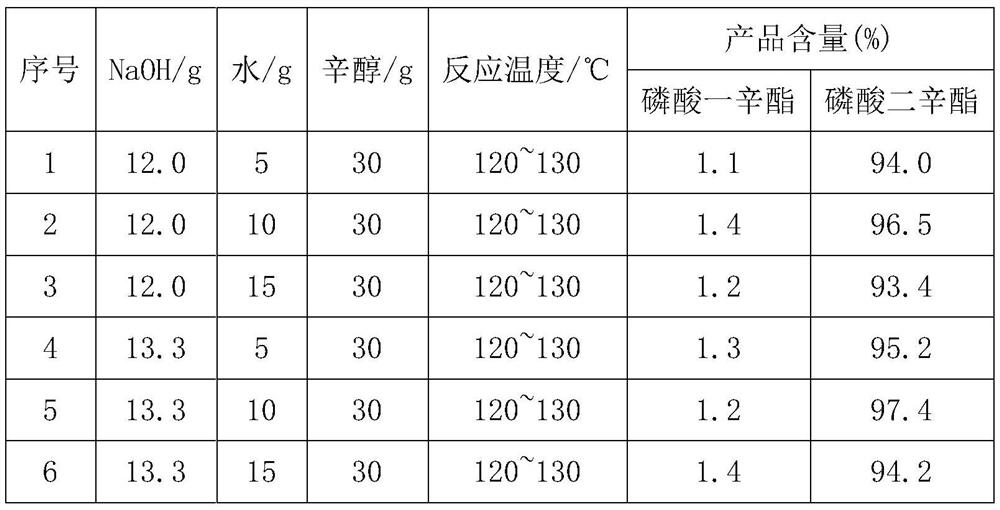

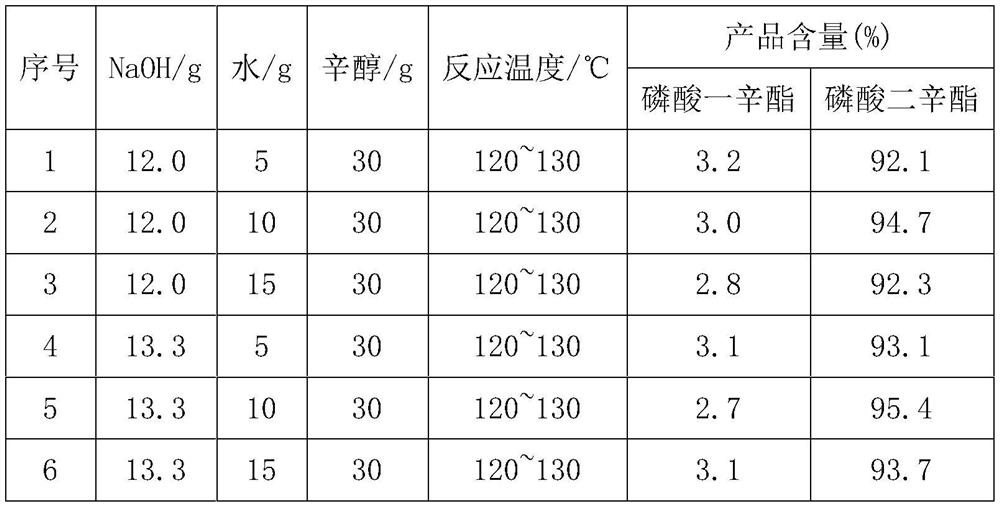

[0027] Add 100g of mixed octyl phosphates into a 250mL three-necked flask equipped with a stirring rod (wherein, the mass fraction of dioctyl phosphate is 66-68%, the mass fraction of monooctyl phosphate is 2-4%, and the mass fraction of trioctyl phosphate The mass fraction is 30~33%, and this mixed octyl phosphate comes from the by-product produced in the production process of trioctyl phosphate), 10g water, 30g octanol, carry out reaction at 120~130 ℃ for 6 hours, after the reaction finishes, go to Slowly add 100g of normal temperature water into the material, then acidify with concentrated hydrochloric acid until the pH value reaches 2-7, stir for 10-20 minutes, separate the layers after standing still, and separate the water phase. Then wash with 100g of water at 60-70°C for 3 times, then add 40-50g of hot water at 60-70°C and acidify with concentrated hydrochloric acid until the pH value is less than 1, stir for 10-20 minutes, separate the water phase, and then the organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com