A synergist for refractory copper oxide ore flotation

A synergist, copper oxide technology, applied in flotation, solid separation, etc., can solve the problem of few research reports on flotation synergists, achieve obvious technical and economic advantages and environmental benefits, good adaptability, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of this synergist, concrete steps are as follows:

[0021] First, powdery 8-hydroxyquinoline and ammonium sulfate are mixed to obtain a powdery mixed solid;

[0022] Then mix liquid dioctyl phosphate, kerosene and ethanol to obtain a liquid drug solution;

[0023] Then, adding the powdery mixed solid into the mixed liquid drug solution, adding water to prepare a solution with a volume fraction of 30%-35%;

[0024] Finally, place the prepared flotation reagent mixture solution in a 1kW microwave field for radiative heating, keep the temperature at 40°C to 50°C, heat, stir and mix evenly at a speed of not less than 800 rpm, The heat preservation and stirring time is 15-20 minutes.

[0025] The stock solution of the flotation synergist prepared according to the above requirements is directly added to the grinding operation, so that the flotation synergist and minerals can fully contact and play a role in the ball mill.

Embodiment 1

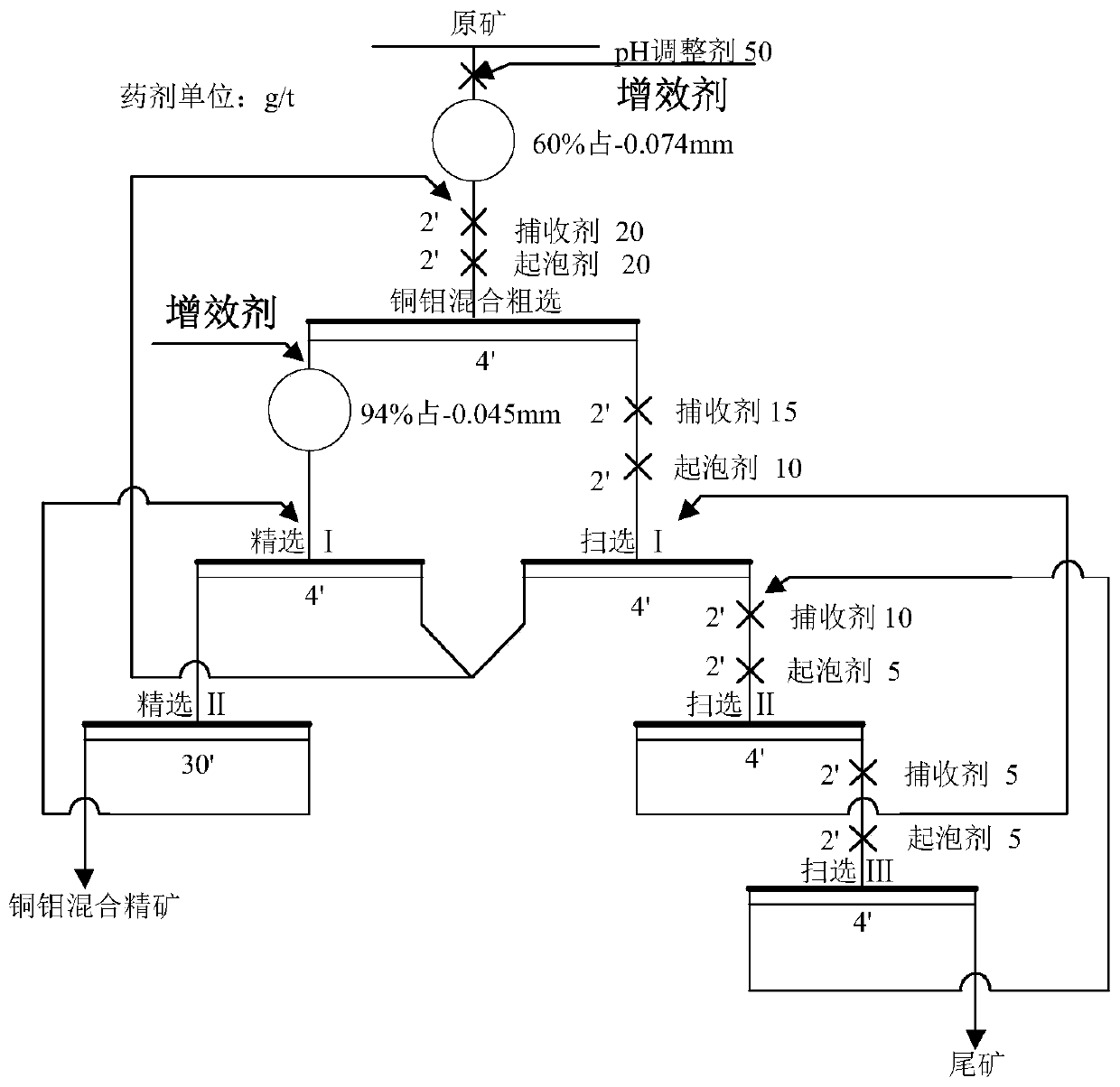

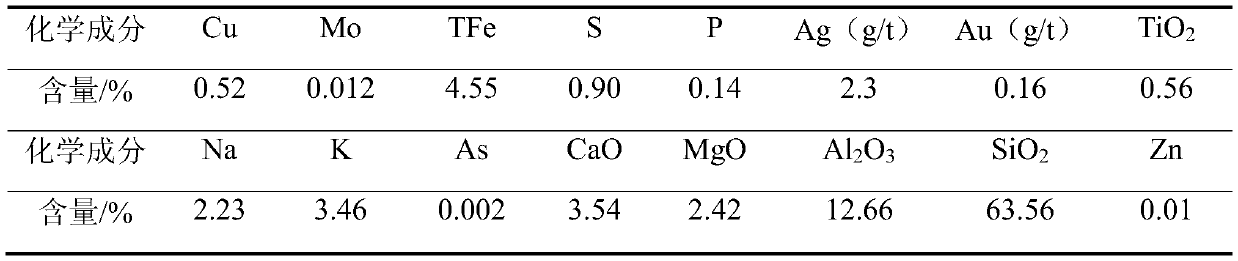

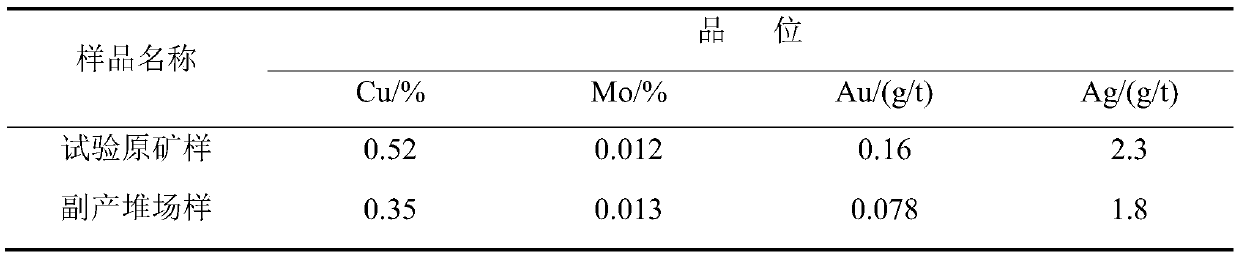

[0027] Yunnan Pulang Copper is a typical porphyry-type copper-molybdenum ore. The main valuable recoverable elements in the ore are copper and molybdenum, with grades of 0.52% and 0.012%, respectively. The results of chemical multi-element analysis are shown in Table 1. The by-product stockpile sample is the main ore supply for the initial operation of the dressing plant, and has a high oxidation rate. The content of the main valuable recovered elements was determined, and the results are shown in Table 2.

[0028] Table 1 Chemical multi-element analysis results of raw ore

[0029]

[0030] Table 2 Analysis results of chemical elements in by-product stockyard samples

[0031]

[0032] The main valuable recoverable elements of this ore are copper and molybdenum, with grades of 0.52% and 0.012% respectively; gold and silver are the main associated precious metal elements, with contents of 0.16g / t and 2.3g / t respectively. The useful minerals in the ore are chalcopyrite and...

Embodiment 2

[0039] Copper resources are abundant in Tibet, but most copper deposits are oxidized to varying degrees. The original ore of a copper oxide mine in Tibet contains 2.50% copper, high CaO content, Fe 2 o 3 The content is 29.908%. The ore belongs to refractory copper oxide ore. The chemical multi-element analysis results are shown in Table 4.

[0040] Table 4 Raw ore chemical multi-element analysis results / %

[0041]

[0042] From the multi-element analysis results of the raw ore, it can be seen that the valuable recoverable element in the ore is mainly copper, and the contents of other beneficial associated components and harmful elements are relatively low. The results of copper phase analysis show that the oxidation rate of copper in the ore is as high as 90.32%, and the ore is copper oxide ore. The main metal minerals in the ore are malachite, chrysocolla, copperite, chalcopyrite, chalcocite, magnetite, hematite, limonite, pyrite, etc. The gangue minerals are mainly cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com