New method of using novel extracting agent to extract scandium oxide from titanium dioxide waste acid

A technology of titanium dioxide waste acid and extraction agent, which is applied in the preparation/processing of scandium oxide/hydroxide, rare earth metal oxide/hydroxide, rare earth metal compound, etc., can solve the economic loss of low recovery rate and waste of resources , extracting scandium oxide with low purity, etc., to achieve the effect of high recovery rate, good effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

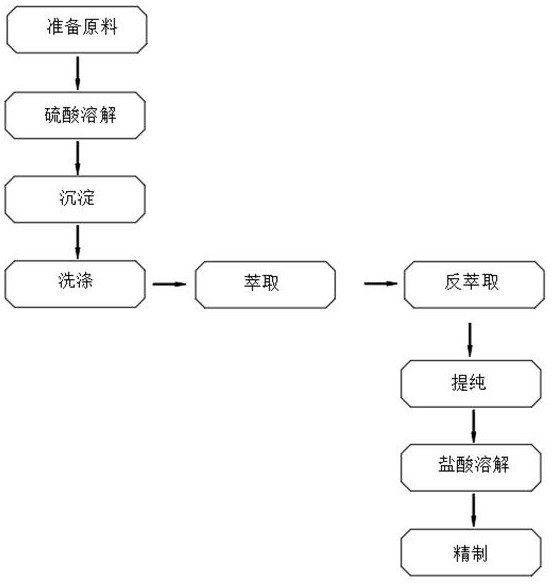

Image

Examples

Embodiment 1

[0033] A new method for proposing scandium oxide from titanium white waste acid by a new type of extractant, comprising the following steps:

[0034] S1 Prepare raw materials: titanium white waste acid water raw materials, concentrated sulfuric acid raw materials;

[0035] S2 sulfuric acid dissolution: add water and concentrated sulfuric acid solution to the titanium white waste acid water and stir and mix;

[0036] S3 Precipitation: add flocculant to the mixed solution, the cost of the flocculant is low, carry out precipitation, and filter the solution after precipitation;

[0037] S4 washing: add water, sulfuric acid and hydrogen peroxide to the filtered solution and mix and stir. The mixture of sulfuric acid and hydrogen peroxide reacts with titanium in the scandium-titanium organic phase more efficiently, and achieves the purpose of separating scandium;

[0038] S5 extraction: add dioctyl phosphate and tributyl phosphate to the washed mixed solution for extraction, diocty...

Embodiment 2

[0047] S1 Prepare raw materials: titanium white waste acid water raw materials, concentrated sulfuric acid raw materials;

[0048] S2 sulfuric acid dissolution: add water and concentrated sulfuric acid solution to the titanium white waste acid water and stir and mix;

[0049] S3 Precipitation: add flocculant to the mixed solution, the cost of the flocculant is low, carry out precipitation, and filter the solution after precipitation;

[0050] S4 washing: add water, sulfuric acid and hydrogen peroxide to the filtered solution and mix and stir. The mixture of sulfuric acid and hydrogen peroxide reacts with titanium in the scandium-titanium organic phase more efficiently, and achieves the purpose of separating scandium;

[0051] S5 extraction: add dioctyl phosphate and tributyl phosphate to the washed mixed solution for extraction, dioctyl phosphate and tributyl phosphate can further purify scandium oxide;

[0052] S6 stripping: add sodium hydroxide to the mixed extract, heat it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com