Manufacturing method of anti-static filtering material and anti-static filtering material

A technology of filter material and production method, which is applied in the field of materials to achieve the effect of avoiding electrostatic hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

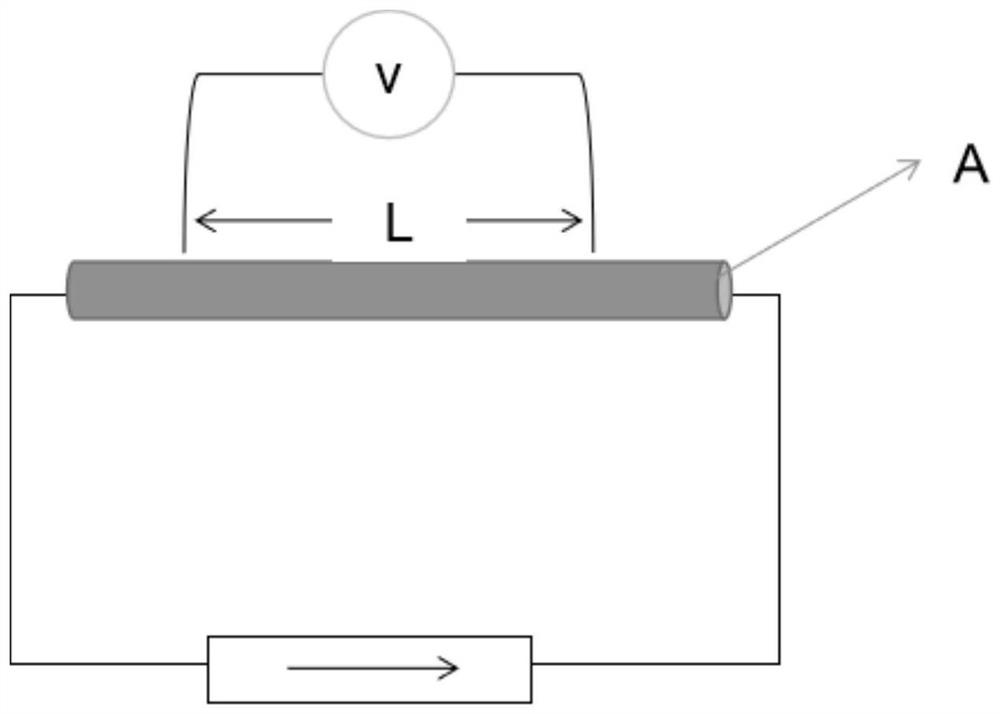

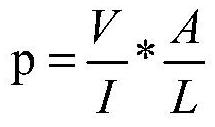

Image

Examples

Embodiment 1

[0035] 1. Modified nano tourmaline

[0036] The nano-tourmaline that takes 5g joins and joins in the 30ml toluene and the water mixed solvent that solid-liquid ratio is 1:6, is placed on there-necked flask then, adds coupling agent (isopropyl trititanic acid) in flask, makes in whole The mass fraction of the coupling agent in the mixture system is 2%. Add the reaction solvent toluene to the flask, and continue the reaction in an oil bath at 90°C for 3 hours. Then wash with distilled water and absolute ethanol for 3 times, put it in a centrifuge at a speed of 8000r / min for centrifugation, and dry it at 80°C after centrifugation to obtain surface-modified tourmaline, and grind it to 10nm particle size;

[0037] 2. Preparation of PTFE / tourmaline blend fiber

[0038] PTFE micropowder and modified tourmaline are mixed according to a certain mass ratio, and then mixed with aviation kerosene, PTFE micropowder: modified tourmaline: aviation kerosene = 17:3:5.3, and the mixed powder...

Embodiment 2

[0044] 1. Modified nano tourmaline

[0045] The nano-tourmaline that takes 7g joins and joins in the 42ml toluene and the water mixed solvent that solid-liquid ratio is 1:6, is placed on there-necked flask then, adds coupling agent (isopropyl trititanic acid) in flask, makes in whole The mass fraction of the coupling agent in the mixture system is 1%. Add the reaction solvent toluene to the flask, and continue the reaction in an oil bath at 90°C for 3 hours. Then wash with distilled water and absolute ethanol for 3 times, put it in a centrifuge at a speed of 5000r / min for centrifugation, and dry it at 60°C after centrifugation to obtain surface-modified tourmaline, and grind it to 60nm particle size.

[0046] 2. Preparation of PTFE / tourmaline blended fiber

[0047] PTFE micropowder and modified tourmaline are mixed according to a certain mass ratio, and then mixed with aviation kerosene, PTFE micropowder: modified tourmaline: aviation kerosene = 17:3:5.3, and the mixed powd...

Embodiment 3

[0053] 1. Modified nano tourmaline

[0054] The nano-tourmaline that takes by weighing 10g joins in the 60ml toluene and the water mixed solvent that solid-liquid ratio is 1:6, is placed in there-necked flask then, adds coupling agent (isopropyl trititanic acid) in flask, makes in whole The mass fraction of the coupling agent in the mixture system is 3%. Add the reaction solvent toluene to the flask, and continue the reaction in an oil bath at 90°C for 3 hours. Then wash with distilled water and absolute ethanol for 3 times, put it in a centrifuge at a speed of 6000r / min for centrifugation, and dry it at 70°C after centrifugation to obtain surface-modified tourmaline, and grind it to 100nm .

[0055] 2. Preparation of PTFE / tourmaline blended fiber

[0056] PTFE micropowder and modified tourmaline are mixed according to a certain mass ratio, and then mixed with aviation kerosene, PTFE micropowder: modified tourmaline: aviation kerosene = 17:3:5.3, and the mixed powder is age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com