Special antistatic agent for light fuel oil and preparation method and application thereof

A technology of light fuel oil and antistatic agent, used in fuel additives, fuels, liquid carbon-containing fuels, etc., can solve the problems of continuous decline in the electrical conductivity of oil products, achieve good mutual solubility and dispersibility, no three waste emissions, Good oil stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment discloses a preparation method of a special antistatic agent for light fuel oil, comprising the following steps:

[0035] 1: Preparation of imidazoline intermediates

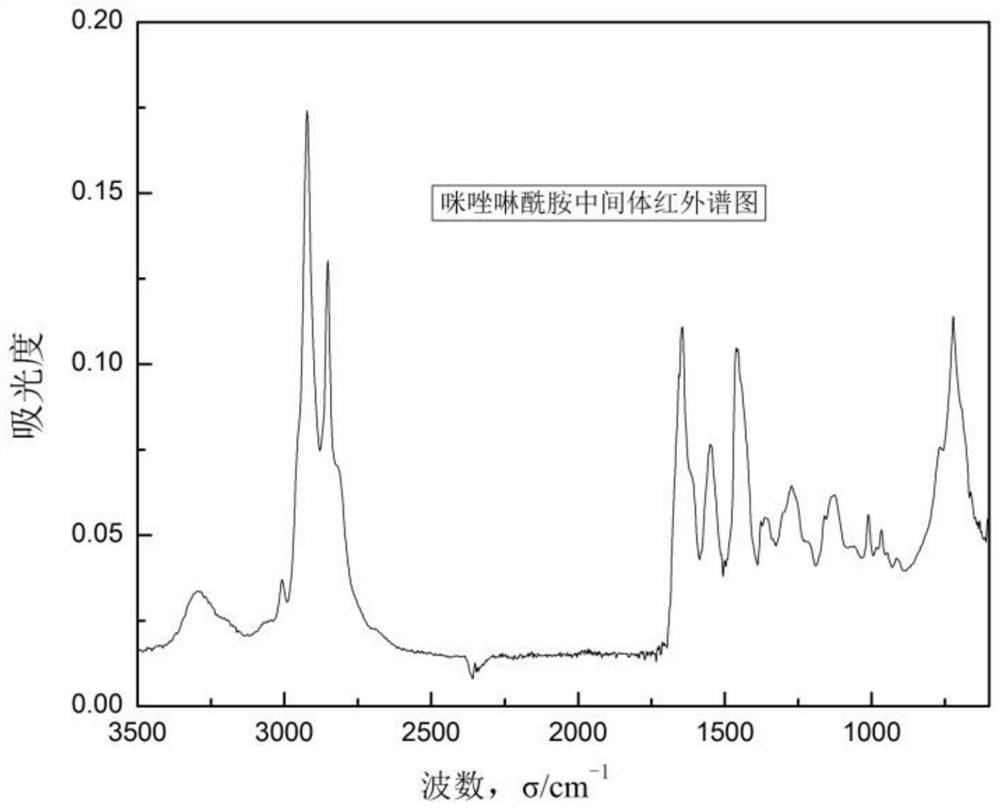

[0036] Preparation of imidazoline intermediate: weigh 280 parts of octadecenoic acid (hexadecenoic acid), add 150 parts of triethylenetetramine (diethylenetriamine, tetraethylenepentamine), and 10 parts of xylene as water separating agent After 4-6 hours of reaction at 130-140°C, it was raised to 220-240°C for 4-6 hours of reaction. The infrared spectrum of its imidazoline (amide) intermediate is as follows figure 1 shown, 1600cm in the infrared spectrum -1 The peak is the characteristic peak of imidazoline.

[0037] 2: Preparation of imidazoline polyoxyethylene ether intermediate:

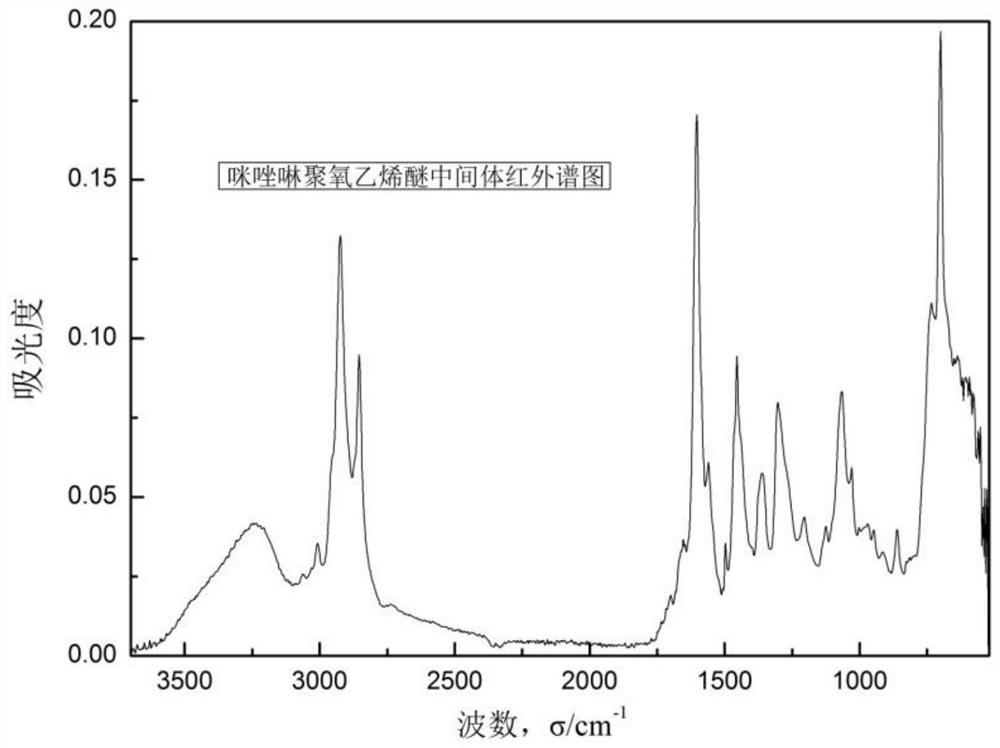

[0038] Weigh 100 parts of the imidazoline intermediate and add it into the autoclave, add 0.1 gram of potassium hydroxide, and pass through the propylene oxide addition reaction. The addition ratio...

Embodiment 2

[0047] The present embodiment discloses a preparation method of a special antistatic agent for light fuel oil, comprising the following steps:

[0048] 1: Preparation of imidazoline intermediates

[0049] Preparation of imidazoline intermediate: weigh 280 parts of octadecenoic acid (hexadecenoic acid), add 150 parts of triethylenetetramine (diethylenetriamine, tetraethylenepentamine), and 10 parts of xylene as water separating agent After 4-6 hours of reaction at 130-140°C, it was raised to 220-240°C for 4-6 hours of reaction.

[0050] 2: Preparation of imidazoline polyoxyethylene ether intermediate:

[0051] 100 parts of imidazoline intermediates were weighed into the autoclave, 0.1 g of potassium hydroxide was added, and ethylene oxide was added to the reaction vessel. The addition ratio of ethylene oxide is 1-1.2 times the mass of the imidazoline intermediate.

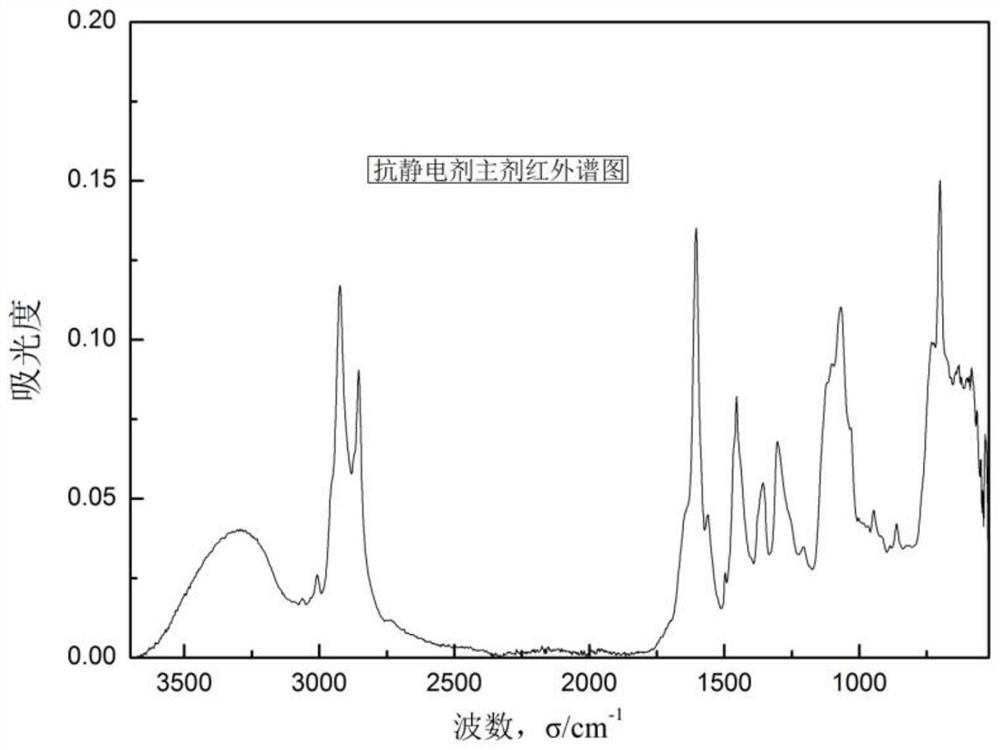

[0052] 3: Preparation of main agent of antistatic agent:

[0053]Weigh 450 parts of imidazoline polyoxyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com