Patents

Literature

37results about How to "Enough suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

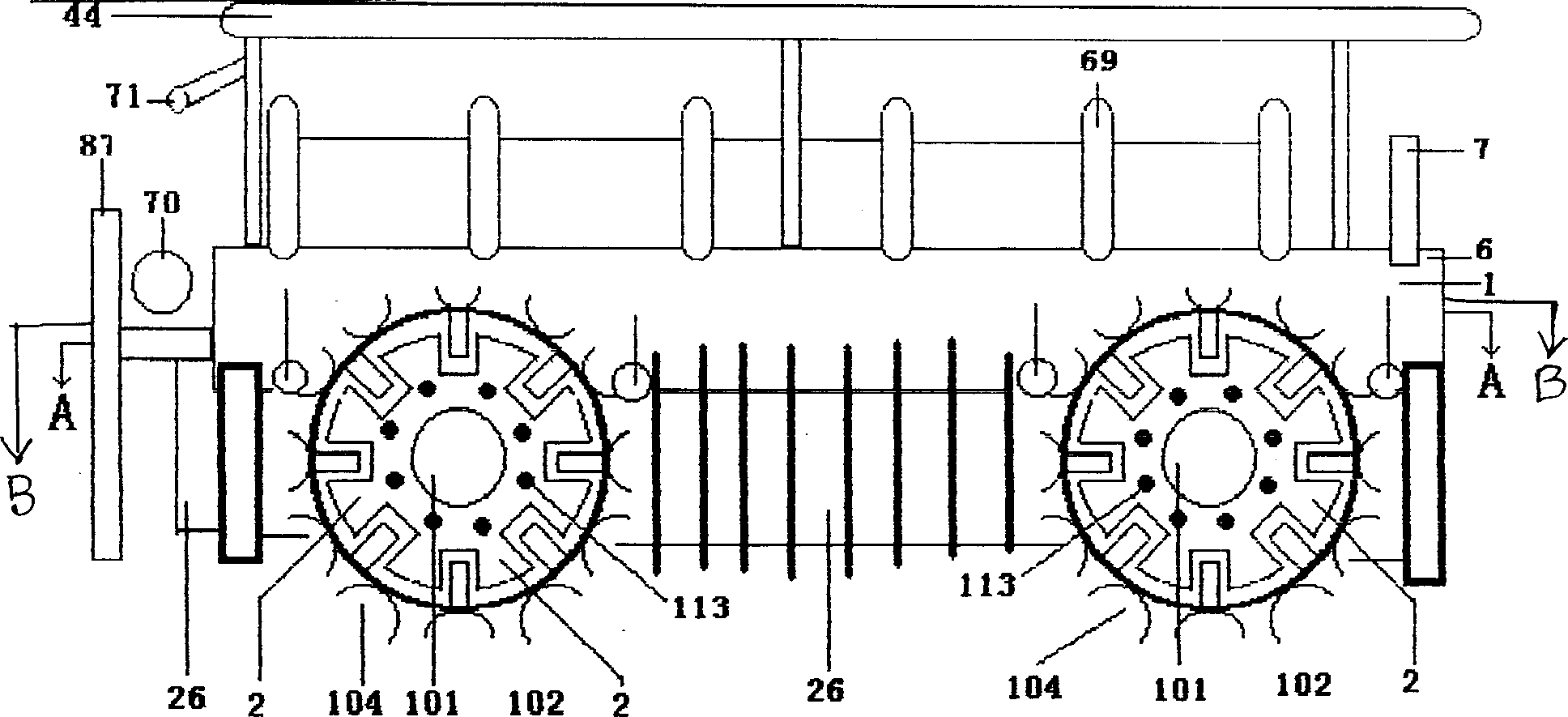

Multifunctional cleaning device for building surface

InactiveCN1511650AEffective guarantee of supplyEffective controlCleaning using liquidsBuilding support scaffoldsDrive wheelVehicle frame

The multifunctional cleaning apparatus for building surface consists of carriage, cleaning mechanism on leveling platform and driving wheel mechanism. The carriage is provided with solar cell plate, platform with guard rail, video camera, lamp, waterproof hood, clear water tank, waste water tank, electric interface, track, etc. The cleaning mechanism is provided with ice thawing unit, two rolling brushes, two pollutant sucking units, two scrapers, stoving unit and blower. The carriage is provided also wheels or circular caterpillar bands with sucking disc or combined forcepated wheels on special tracks. The present invention can operate on the surface of different buildings day and night.

Owner:李京岐

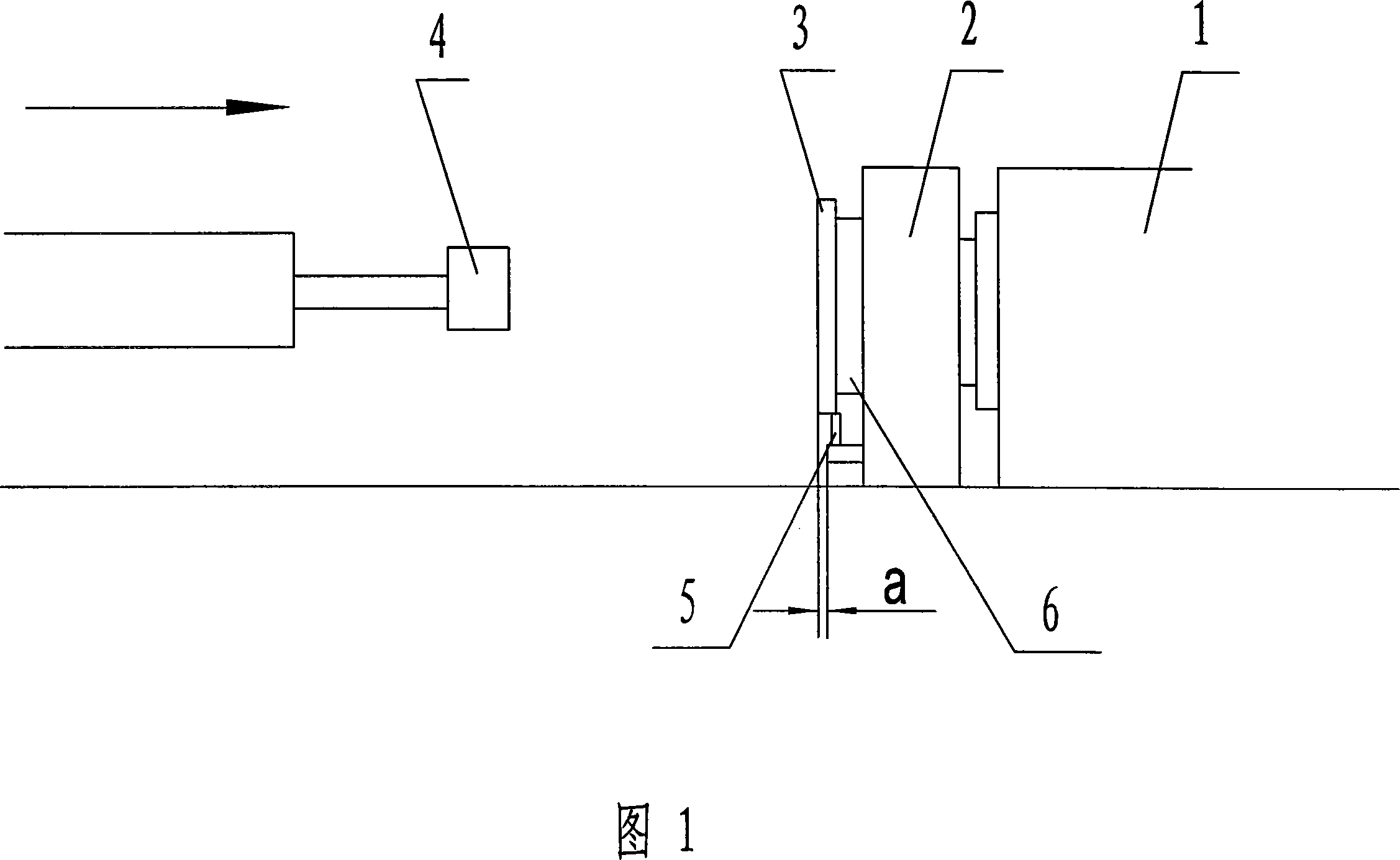

Non warping surface grinding method for angular-contact roller bearing ferrule

InactiveCN101186021AEnough suctionReduce stressPlane surface grinding machinesSurface grindingGrinding wheel

The invention relates to a non-warp plane grinding method used for a thrust roller bearing ferrule. An electromagnetic non-core clamp is used as a work piece clamp on a machine tool. The work piece of the thrust roller bearing ferrule is arranged on the clamp and the work piece turns together with a grid of the electromagnetic non-core clamp. The end face of the bearing ferrule is grinded by the end face of a boring grinding wheel. A low magnetic force of the electromagnetic non-core clamp is adopted to clamp the processing ferrule plane of the thrust roller bearing ferrule so as to reduce the stress to the work piece and to reduce an elastic distortion degree of the work piece in a clamping process. Then a parallel difference and a plane degree of the grinded place can be guaranteed and the parallel difference and the warp are all less than 0.002mm. A warp distortion of the work piece is just the 1 to 2 percent of that caused by the common processing method, almost without any warp.

Owner:LUOYANG BEARING SCI & TECH CO LTD

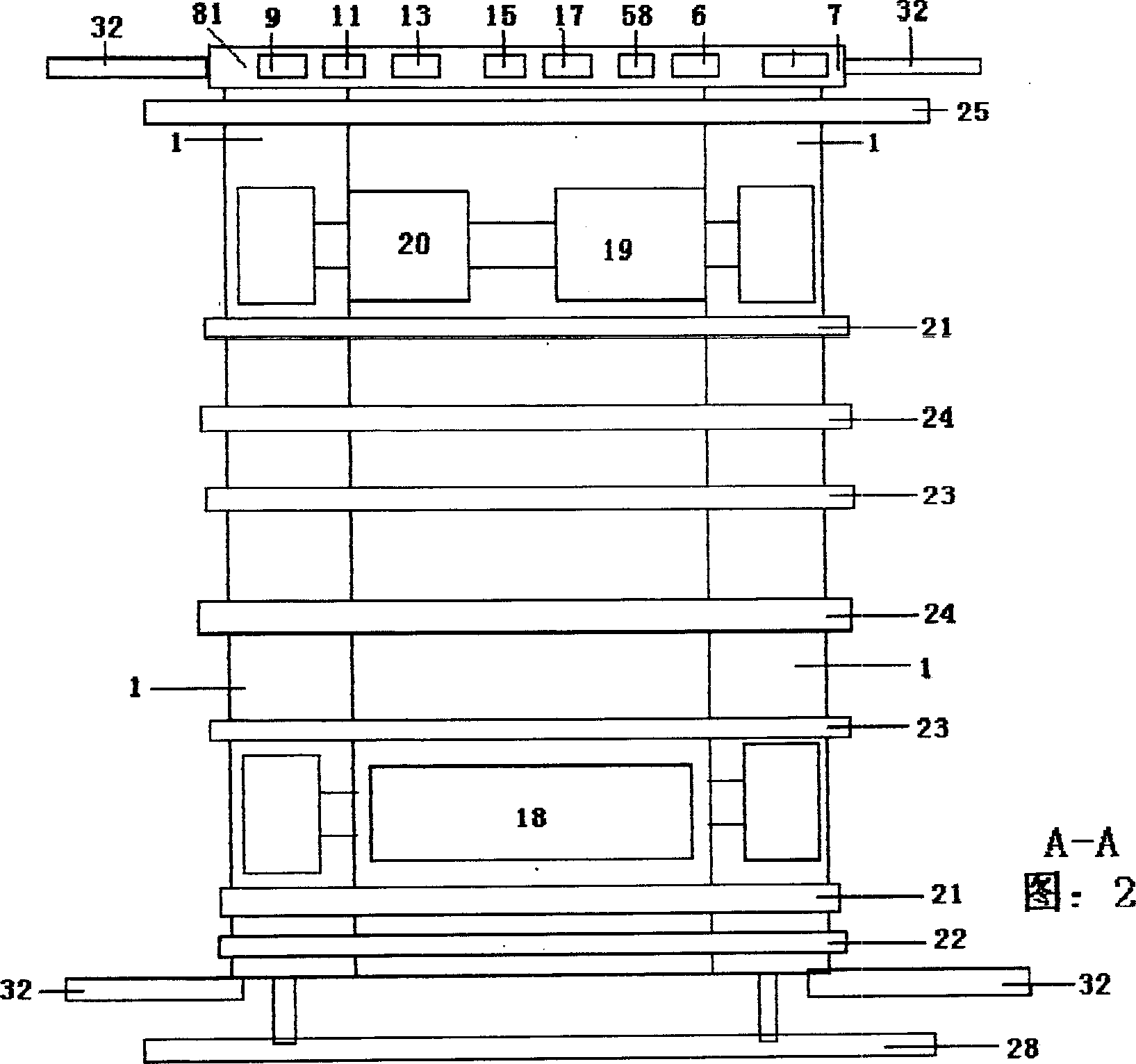

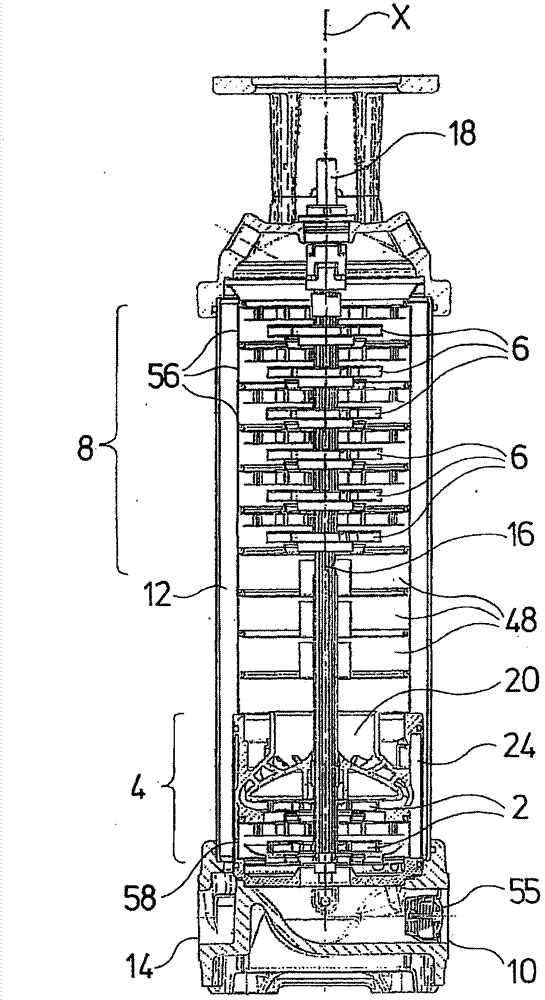

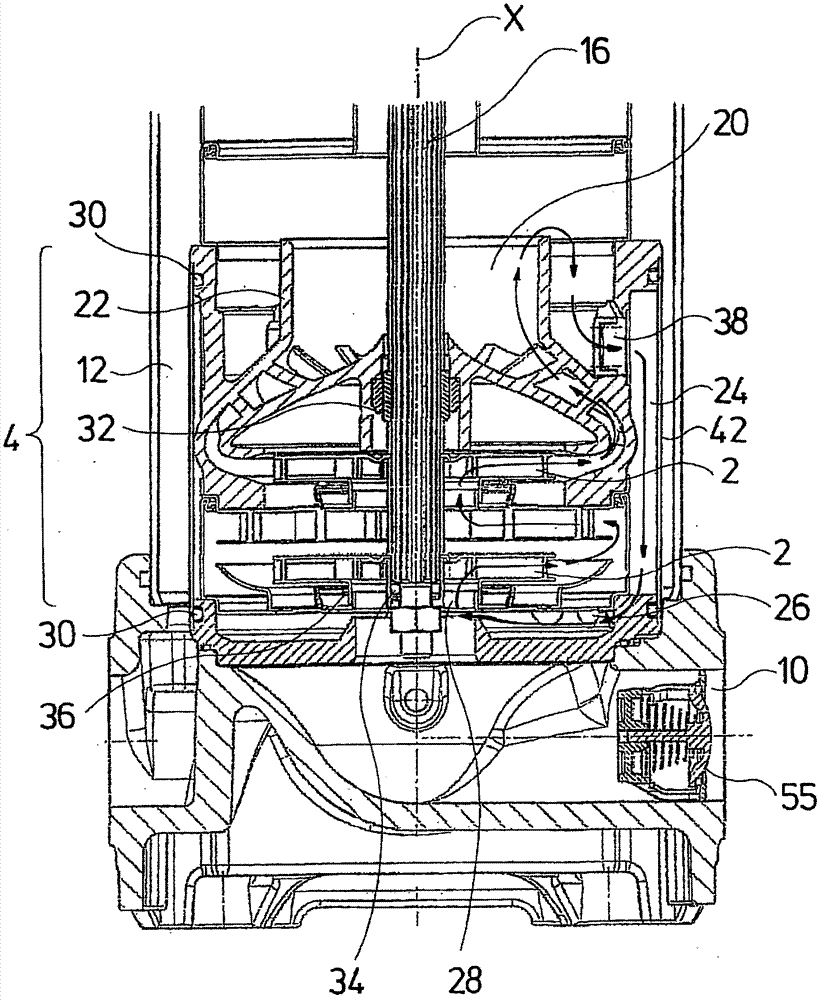

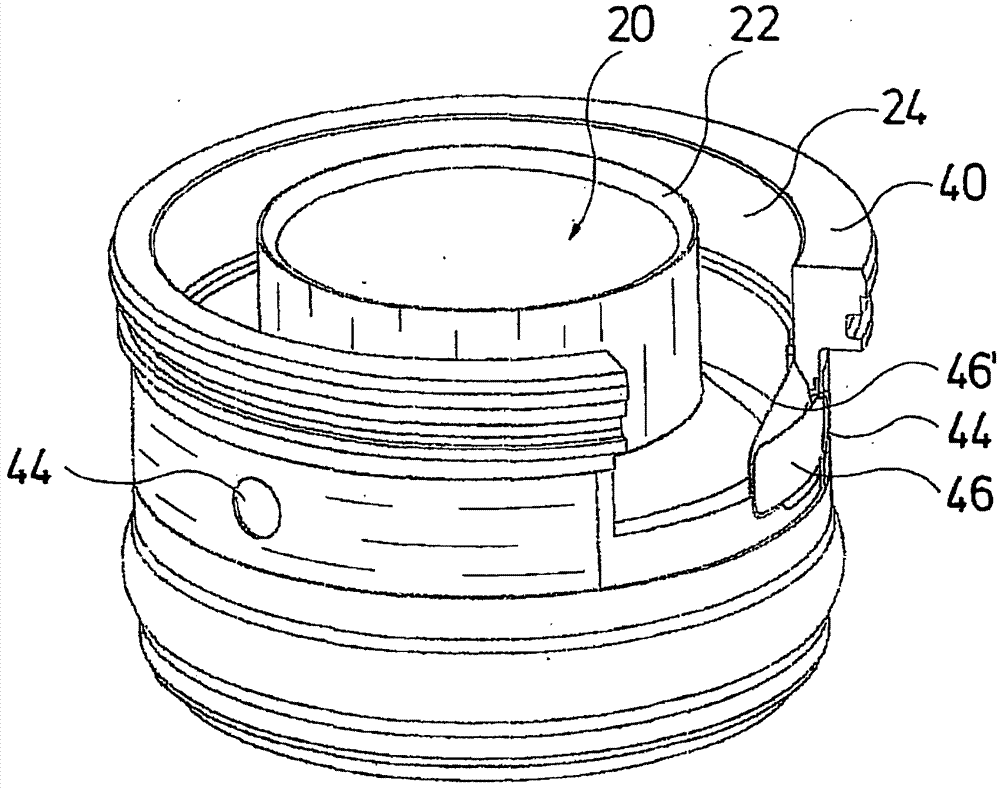

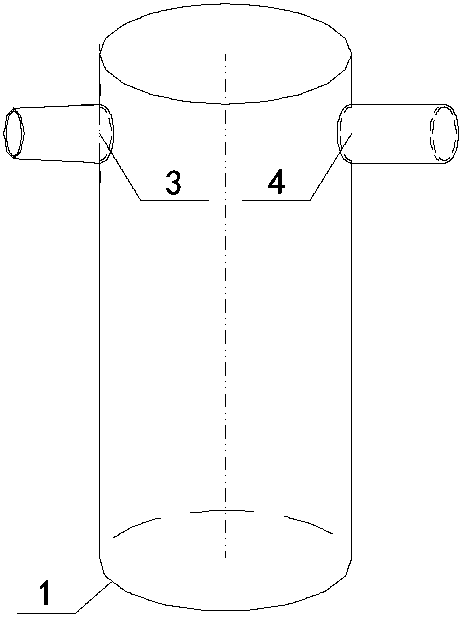

Multi stage centrifugal pump system

InactiveCN102734176AFull flowEnough suctionPump componentsPriming pumpWaste managementCentrifugal pump

A multi-stage centrifugal pump assembly includes at least two impellers (2, 6) and two impeller groups (4, 8) which are consecutive in a flow direction and each with at least one impeller (2, 6). A backflow channel (24) connects an exit side of the first impeller group (4) to an entry side thereof is located in a first impeller group (4) of the two impeller groups (4, 8).

Owner:GRUNDFOS MANAGEMENT AS

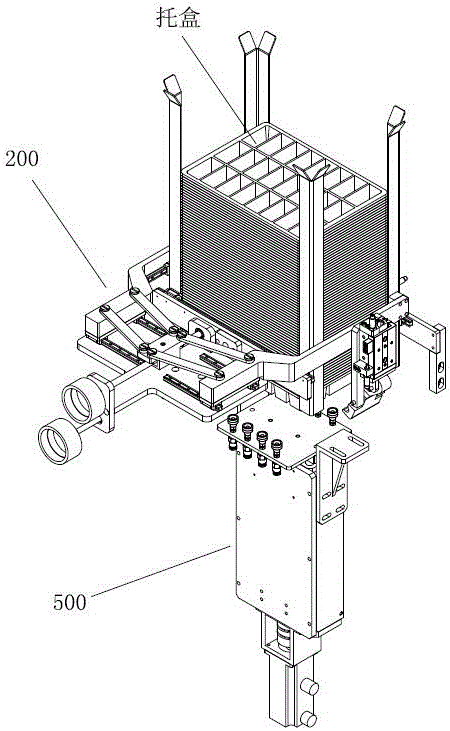

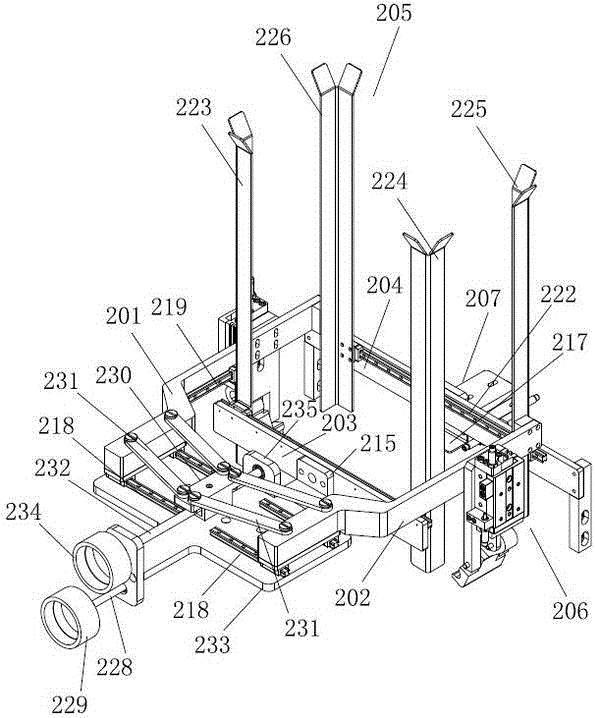

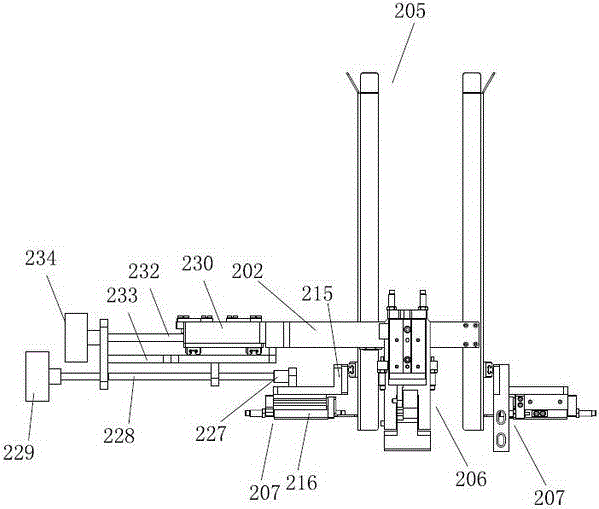

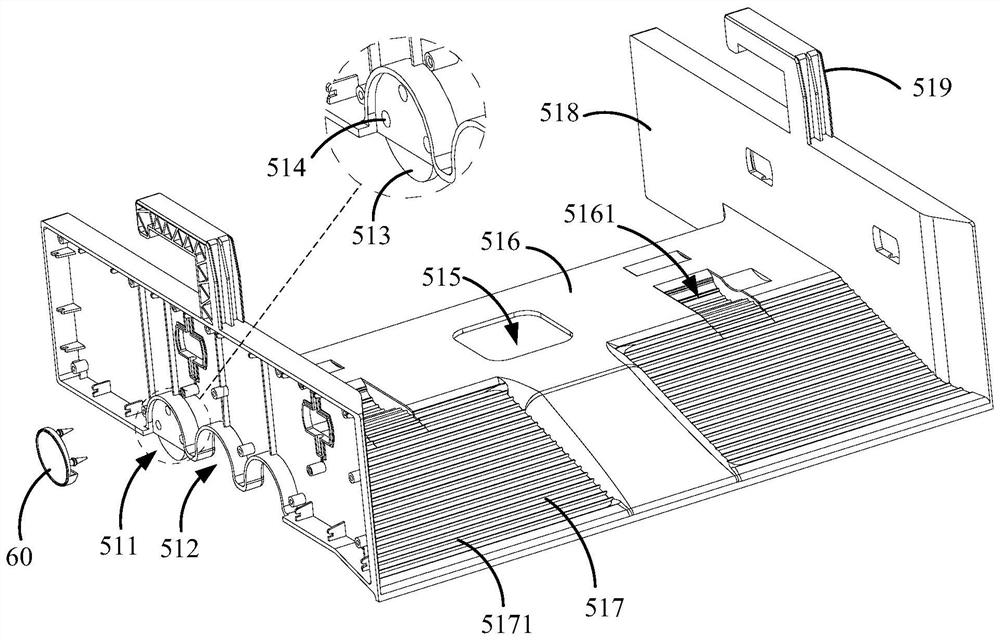

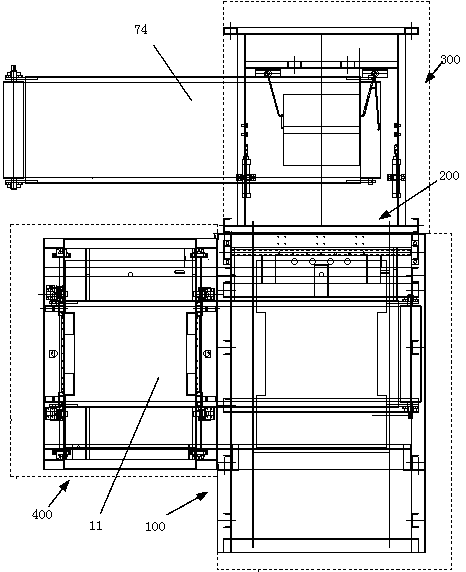

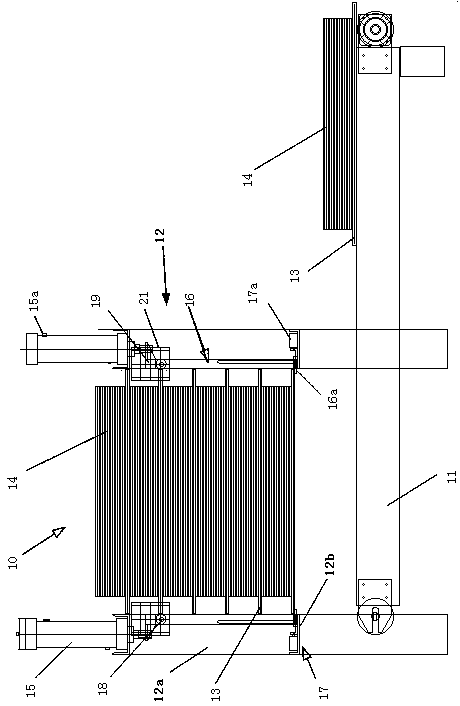

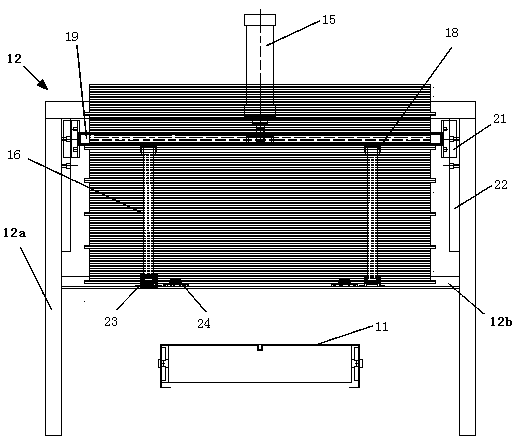

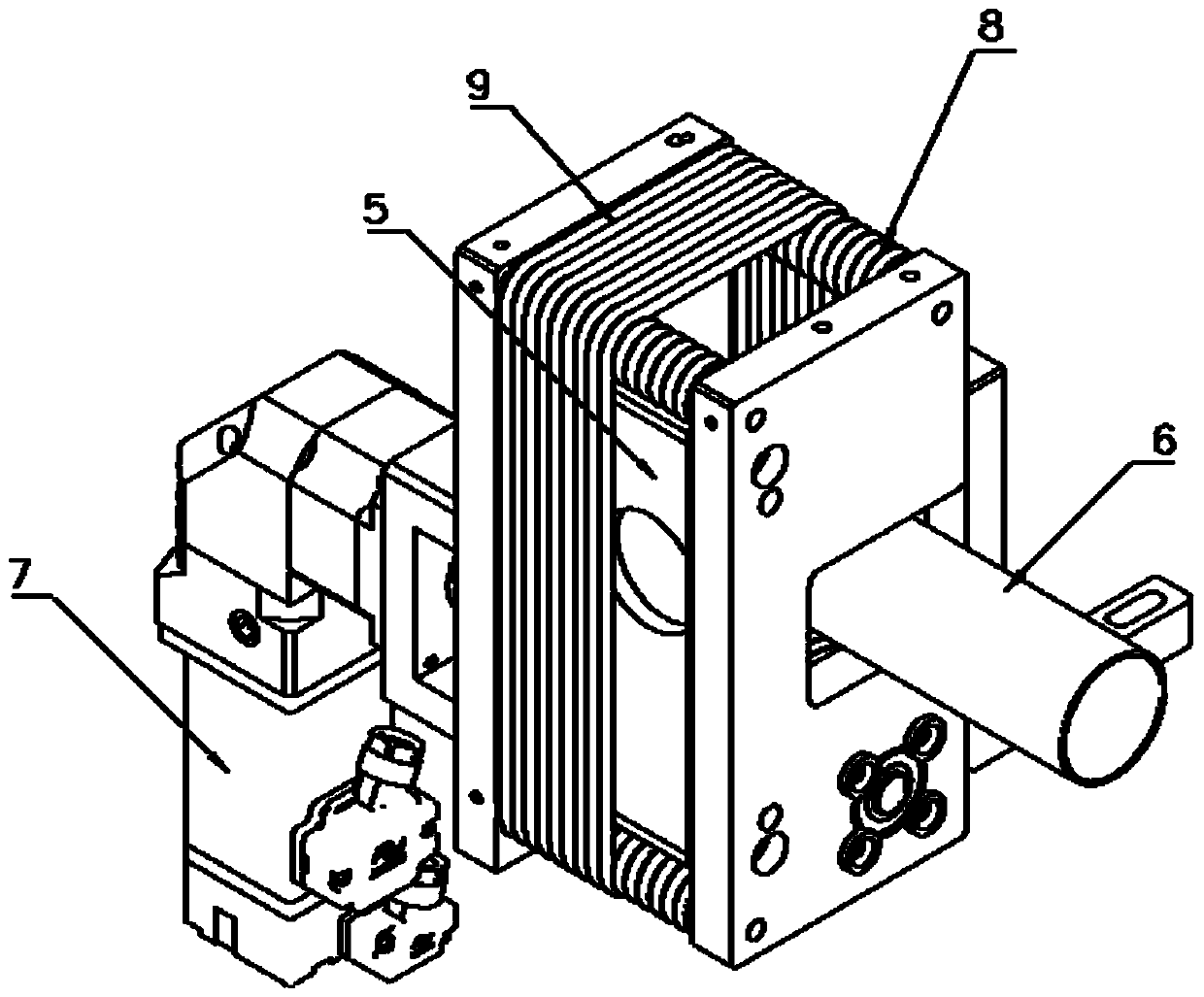

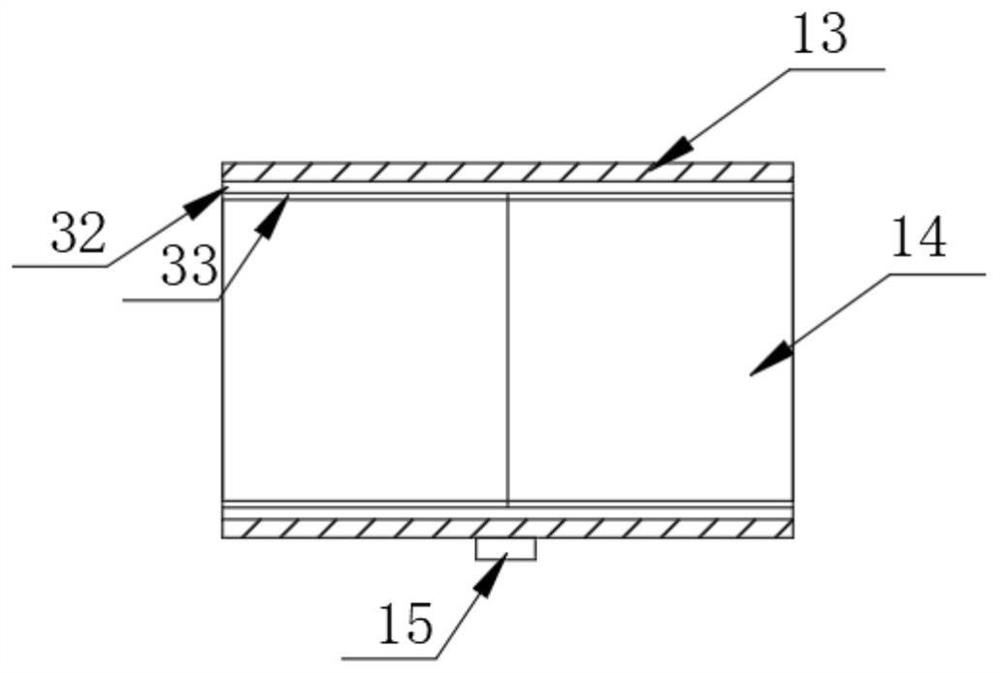

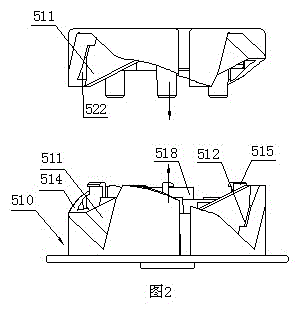

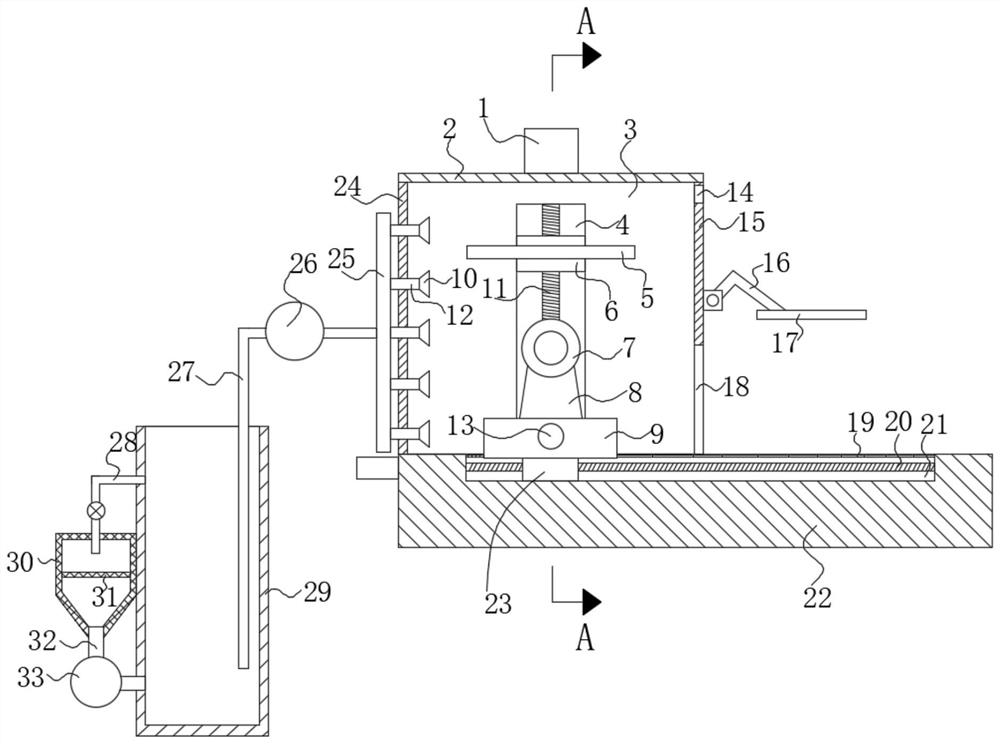

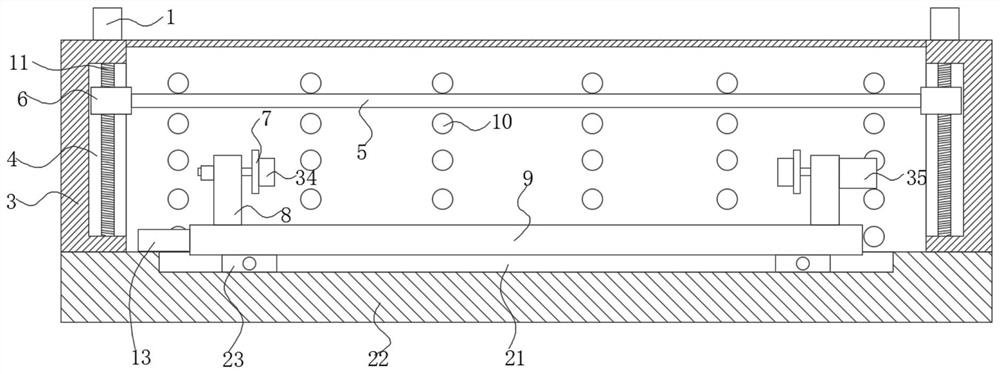

Box filling frame assembly of box discharge mechanism

ActiveCN106043813AMeet the requirements for storing trays of different sizesAccurate separationPackagingEngineeringMechanical engineering

The invention relates to the field of machining box filling, in particular to a box filling frame assembly of a box discharge mechanism. The box filling frame assembly comprises an adjustable box filling frame and a lifting suction part located below the adjustable box filling frame. The adjustable box filling frame comprises an installation left plate, an installation right plate, an installation front plate and an installation rear plate. The left-right interval can be adjusted through the installation left plate and the installation right plate. The front-back interval can be adjusted through the installation front plate and the installation rear plate. The installation left plate, the installation right plate, the installation front plate and the installation rear plate are each vertically provided with a protection plate for limiting supporting boxes. A supporting box storage space for containing the supporting boxes is defined by the protection plates. For the situation that the supporting boxes are closely stacked or horizontal edges of the supporting boxes are not obvious, the supporting boxes which are closely stacked can be accurately separated. The left-right interval and the front-back interval can be adjusted through the adjustable box filling frame, and therefore the left-right size and the front-back size of the supporting box storage space are adjusted in a driving manner, and the box filling frame assembly can adapt to box discharge processing conducted on the supporting boxes of different sizes.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

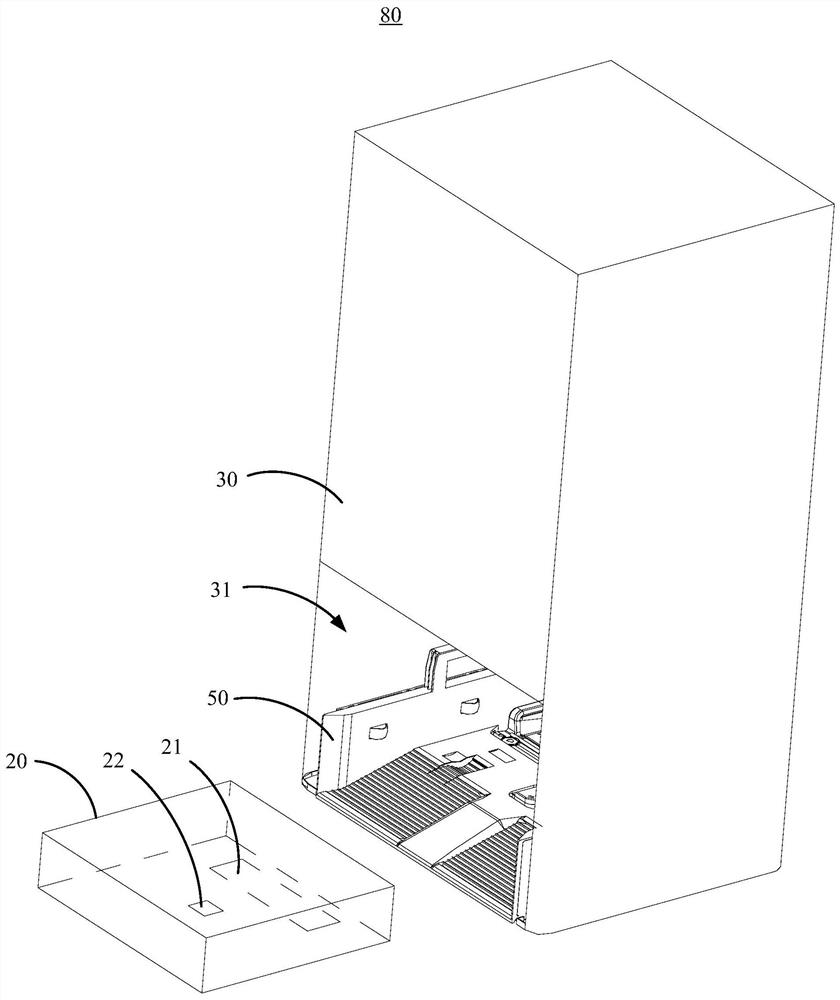

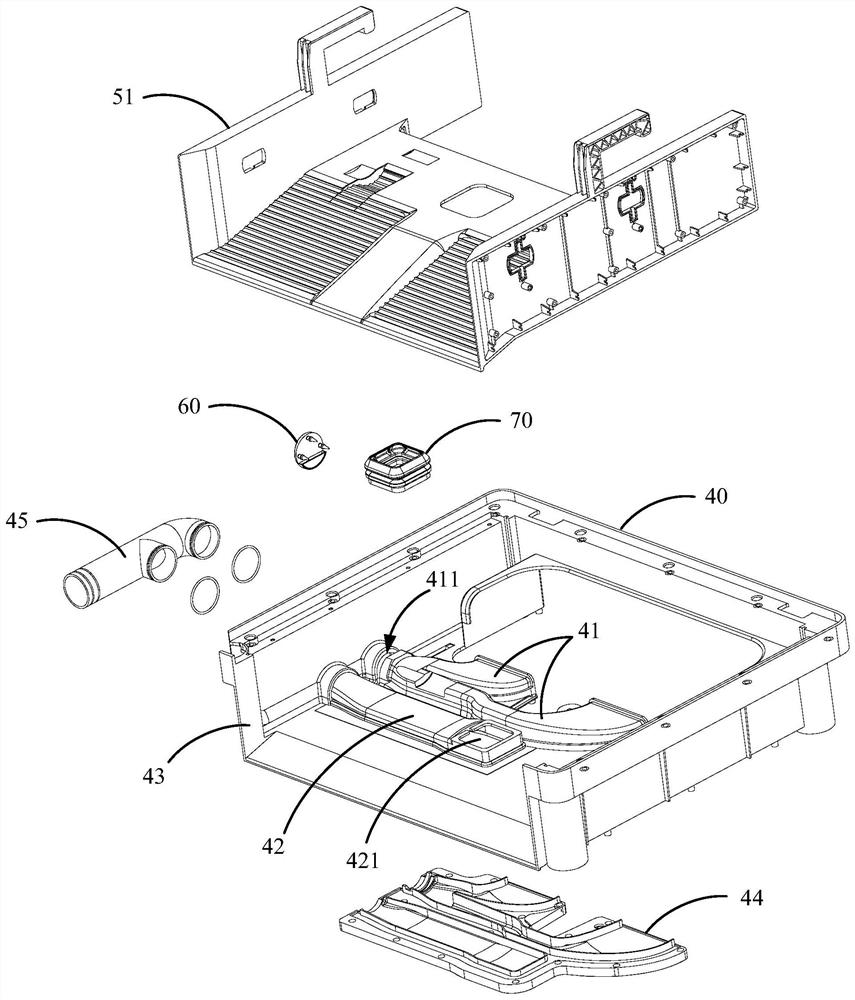

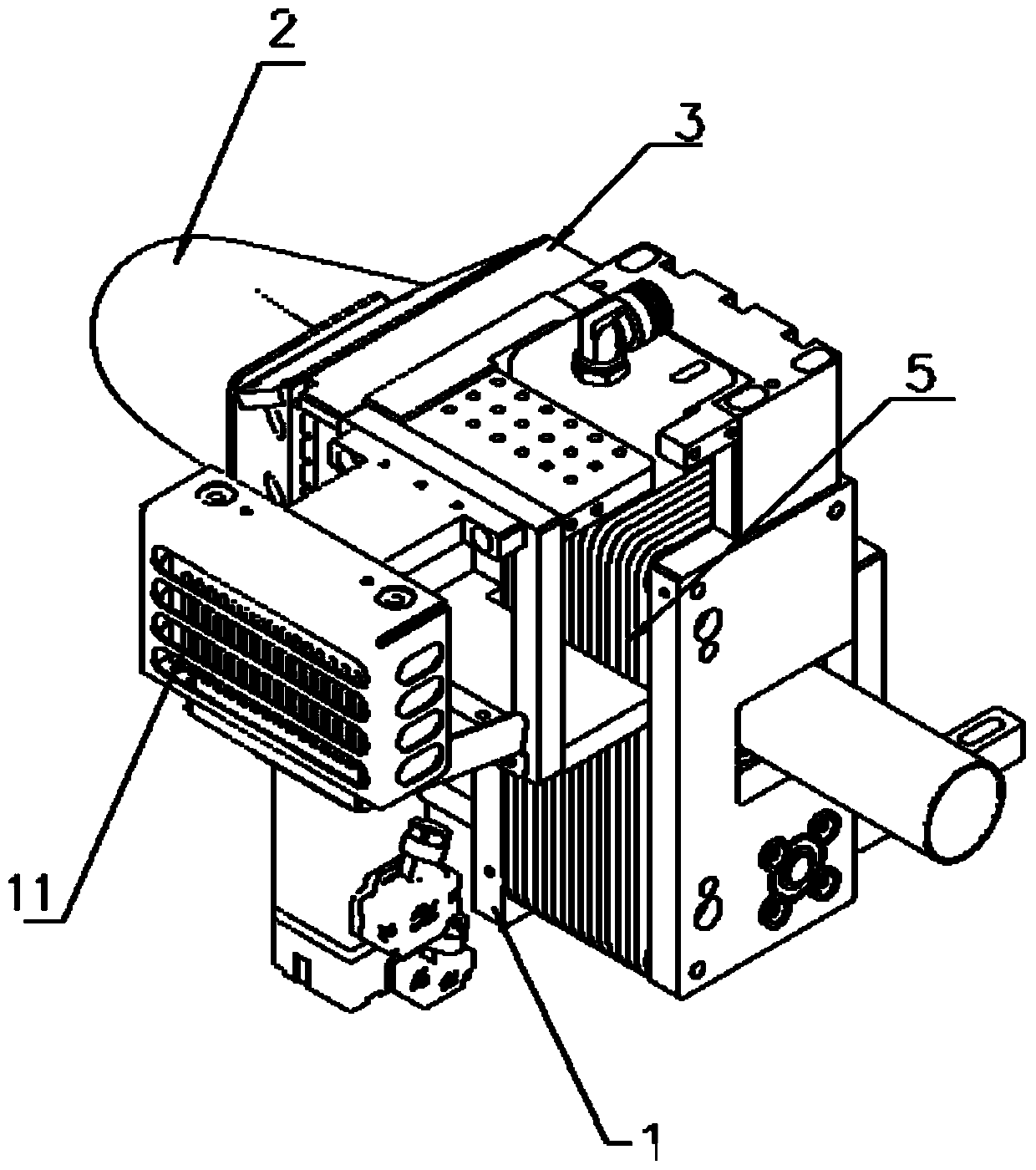

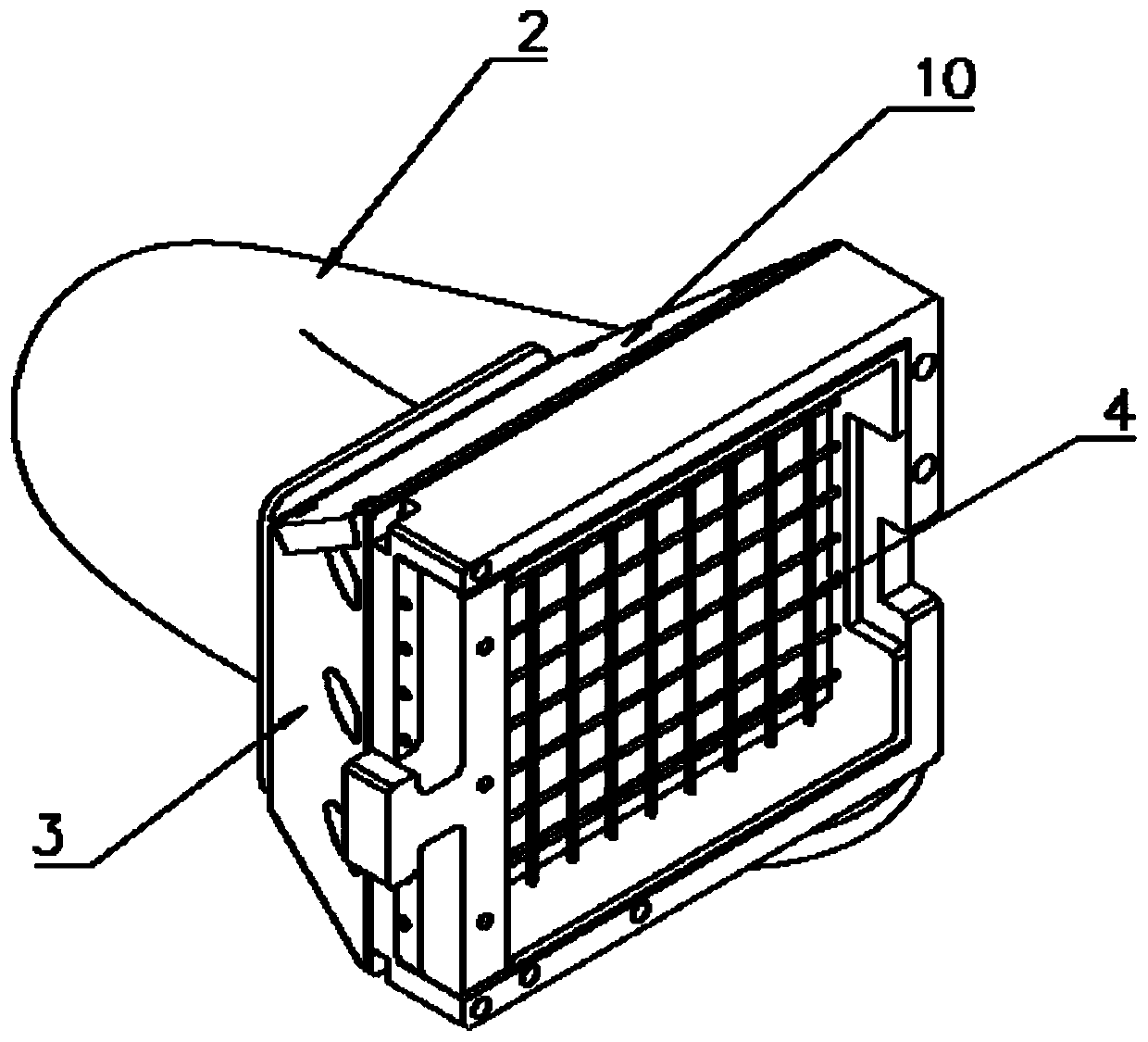

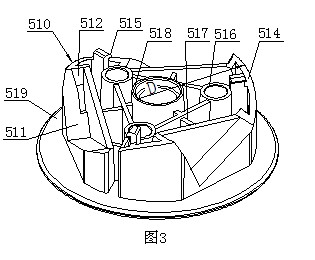

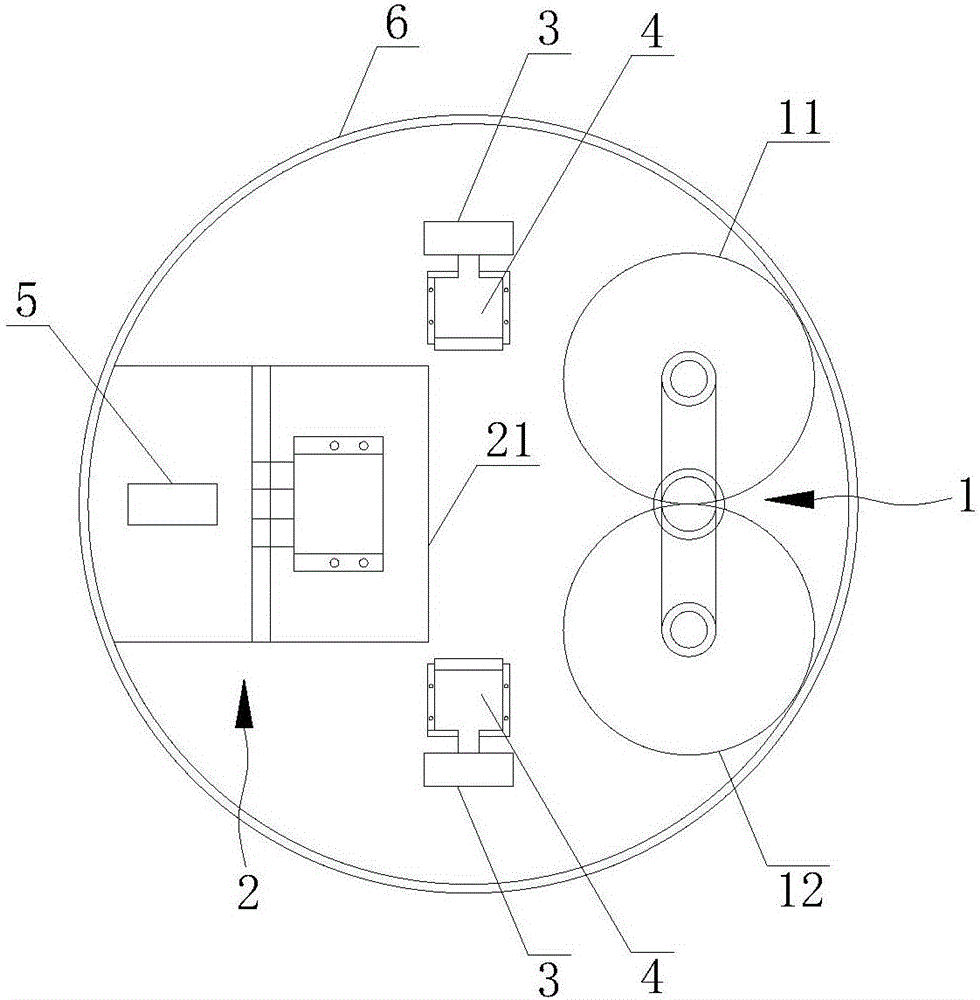

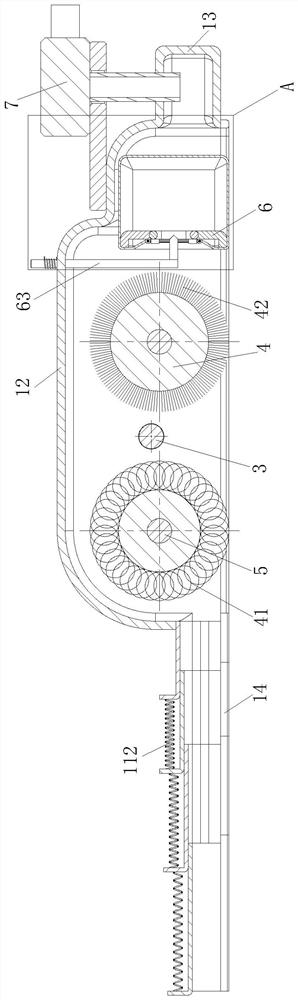

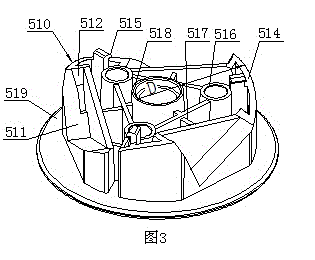

Sweeping robot base station and cleaning equipment

PendingCN112353327AReduce manufacturing costReduce overall volume and floor spaceCarpet cleanersFloor cleanersMoving partsEngineering

The invention discloses a sweeping robot base station. The sweeping robot base station comprises a base station body, an air duct assembly and a switch assembly. The base station body is provided witha cleaning cavity, the cleaning cavity is provided with an opening for the sweeping robot to enter and exit, and a fan is further arranged in the base station body. The air duct assembly is installedin the cleaning cavity and comprises a plurality of air ducts, one end of each air duct is communicated with the draught fan, and the other end of each air duct is communicated with the cleaning cavity. The switch assembly is installed in the cleaning cavity and comprises a moving part and a driving part for driving the moving part to move, and the moving part is driven by the driving part to selectively open at least one of the multiple air ducts and close the remaining air ducts. The sweeping robot base station can reduce the production cost.

Owner:SHEN ZHEN 3IROBOTICS CO LTD

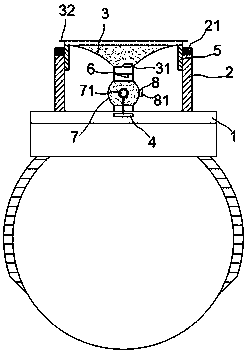

Efficient fixing device for monitor

InactiveCN107830379AWon't breakImprove convenience and efficiencyMachine supportsClosed circuit television systemsExhaust valveEngineering

The invention relates to an efficient fixing device for a monitor. The efficient fixing device for the monitor comprises a base. A support cylinder is fixedly arranged on the base. A positioning sucker is mounted on the axis of the support cylinder. An air guide hole is formed in the center of the positioning sucker. A one-way exhaust valve is mounted at the end of the air guide hole. A suction cavity is connected to the tail end of the one-way exhaust valve. A heating body is mounted in the suction cavity in an air tight manner. The heating body is electrically connected into a circuit in thebody. A controller for timing circuit connection / disconnection is connected to the circuit board on the heating body in series. A normally-closed pressure-limiting valve is arranged on the suction cavity. A connection / disconnection switch is arranged on the normally-closed pressure-limiting valve. The connection / disconnection switch is electrically connected into a line of the heating body and the controller. The fixing device can be mounted on the wall body and the surface of a ceiling conveniently and is effectively prevented from falling off; and meanwhile damage to the wall body or the ceiling is avoided during dismantlement, and the original decoration is restored effectively.

Owner:李峥炜

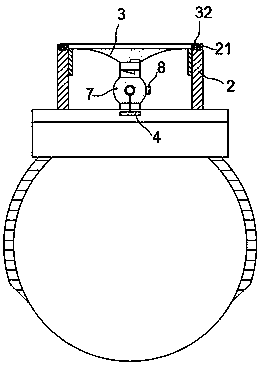

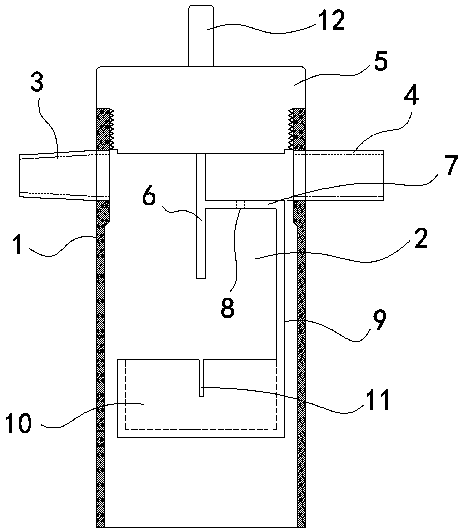

Backflow prevention device for medical negative treatment drainage device

ActiveCN109498860APrevent backflowAvoid infectionSuction drainage systemsWound healingBackflow prevention device

The invention relates to the technical field of medical drainage auxiliary instruments, and discloses a backflow prevention device for a medical negative treatment drainage device. The backflow prevention device comprises the drainage device, a negative-pressure pipe, a fixed pipe and a limiting pipe, the limiting pipe is connected at one end of the fixed pipe in a threaded and sleeving manner, the inside of the fixed pipe is communicated with the inside of the limiting pipe, a first flow guide pipe is communicated between the drainage device and the fixed pipe, a second flow guide pipe is communicated between the limiting pipe and the negative-pressure pipe, a drainage pipe is communicated with the other end of the limiting pipe, and a sealing cover is arranged at the top end of the negative-pressure pipe in a threaded and sleeving manner. According to the backflow prevention device for the medical negative treatment drainage device, drainage is implemented by suction of the drainagedevice, a movable piston is moved to the bottom of the negative-pressure pipe, so that negative pressure is formed in the negative-pressure pipe, liquid in the negative-pressure pipe is prevented fromreturning into a body of a patient by the aid of negative-pressure suction in the negative-pressure pipe when suction of the drainage device is lost, postoperative infection of the patient is prevented, and postoperative wound healing is facilitated.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

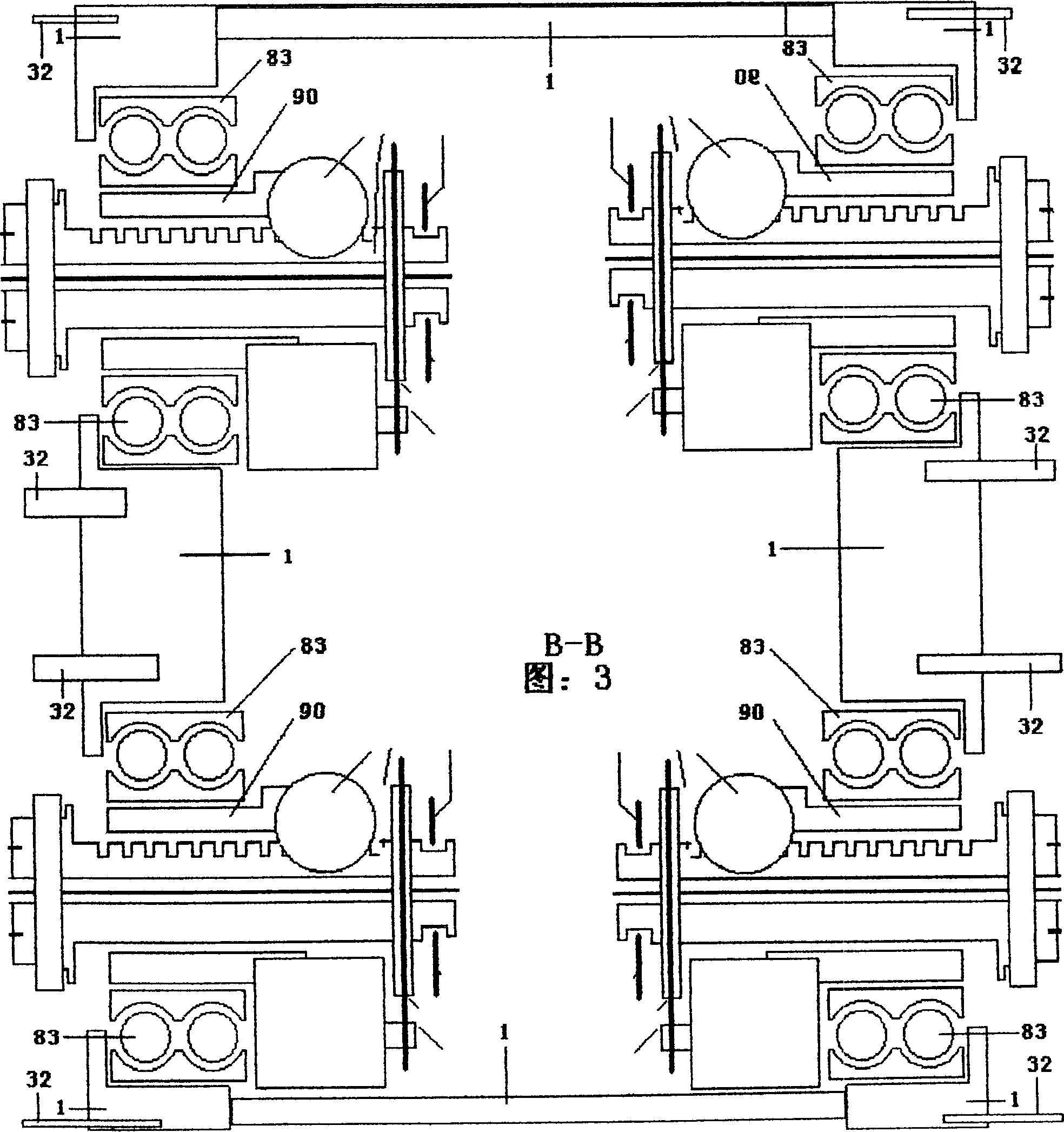

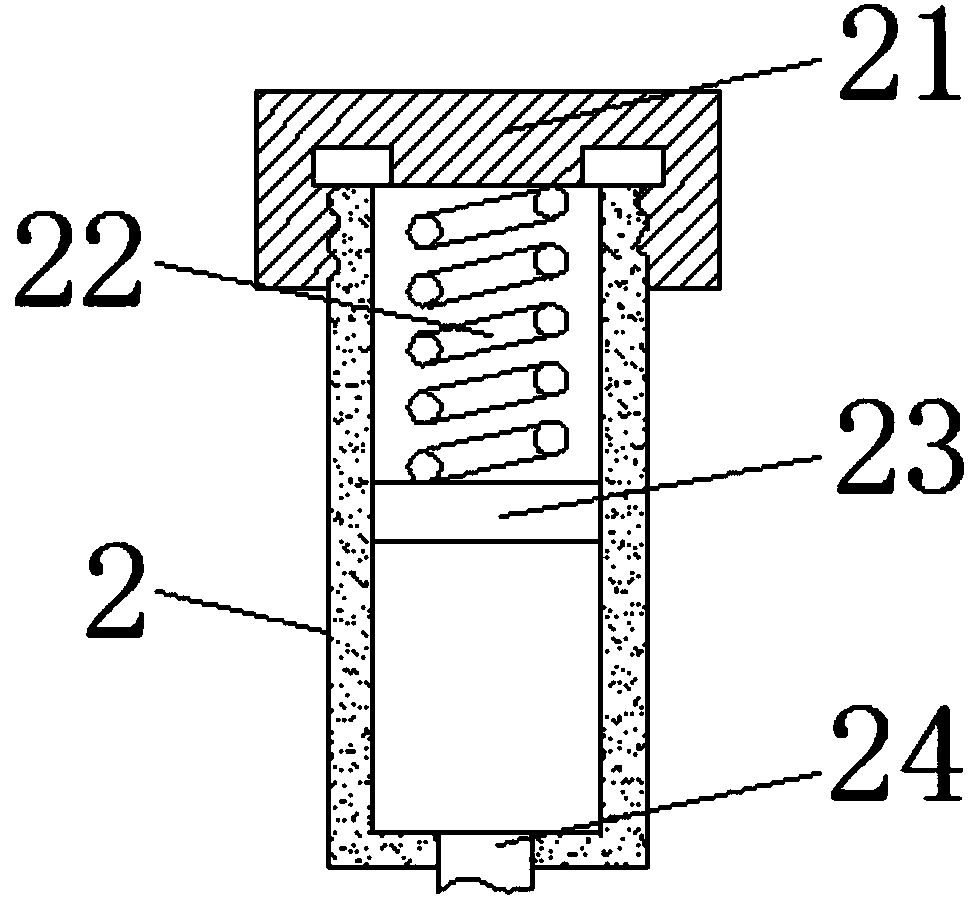

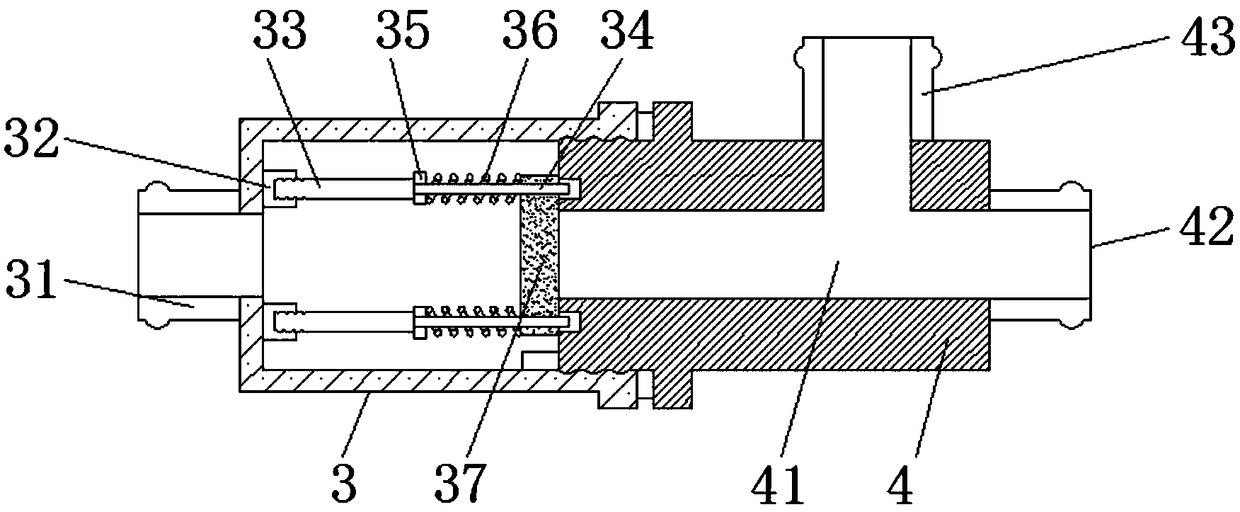

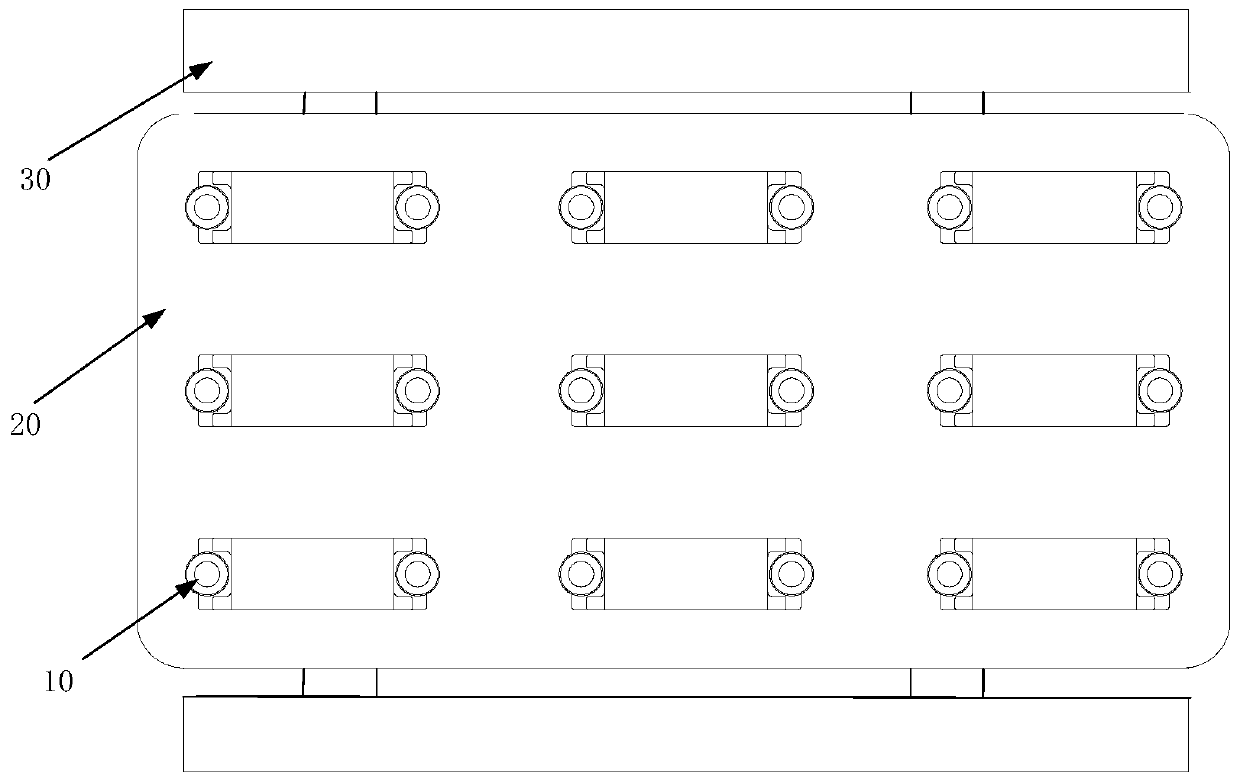

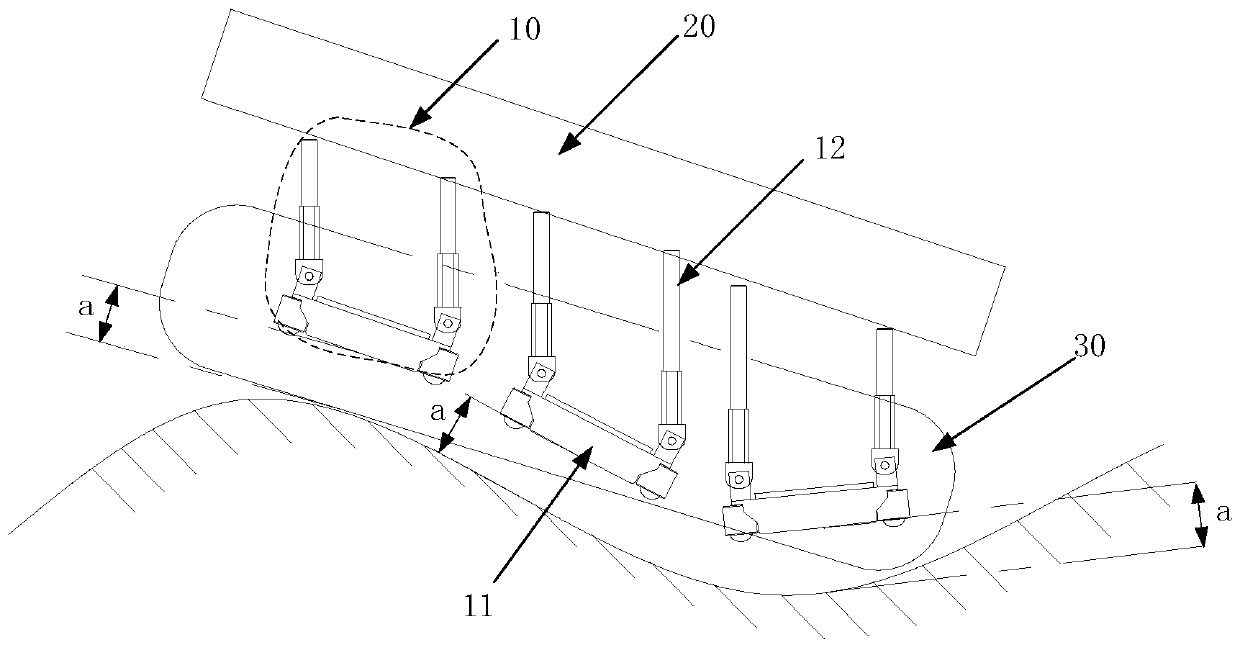

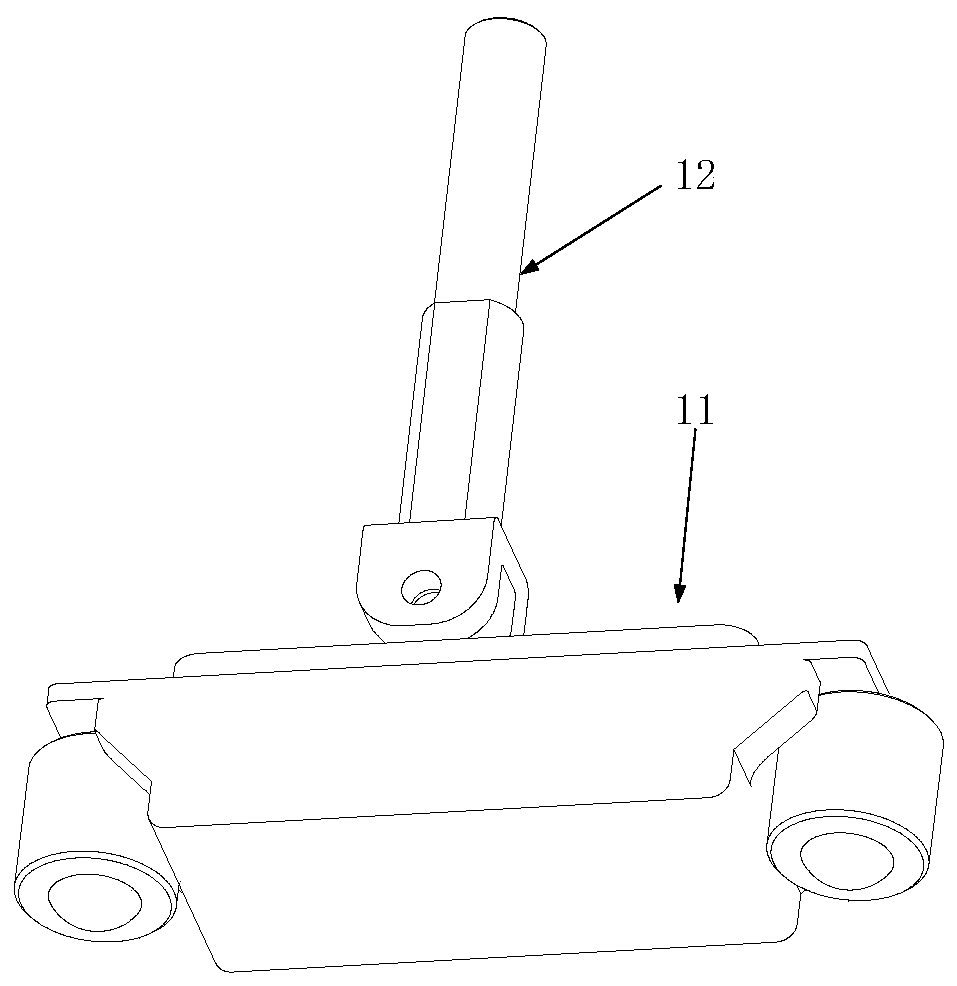

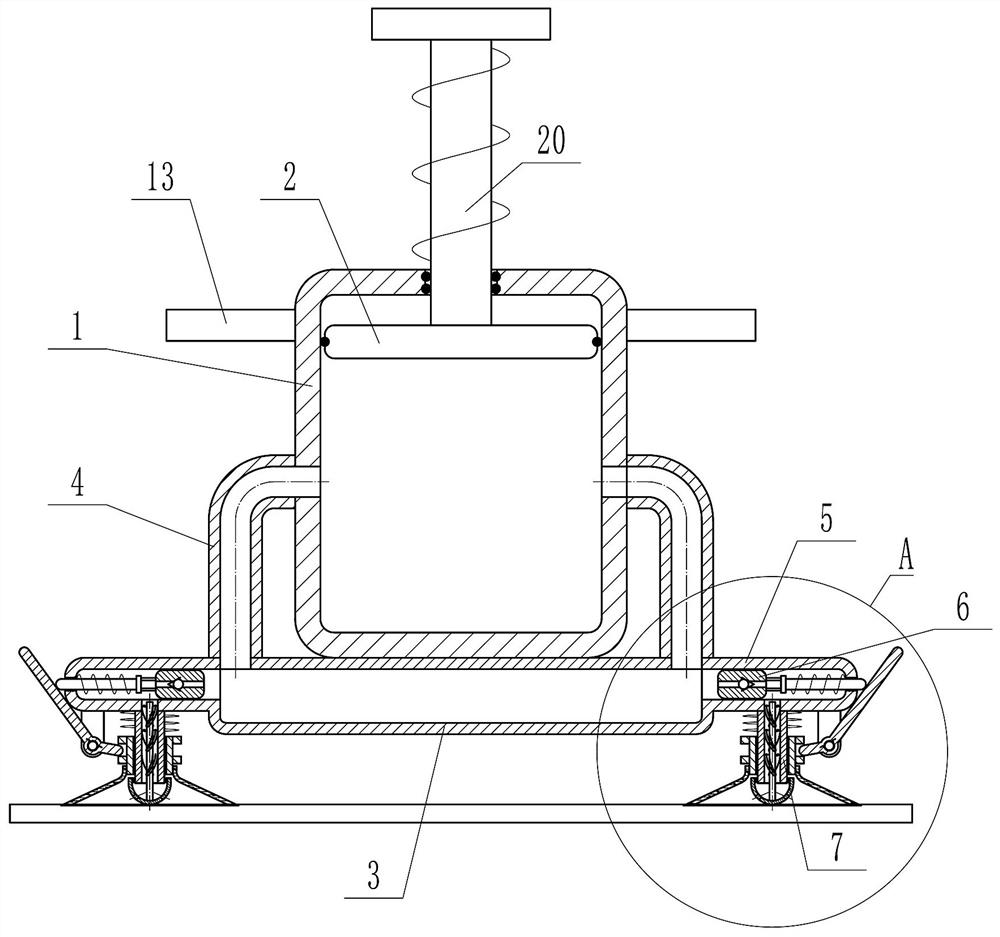

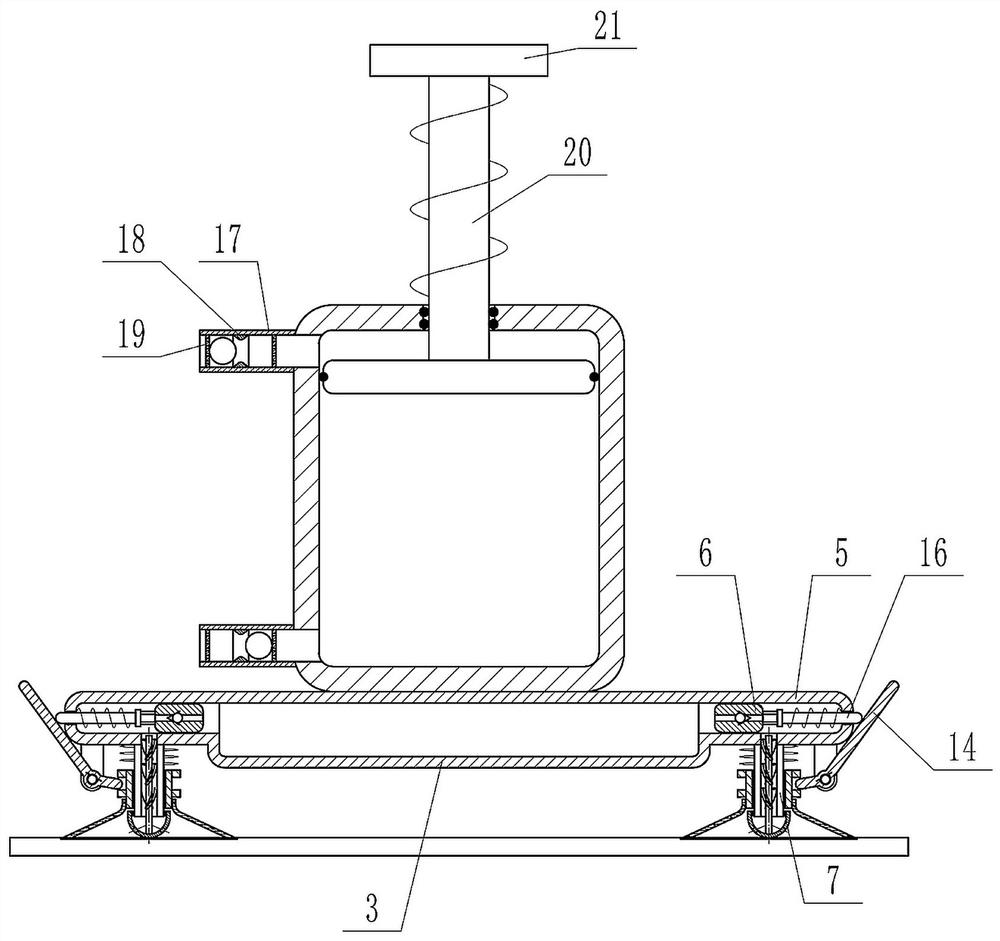

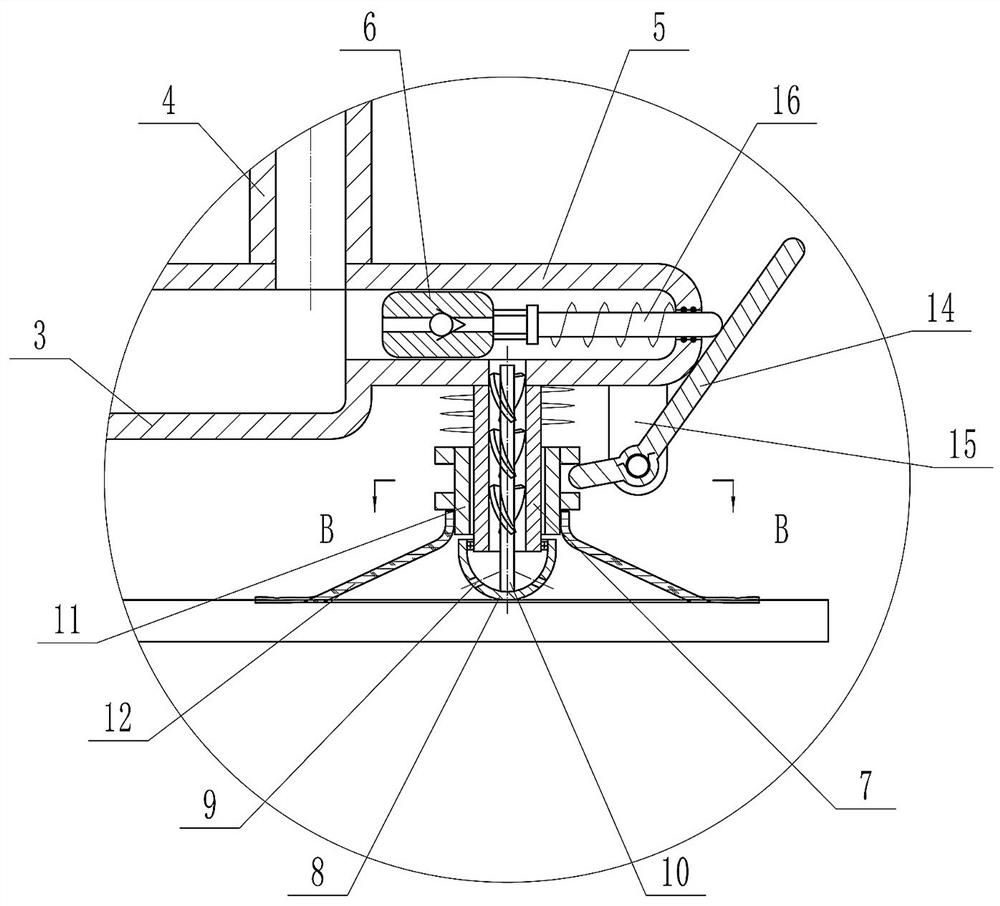

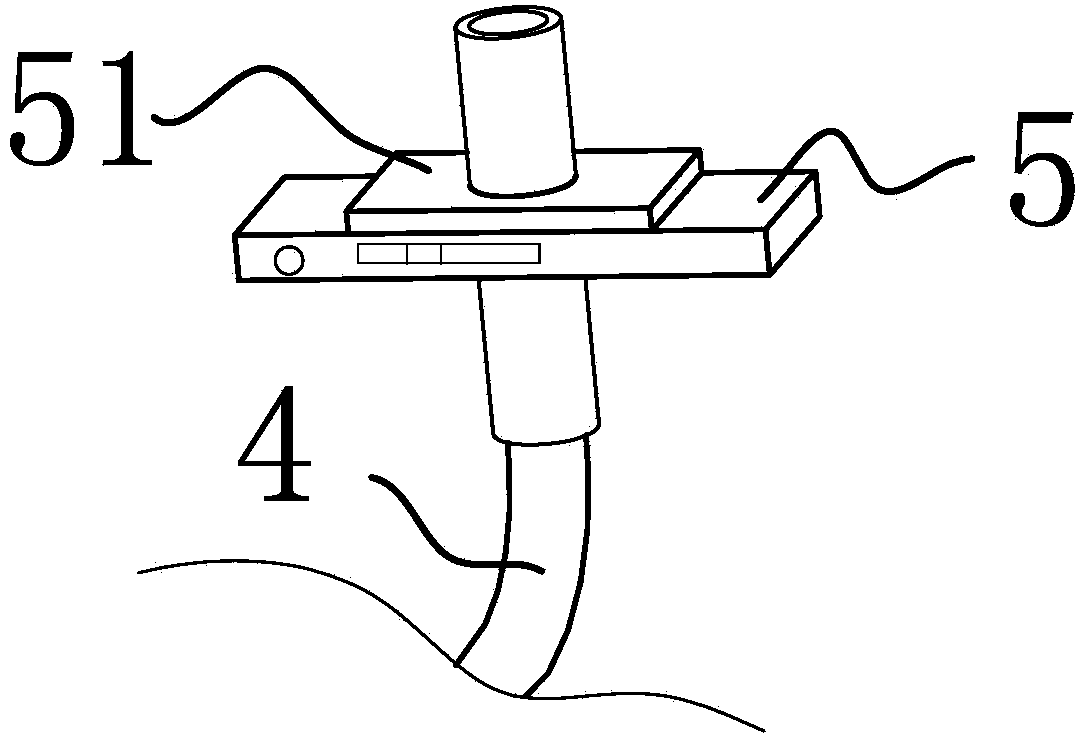

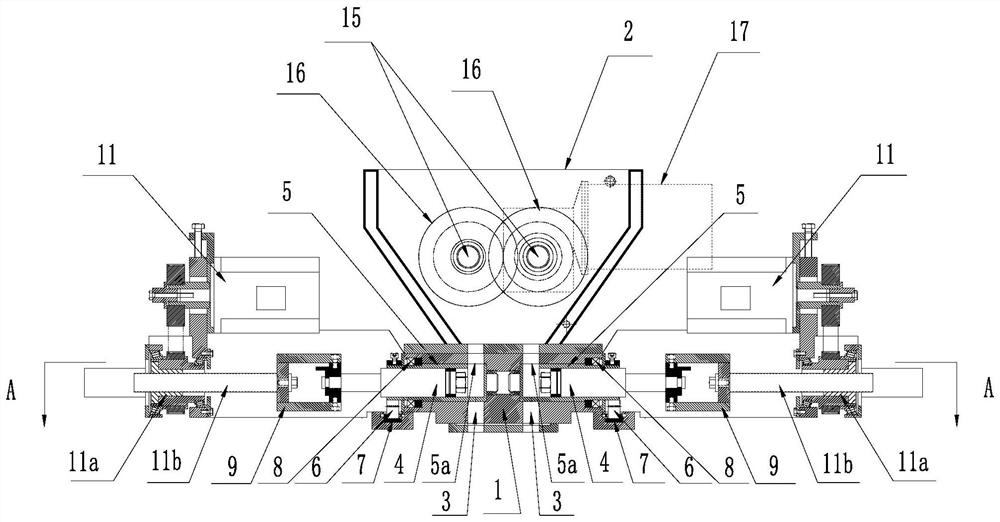

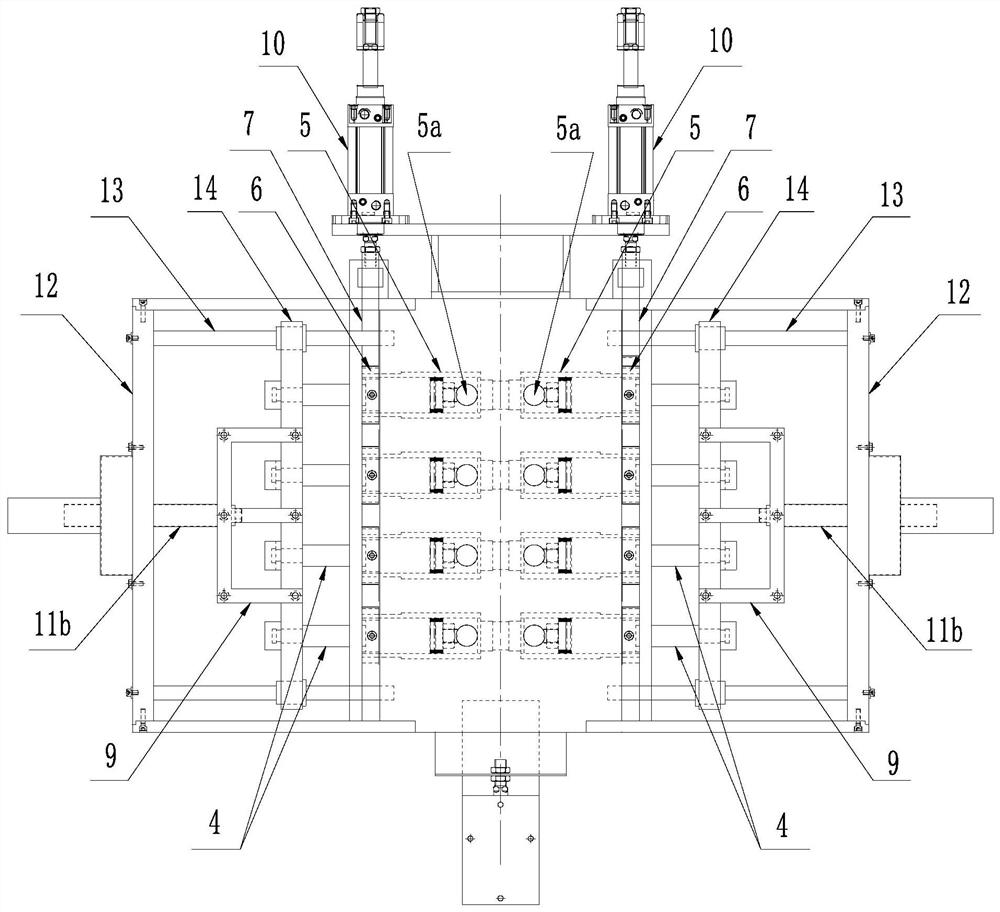

Magnetic adsorption device and crawling robot

The invention relates to a magnetic adsorption device and a crawling robot. The magnetic adsorption device is applied to the crawling robot, and the crawling robot comprises a frame and a moving mechanism arranged on the frame. The magnetic adsorption device comprises a plurality of magnetic adsorption assemblies and a plurality of stretchable mechanisms, wherein the magnetic adsorption assembliesare arranged below the frame in an array mode, and each magnetic adsorption assembly is correspondingly provided with at least one of the stretchable mechanisms; and first ends of the stretchable mechanisms are connected to the frame, and second ends of the stretchable mechanisms are connected to the magnetic adsorption assemblies, so that a gap between the magnetic adsorption assemblies and a to-be-adsorbed surface is changed. The magnetic adsorption device can adapt to the curved surfaces of different radians so as to enable the gap between the magnetic adsorption assemblies and the to-be-adsorbed surface to be adjusted according to requirements, so that it is guaranteed that the crawling robot obtains enough suction and stably crawls.

Owner:BEIJING BO TSING TECH CO LTD

Packaging bag feeding, taking and supporting equipment and method

PendingCN111409904APrecise positioningEasy to moveSolid materialPackaging automatic controlStructural engineeringBar pressing

The invention discloses packaging bag feeding, taking and supporting equipment and method, and belongs to the field of packaging equipment. A bag warehouse and a bag taking device are respectively arranged above the start point and the end point of a conveyor belt of the equipment; a product conveyor belt is arranged behind the conveyor belt; a bag supporting device is further arranged at the rearend of the bag taking device; a small hopper and a bag opening fixing device are arranged above the start point of the product conveyor belt; the bag taking device comprises a bag taking device body,a bag pressing mechanism, a bag clamping sliding mechanism, a bag dividing cross bar and a pressing rod mechanism; the bag supporting device comprises a bag opening mechanism and a bag supporting rotating mechanism; and the bag opening fixing device comprises a discharge hopper, a bag opening clamping plate mechanism, a bag opening tensioning mechanism and a packaging bag baffle mechanism. According to the packaging bag feeding, taking and supporting equipment and method, the length of the conveyor belt can be reduced, packaging bags are accurately positioned and fed and are prevented from shifting, folds and folded corners can be flattened, bag openings can be made to be parallel to the rear edge of a platform, the failure rate and energy consumption of the equipment are reduced, and theproduction efficiency is improved.

Owner:吕彦民

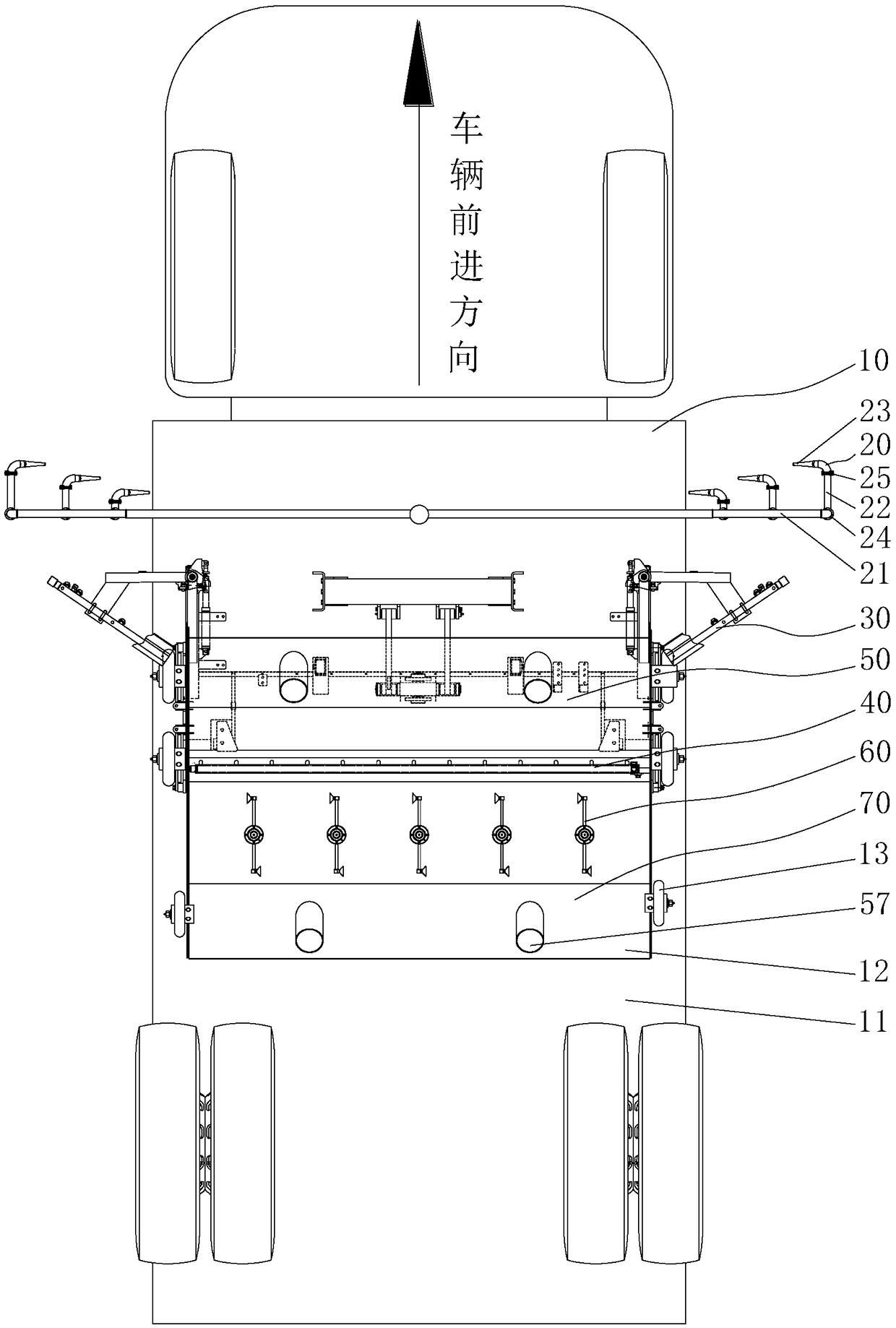

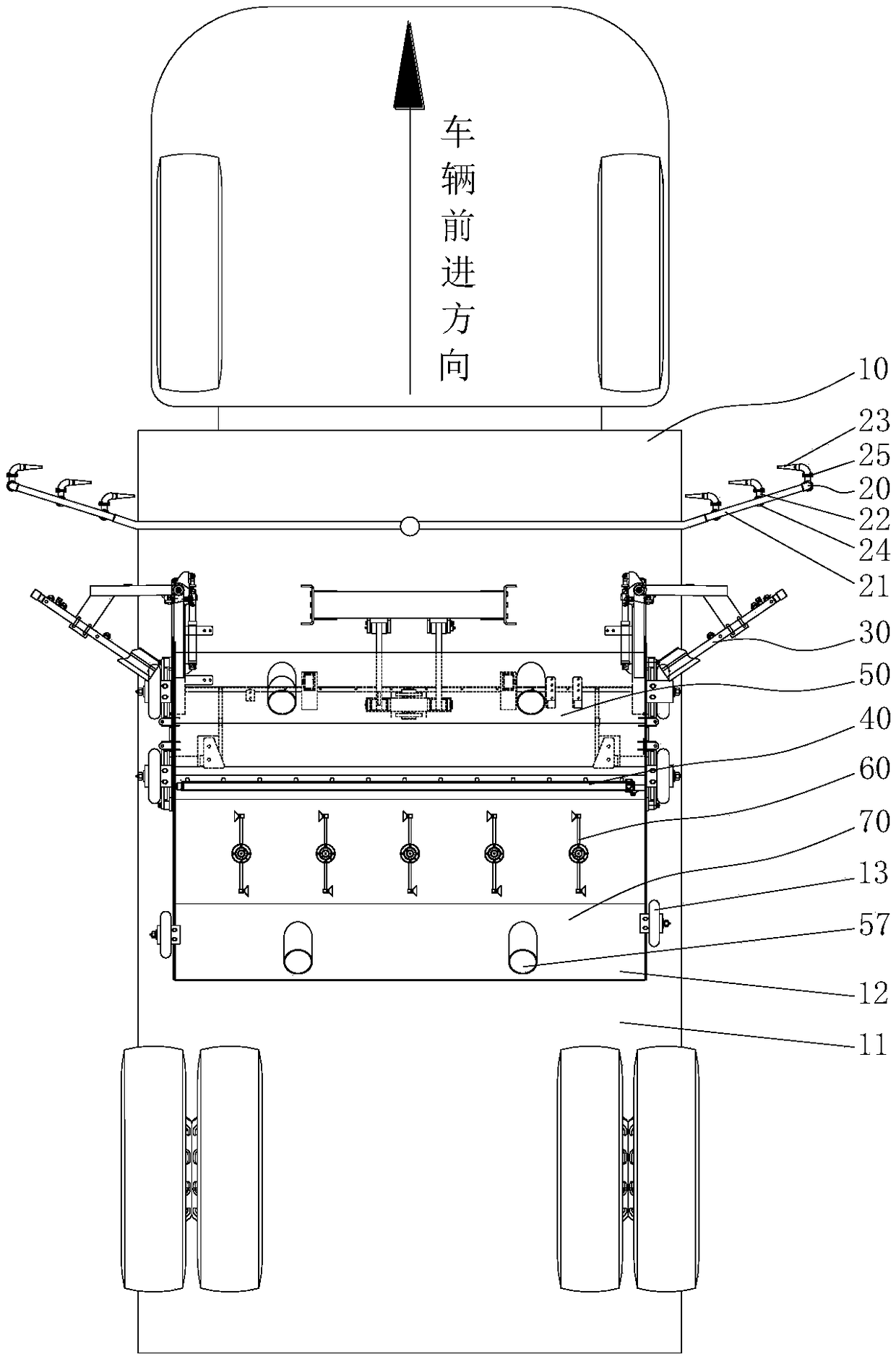

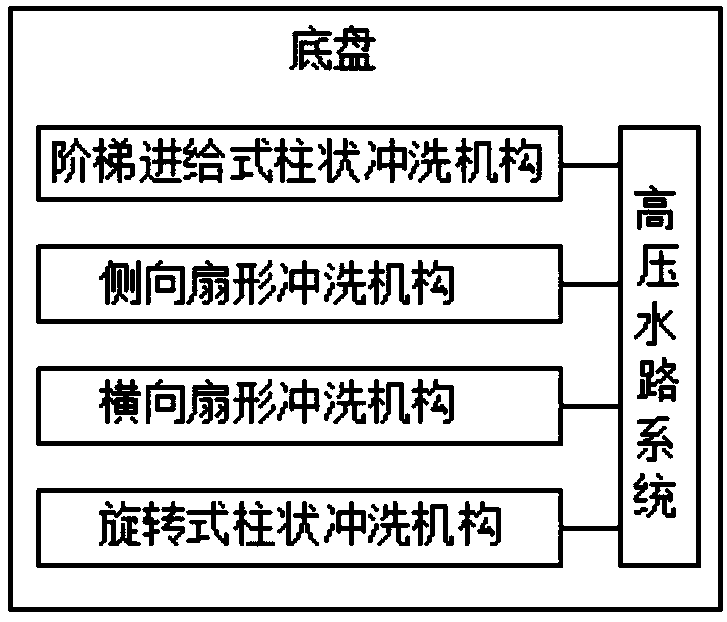

Road surface sanitation vehicle and working method thereof

PendingCN109371885AAdjustable sizeReduce water consumptionRoad cleaningRoad surfaceHigh pressure water

The invention relates to a road surface sanitation vehicle and a working method thereof. The road surface sanitation vehicle comprises a chassis provided with a high-pressure water path system. Step feeding type columnar flushing mechanisms, lateral sector flushing mechanisms, a transverse sector flushing mechanism and a rotary columnar flushing mechanism are sequentially arranged on the chassis in the front-and-back direction and communicate with the high-pressure water path system. A first suction mechanism and a second suction mechanism are arranged on the front side and the back side of the rotary columnar flushing mechanism correspondingly. The working method of the road surface sanitation vehicle comprises a conventional clean-keeping working method, a high-speed clean-keeping working method and a deep clean-keeping working method.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

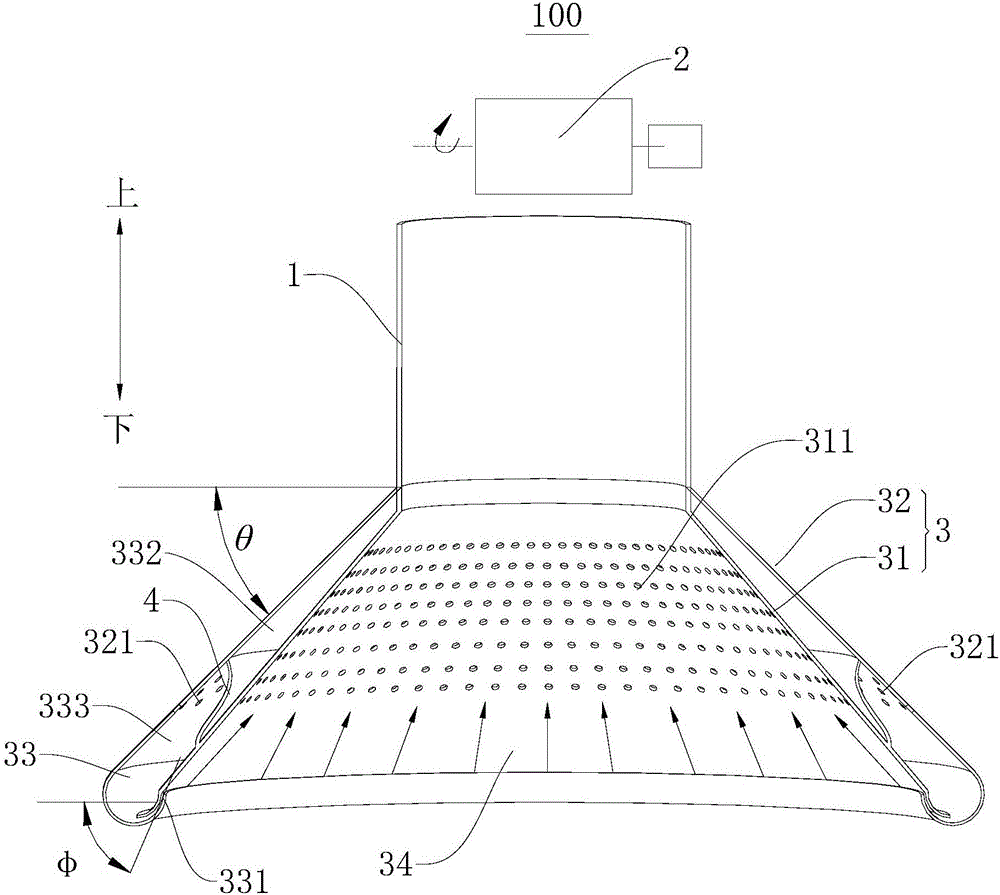

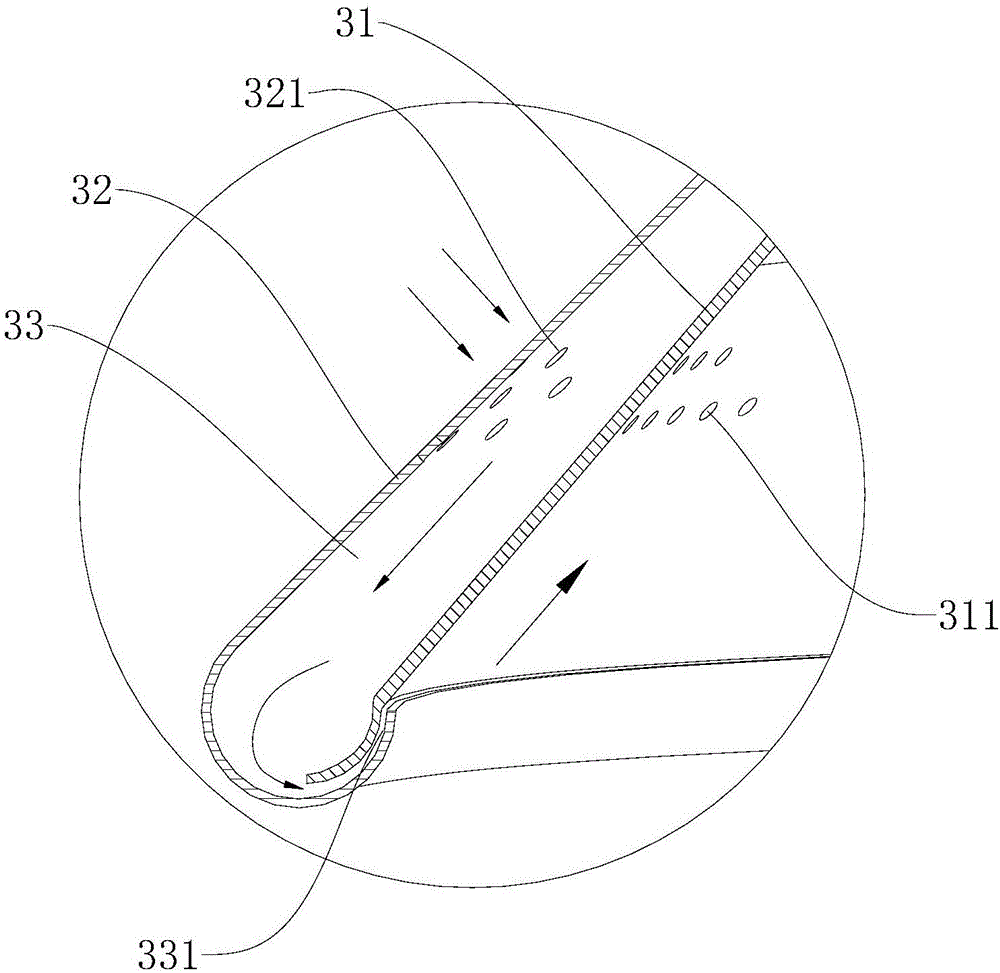

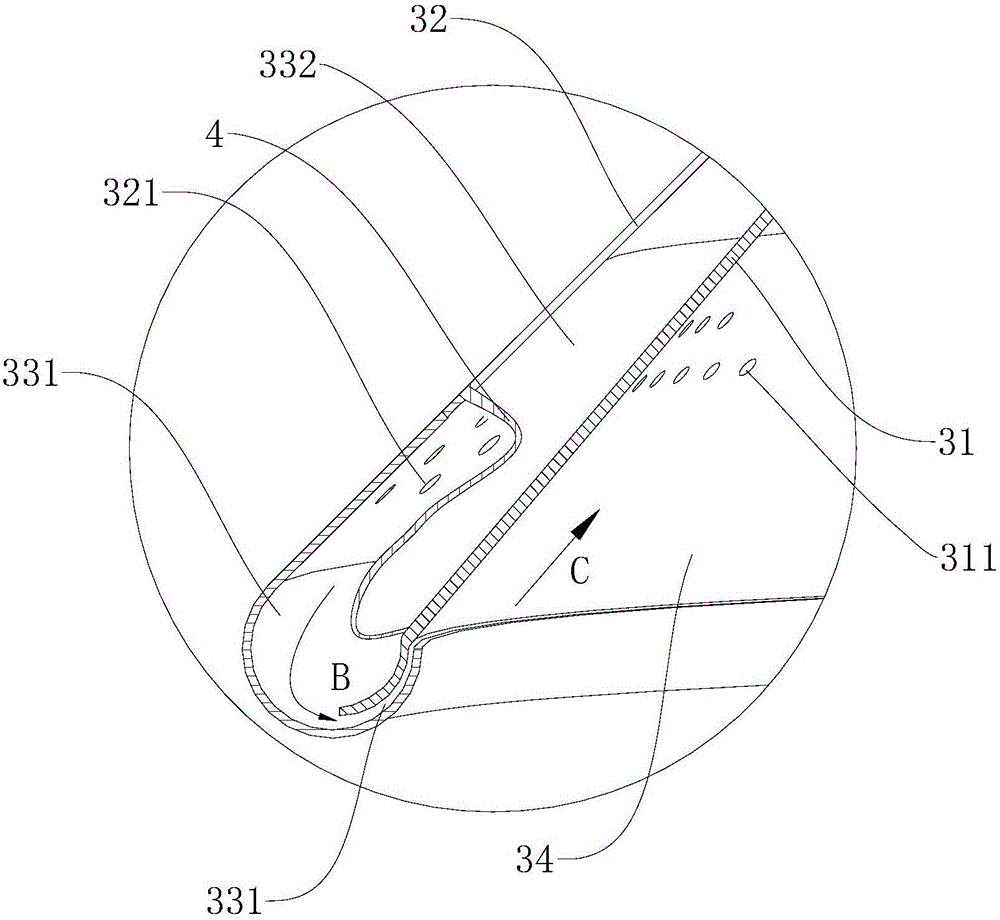

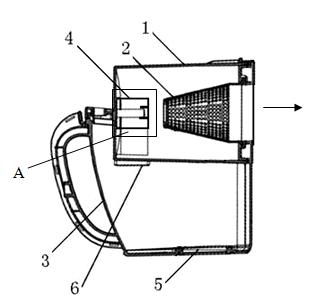

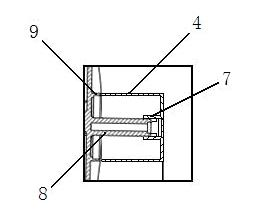

Smoke exhaust ventilator

ActiveCN106482190AImprove the smoke effectSpeed up the flowDomestic stoves or rangesLighting and heating apparatusEngineeringTuyere

The invention discloses a smoke exhaust ventilator. The smoke exhaust ventilator comprises a machine body, a draught fan system, a lampblack collecting cover and an auxiliary draught fan; the draught fan system is connected with the machine body and suitable for generating the air flow; the lampblack collecting cover is connected with the machine body, an air way communicated with the draught fan system is limited by the lampblack collecting cover, the lampblack collecting cover comprises an inner cover body and an outer cover body which are arranged in a spaced manner, an auxiliary air way is limited between the inner cover body and the outer cover body, an air inlet communicated with the auxiliary air way is formed in the outer cover body, and air outlets communicated with the air way are formed in the bottom of the inner cover body and the bottom of the outer cover body in a spaced manner; the auxiliary draught fan is arranged in the auxiliary air way to generate the air flow. According to the smoke exhaust ventilator, lampblack can be promoted to flow, the aim of strong sucking of the lampblack can be achieved, and the lampblack sucking effect of the smoke exhaust ventilator is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Aluminum piece product detection device based on digital test technology

ActiveCN113091691AHigh degree of automationThe detection process is fastUsing optical meansElectromagnetic wave reradiationEngineeringMechanical engineering

The invention provides an aluminum piece product detection device based on a digital test technology, and relates to the field of detection devices. The aluminum piece product detection device based on the digital testing technology comprises a base used for fixing the whole detection device, a reset assembly arranged at the top end of the base and arranged on the front side of a first turning conveyor, and a reinspection assembly arranged on the front side of a second turning conveyor. The reset assembly is arranged at the top end of the base, the reinspection assembly is arranged at the top end of the base and arranged on the right side of the reset assembly, the overturning assembly is arranged at the top end of the base, and the initial inspection assembly is arranged at the top end of the base. The area, needing to be accurately detected, of the surface of the aluminum piece is determined through cooperation of the initial detection assembly and the controller, the aluminum piece is detected in a targeted mode through the redetection assembly, the aluminum piece is overturned through cooperation of the position sensor and the controller and the overturning assembly, the device automatically detects the two surfaces of the aluminum piece, and the detection efficiency is improved.

Owner:QUZHOU COLLEGE OF TECH

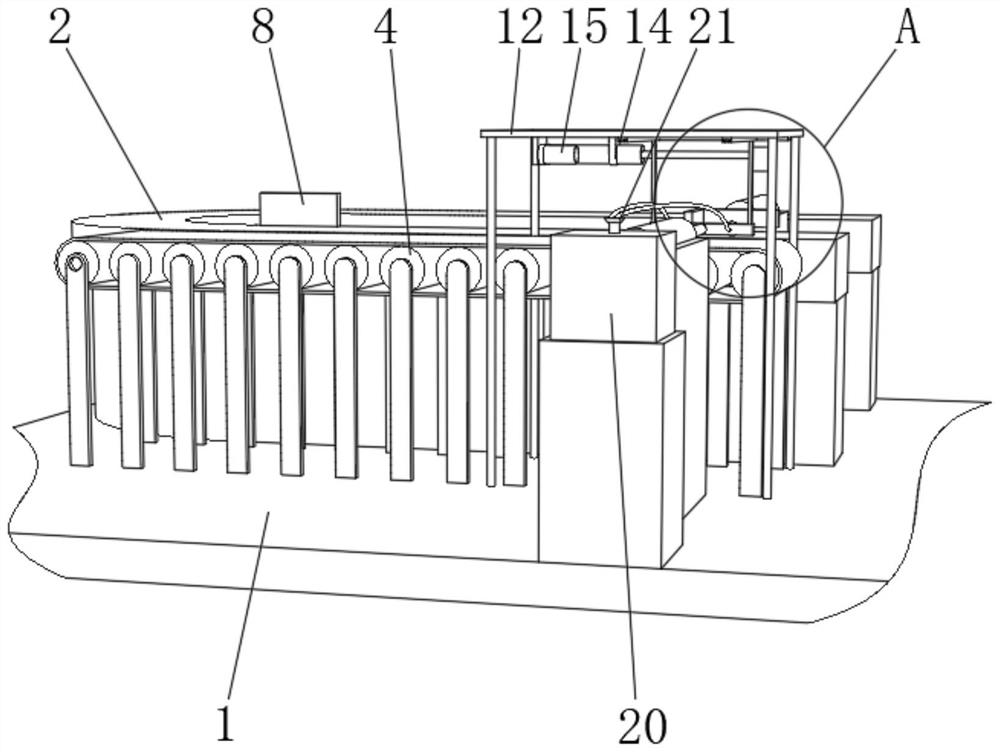

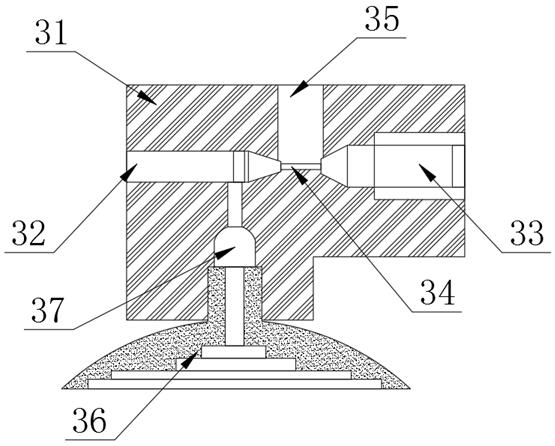

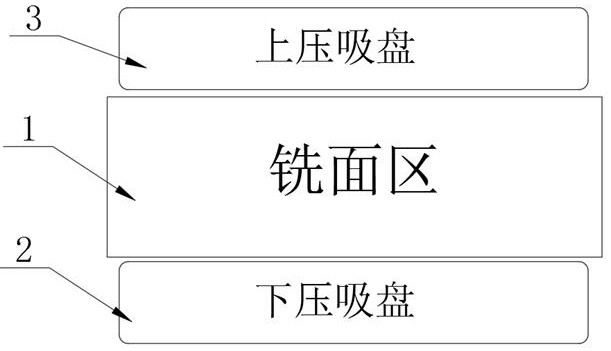

Precision machining tool and method for integral ribbed wallboard

InactiveCN112719382AAdequate fitGuaranteed process requirementsWorkpiecesMilling equipment detailsNumerical controlSuction force

The invention discloses a precision machining tool and method for an integral ribbed wallboard, and particularly relates to the field of aluminum alloy machining. The precision machining tool for the integral ribbed wallboard comprises a surface milling area and a vacuum storage tank, wherein a downward pressing sucker and an upward pressing sucker are arranged on the two sides of the surface milling area respectively; and a vacuum pump is arranged on one side of the vacuum storage tank. According to the precision machining tool and method for the integral ribbed wallboard provided by the invention, steel formworks are machined according to the boundary dimensions of different wall plates, a set of vacuum suction cup device is additionally arranged between the steel formworks and a bottom plate, and a plurality of rectangular suction cups are adopted, so that enough suction force can be guaranteed, and the enough attachment degree between the bottom plate and the suction cups can be met; the suction cups are pressed downwards to integrally adsorb the wallboard, and more than one ton of gravity acts on an aluminum plate, so that the surface milling area can meet the machining requirement, the milling operation is completed section by section by adopting a numerical control milling machine according to the plate length, and the precision requirement of 1.5 mm + / -0.2 mm can be met by measuring the surface milling thickness through an off-line ultrasonic thickness gauge.

Owner:许晨玲

Lithium battery electrode tab cutting and dust removal device and lithium battery electrode tab cutting device

PendingCN111390400AGuaranteed qualityTimely and effective extractionLaser beam welding apparatusDust controlEngineering

The embodiment of the application belongs to the technical field of lithium battery cutting, and relates to a lithium battery electrode tab cutting and dust removal device and a lithium battery electrode tab cutting device. According to the technical scheme, the lithium battery electrode tab cutting and dust removal device includes a machine body, a dust removal pipe and a suction fan, wherein themachine body is provided with a dust removal cavity, a filter screen is arranged on the side, facing a processing area of the lithium battery electrode tab cutting device, of the dust removal cavity,the dust removal pipe is arranged on the side, opposite to the filter screen, on the dust removal cavity, and the dust removal pipe is connected with the suction fan, so that the dust removal cavitycan suck generated dust, and the dust can be timely and effectively removed by the dust removal cavity, an electrode is effectively protected against dust pollution in the process of cutting a tab, and thus the quality of a lithium battery is effectively guaranteed; a material belt of the lithium battery electrode tab cutting device is adsorbed on a vacuum belt to prevent the material belt of thelithium battery electrode tab cutting device from jittering in the process of cutting the tab, so that the stability of cutting the tab is ensured.

Owner:深圳市大族贝瑞装备有限公司

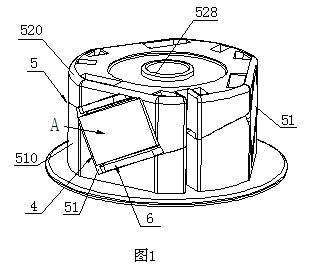

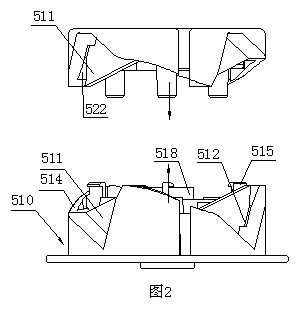

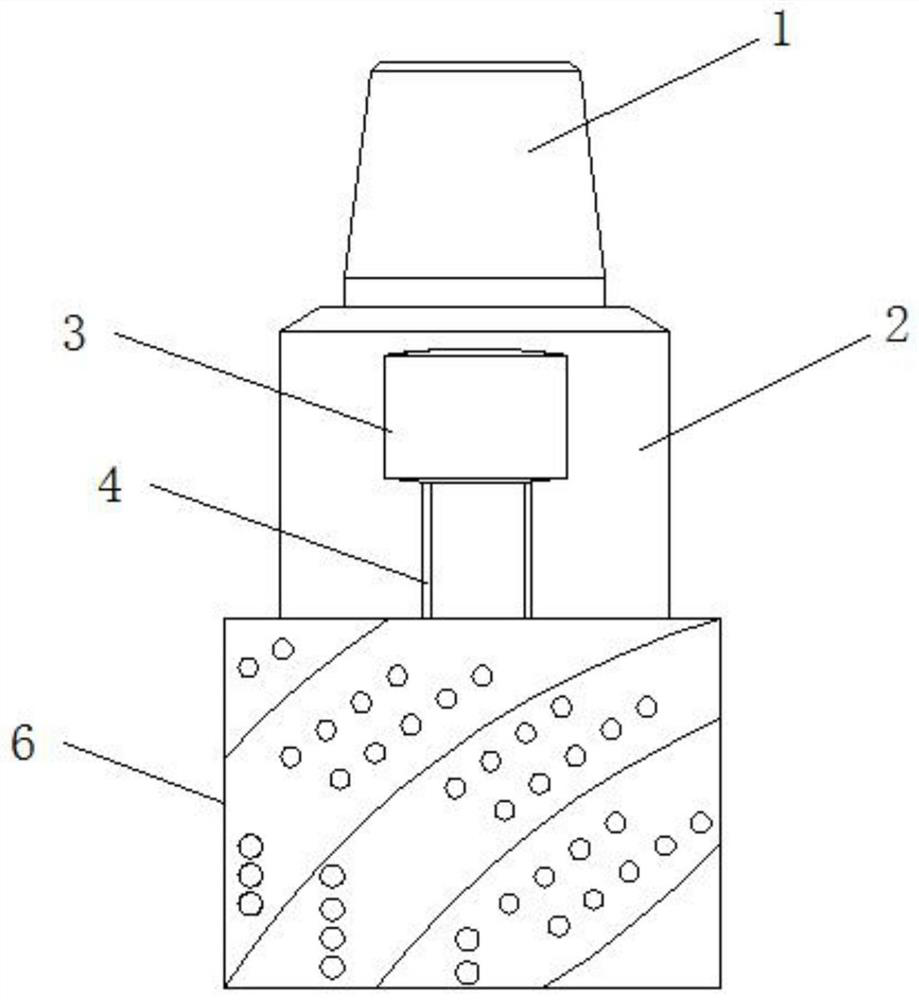

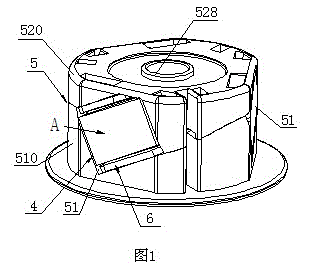

Tile-sucking disc device

ActiveCN102100971AImprove transmission efficiencyIncrease productivityIndoor gamesManufacturing cost reductionAcute angle

The invention relates to a tile-sucking disc device which comprises a tile-sucking disc and magnets, wherein the tile-sucking disc comprises a base part and a splicing part; the circumferential sides of the base part and the splicing part are respectively provided with three first grooves and three second grooves which correspond to each other and uniformly distributed; the base part and the splicing part are spliced to each other in the axial direction; after the base part and the splicing part are spliced, magnet grooves which are uniformly distributed and are composed of corresponding first grooves and second grooves are formed on the circumferential sides; the included angle between the center line in the length direction of each magnet groove and the axial line of the tile-sucking disc is an acute angle alpha; and the magnets are arranged in the magnet grooves. The invention has the following advantages: 1) in the tile transport process, the tiles can not be scraped down by guideplates or be stuck at the inlet end, thereby achieving high transport efficiency and ensuring the normal operation of the mahjong machine; 2) the magnets on the tile-sucking disc can be conveniently and quickly fixed, thereby improving the production efficiency of components and parts of the mahjong machine; and 3) the quantity of magnet sheets is reduced by 1 / 4, thereby saving the rare earth material and lowering the manufacturing cost.

Owner:ZONGYANG COUNTY ZHONGBANG TECH INFORMATION CONSULTING CO LTD

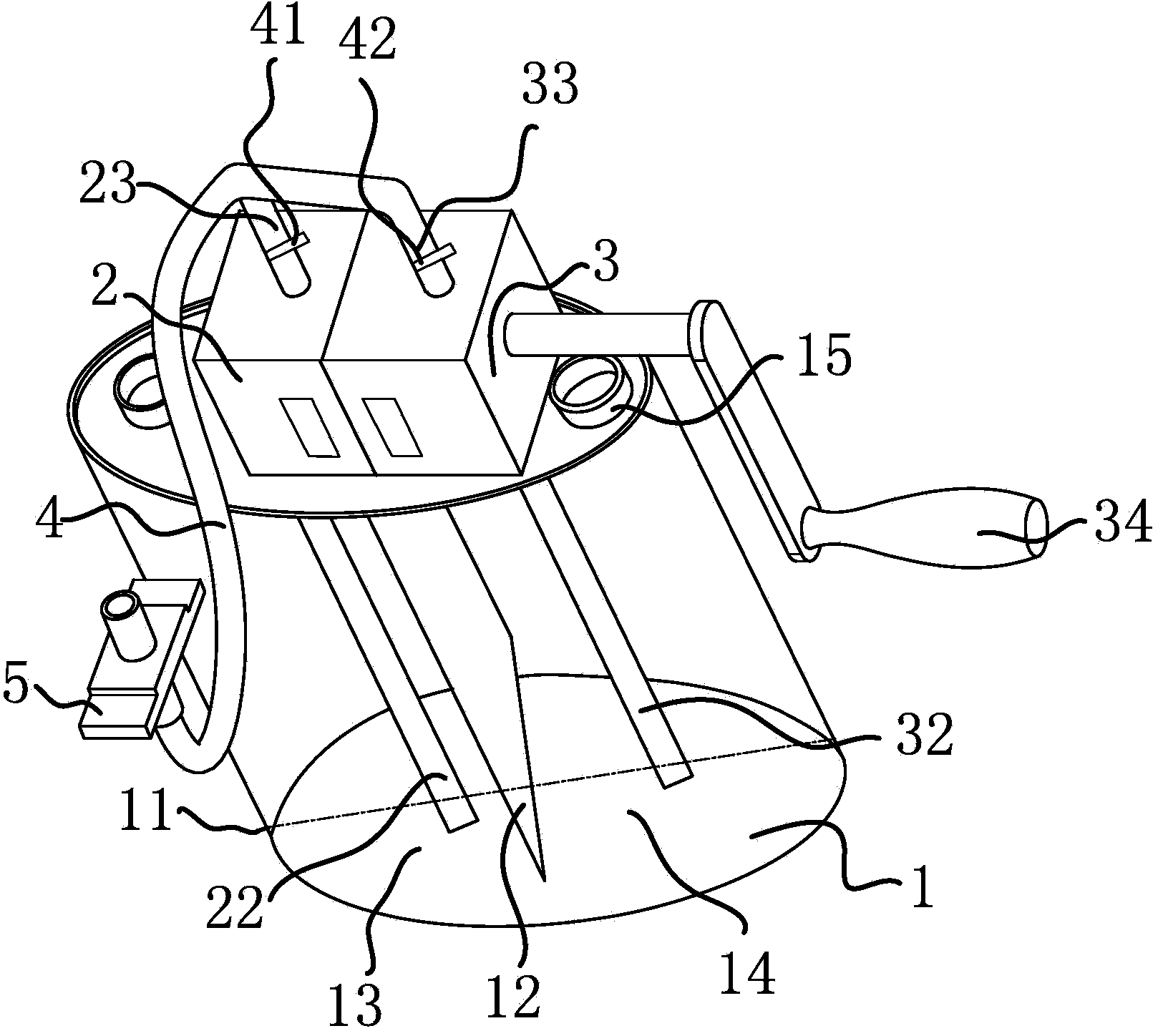

House building porcelain taking device

The invention provides a house building porcelain taking device. The problems that an existing ceramic tile drawing tool is too complex and is not suitable for drawing ceramic tiles in pits in tunnelwalls are effectively solved. According to the technical scheme, the house building porcelain taking device comprises a cylinder, a piston plate is arranged in the cylinder, a shell is arranged at thelower end of the cylinder, a pipeline is arranged on the shell, the other end of the pipeline communicates with the middle of the cylinder, a cylindrical shell is arranged on the side wall of the shell, a sliding block is arranged in the cylindrical shell, and a one-way valve is arranged on the sliding block; a vertical barrel is arranged on the lower side of the cylindrical shell, a hemispherical shell is arranged at the lower end of the vertical barrel, air outlets are formed in the side wall of the hemispherical shell, a rotating shaft is arranged in the vertical barrel, and a plurality ofscrew blades are arranged on the rotating shaft; and a sliding barrel sleeves the vertical barrel, a rubber suction cup is installed at the lower end of the sliding barrel, and cross rods are arranged on the two sides of the upper end of the air cylinder. The house building porcelain taking device is ingenious in structure, capable of drawing ceramic tiles in a narrow space, capable of reducing flying dust as much as possible under the condition that it is guaranteed that the suction cup has enough suction force, convenient to use, easy to operate and wide in application range, and accumulated dust on an adsorption area can be rapidly removed.

Owner:SHENGDA ECONOMICS TRADE & MANAGEMENT COLLEGE OF ZZ

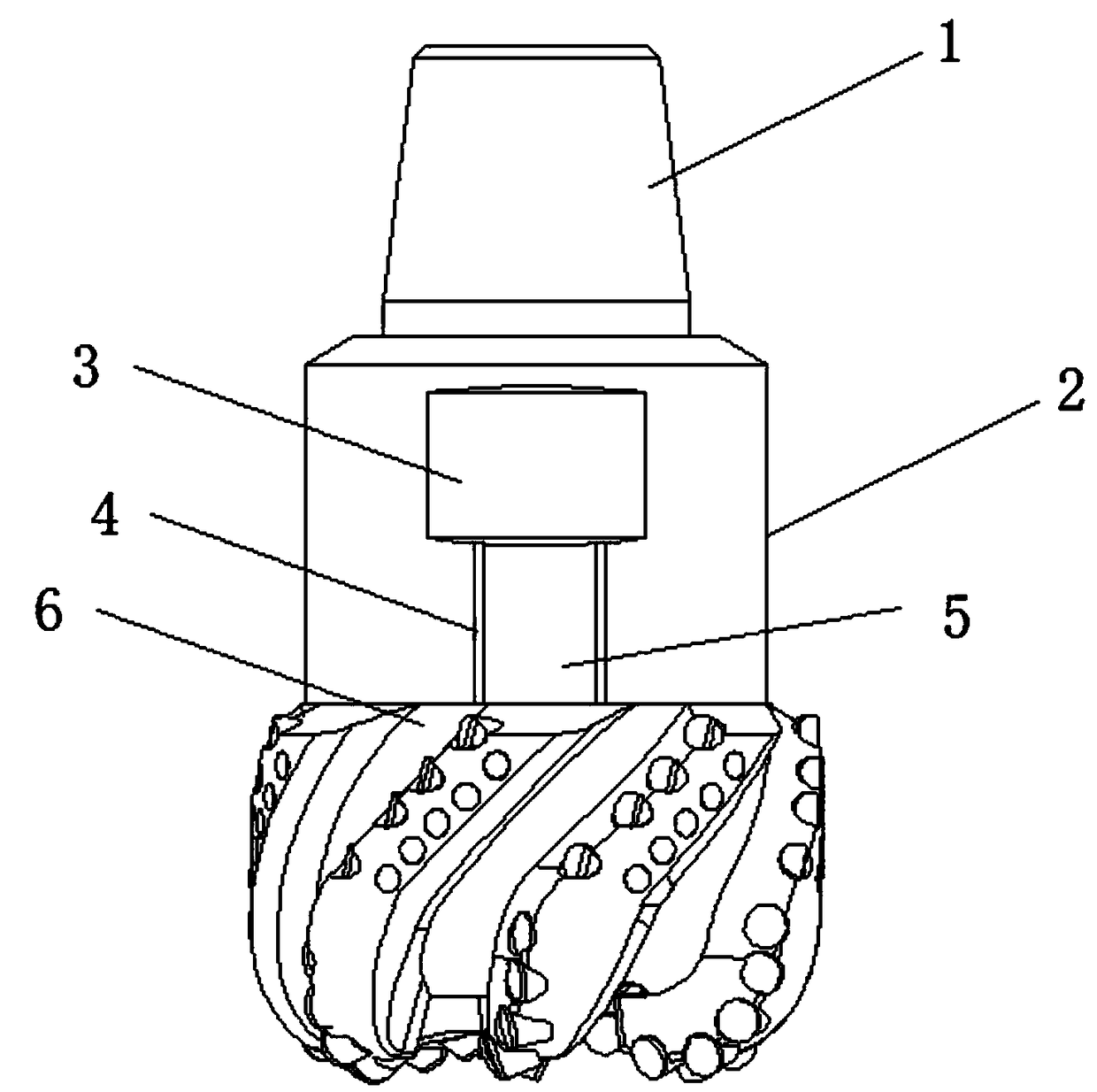

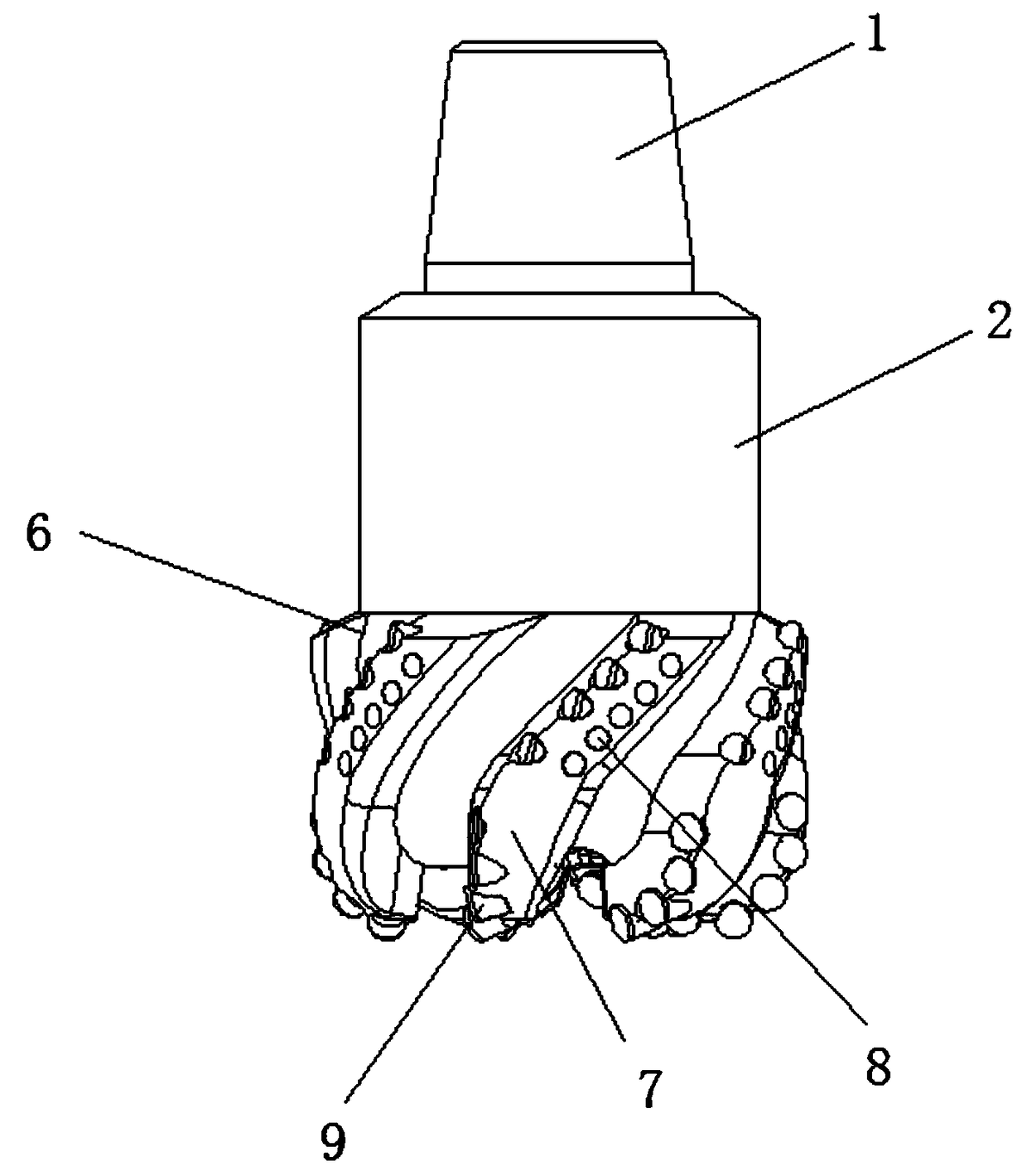

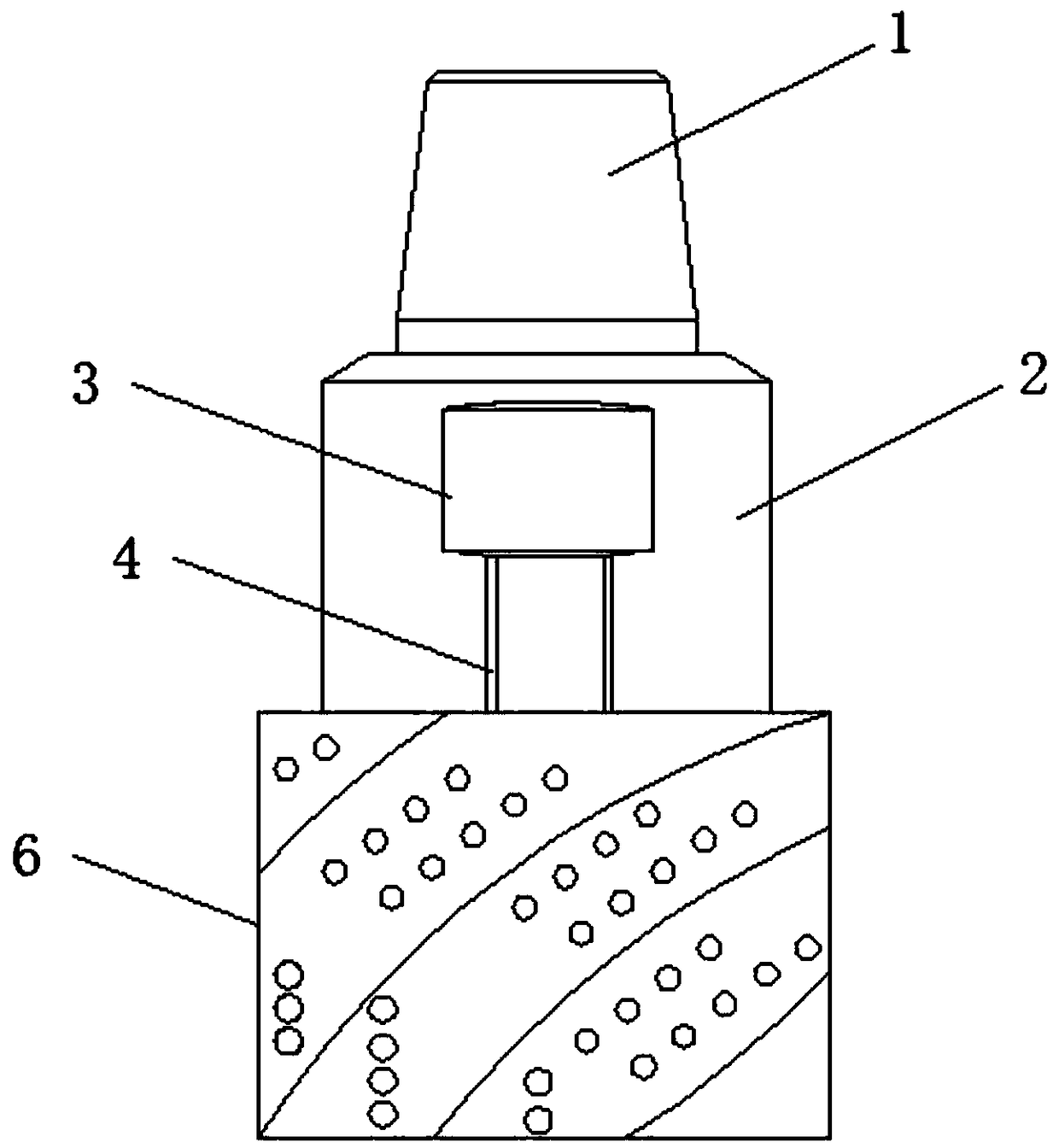

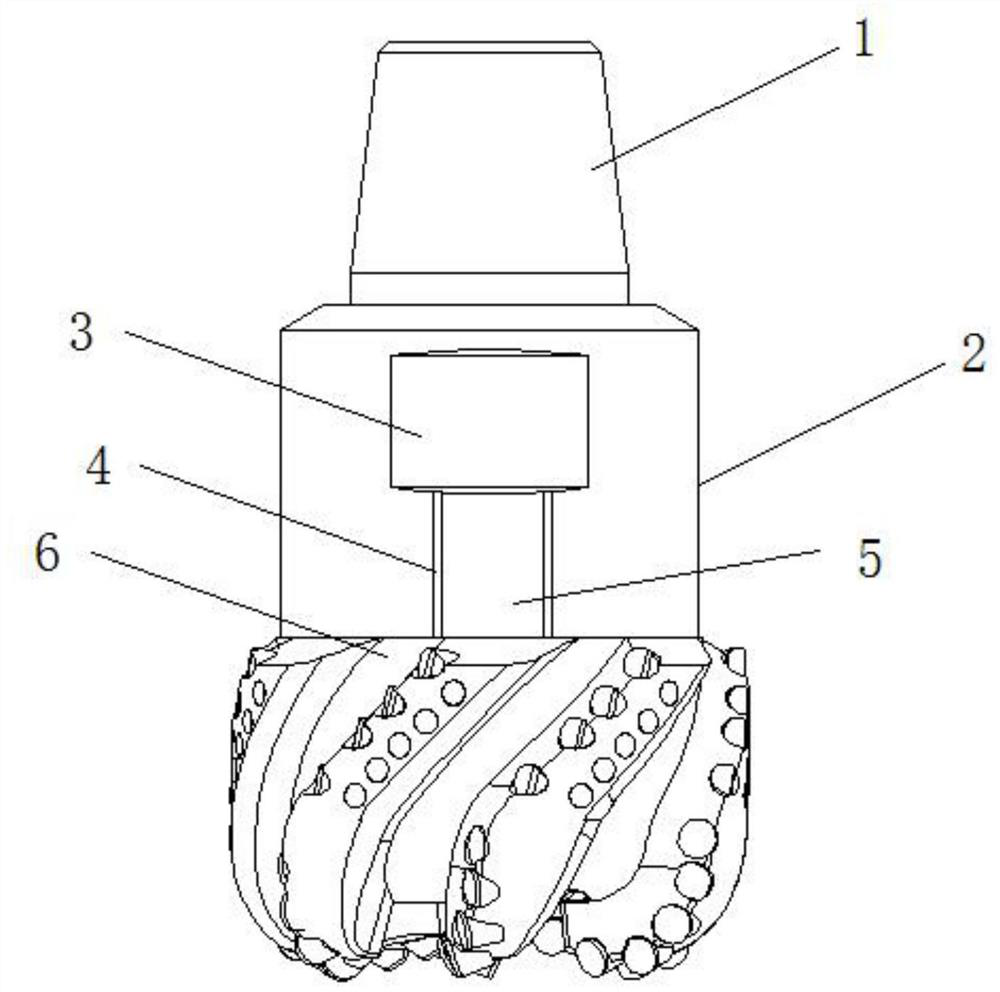

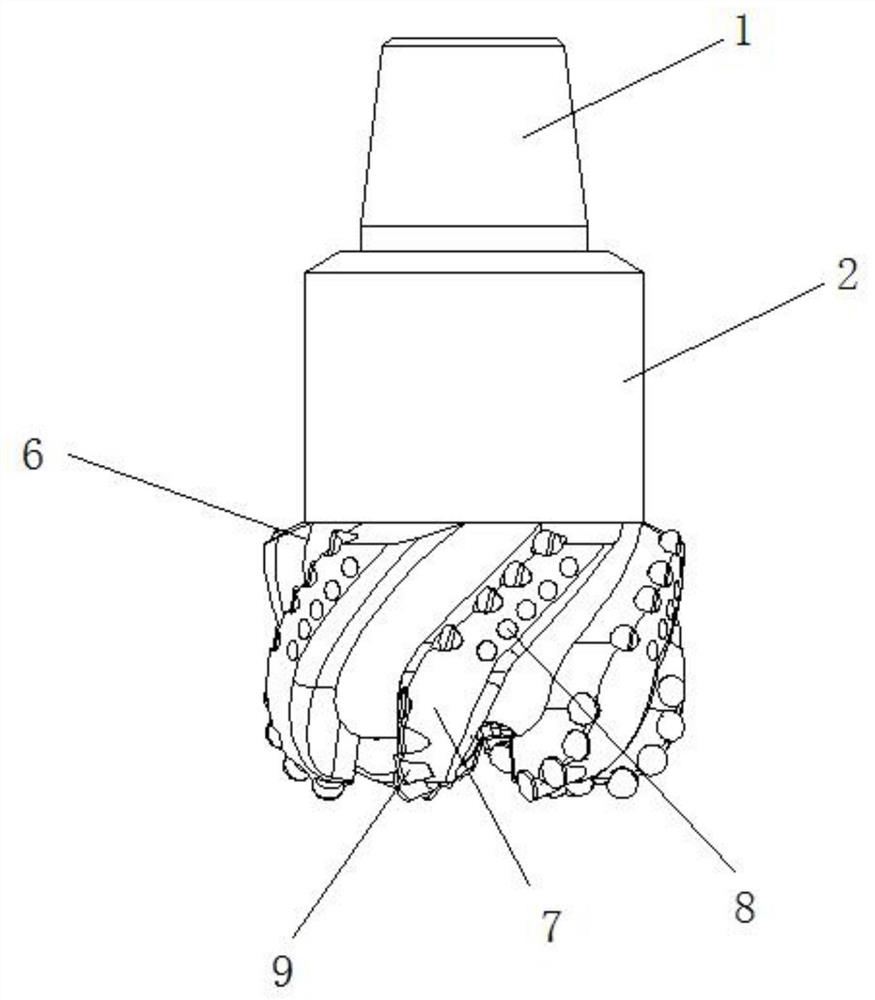

Powerful dust-absorbing drill bit

ActiveCN109025863AGuaranteed normal operationEnough suctionDrill bitsConstructionsAbsorption effectSmall hole

The invention discloses a powerful dust-absorbing drill bit, and can solve problems that dust absorption of the side wall, the edge and the bottom of the drill bit the traditional dust-absorbing drillbit cannot be achieved at the same time due to the small hole coverage range of the traditional dust-absorbing drill bit, the absorption effect is poor, meanwhile, the pipeline connected with the hole is easy to fall off during high-speed operation of the drill bit and absorption cannot run normally, and the dust absorbed by the drill bit is difficult to clean as the drill bit is of an integral structure and cannot be disassembled. The powerful dust-absorbing drill bit comprises a connection pole and a drill body connected to the bottom end of the connection pole, the bottom end of the drillbody is connected with a drill bit, the top end of the connection pole is provided with a docking hole, and the outer wall of the drill body is provided with a machine box completely embedded, an airsuction pump is installed inside the machine box, and a built-in power source is installed on the side wall of the air suction pump. The powerful dust-absorbing drill bit can realize more comprehensive adsorption of dust during work, and the dust adsorbed inside the drill bit after use can be cleaned conveniently.

Owner:山东兖能泰德重工有限公司

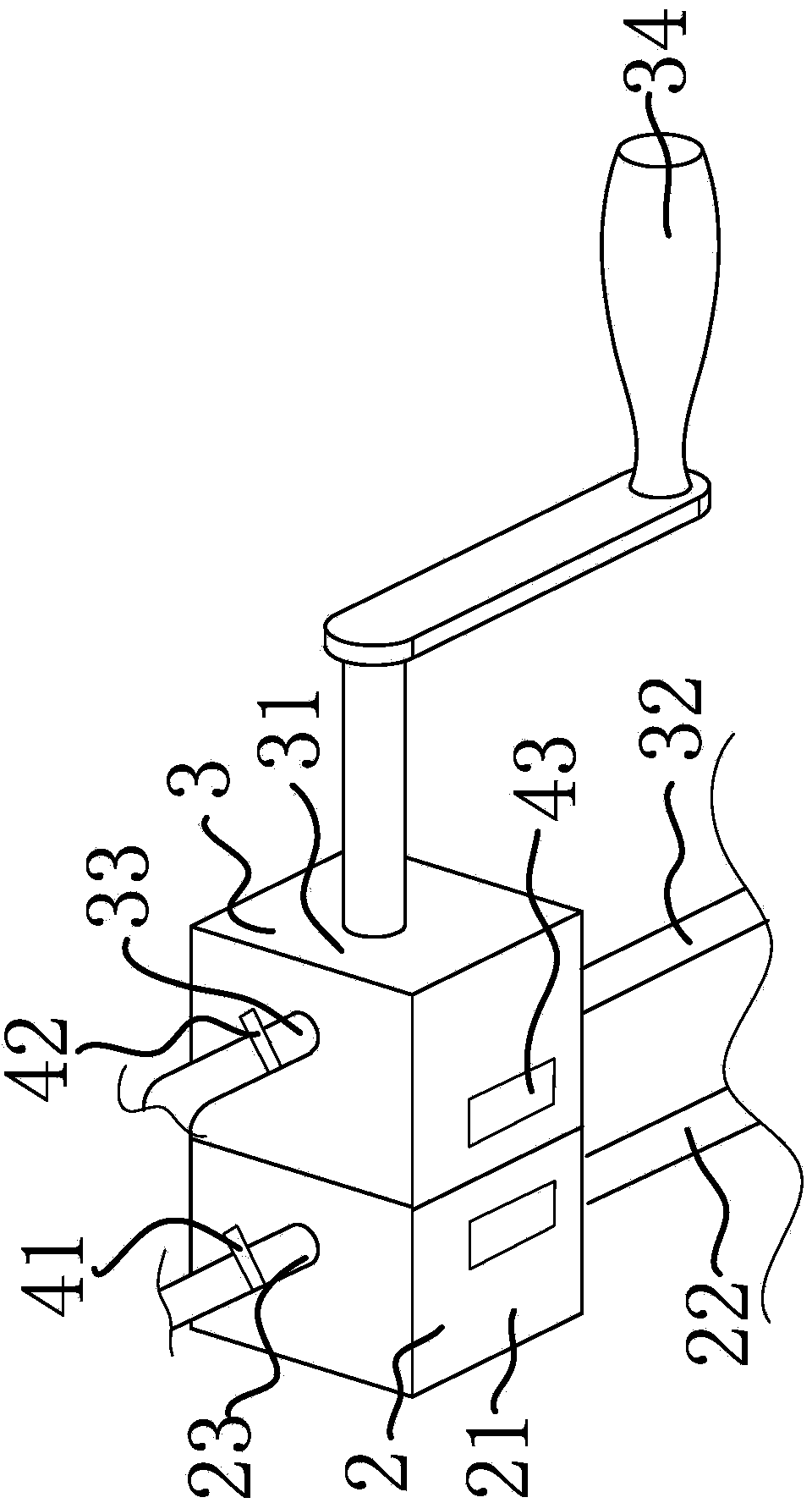

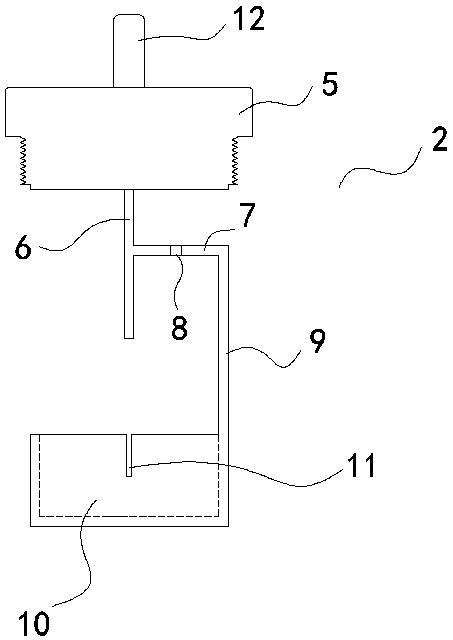

Automobile gearbox oiler

ActiveCN103771328AEnough suctionReduce manpower consumptionLiquid transferring devicesLinings/internal coatingsCorrosionFuel tank

The invention relates to an automobile gearbox oiler, which comprises an oil tank, an automatic oil filling device, a manual oil filling device, an oil filling pipe and an adsorption device, wherein the automatic oil filling device and the manual oil filling device are arranged at the top end of the oil tank; the automatic oil filling device comprises an oil pump, an automatic oil pumping tube and an automatic oil draining tube; the automatic oil pumping tube is arranged vertically in the oil tank; the upper end of the automatic oil pumping tube is connected with an oil pump, and the lower end opening of the automatic oil pumping tube is close to the bottom of the oil tank; the two ends of the automatic oil draining tube are connected with the oil filling pipe and the oil pump respectively; the manual oil filling device comprises a gear pump, a manual oil pumping tube, a manual oil draining tube and a swinging rod; the manual oil pumping tube is vertically arranged in the oil tank; the upper end of the manual oil pumping tube is connected with the gear pump, and the lower end opening of the manual oil pumping tube is close to the bottom of the oil tank; the two ends of the manual oil draining tube are connected with the oil filling pipe and the gear pump respectively; the swinging rod is fixedly connected to a gear shaft of the gear pump; the adsorption device is arranged at the upper end of the oil filling pipe; the inner surface of the oil tank is coated with a coating which is 0.05-0.2 millimeter in thickness. The automobile gearbox oiler disclosed by the invention has the advantages of no oil leakage, corrosion resistance and integration of automatic and manual oil filling.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

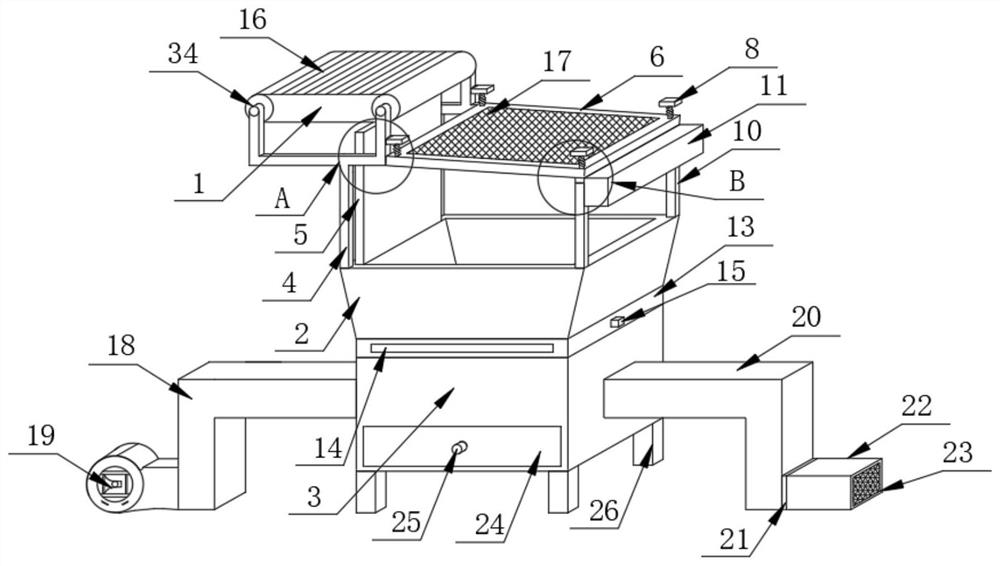

Tea leaf screening, drying and impurity removing integrated device

PendingCN112547516AAvoid Insufficiently Screened QuestionsQuality improvementSievingGas current separationAgricultural engineeringDust control

The invention discloses a tea leaf screening, drying and impurity removing integrated device and a tea leaf processing method. The tea leaf screening, drying and impurity removing integrated device comprises a conveying mechanism, a feeding box and a dust removing box. The conveying mechanism comprises a rotating roller and a caterpillar band, the rotating roller is sleeved with the caterpillar band and is electrically driven, a supporting frame is arranged below the rotating roller, and the rotating roller is in rotating fit with the joint of the supporting frame. The feeding box is fixedly connected to the bottom end of the supporting frame, a supporting column is fixedly arranged above one side of the feeding box, a screen is embedded in the mounting frame, springs are fixedly arrangedat the four corners of the mounting frame, a vibration generator is arranged at one end of each spring, a collecting box is arranged on one side of the mounting frame, and a connecting block is fixedly arranged below the feeding box. By arranging the dust removing box, an air blower, an exhaust fan and an impurity collection box, in the dust removing box, hot air blown out of the air blower is used for drying and removing dust from tea leaves, blown-out impurities can enter the impurity collection box, the tea leaves can be dried through the method, fine impurities in the tea leaves can be rapidly and efficiently screened out, and the quality of the tea leaves is improved.

Owner:吴博文

Full-automatic intelligent household robot cleaner

InactiveCN106618387ASave spaceGuaranteed uptimeCarpet cleanersFloor cleanersWaste collectionElectric machinery

The invention provides a full-automatic intelligent household robot cleaner. The full-automatic intelligent household robot cleaner comprises a shell, a garbage collecting and disposing device and a floor mopping device, wherein the shell is round, the garbage collecting and disposing device and the floor mopping device are fixed at two ends of the upper part of the shell oppositely, a universal wheel is fixed at the position, below the garbage collecting and disposing device, on the bottom of the shell, rolling wheels are symmetrically arranged below the part, between the garbage collecting and disposing device and the floor mopping device, on the bottom of the shell, the rolling wheels are connected with drive motors respectively, and the rolling wheels and the universal wheel are in triangular distribution. The full-automatic intelligent household robot cleaner provided by the invention is small in size, moves flexibly, is convenient to use, is suitable for use in families, and integrates the functions of collecting garbage, absorbing dust and mopping the floor.

Owner:阜阳科技工程学校

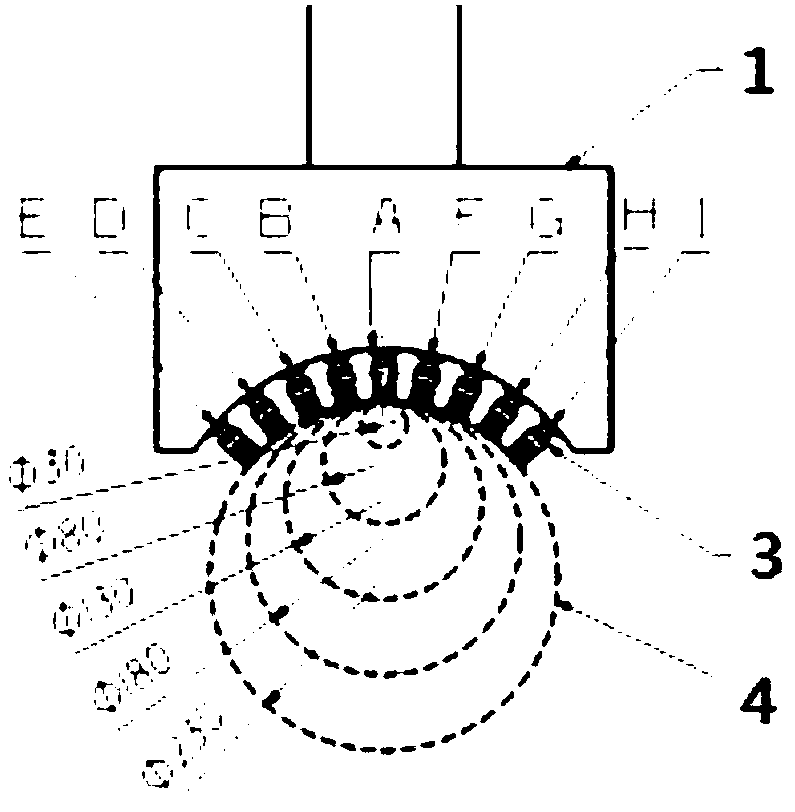

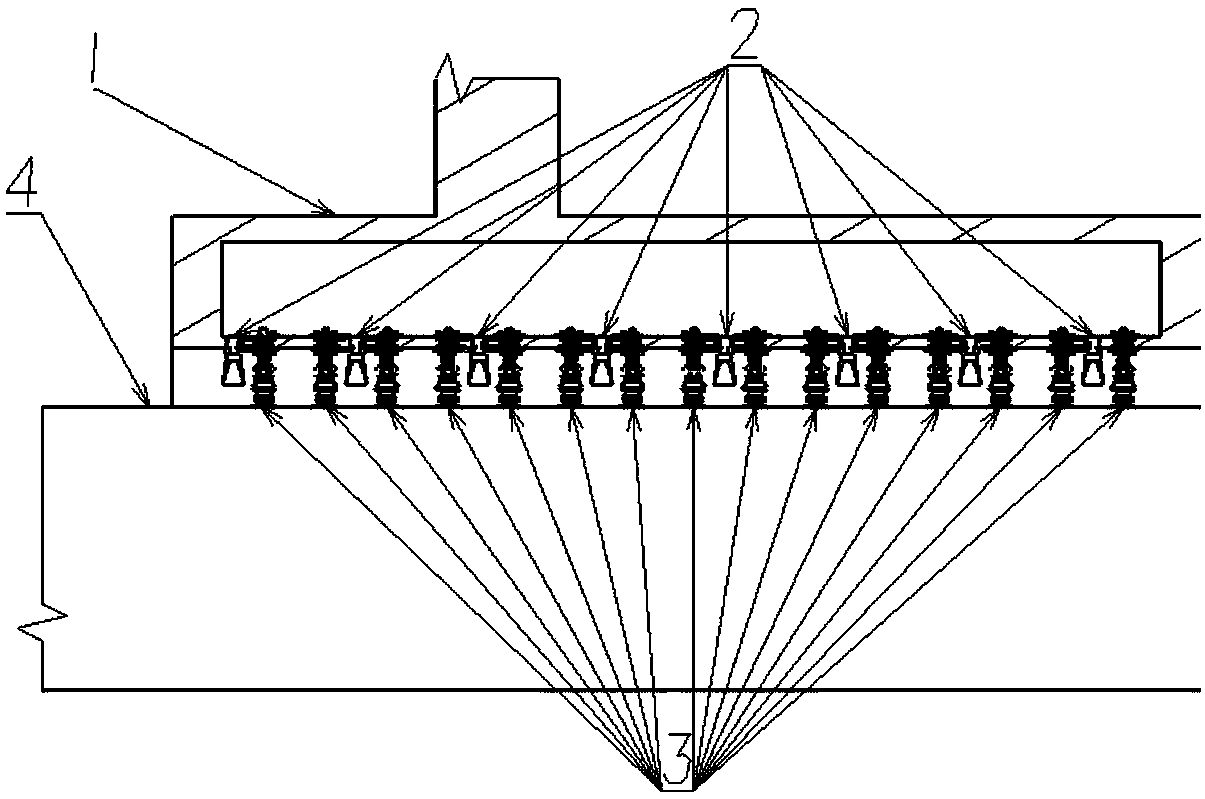

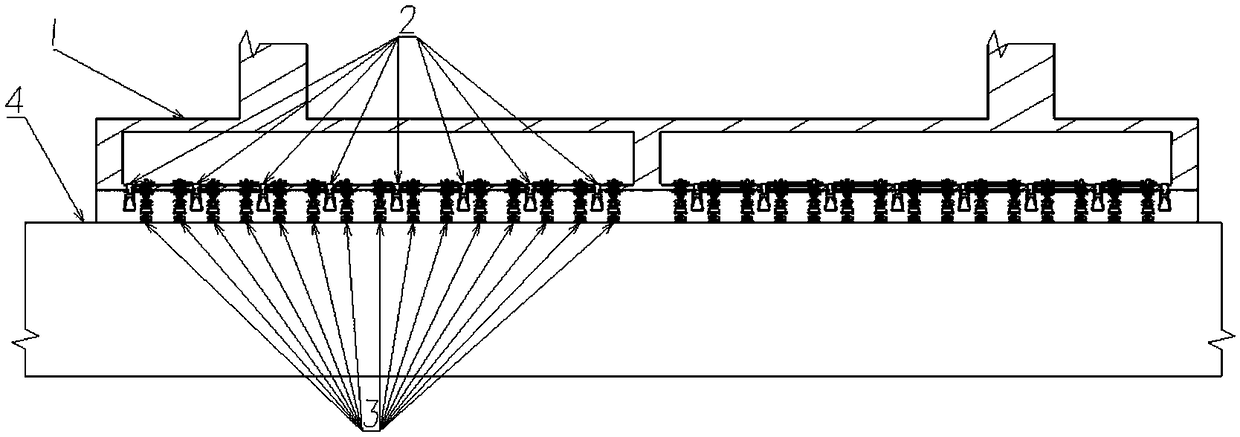

Optical fiber preform rod pickup device for pickling procedure and pickup method

ActiveCN108059337AEnough suctionPlay the role of spring bufferGlass making apparatusSpray nozzleEngineering

The invention discloses an optical fiber preform rod pickup device for a pickling procedure and a pickup method, and belongs to the field of optical fiber production and manufacturing. The pickup device comprises suction disks, nozzles and a bearing frame, wherein the pickup surface of the bearing frame is a semicylindrical arc-shaped surface; the suction disks and the nozzles are uniformly distributed on the axial direction of the semicylindrical arc-shaped surface; multiple groups of suction disks are in fan-shaped arrangement in the radial direction of the semicylindrical arc-shaped surface. The optical fiber preform rod pickup device for the pickling procedure can be applied to carrying of optical fiber preform rods of different specifications in the pickling procedure.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

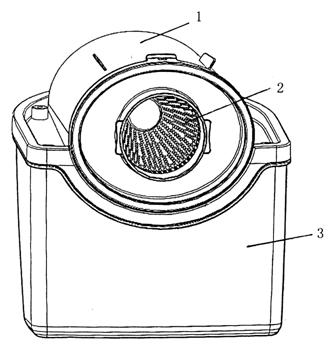

Dust collection device with simplified barrel nut structure

InactiveCN102525347ASimplified Cylindrical Cap StructureReduce mold development costsSuction filtersEngineeringPhencyclone

The invention discloses a dust collection device with a simplified barrel nut structure. The dust collection device comprises a dust collection barrel, a cyclone separator and a filter which is horizontally arranged inside the barrel body of the cyclone separator, wherein a barrel nut is arranged on the inner side at the closed end of the cyclone separator, and is integrated with the barrel body of the cyclone separator. According to the dust collection device with the simplified barrel nut structure, the barrel nut is formed by integrating with the barrel body of the cyclone separator, and the structure in such a way has the advantages that: firstly, a cylinder, screws and other original components are reduced in such a structure, and the cost for developing dies of corresponding components is reduced; secondly, a gap is not reserved between the barrel nut and the barrel body of the cyclone separator, so that dust cannot be accumulated, and the device is easier to clean; and thirdly, fixation does not require bolts, so that manual operation is reduced, the rejection rate of products is reduced, and the barrel nut can be ensured to be positioned on the same central axis with the filter.

Owner:NANJING LG PANDA APPLIANCES

Powerful Vacuum Drill

ActiveCN109025863BGuaranteed normal operationEnough suctionDrill bitsConstructionsEngineeringAdsorption effect

The invention discloses a powerful dust-absorbing drill bit, and can solve problems that dust absorption of the side wall, the edge and the bottom of the drill bit the traditional dust-absorbing drillbit cannot be achieved at the same time due to the small hole coverage range of the traditional dust-absorbing drill bit, the absorption effect is poor, meanwhile, the pipeline connected with the hole is easy to fall off during high-speed operation of the drill bit and absorption cannot run normally, and the dust absorbed by the drill bit is difficult to clean as the drill bit is of an integral structure and cannot be disassembled. The powerful dust-absorbing drill bit comprises a connection pole and a drill body connected to the bottom end of the connection pole, the bottom end of the drillbody is connected with a drill bit, the top end of the connection pole is provided with a docking hole, and the outer wall of the drill body is provided with a machine box completely embedded, an airsuction pump is installed inside the machine box, and a built-in power source is installed on the side wall of the air suction pump. The powerful dust-absorbing drill bit can realize more comprehensive adsorption of dust during work, and the dust adsorbed inside the drill bit after use can be cleaned conveniently.

Owner:山东兖能泰德重工有限公司

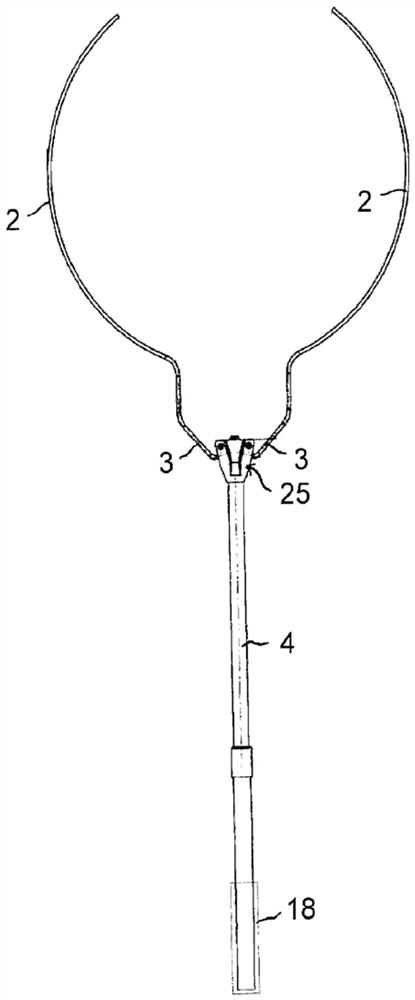

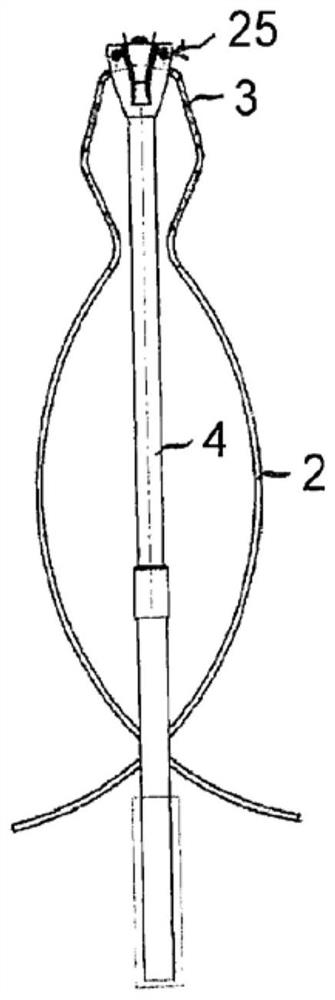

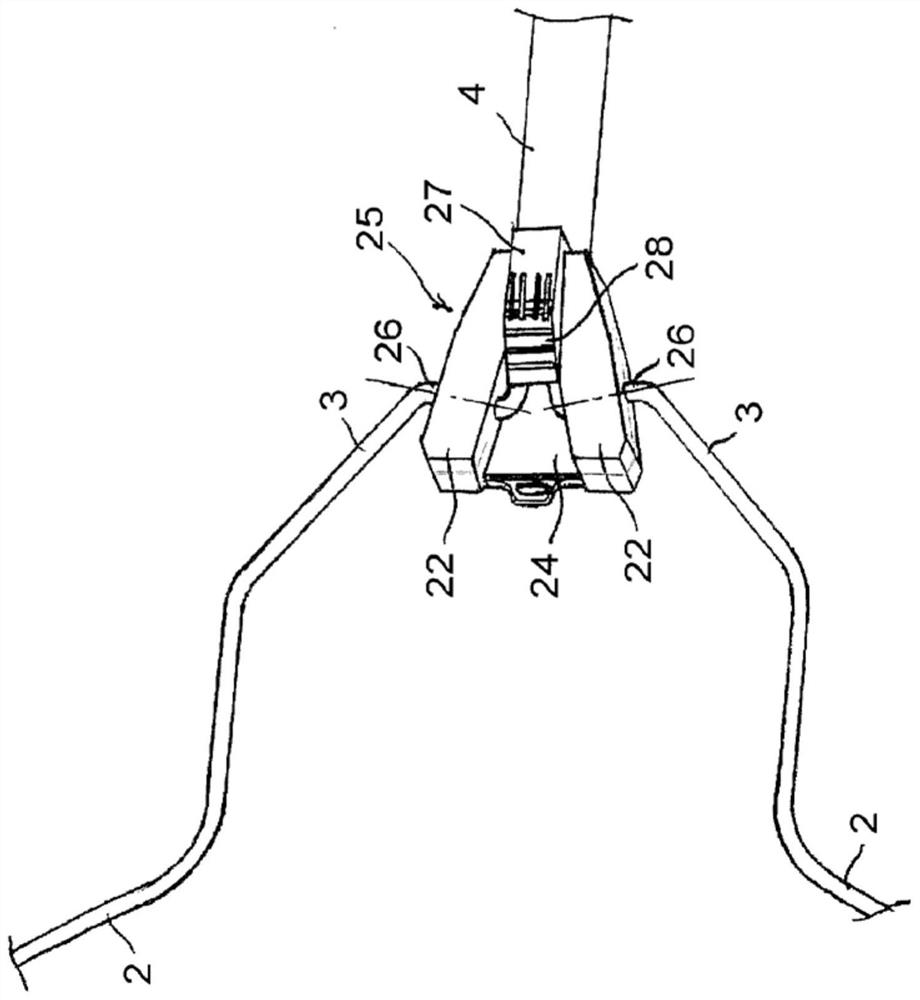

Collapsible cooking oil fire extinguishing device

The present invention discloses a collapsible cooking oil fire extinguishing device having a shaft with two rigid support arms for support of a fire resistant material. An automatic locking mechanismwith a manual pivot mechanism enables changing the device between a collapsed storage position and an expanded usage position. The rigid support arms extend only partially around the perimeter of thefire resistant material, which enables the fire resistant material to tightly cover a cooking oil fire in a vessel with a handle. The pivot mechanism, automatic locking means, and rigid support arms allow the user to exert downward pressure on the burning vessel, thereby creating an airtight seal, cutting off the supply of oxygen and extinguishing the fire. The spring in the automatic locking mechanism is not under compression in the storage position, which increases reliability and prevents malfunction during long periods of time in the storage position.

Owner:H J 芮曼 +1

Multifunctional sputum and pus suction, shunting and collecting device

PendingCN109529137AReduced Risk of Contaminant AttacksEnsure safetyCatheterIntravenous devicesSuction forceMedicine

The invention provides a multifunctional sputum and pus suction, shunting and collecting device. The device is matched with a drain tube with an anti-blocking function for use, sputum is collected andseparated by cooperation of an outer cannula and a sputum collecting inner container, the sputum collecting inner container is arranged in the outer cannula, visible things are reserved in a sputum collecting tank, liquid substances are reserved at the bottom of the outer cannula, and the visible things and the liquid substances are separated in a negative-pressure suction process; meanwhile, a barrier plate is further arranged in the sputum collecting inner container, substances which are sucked out by negative pressure firstly impact on the barrier plate, then slide into the sputum collecting tank and cannot be sucked into a negative-pressure inlet pipe. With the adoption of the design, not only is effective isolation of the negative-pressure inlet pipe guaranteed, but also sufficient suction force of the negative pressure is guaranteed, the device has the technical effects that the visible things and the liquid substances are easily separated and pollution to a negative pressure source is avoided, and meanwhile, the device has the anti-blocking effect.

Owner:广州志和医疗器械有限责任公司

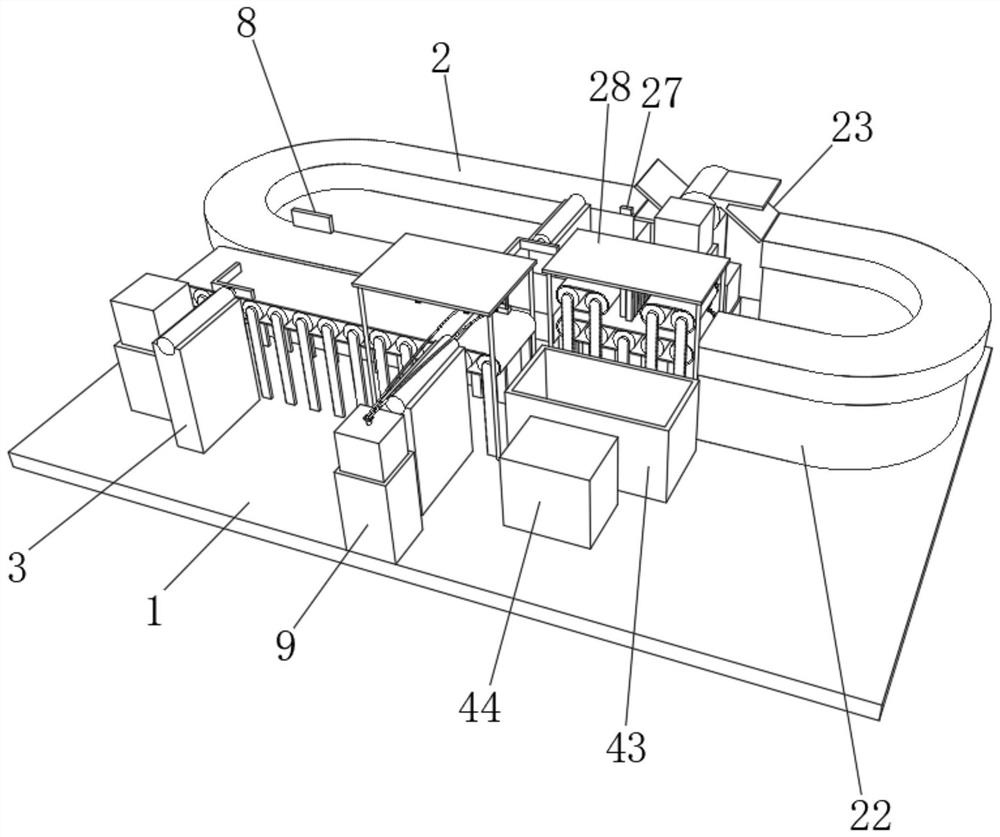

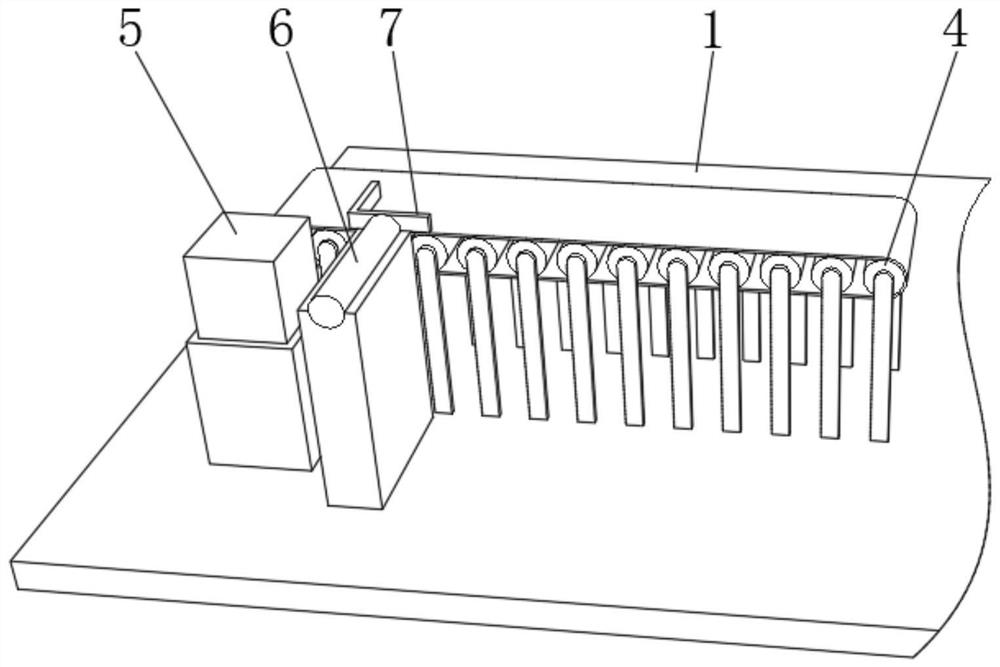

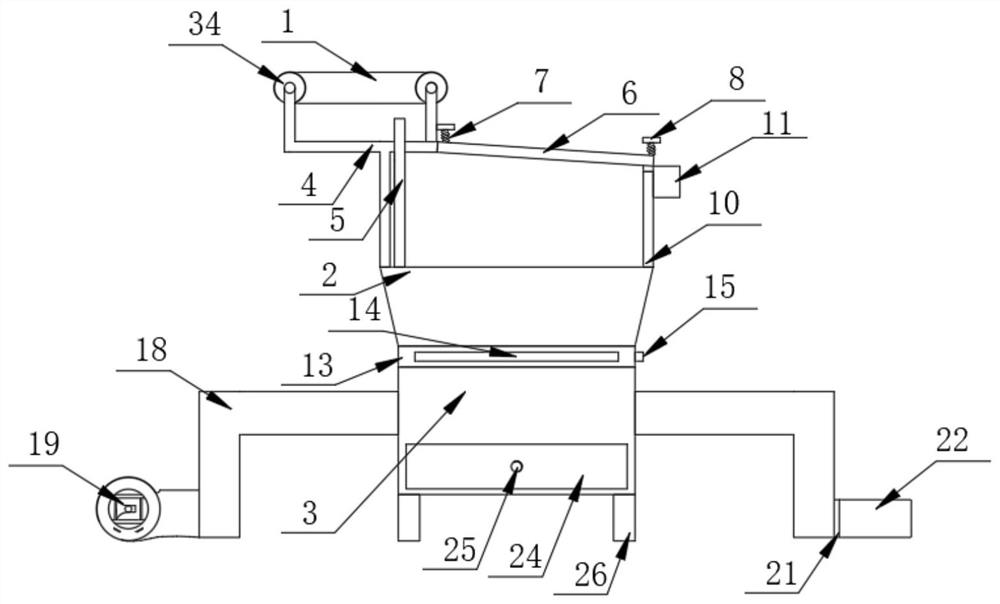

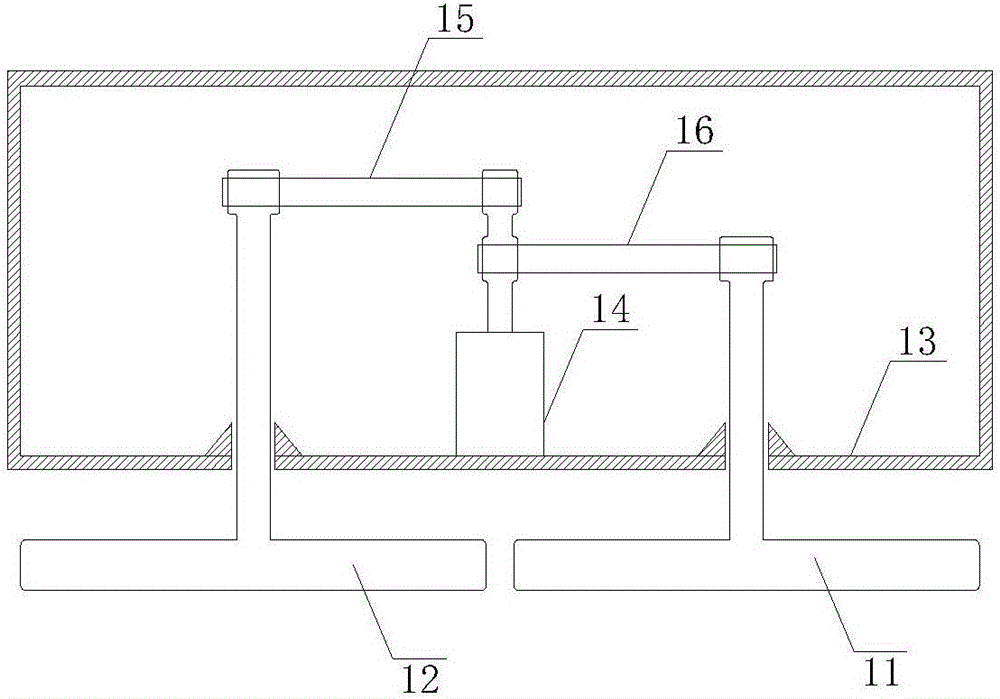

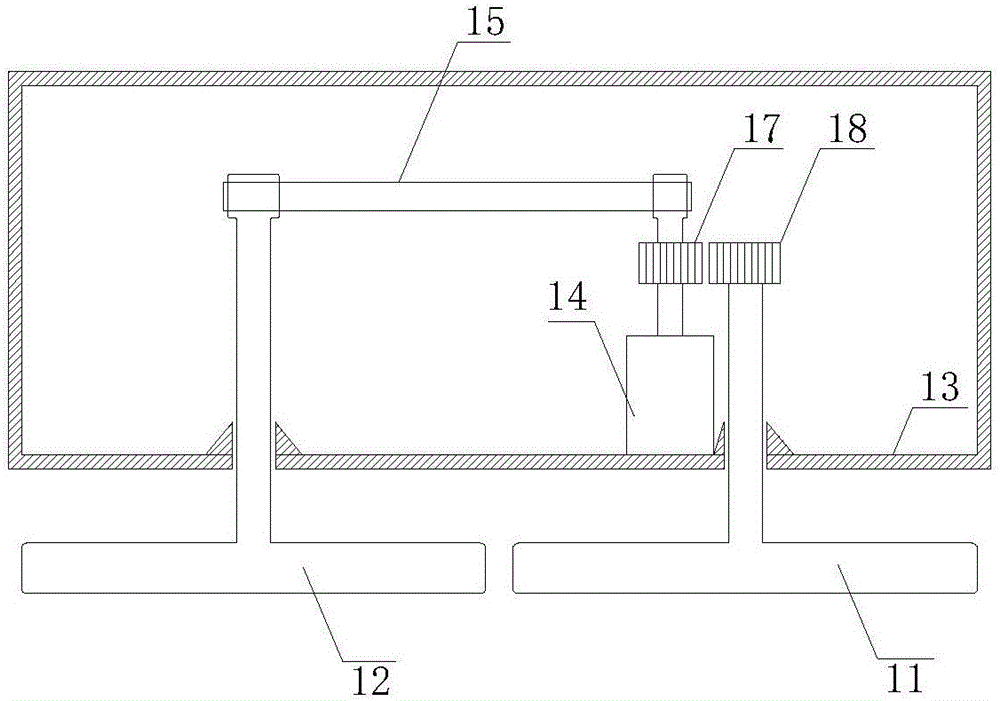

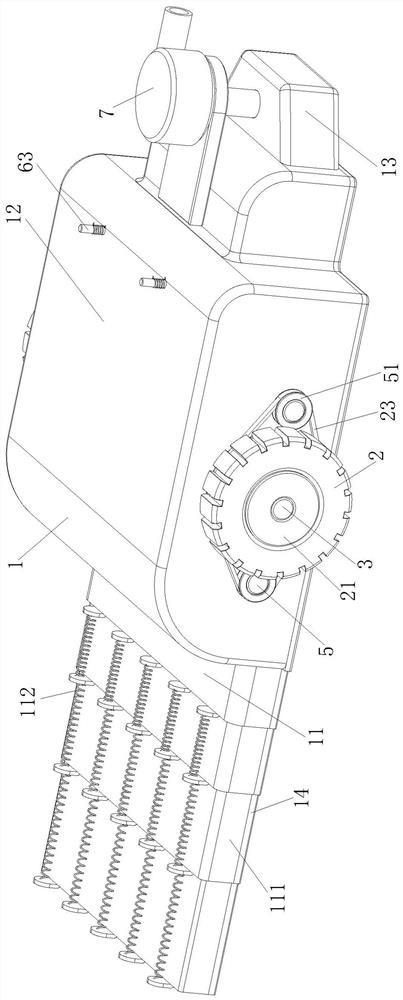

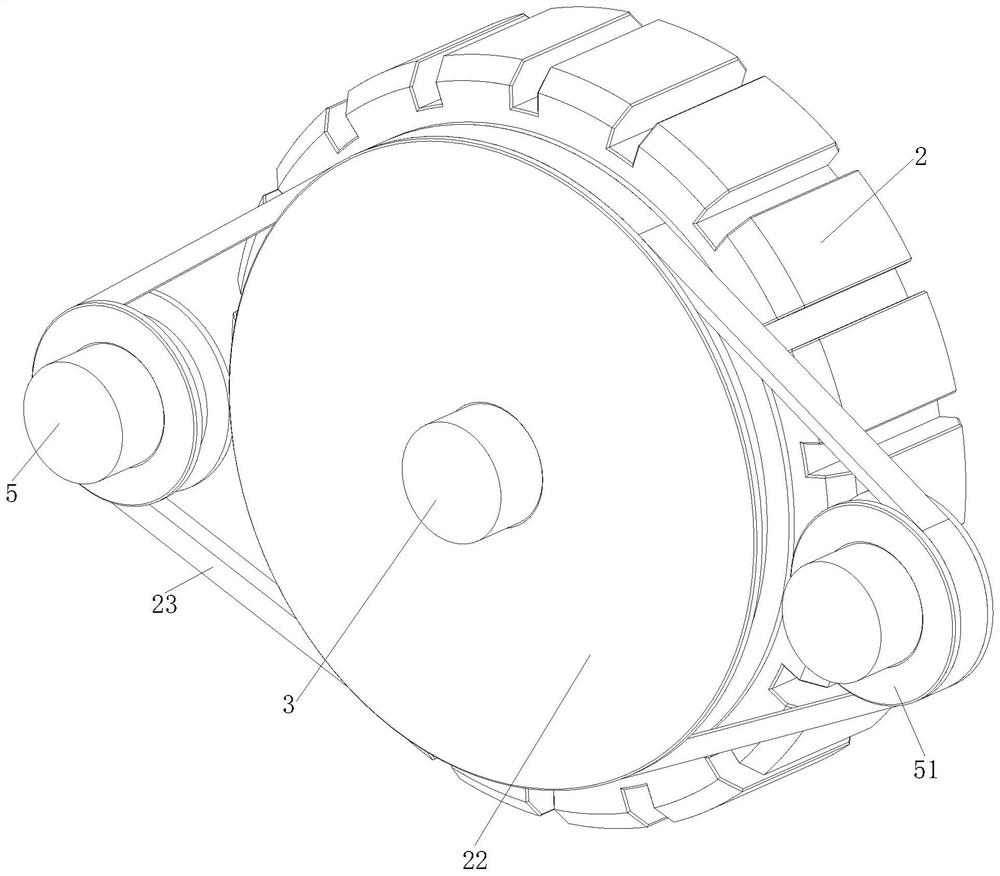

A swimming pool bottom sediment removal device

ActiveCN112664011BReduce flowImprove cleanlinessGymnasiumSwimming poolsSuction forceElectric machinery

The invention belongs to the technical field of water treatment equipment, in particular to a swimming pool bottom sediment removal device, comprising a casing, a driving roller, a No. 1 shaft, a roller brush, a No. 2 rotating shaft, a filter screen mechanism and a centrifugal water pump; the invention The drive roller is driven to rotate by the hub motor, which drives the removal device to move at the bottom of the pool, and the hub motor drives the No. 1 pulley to rotate, drives the No. 2 pulley to rotate, and drives the roller brush to clean up the sediment attached to the bottom of the pool. The sediment attached to the bottom of the pool is suspended in the water, and the suction of the centrifugal pump sucks the water in the shielding cover and the cleaning cover into the pumping cavity through the filter mechanism, and the filter mechanism filters the sediment suspended in the water and removes the sediment. Collected in the filter mechanism to remove the sediment from the bottom of the swimming pool; the shielding cover forms a low and small shielding area, so that the suction can absorb all the water in the shell, so that all the sediment in the shell is collected in the filter mechanism. , to improve the removal of sediments from the bottom of the swimming pool.

Owner:JIANGSU BEYOND SWIMMING POOL EQUIP

Tile-sucking disc device

ActiveCN102100971BImprove transmission efficiencyIncrease productivityIndoor gamesManufacturing cost reductionAcute angle

The invention relates to a tile-sucking disc device which comprises a tile-sucking disc and magnets, wherein the tile-sucking disc comprises a base part and a splicing part; the circumferential sides of the base part and the splicing part are respectively provided with three first grooves and three second grooves which correspond to each other and uniformly distributed; the base part and the splicing part are spliced to each other in the axial direction; after the base part and the splicing part are spliced, magnet grooves which are uniformly distributed and are composed of corresponding first grooves and second grooves are formed on the circumferential sides; the included angle between the center line in the length direction of each magnet groove and the axial line of the tile-sucking disc is an acute angle alpha; and the magnets are arranged in the magnet grooves. The invention has the following advantages: 1) in the tile transport process, the tiles can not be scraped down by guideplates or be stuck at the inlet end, thereby achieving high transport efficiency and ensuring the normal operation of the mahjong machine; 2) the magnets on the tile-sucking disc can be conveniently and quickly fixed, thereby improving the production efficiency of components and parts of the mahjong machine; and 3) the quantity of magnet sheets is reduced by 1 / 4, thereby saving the rare earth material and lowering the manufacturing cost.

Owner:ZONGYANG COUNTY ZHONGBANG TECH INFORMATION CONSULTING CO LTD

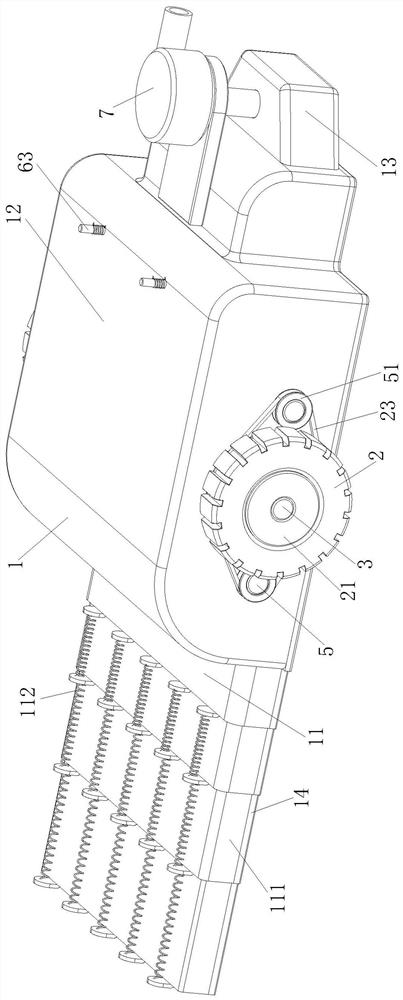

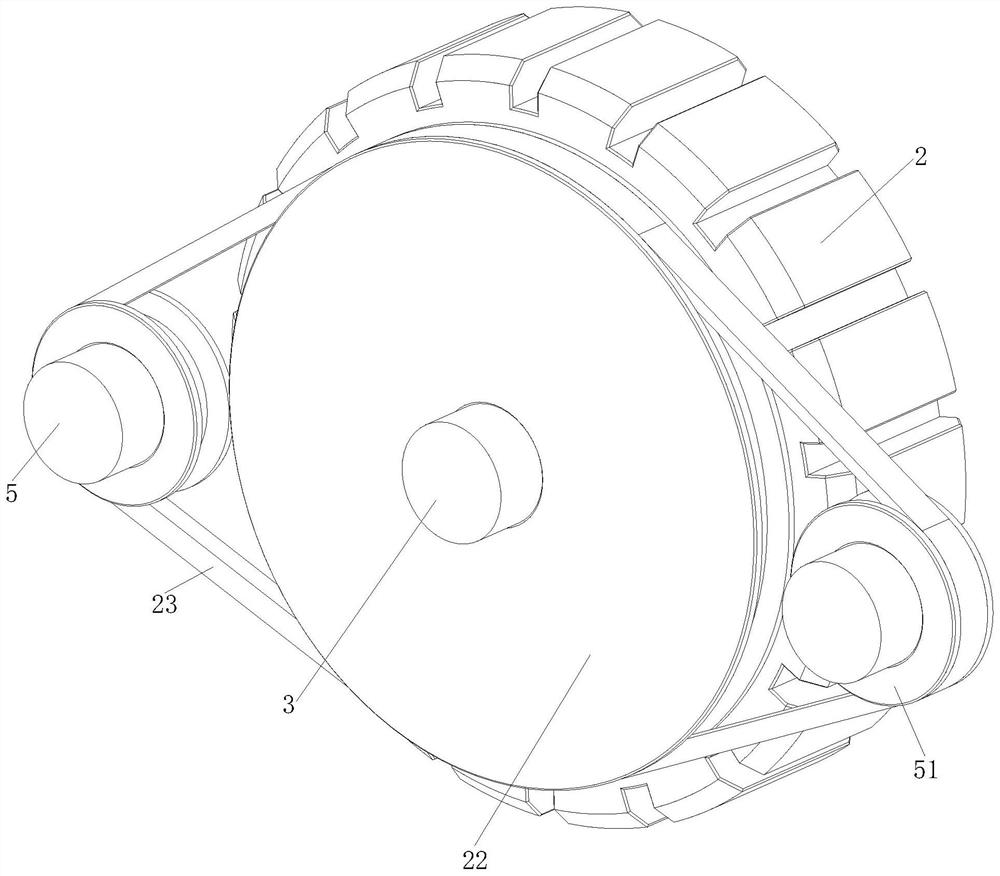

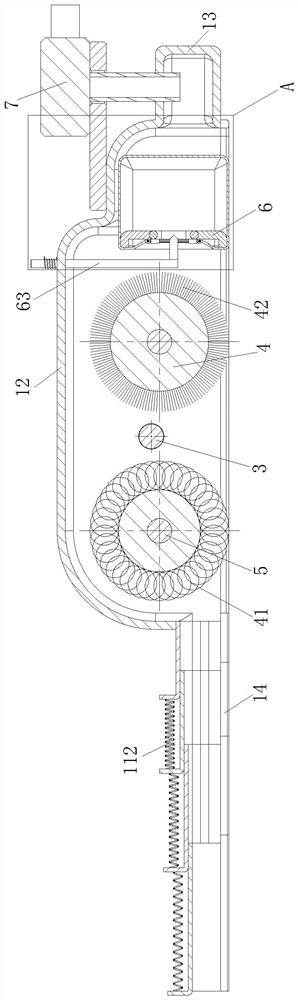

Swimming pool underwater sediment removing device

The invention belongs to the technical field of water treatment equipment, and particularly relates to a swimming pool underwater sediment removing device. The device comprises a shell, a driving roller, a first shaft, a rolling brush, a second rotating shaft, a filter screen mechanism, and a centrifugal water pump. According to the swimming pool underwater sediment removing device, a hub motor drives the driving roller to rotate and drives a cleaning device to move at the bottom of a pool; the hub motor drives a first belt wheel to rotate, drives a second belt wheel to rotate and drives the rolling brush to clean sediments attached to the bottom of the pool and suspend the sediments attached to the bottom of the pool in water; meanwhile, water in a shielding cover and a cleaning cover is sucked into a water pumping cavity through a filter screen mechanism by the suction force of the centrifugal water pump, the filter screen mechanism filters the sediments suspended in the water, and the sediments are collected in the filter screen mechanism, so that the sediments at the water bottom of the swimming pool are removed; and the shielding cover forms a low and small shielding area, so that the water in the shell can be completely sucked away by suction force, all the sediments in the shell are collected in the filter screen mechanism, and the cleaning effect of the sediments at the water bottom of the swimming pool is improved.

Owner:JIANGSU BEYOND SWIMMING POOL EQUIP

Chocolate whole kernel mixed pouring head

The invention discloses a chocolate whole kernel mixing pouring head which comprises a shell, a hopper and a plunger mechanism, a pouring gate mechanism is arranged in the shell and comprises a pouring gate longitudinally arranged in the shell in a penetrating mode, and the upper end of the pouring gate is communicated with the hopper. The plunger mechanism comprises a plunger channel, a plunger and a plunger driving mechanism, the plunger channel is arranged in the shell and communicated with the pouring channel, the plunger is arranged in the plunger channel, and the plunger driving mechanism is connected with the plunger and drives the plunger to telescopically move along the plunger channel, and is characterized in that a spiral conveying mechanism is arranged in the hopper, and the pouring channel mechanism further comprises a blanking sleeve which is arranged in the plunger channel and sleeves the plunger; the front end of the blanking sleeve extends into the pouring channel and is communicated with the pouring channel through an opened side hole, the blanking sleeve driving mechanism is used for driving the blanking sleeve to rotate around the plunger, and the blanking sleeve is respectively communicated with the upper end and the lower end of the pouring channel by means of upward rotation and downward rotation of the side hole. The pouring device can smoothly and efficiently realize pouring of chocolate paste mixed with whole nuts, and is simple in structure and convenient to use.

Owner:苏州姑苏食品机械有限公司

Burr grinding workbench for mechanical pipe fitting production

InactiveCN112643505APrevent spillageCompact structureEdge grinding machinesRevolution surface grinding machinesPipe fittingEngineering

The invention aims to provide a burr grinding workbench for mechanical pipe fitting production, and the burr grinding workbench comprises a base, a grinding table, two shaft seats and a cutter mounting plate. A cover body with an opening in the bottom is mounted on the rear side of the base, a relatively-sealed grinding cavity is formed in the cover body, and the cover body is jointly defined by a front end plate, a rear end plate, a top plate and two side plates. The cutter mounting plate is longitudinally and slidably mounted in the cover body, the grinding table is transversely and slidably mounted on the base, an opening allowing the grinding table to penetrate through slidably is formed in the bottom of the front end plate, the two shaft seats are slidably mounted on the grinding table in the length direction, and rotating plates are rotatably mounted on the opposite inner sides of the shaft seats. A cylindrical plug is coaxially and fixedly mounted at the inner ends of the rotating plates, a sealing door capable of being opened and closed is arranged at an opening of the front end plate, a plurality of air suction pipes are fixedly mounted on the rear end plate, at least one air inlet is formed in the front end plate, and the outer ends of the air suction pipes are all fixedly mounted on an air inducing box.

Owner:安徽智恒装配式消防科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com