Tile-sucking disc device

A technology of wheel-by-base and plug-in parts, applied in the field of parts and components in mahjong machines, can solve the problems of large differences in arrangement shape, stuck at the entrance end, scraped off guide pieces, etc., so as to reduce the manufacturing cost and the number of use. , the effect of saving rare earth materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

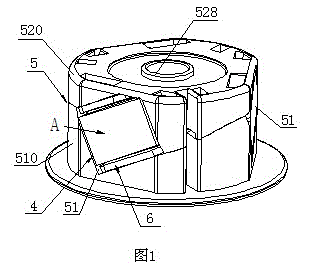

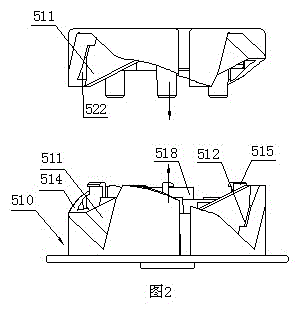

[0033] control figure 1 , Suction card wheel device is mainly made up of suction card wheel 5 and magnet 4. An injection molded part on the suction card wheel 5 is composed of a base part 501 and a plug-in part 502, and the two are inserted into each other along the axial direction. Please refer to figure 2 .

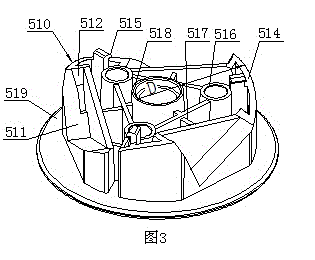

[0034] control image 3 , The base member 501 is mainly composed of a first cylinder 514 , a first end plate 519 , a sleeve seat 518 and a socket 516 . The first end plate 519 is circular, and the circumferential side of the first cylinder 514 is connected by evenly distributed arc surfaces and planes. The diameter of the end plate is greater than the diameter D of the arc surface on the circumferential side of the first cylinder. , so that the card-absorbing wheel body has a rib to prevent the mahjong tiles from slipping out of the card-absorbing wheel. The first cylinder 514 is arranged on one side of the end plate, the sleeve seat 518 is located in the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com