Road surface sanitation vehicle and working method thereof

A technology for cleaning cars and vehicles, applied in road cleaning, cleaning methods, construction, etc., can solve problems such as low efficiency, fast consumption, limited operation, etc., and achieve the effect of small water consumption, excellent effect, and concentrated water column flushing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

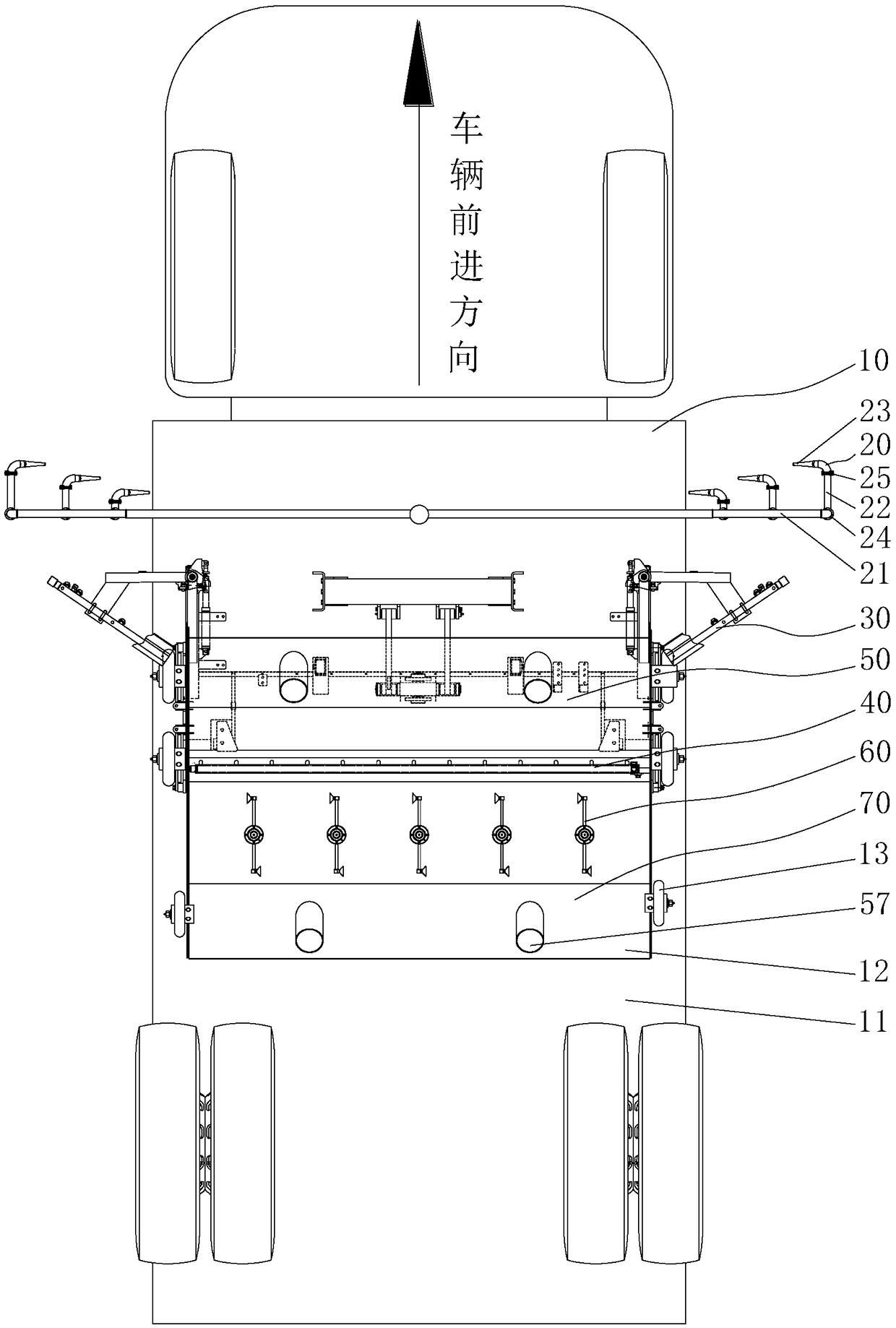

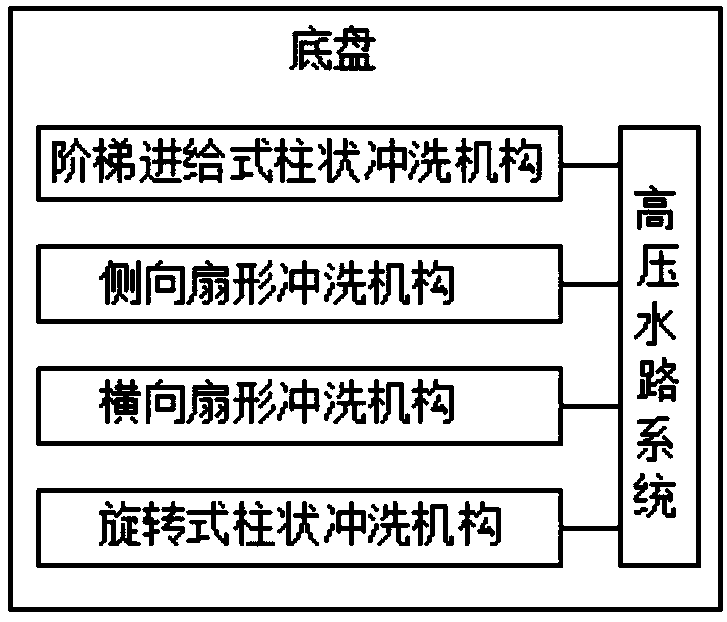

[0052] Such as figure 1 As shown, one end of the first nozzle 21 is vertically connected to the chassis 10 , and the lengths of the plurality of first connecting pipes 22 increase sequentially along the length direction of the first nozzle 21 from one end of the first nozzle 21 to the other end.

Embodiment 2

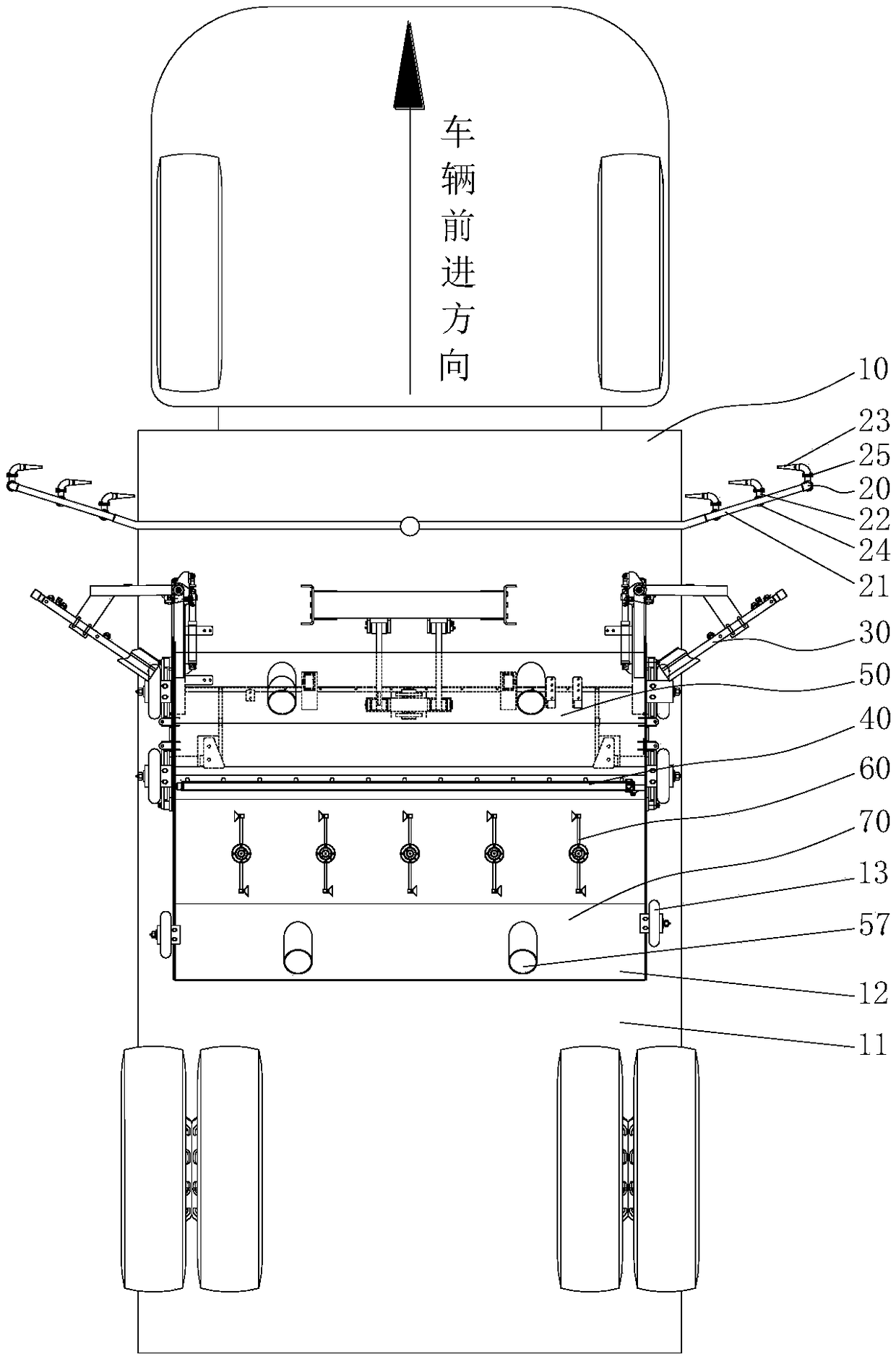

[0054] Such as figure 2 As shown, one end of the first nozzle 21 is obliquely connected to the chassis 10 , the first included angle formed by the first nozzle 21 and the forward direction of the vehicle is an acute angle, and the lengths of the plurality of first connecting pipes 22 are all the same.

[0055] Such as Figure 4 As shown, as an embodiment, the first connecting member 24 is a horizontal flange, and the horizontal flange is used to adjust the second angle formed between the first connecting pipe 22 and the forward direction of the vehicle; The two connecting parts 25 are longitudinal flanges, and the longitudinal flanges are used to adjust the third angle formed between the spraying direction of the first nozzle 23 and the forward direction of the vehicle and the fourth angle formed between the spraying direction of the first nozzle 23 and the road surface. number of angles.

[0056] Such as Figure 5 As shown, as another embodiment, the first connecting memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com