Optical fiber preform rod pickup device for pickling procedure and pickup method

An optical fiber preform and pick-up device technology, which can be used in manufacturing tools, glass manufacturing equipment, etc., and can solve problems such as narrow size of pickling tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

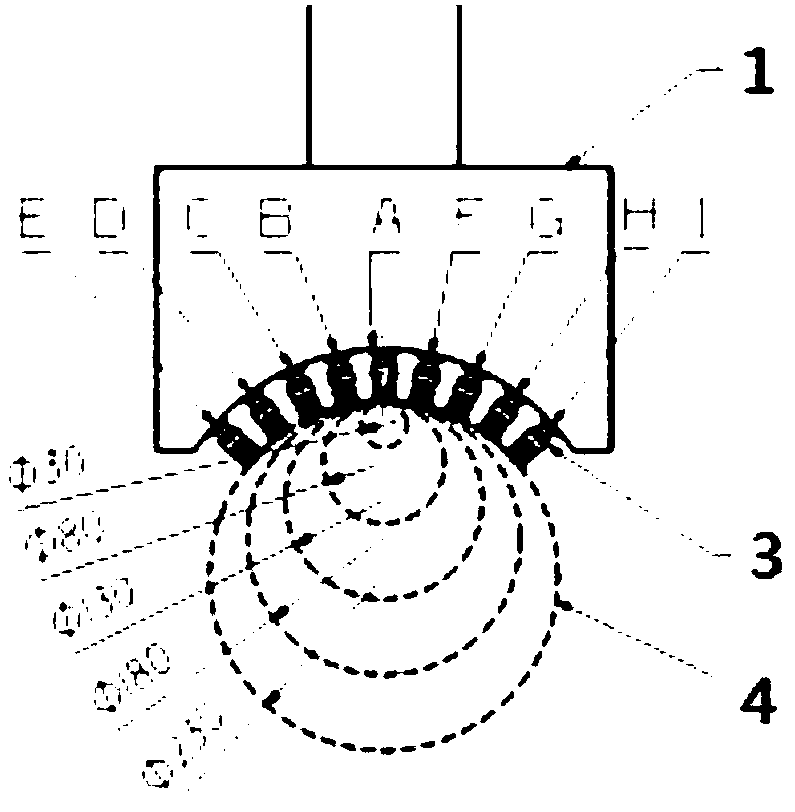

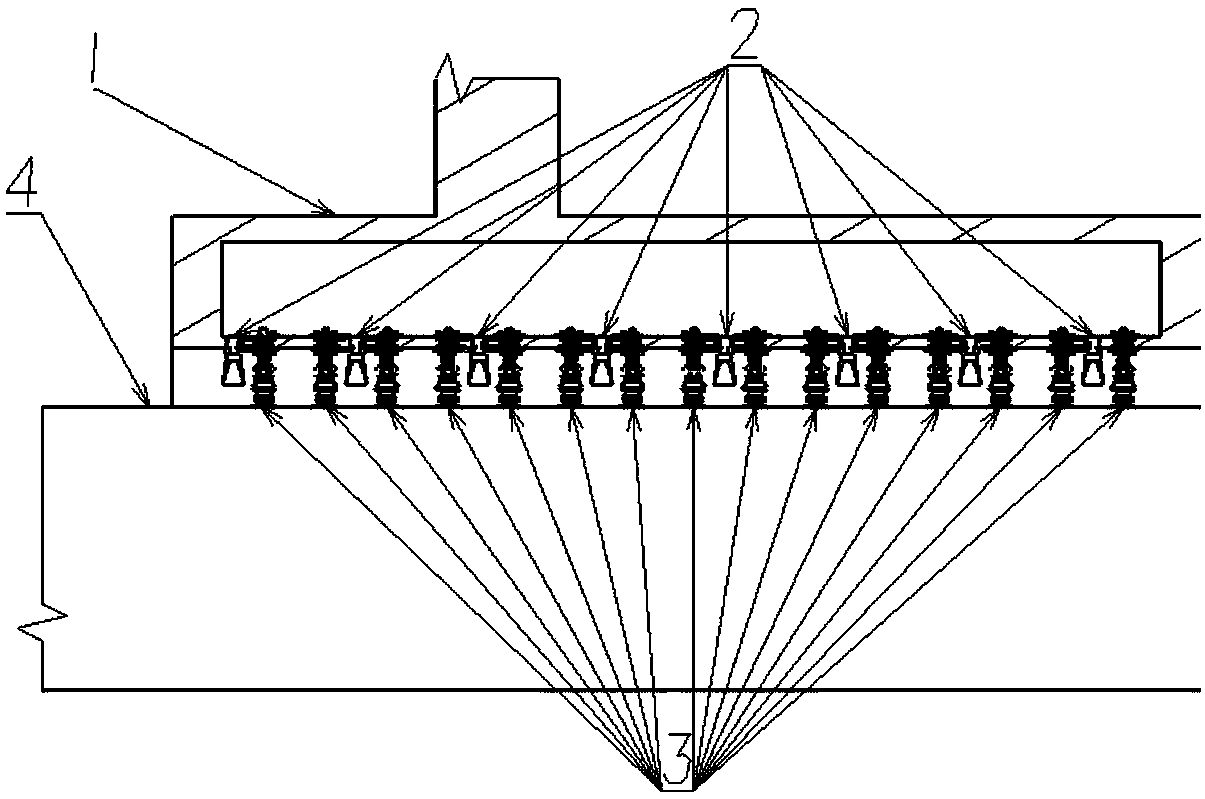

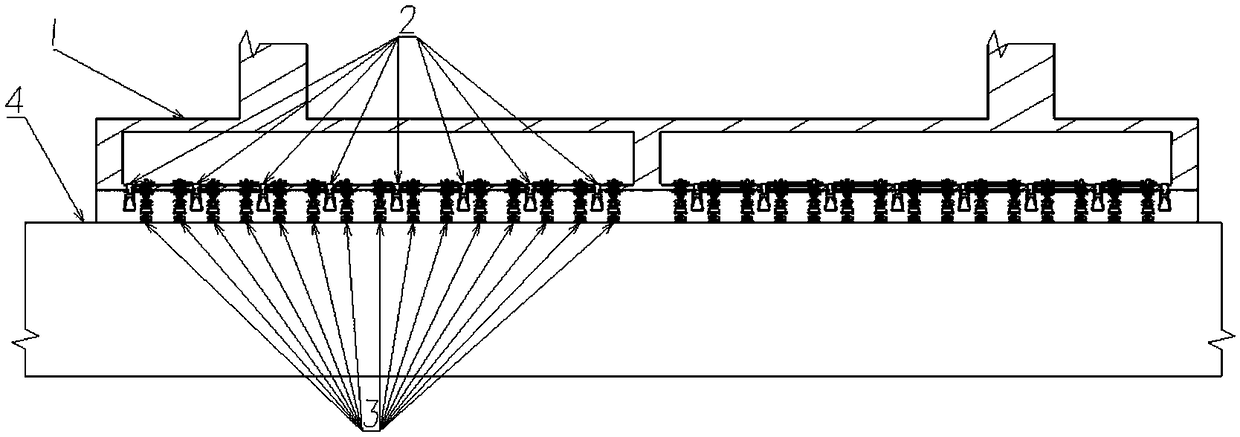

[0044] Such as figure 1 , Figure 5 As shown, a pick-up device for an optical fiber preform 4 used in the pickling process according to the present invention includes a suction cup 3, a nozzle 2, and a load-bearing frame 1. The pick-up surface of the load-bearing frame 1 is a semi-cylindrical arc surface, so The suction cups 3 and nozzles 2 are evenly distributed in the axial direction of the semi-cylindrical arc surface; in the radial direction of the semi-cylindrical arc surface, multiple groups of the suction cups 3 are arranged in a fan shape.

[0045] There are a series of suction cups 3 arranged in a fan shape on the pick-up device of the present invention. The larger the size of the preform rod 4, the more suction cups 3 participate in the work on the device, which can ensure that sufficient suction can be provided for preform rods 4 of various specifications. Suitable for preforms of various sizes4.

[0046] Such as Figure 6 , Figure 8 As shown, along the axial d...

Embodiment 2

[0059] The above-mentioned embodiment 1 is a device embodiment, and this embodiment 2 is a method embodiment. This embodiment and the above-mentioned embodiment 1 belong to the same technical concept. Please refer to the above-mentioned embodiment 1 for details not described in detail in this embodiment.

[0060] A pick-up method using the pick-up device for the optical fiber preform 4 described in Embodiment 1,

[0061] Carry the preform 4 from the rack to the pickling machine for pickling:

[0062] Step S1: The pick-up device moves above the preform 4, and opens the nozzle 2 to blow off the dust and debris on the surface of the preform 4;

[0063] Step S2: Close the nozzle 2, drop the pick-up device to the position of the preform 4, open the suction cup 3, and suck the preform 4 tightly;

[0064] Step S3: The pick-up device lifts the preform 4 and transports it to the pickling tank support, the suction cup 3 is closed, and the pick-up device moves away after the preform 4 i...

Embodiment 3

[0066] The difference between this embodiment and the above-mentioned embodiment 2 is that in embodiment 2, the preform 4 is transported from the rack to the pickling machine for pickling, while in this embodiment, the preform 4 is picked up from the pickling machine after pickling. Pickup method for transfer to storage point in pickling machine.

[0067] A pick-up method using the above-mentioned pick-up device for the optical fiber preform 4 used in the pickling process,

[0068] After the preform 4 is pickled, it is transported from the pickling machine to the storage point:

[0069] Step S1: The pick-up device is moved above the preform 4, and the nozzle 2 is opened to purge the residual acid on the surface of the preform 4;

[0070] Step S2: the nozzle 2 is closed, the pick-up device is lowered to the position of the preform 4, the suction cup 3 is opened, and the preform 4 is sucked tightly;

[0071] Step S3: The pick-up device lifts the preform 4 and transports it to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com