Burr grinding workbench for mechanical pipe fitting production

A workbench and grinding table technology, applied in grinding machines, manufacturing tools, metal processing equipment, etc., can solve problems such as low dust collection efficiency and dust spillage, and achieve the effect of facilitating centralized cleaning, preventing dust spillage, and improving dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

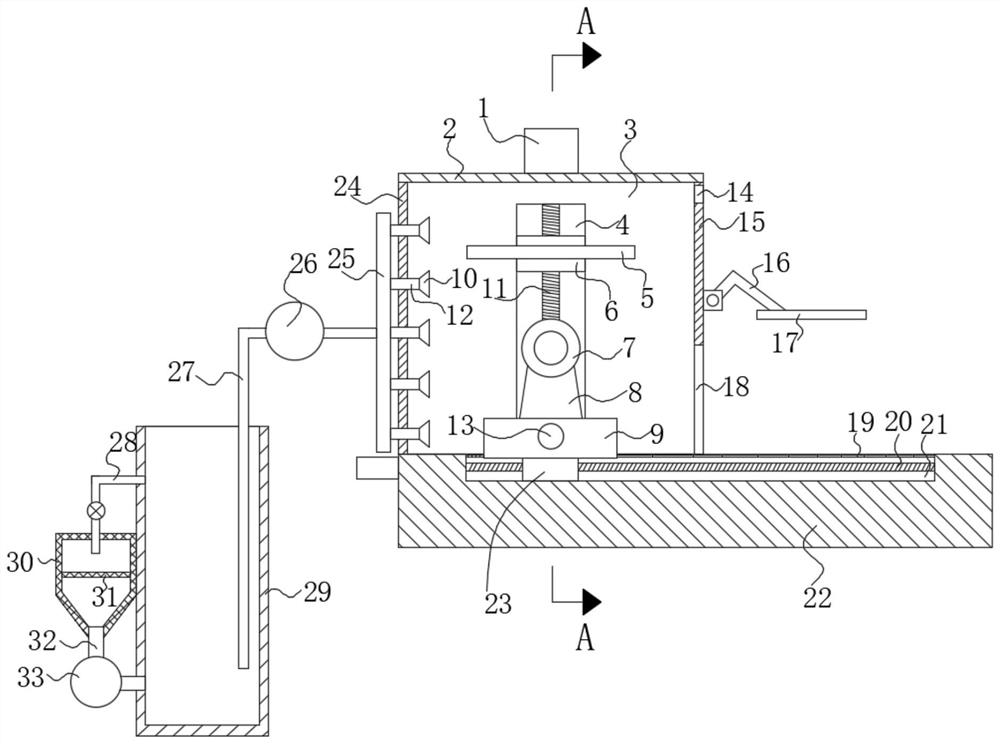

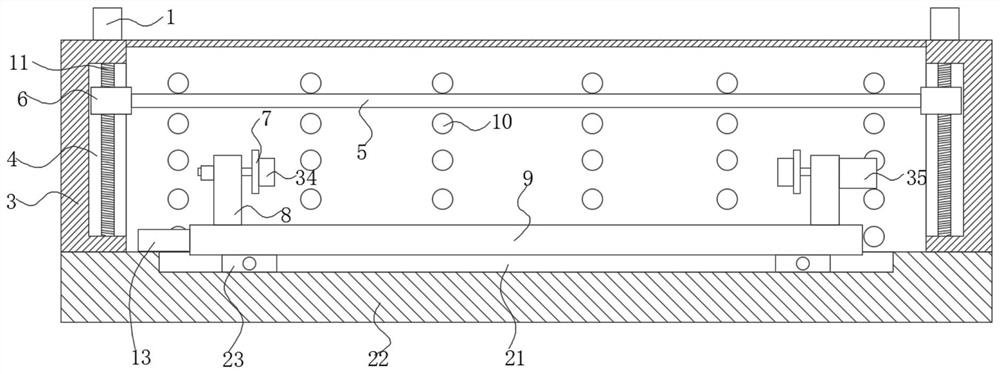

[0023] see Figure 1~2 , figure 1 Schematic diagram of the structure of the burr grinding workbench for the production of mechanical pipe fittings, figure 2 for figure 1 The sectional view of A-A in the middle.

[0024] In this embodiment, a burr grinding workbench for the production of mechanical pipe fittings includes a base 22, a grinding table 9, two shaft seats 8, and a tool mounting plate 5. A cover with a bottom opening 18 is installed on the rear side of the base 22. The cover The body is enclosed by a front end plate 15, a rear end plate 24, a top plate 2, and two side plates 3. The tool mounting plate 5 is longitudinally slid and installed in the cover body, and the tool mounting plate 5 is used for installing a grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com