Chocolate whole kernel mixed pouring head

A technology of whole nuts and pouring head, which is applied in the field of chocolate whole nuts mixing pouring head, which can solve the problems of unsmooth feeding, narrow internal valve hole, small volume, etc., achieve smooth material suction and discharge, and improve quality , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

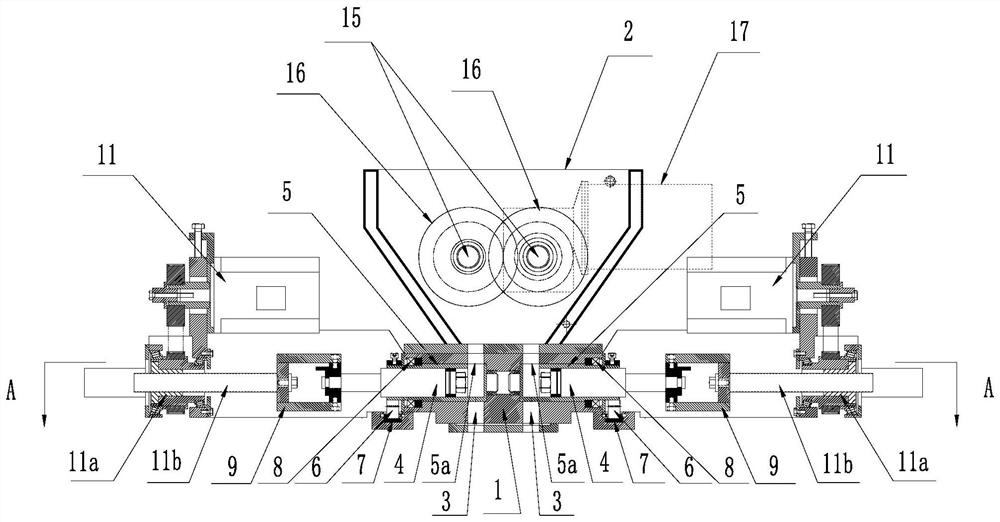

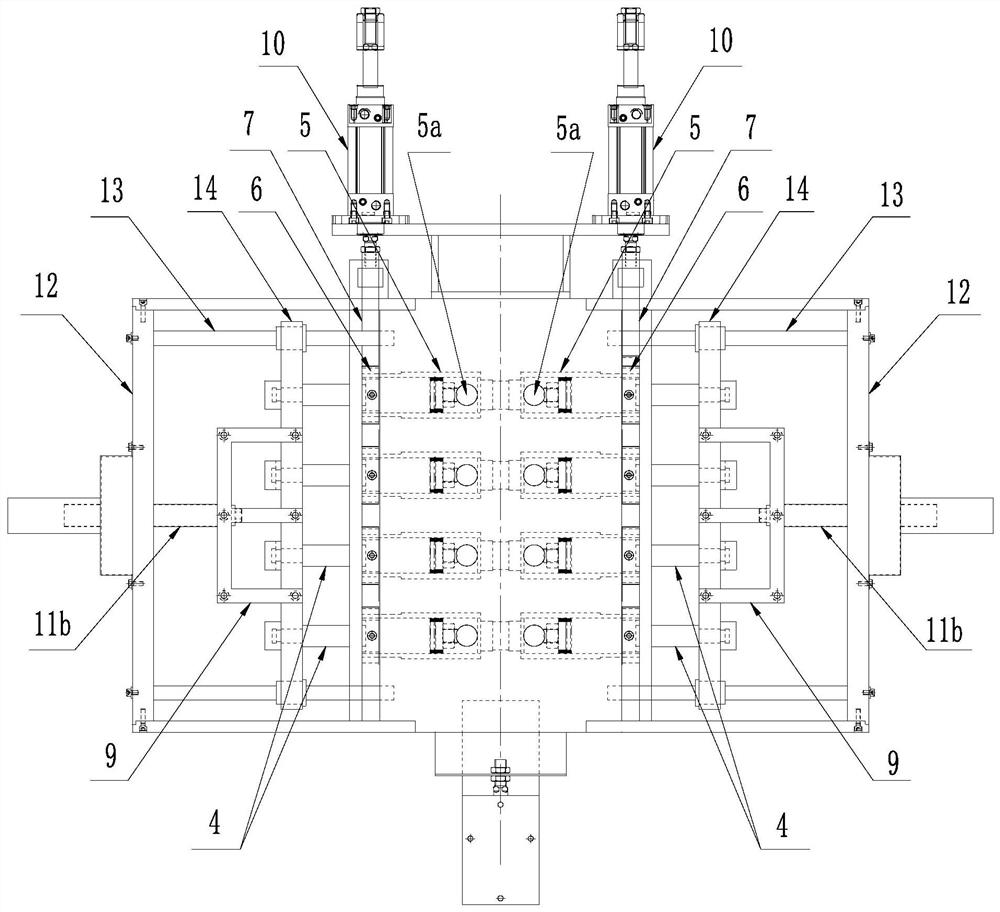

[0034] Example: the following combination figure 1 and figure 2 As shown, the specific embodiment of this chocolate whole nut mixed pouring head provided by the present invention is described in detail as follows:

[0035] The chocolate whole nut mixing pouring head provided in this embodiment is composed of a shell 1 , a hopper 2 fixed above the shell 1 , a screw conveying mechanism arranged in the hopper 2 , and a pouring device arranged in the shell 1 . The channel mechanism and the sprue mechanism cooperate with the plunger mechanism to form together.

[0036] In this embodiment, the screw conveying mechanism adopts double screw feeding rods 15 that rotate in parallel and synchronously in opposite directions. Each screw feeding rod 15 is pivotally arranged in the hopper 2 laterally. There is a helical blade 16 on it; it also includes a screw feeding rod driving mechanism that connects and drives the two screw feeding rods 15 to rotate synchronously and reversely, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com