Patents

Literature

30results about How to "Ensure coverage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

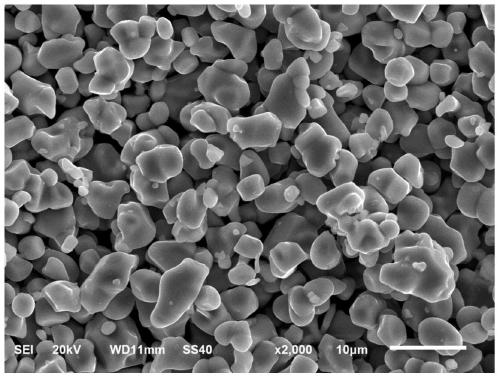

High-nickel ternary positive electrode material with single crystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN111463411AIncrease productionImprove product qualitySecondary cellsPositive electrodesDopantPhysical chemistry

The invention discloses a high-nickel ternary positive electrode material with single crystal morphology and a preparation method of the high-nickel ternary positive electrode material. The positive electrode material is formed by a base material and a coating layer, wherein the base material is prepared from a high-nickel ternary precursor, a lithium source and a doping agent; the doping agent comprises a doping element, the doping element is a metal element, the coating layer is formed by a coating material, the coating material comprises a coating element, and the coating element is a metalelement and / or a non-metal element. The positive electrode material is obtained by mixing the high-nickel ternary precursor, the lithium source and the doping agent, performing primary sintering, then mixing with the coating material, and performing secondary sintering. The high-nickel ternary positive electrode material disclosed by the invention has the advantages of single crystal morphology,smooth surface, small specific surface area and high compaction density, and the single crystallization of the high-nickel ternary positive electrode material improves the specific capacity and cycleperformance of the positive electrode material and prolongs the service life of the positive electrode material. The preparation method is simple in process, easy to implement and beneficial to industrial large-scale production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

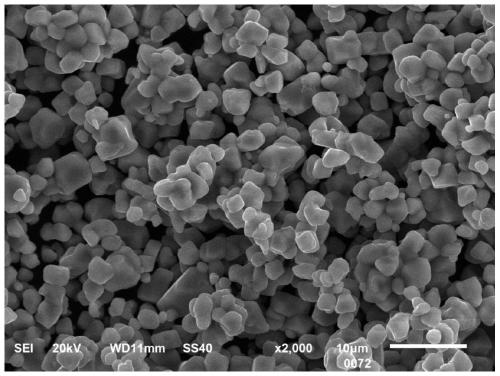

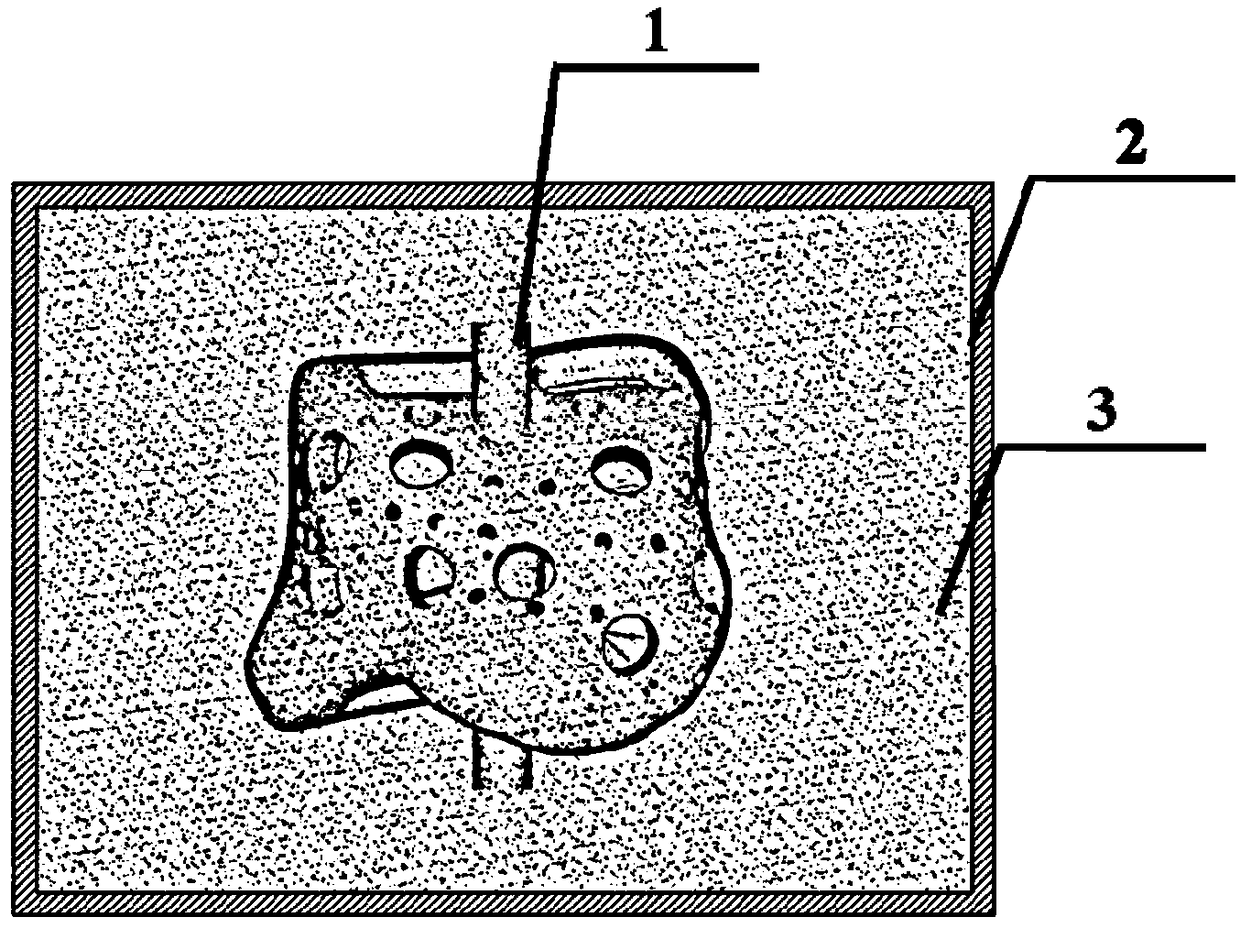

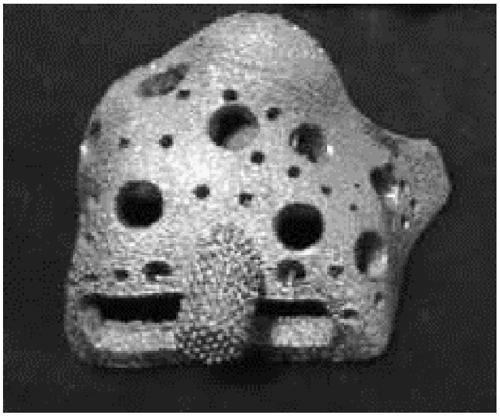

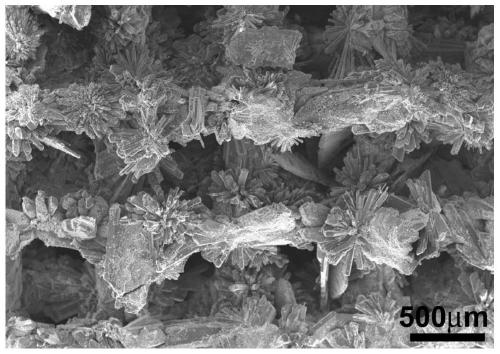

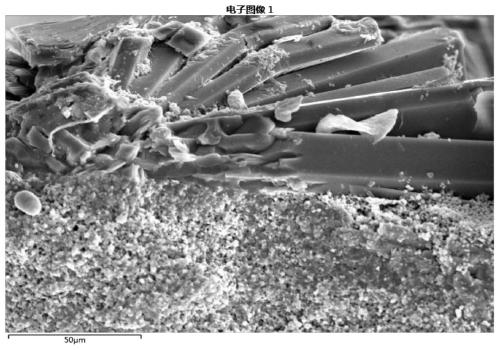

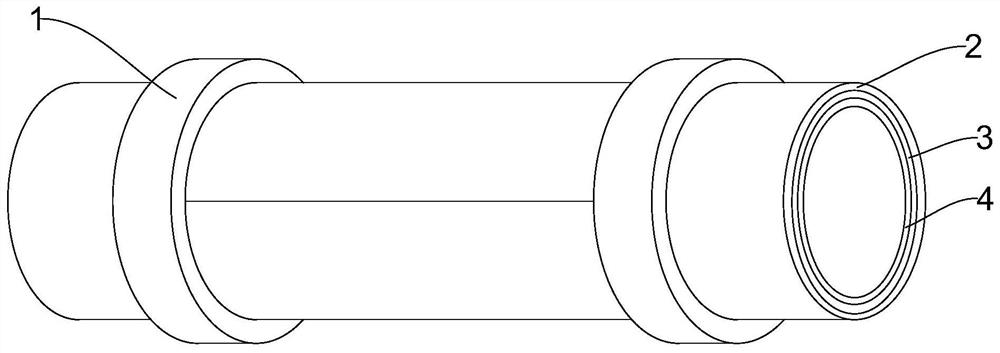

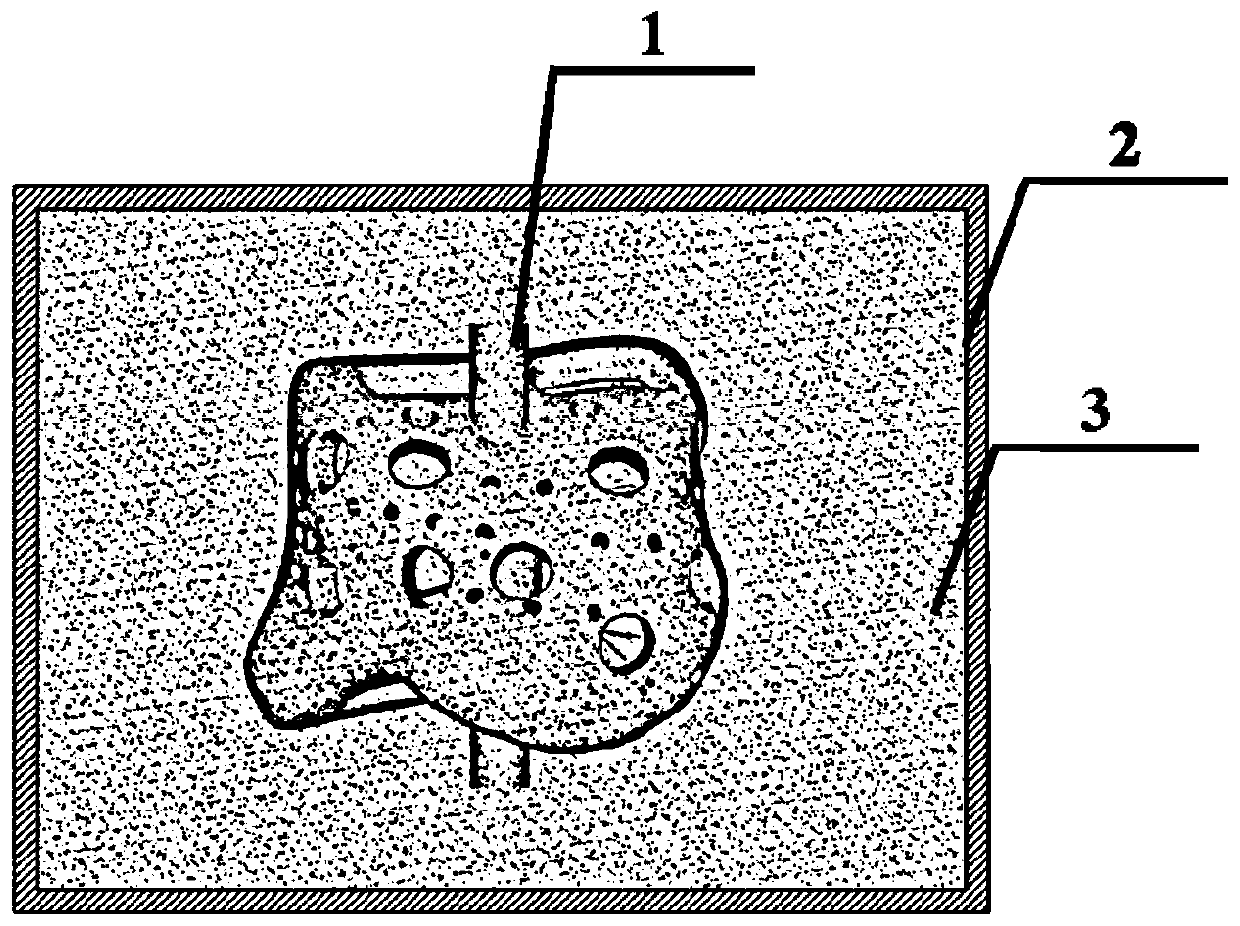

Preparation method of medical porous titanium or titanium alloy materials coated with tantalum coating on surfaces

ActiveCN109261958AImprove bindingSolve poor bondingAdditive manufacturing apparatusTransportation and packagingPorous titaniumTa element

The invention discloses a preparation method of medical porous titanium or titanium alloy materials coated with tantalum coatings on surfaces, which includes the following steps: firstly, preparing aporous titanium frame or a porous titanium alloy frame by adopting the 3D printing method; next etching the porous titanium frame or the porous titanium alloy frame, and cleaning and drying; then totally embedding the porous titanium frame or the porous titanium alloy frame in ultrafine tantalum powder in metal canning, vacuum sealing and diffusion sintering in low temperature; lastly taking out the frame, removing the powder and obtaining the medical porous titanium or titanium alloy materials coated with the tantalum coatings on surfaces. The preparation method of the medical porous titaniumor titanium alloy materials coated with the tantalum coatings on surfaces has the advantages that through embedding in powder and diffusion sintering in low temperature, tantalum coats the surfaces of the porous titanium frame or the porous titanium alloy frame, and metallurgical bonding is formed, thereby greatly enhancing the bonding force between tantalum and the surface of the porous titaniumframe or the porous titanium alloy frame, solving the difficulty of poor bonding force between the tantalum coatings and matrix, and overcoming the disadvantages of high cost and complicated processof the prior preparation method.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

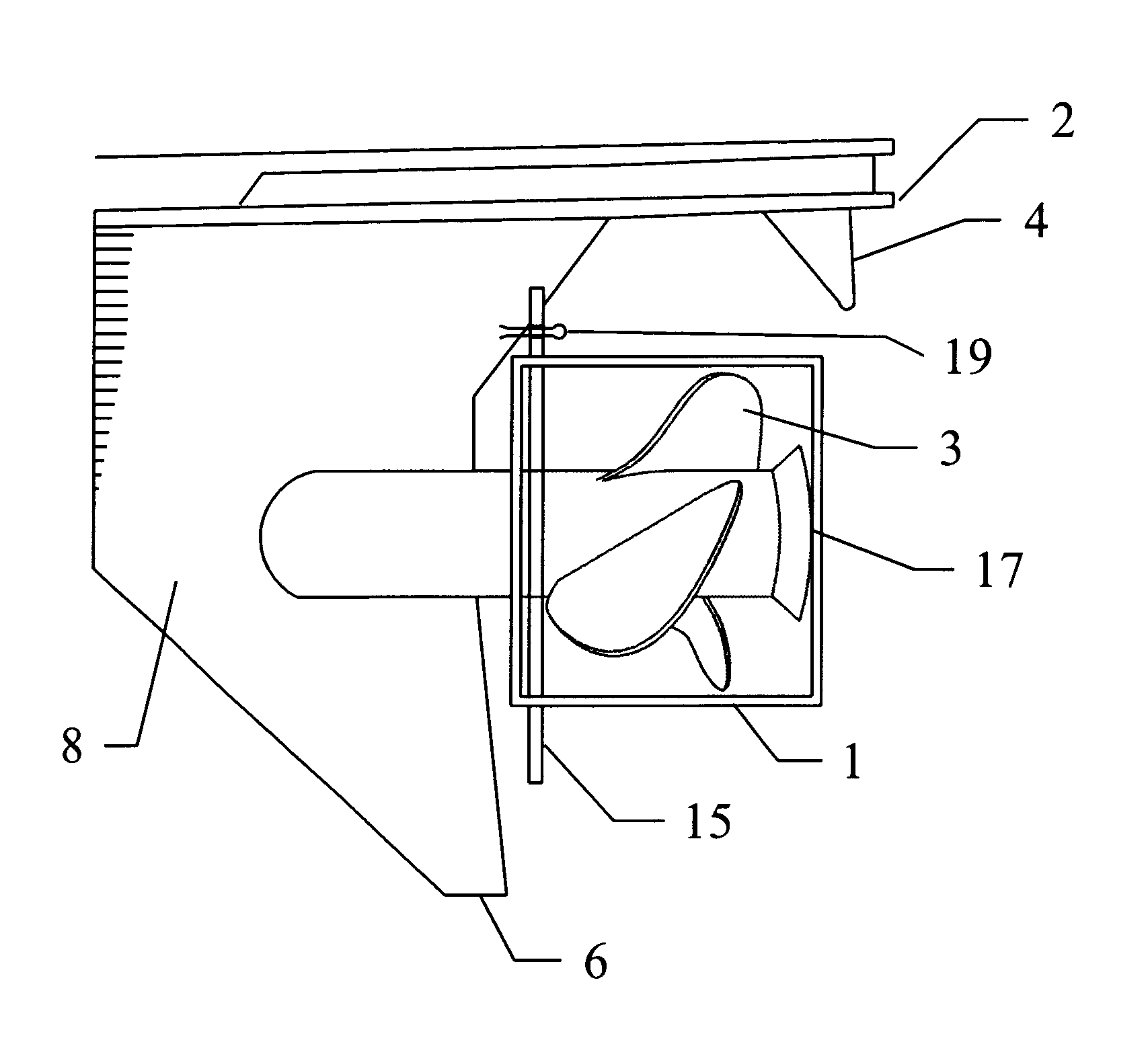

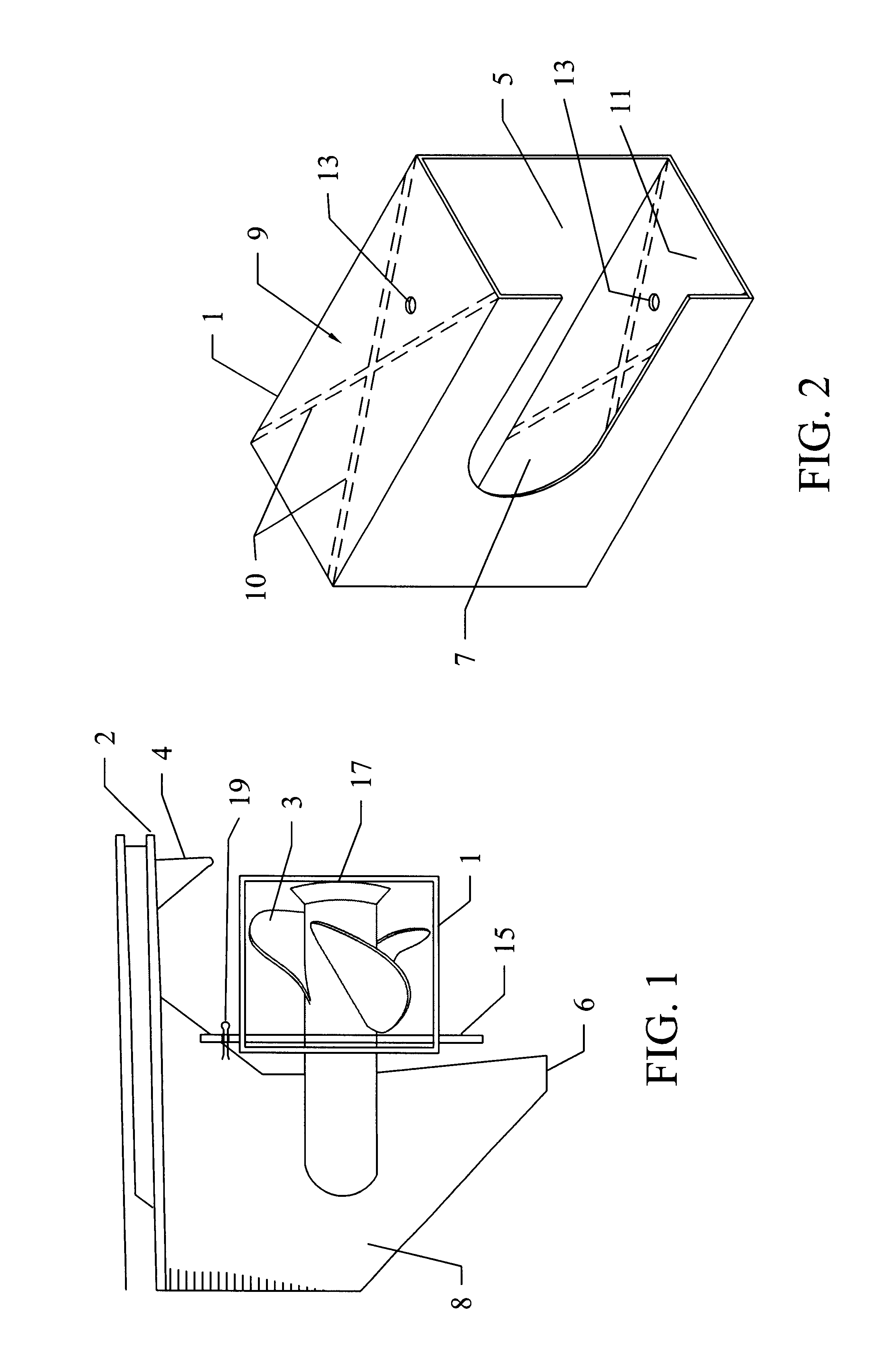

Propeller protector slipper

InactiveUS6609938B1Ensure coveragePromote recoveryFlexible coversWrappersPropellerStructural engineering

Propeller protector slipper to be used on inboard and outboard motors of boats that are anchored, drifting, aground, docked, in storage, or out of water in transit. The propeller protector slipper ensures protection for the propeller from elements that cause pitting and damage to the propeller as well as minimizing propeller related injuries. The protector propeller slipper also provides a gage for projecting the distance of the propeller of a trailored boat from a following vehicle.

Owner:PITHER ALLAN WALTER

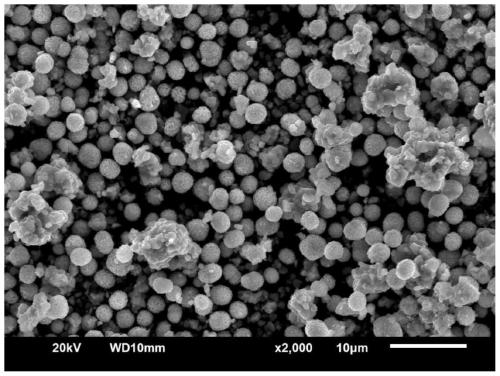

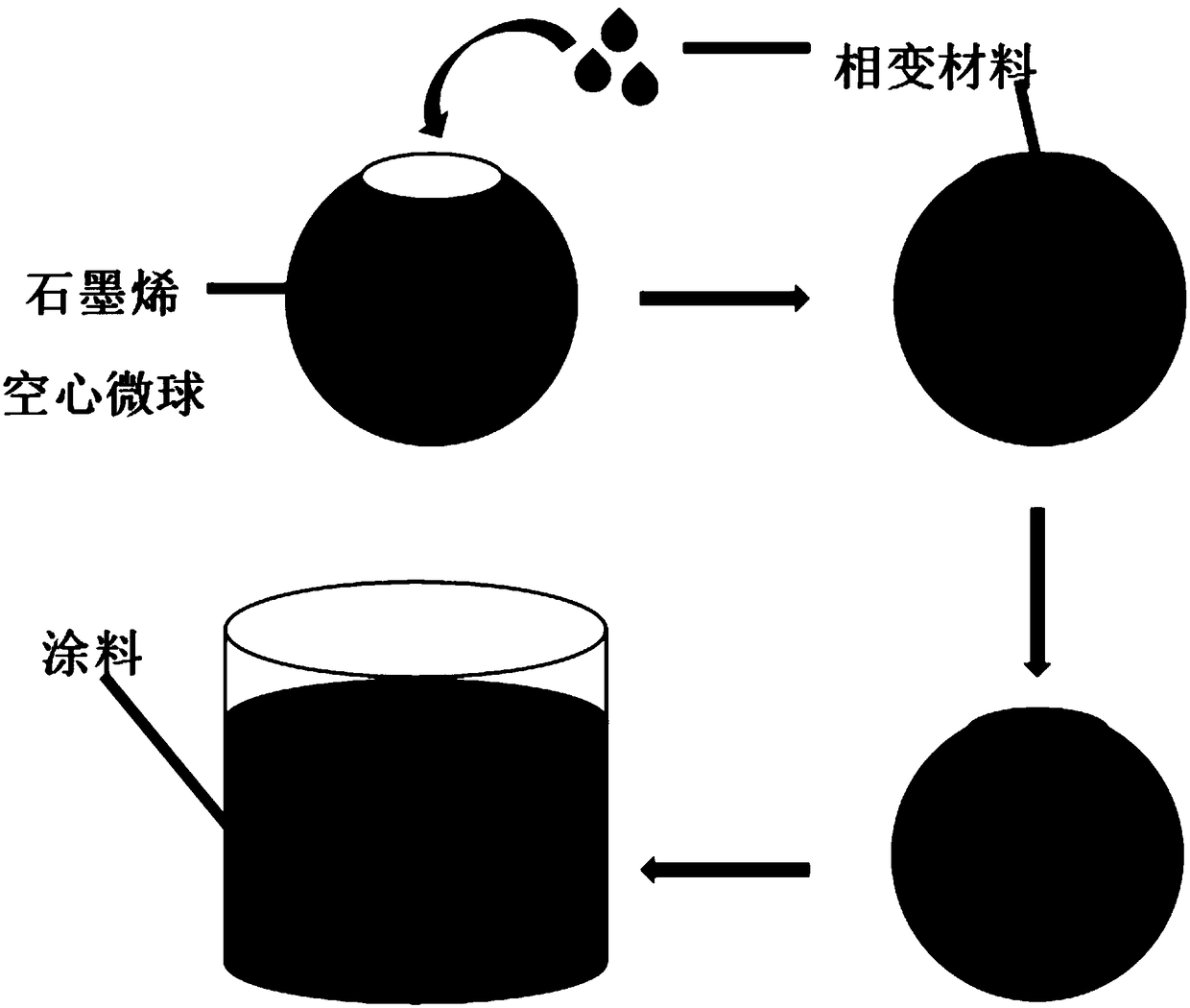

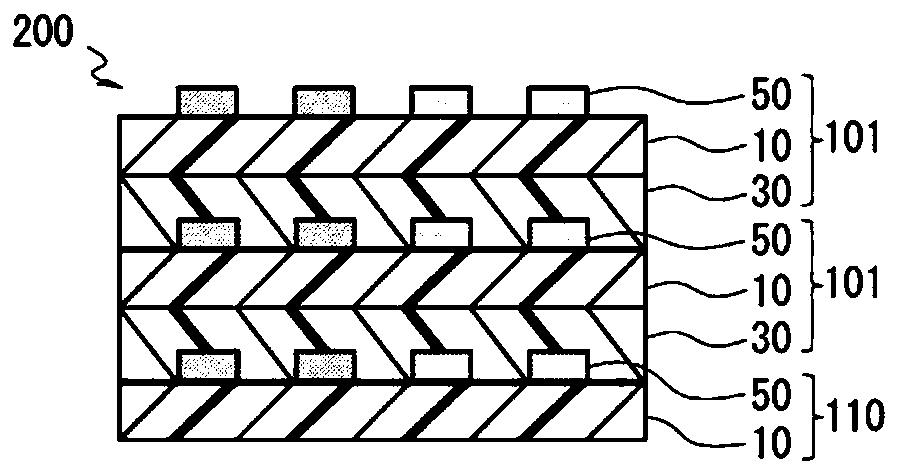

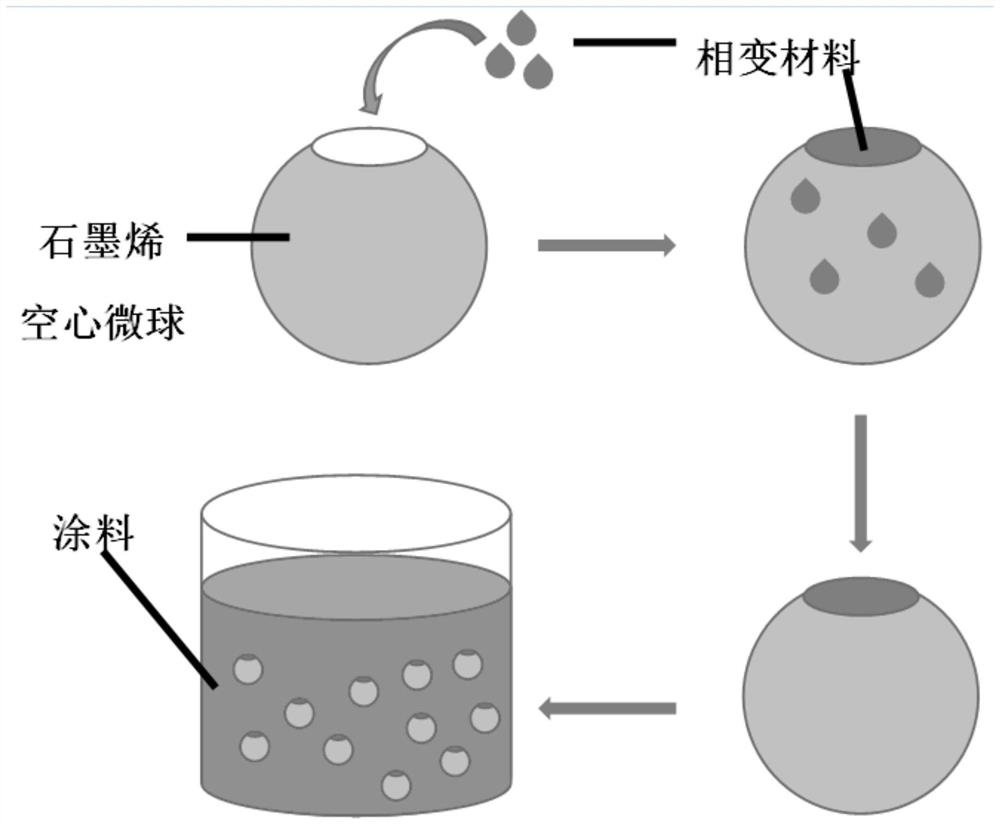

Phase-change temperature regulation coating and preparation method thereof

ActiveCN108948886AEnsure coverageImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesMicrosphereFar infrared

The invention discloses phase-change temperature regulation coating and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out atomization drying andthermal expansion treatment on a graphene oxide water solution to obtain a graphene microsphere with a mesoporous structure; and then fusing a phase-change material and sufficiently penetrating the phase change material into a cavity of the graphene microsphere, so as to obtain a phase-change microsphere with a core-shell structure. According to the phase-change temperature regulation coating, surplus phase-change material on the surface of the phase-change microsphere is removed through a filter pressing method, and the phase-change temperature regulation coating is obtained through adoptinga mechanical mixing method and uniformly mixing all components of the coating. The hollow graphene microsphere is used for covering the phase-change material so that leakage of the phase-change material in a utilization process is extremely reduced and the service life can be remarkably prolonged. The heat exchange between the environment and a coating layer can be effectively promoted through high heat conductivity of graphene and the heat of the coating layer can be stored and released. Furthermore, the graphene has high conductivity and antibacterial and far infrared emission properties, and the coating can obtain various new functions.

Owner:HANGZHOU GAOXI TECH CO LTD +1

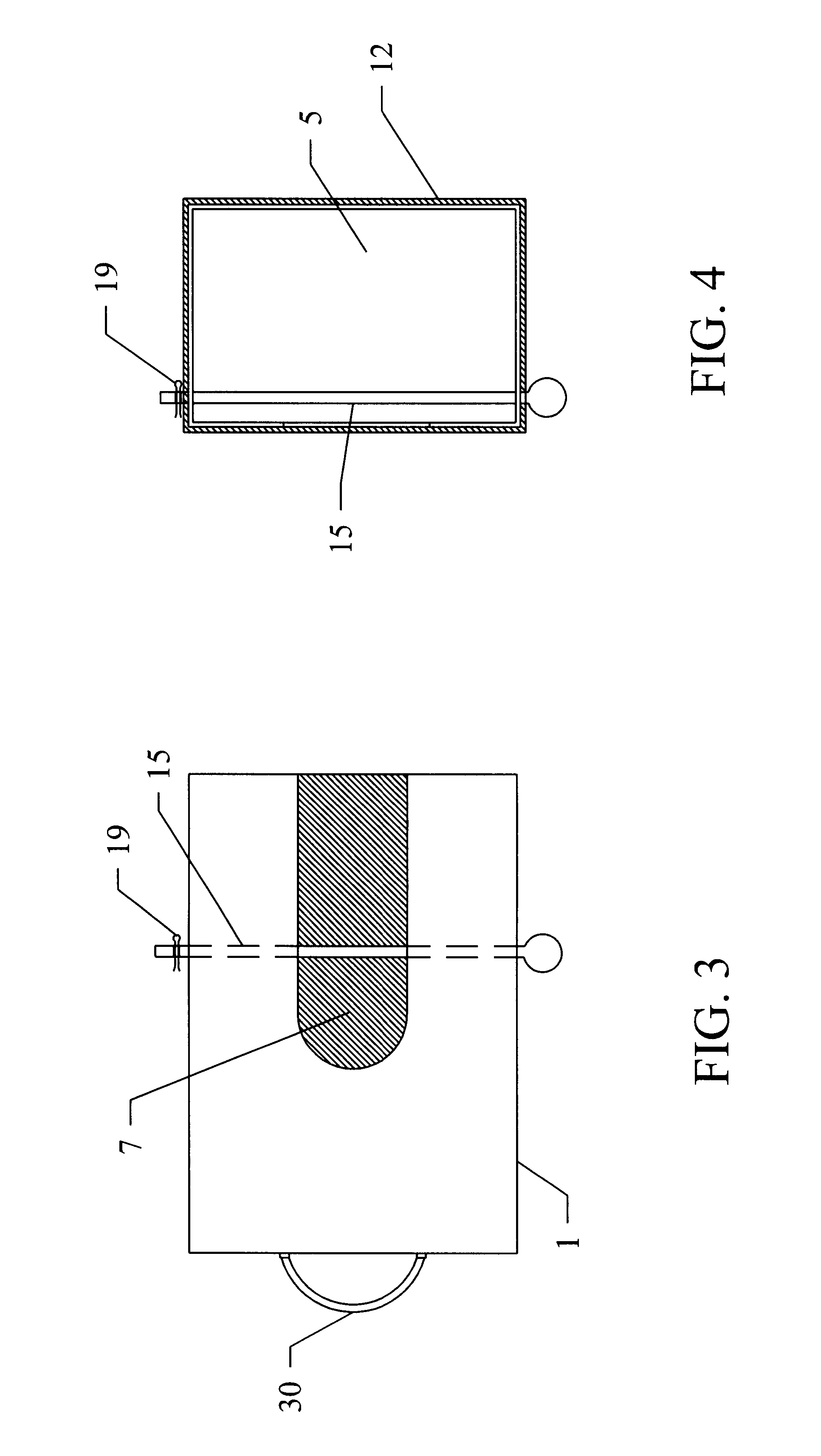

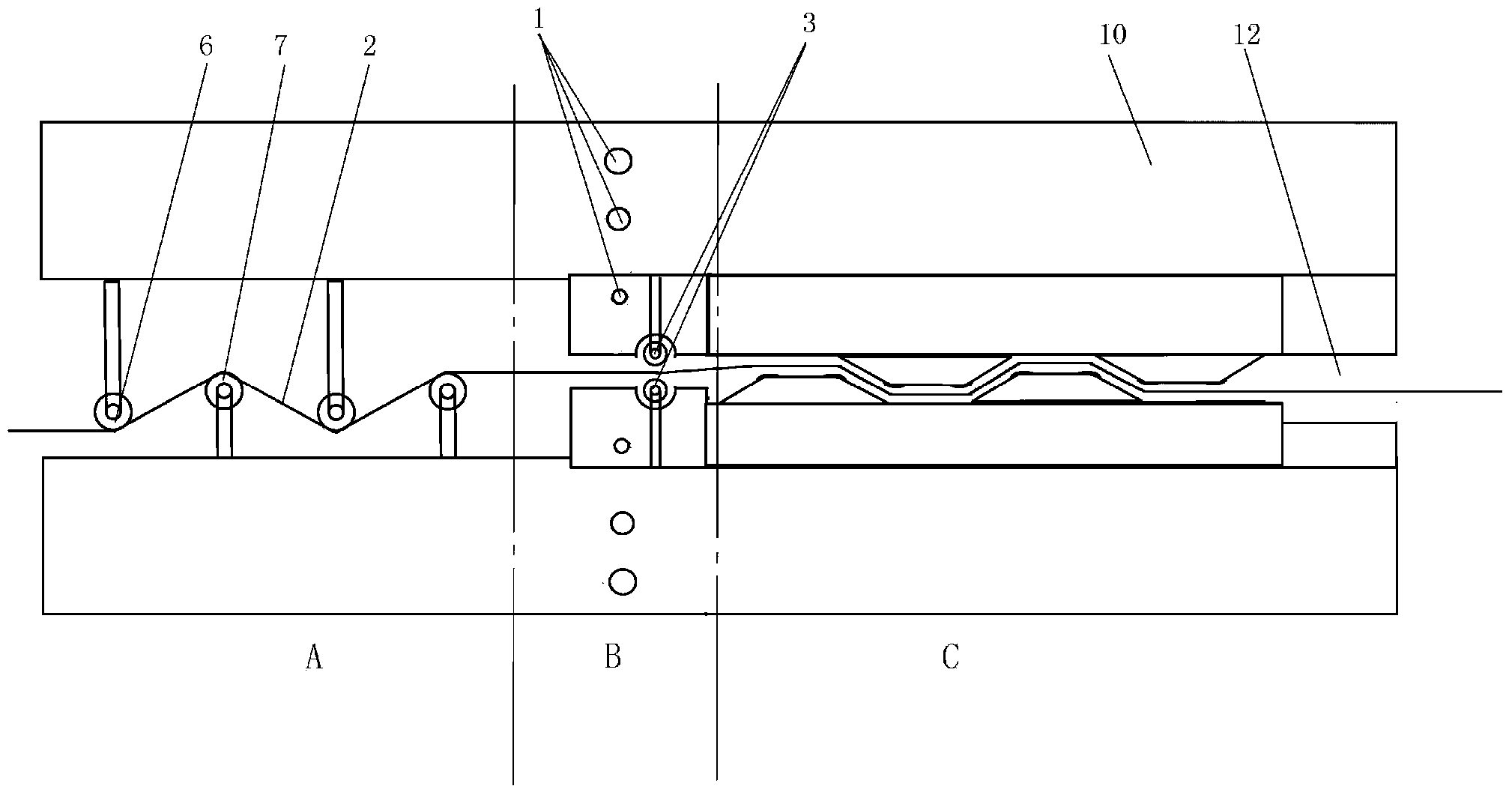

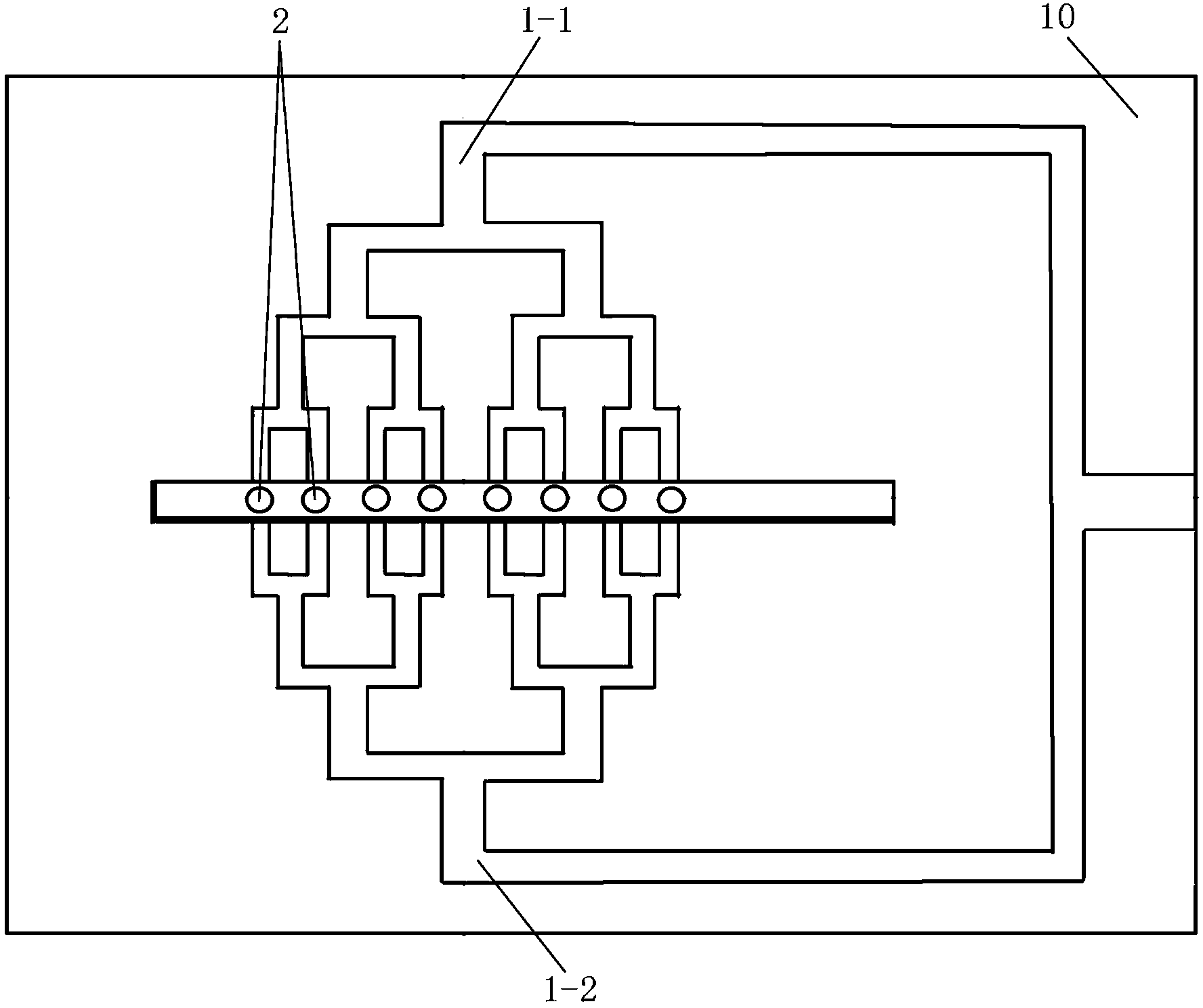

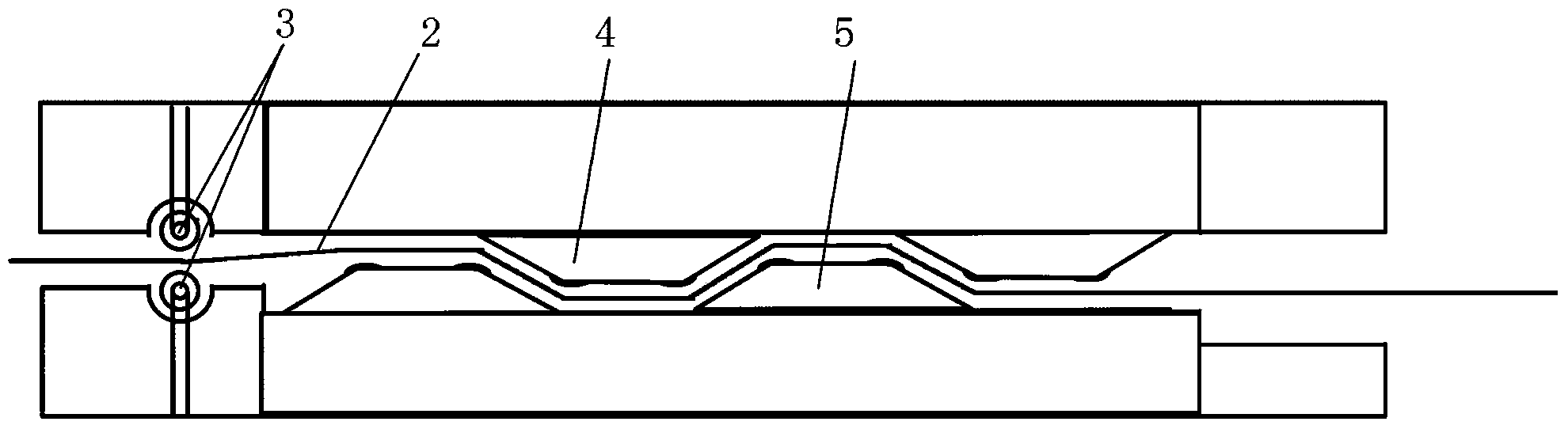

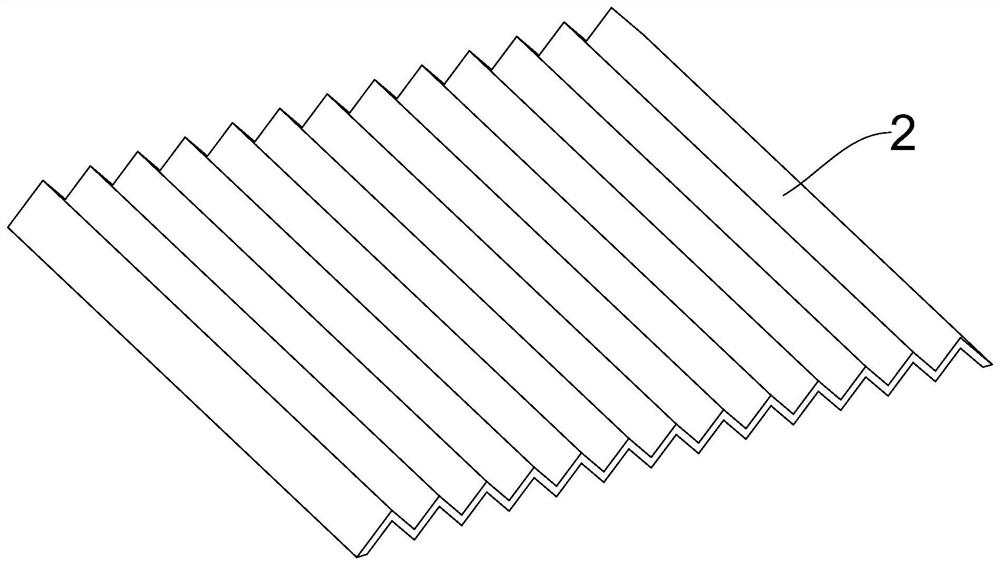

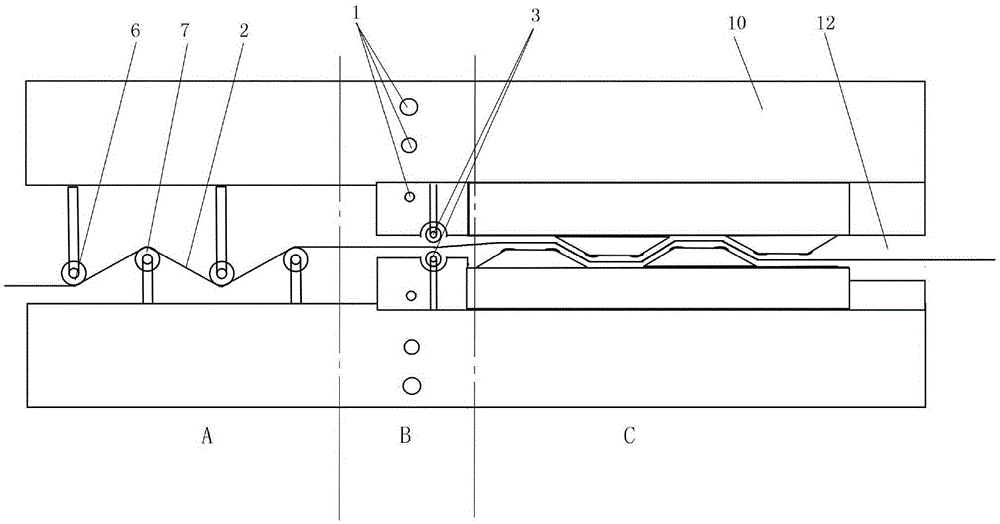

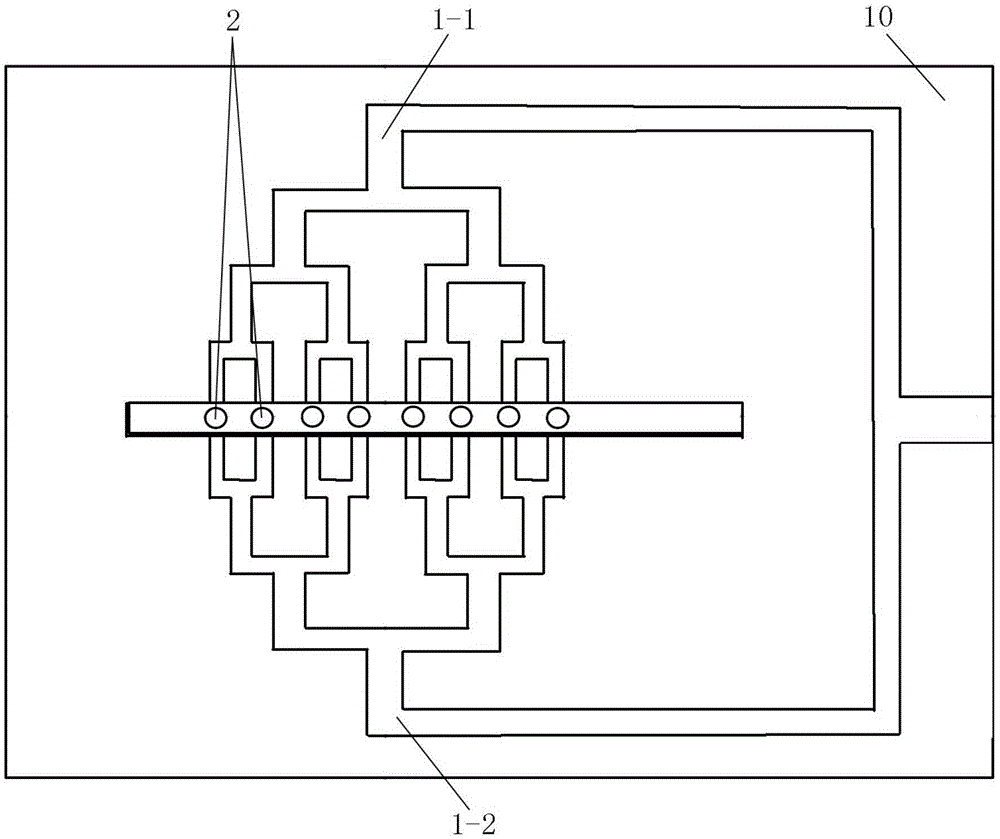

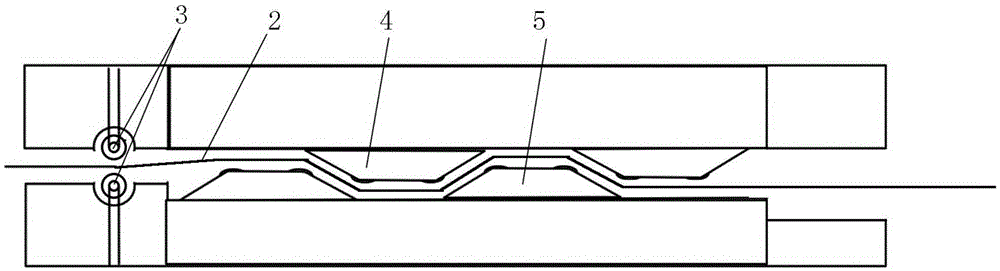

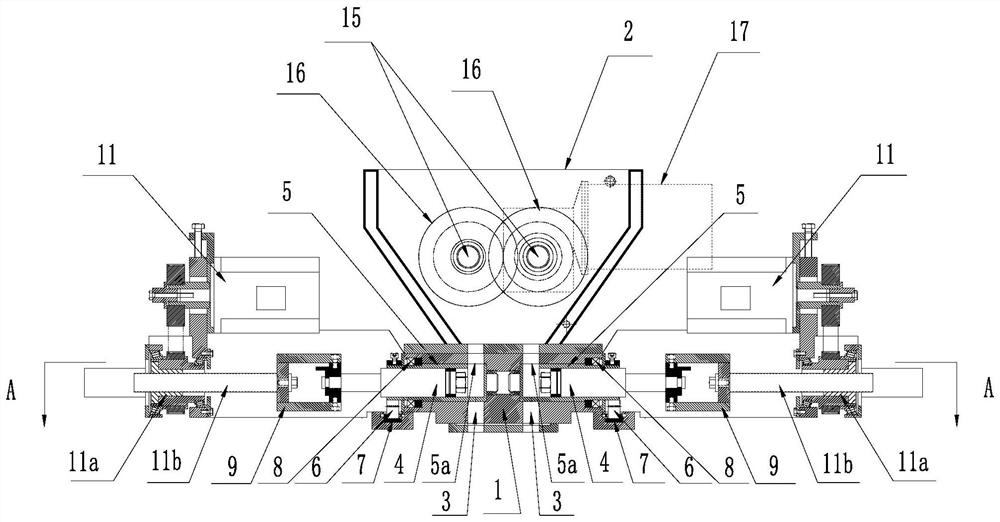

Double-sided melting and impregnating equipment and method for continuous fiber-reinforcing adhesive tape

The invention discloses double-sided melting and impregnating equipment and a method for a continuous fiber-reinforcing adhesive tape. According to the equipment, a fiber pre-dispersion zone, a resin impregnation fiber zone and a fiber re-dispersion zone are arranged in a melting and impregnating equipment head; a pre-dispersion device is arranged in the pre-dispersion zone, and a double-sided distribution runner for distributing a resin melt is arranged in the resin impregnation fiber zone; in the fiber re-dispersion zone, a fiber channel is wavy, and re-dispersion devices are arranged on the upper side and the lower side of the fiber channel; an outlet at the tail end of the fiber channel is rectangular. The method comprises the following steps: firstly predispersing and preheating continuous long fibers, then entirely coating and impregnating through a double-sided distribution runner, and delivering out of the fiber channel after performing fiber redispersion treatment. According to the double-sided melting and impregnating equipment and the method, the impregnation effect of the resin melt to the continuous fiber in the adhesive tape can be balanced, the purposes of entire coating, permeation and impregnation can be achieved, the phenomenon that single-sided coating of the fibers is not tight can be avoided, long-time continuous stable production can be realized, and the output and quality of products can be both increased greatly.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

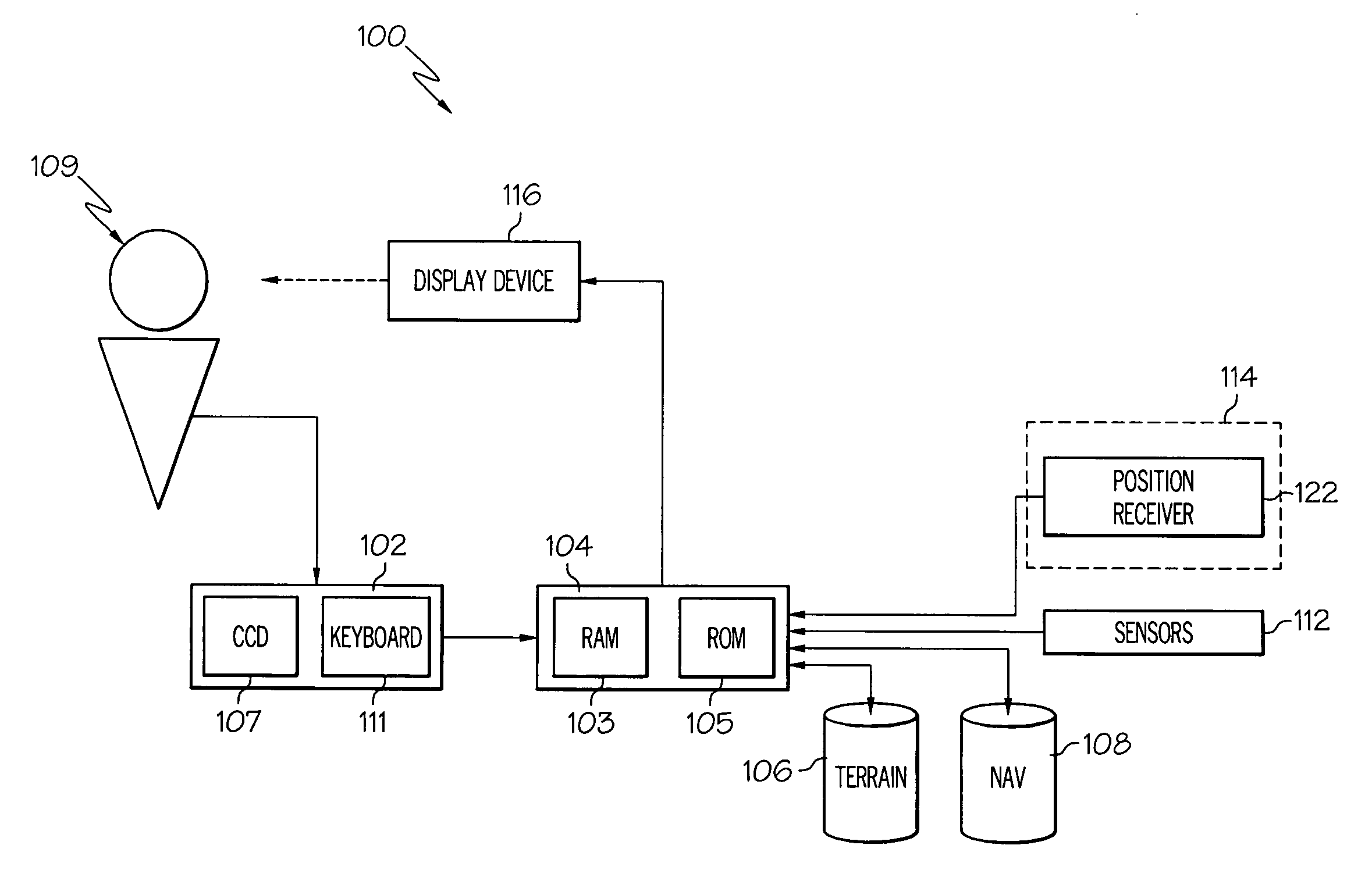

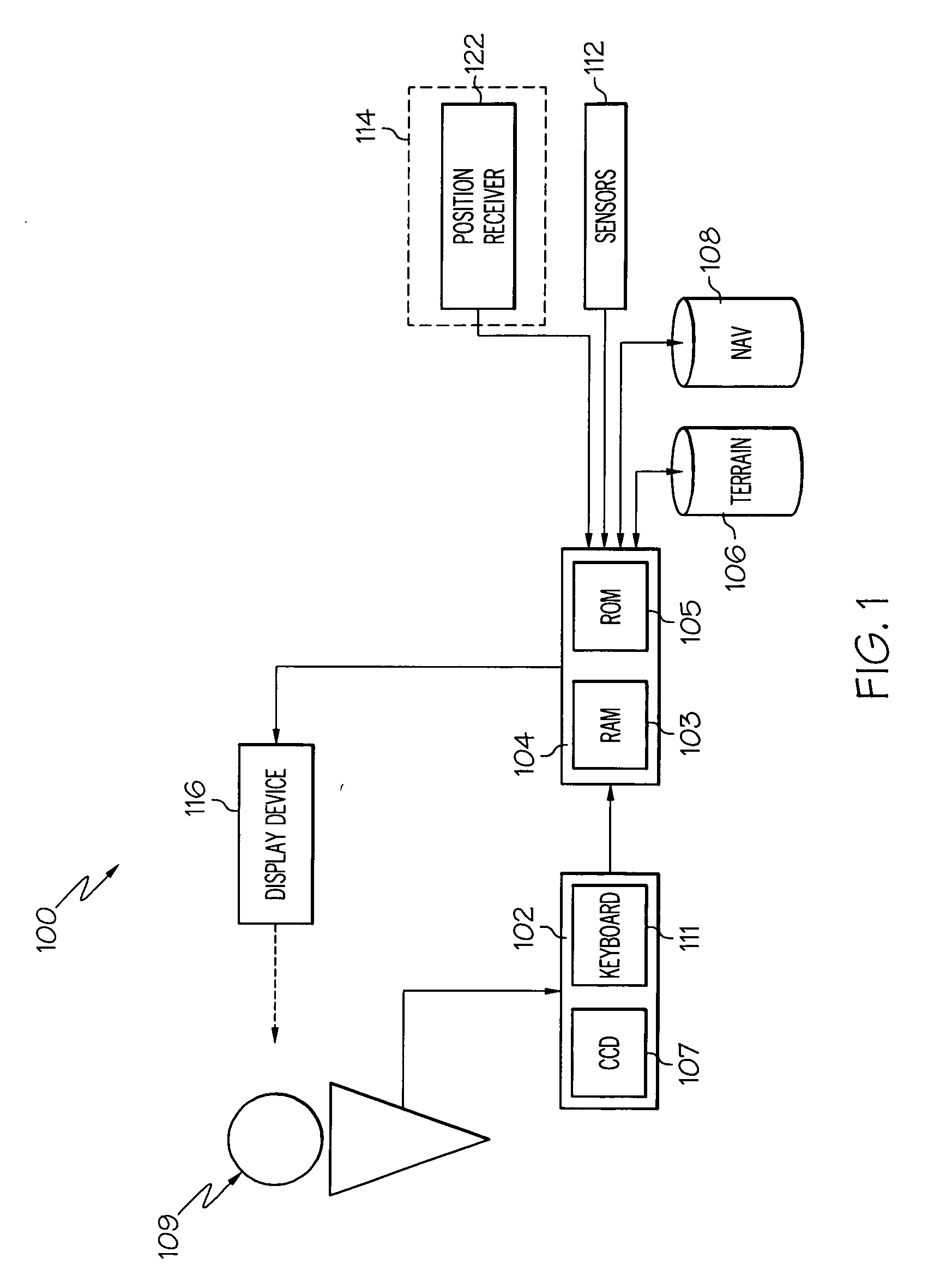

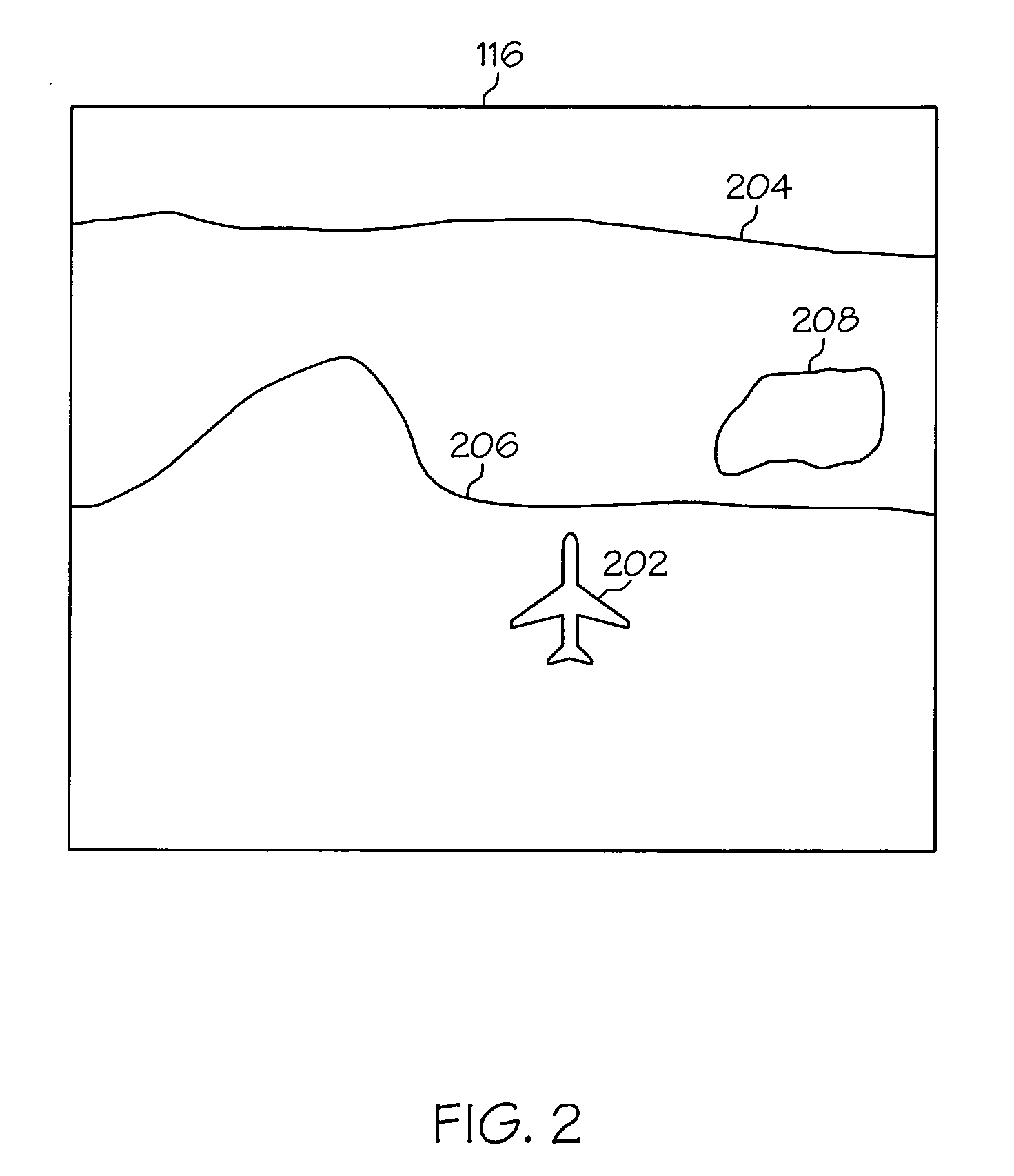

Method for providing search area coverage information

InactiveUS20090327273A1Ensure coverageDetection of traffic movementPhotogrammetry/videogrammetryVisibilityData mining

A method for displaying search area coverage is provided. A searched area (414) is recorded by a moving entity (202, 302), the search area (420) having a width defined by the position of the search entity (202, 302) as it progresses through a search area (420). The search area (420) and the searched area (414) are then displayed on a display (116), thereby illustrating the search area remaining to be searched. Optionally, the width of the searched area (414) may be adjusted in accordance the altitude, speed, or visibility of the search entity (202, 302), and a pattern may be suggested for the search entity (202, 302) to ensure coverage of the search area (420).

Owner:HONEYWELL INT INC

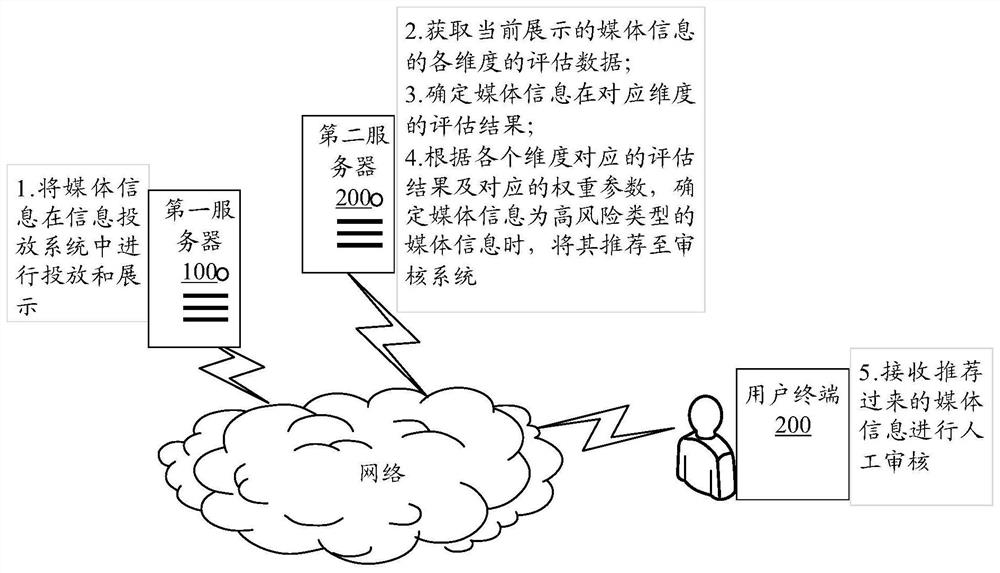

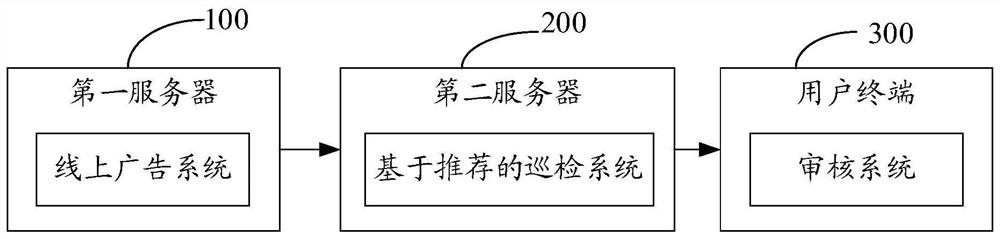

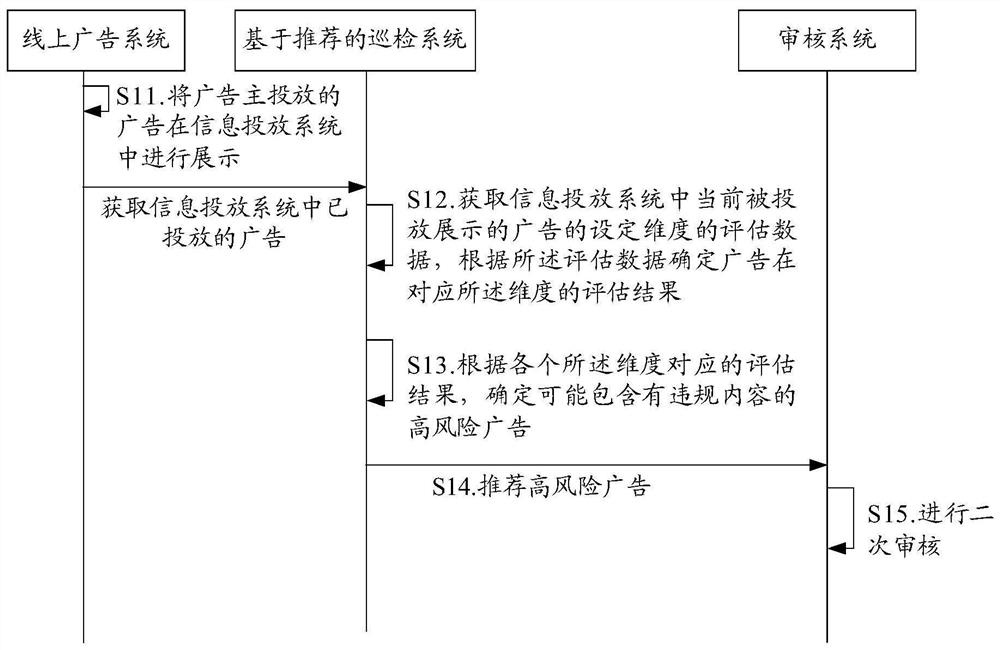

Information inspection method, computer equipment and storage medium

PendingCN111966915AFully determinedSure objectiveDigital data information retrievalSpecial data processing applicationsEvaluation resultSoftware engineering

The embodiment of the invention provides an information inspection method, computer equipment and a storage medium, and the method comprises the steps: obtaining evaluation data of at least one dimension of put media information from an information putting system in real time, and determining an evaluation result, corresponding to the at least one dimension, of the media information according to the evaluation data; determining a risk type of the media information in combination with an evaluation result corresponding to each dimension; and when the media information is the set risk type, triggering the information delivery system to stop delivering the media information. In this way, the media information possibly containing violation content inside can be efficiently and accurately screened out according to the set dimension, and the auditing efficiency and auditing quality are improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

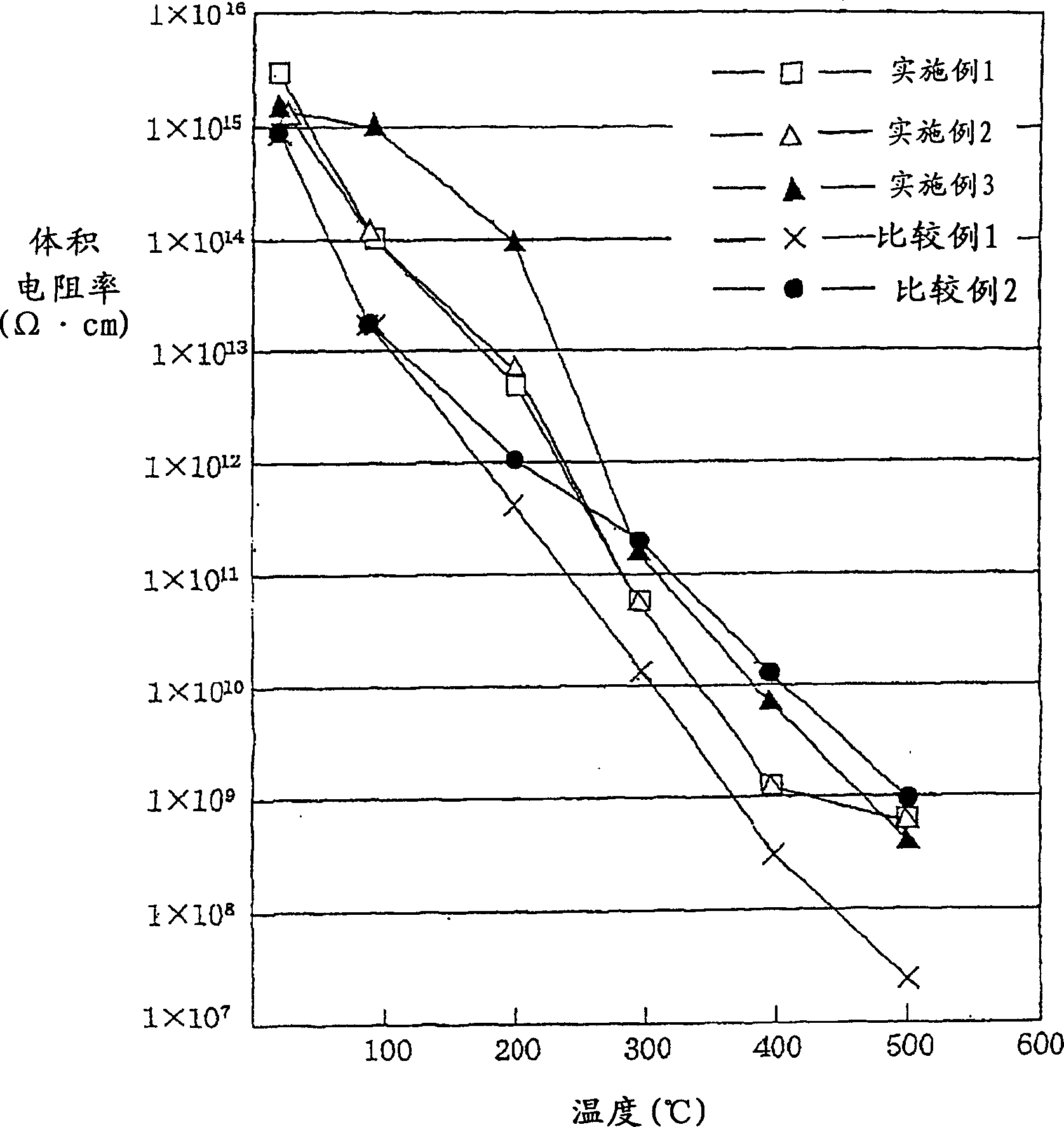

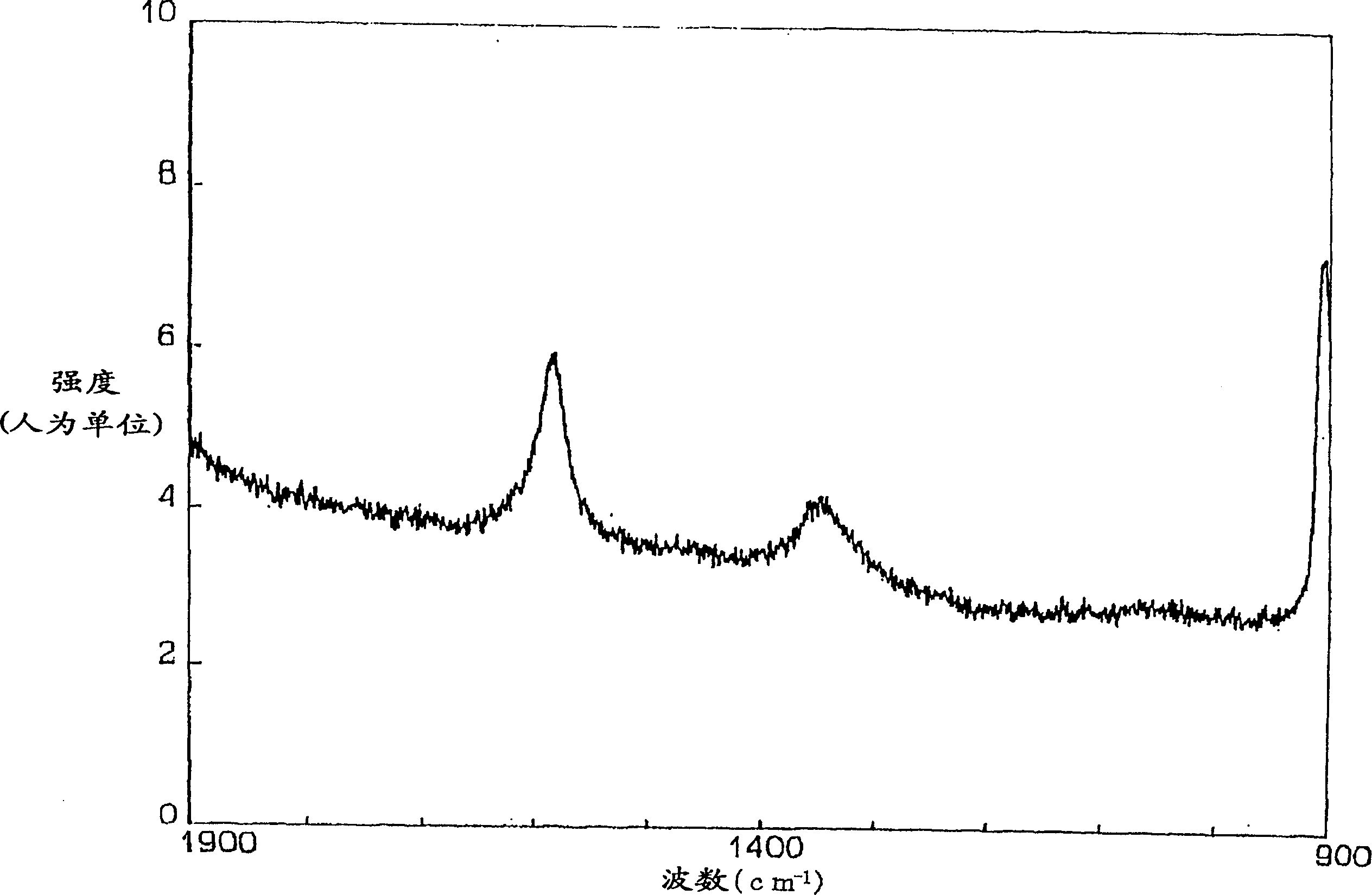

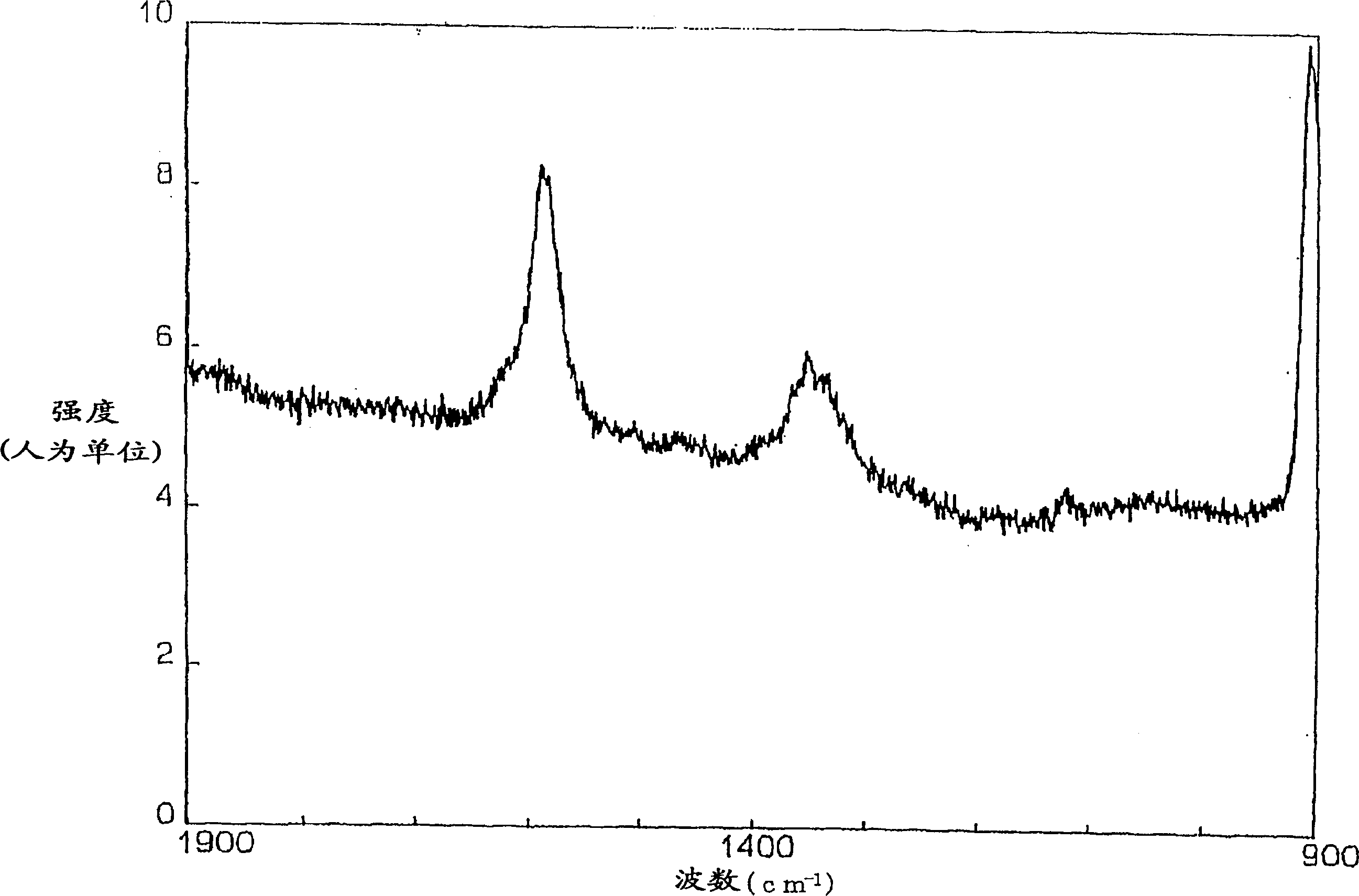

Carbon-containing alumium nitride sintered compact, and ceramic substrate for use in apparatus for manufacturing and inspecting semiconductor

A carbon-containing aluminum nitride sintered compact comprising an aluminum nitride matrix and, incorporated therein, a carbon which has peaks appearing in the vicinity of 1580 cm<-1> and 1355 cm<-1> as measured by the laser Raman spectrometry. The carbon-containing aluminum nitride sintered compact does not suffer from a short circuit due to its satisfactorily high volume resistivity of at least 1 x 10<8> OMEGA - cm in a high temperature region of 200 DEG C or higher (for example, 500 DEG C or so), is excellent in hiding properties, is increased with respect to radiant heat and can secure high accuracy in the measurement by a surface thermometer.

Owner:IBIDEN CO LTD

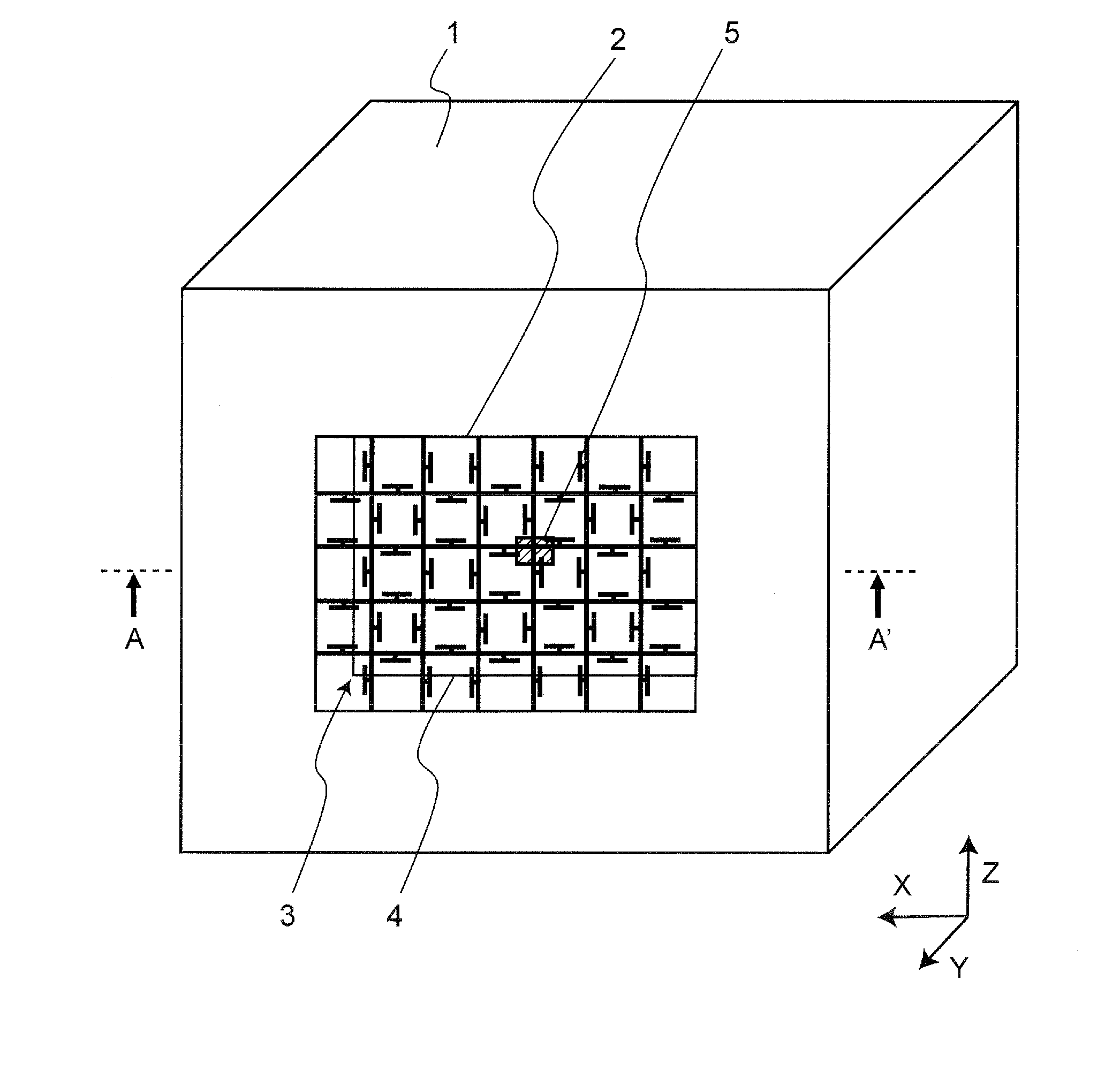

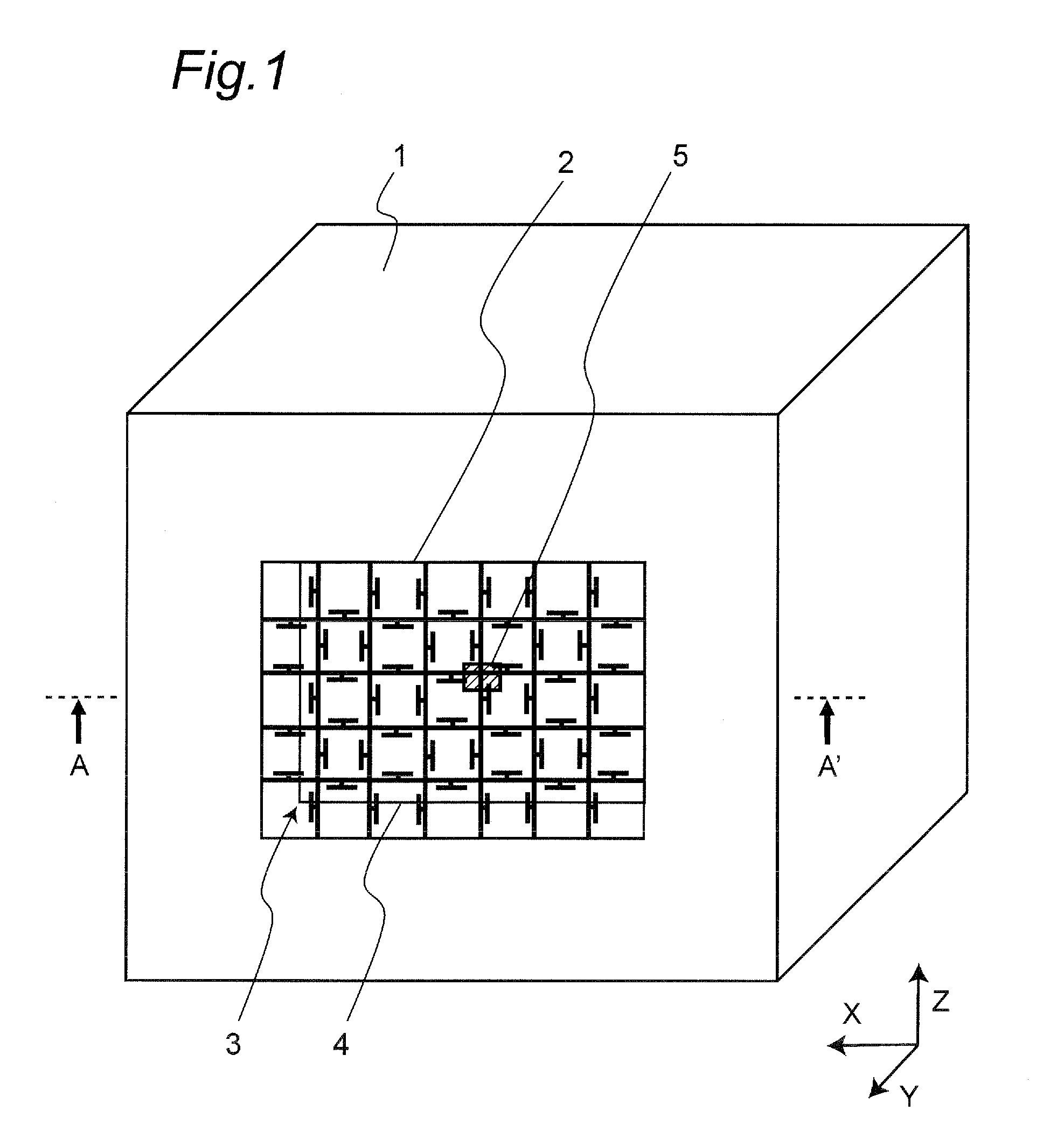

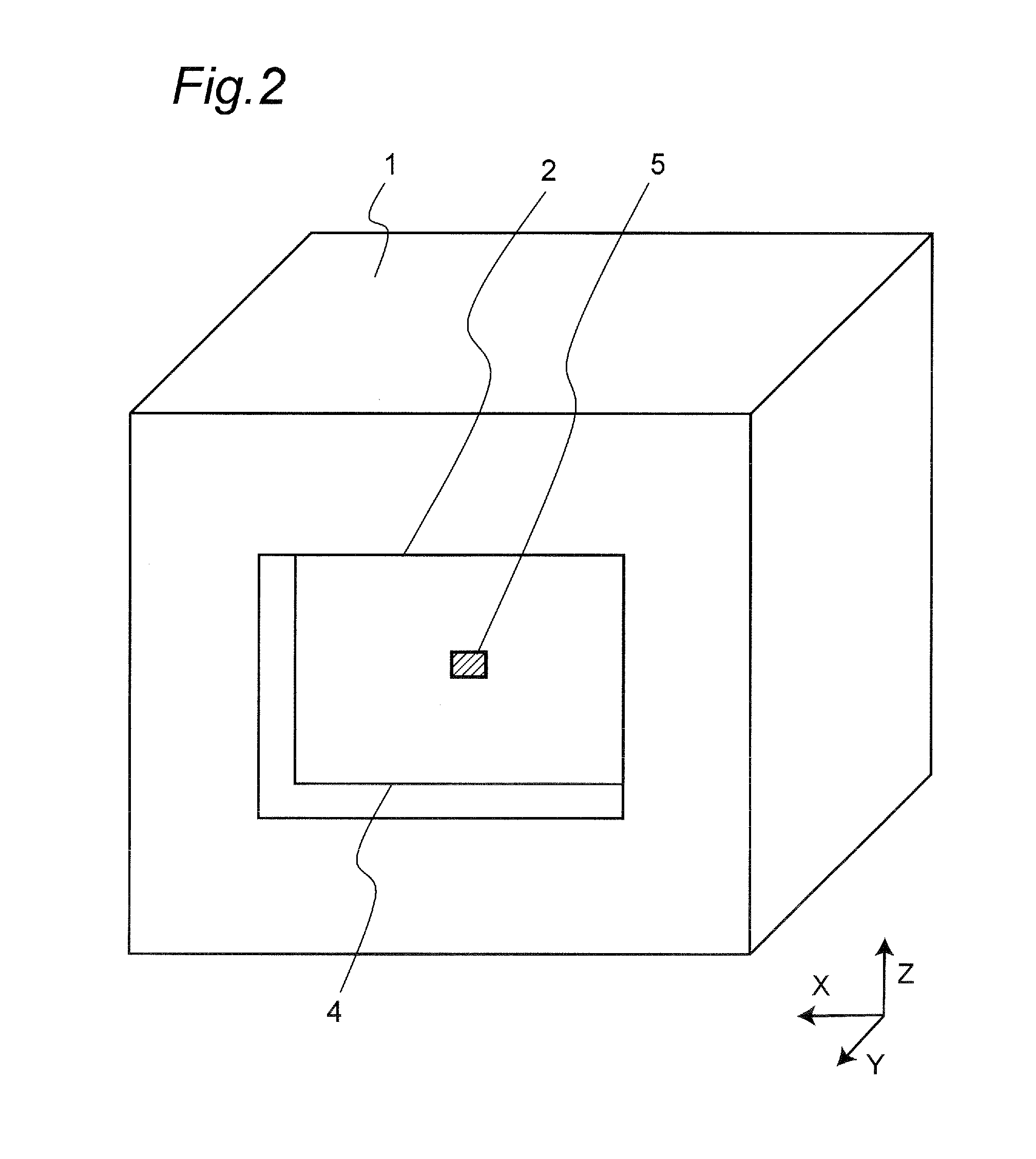

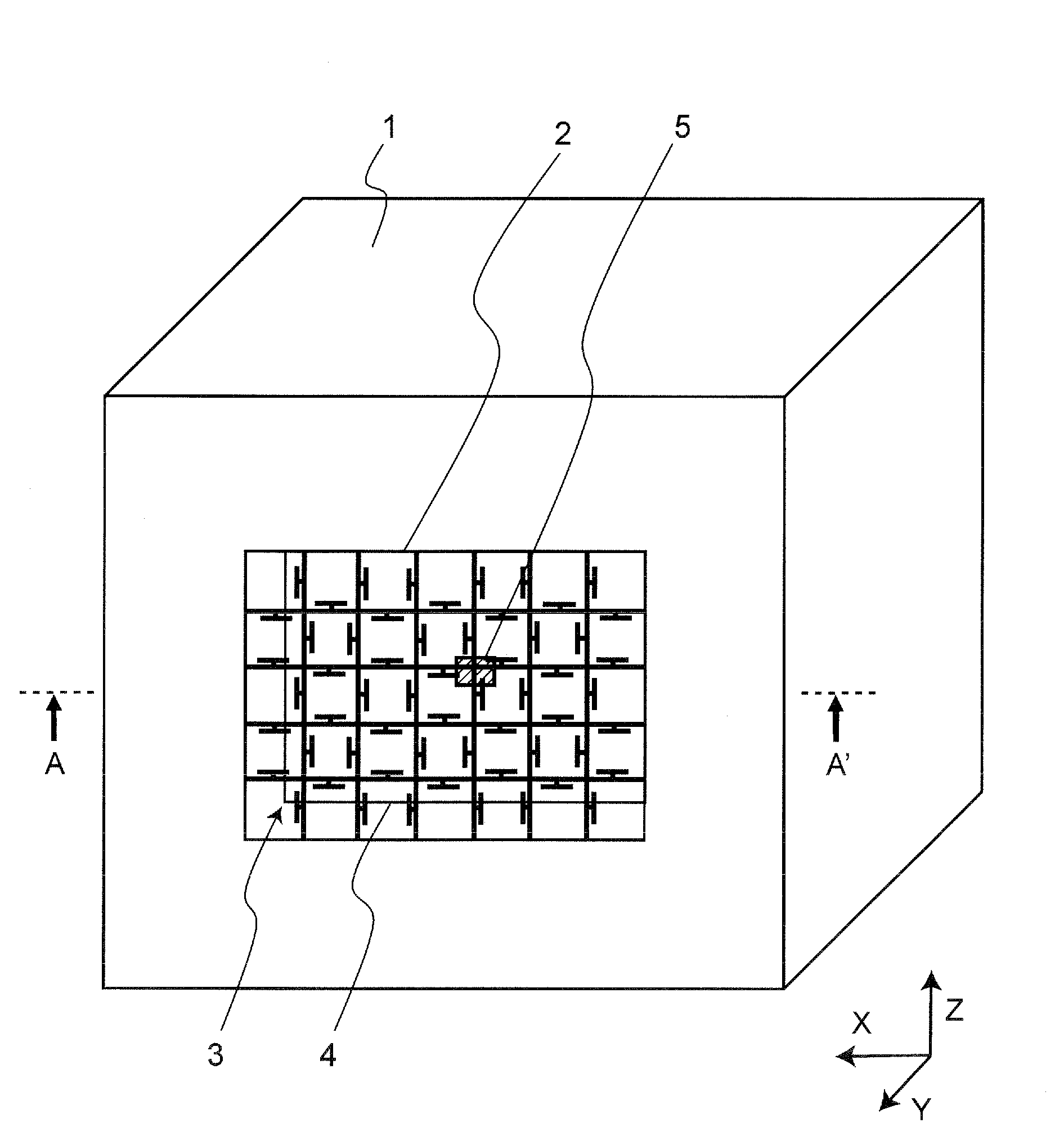

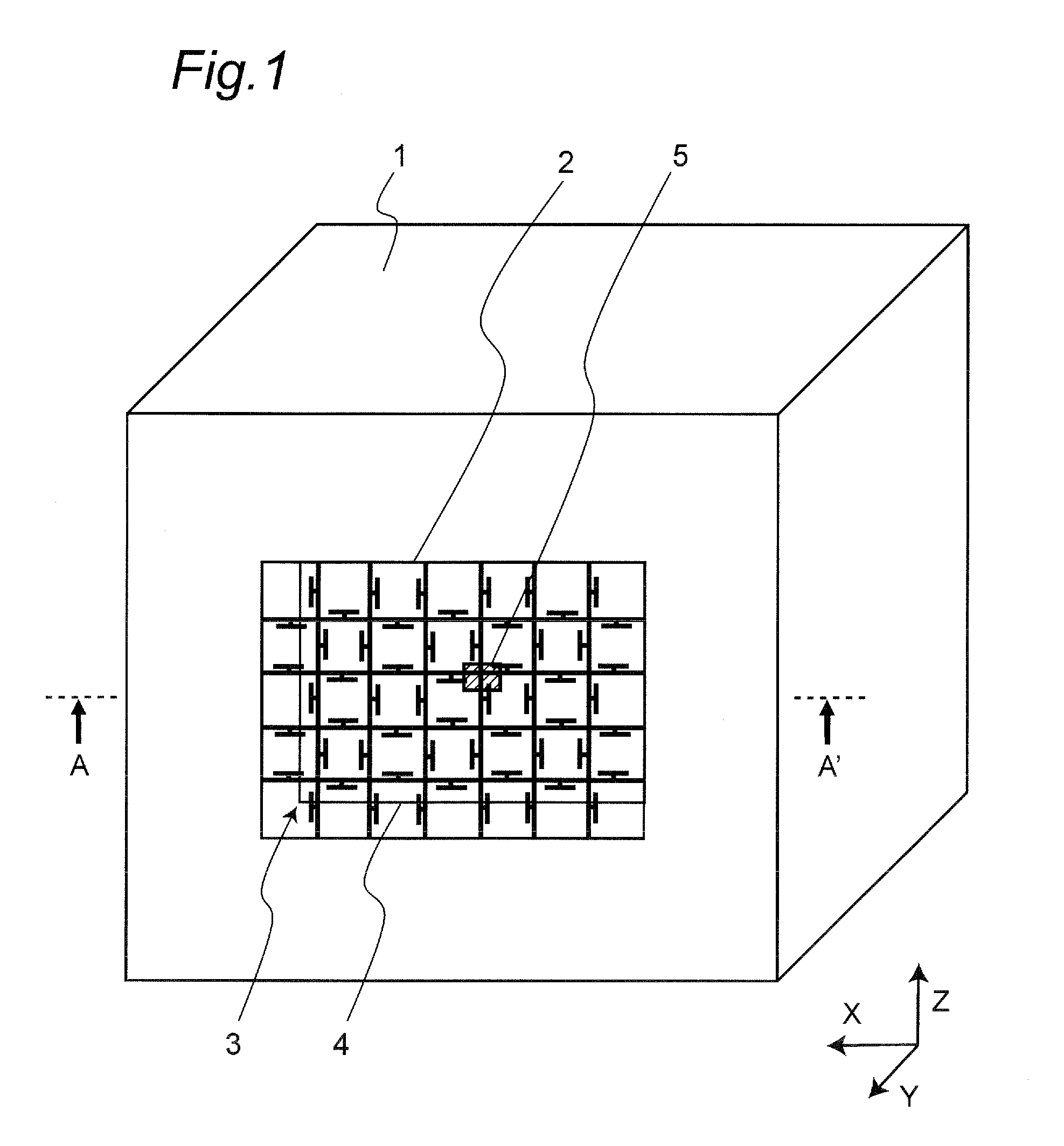

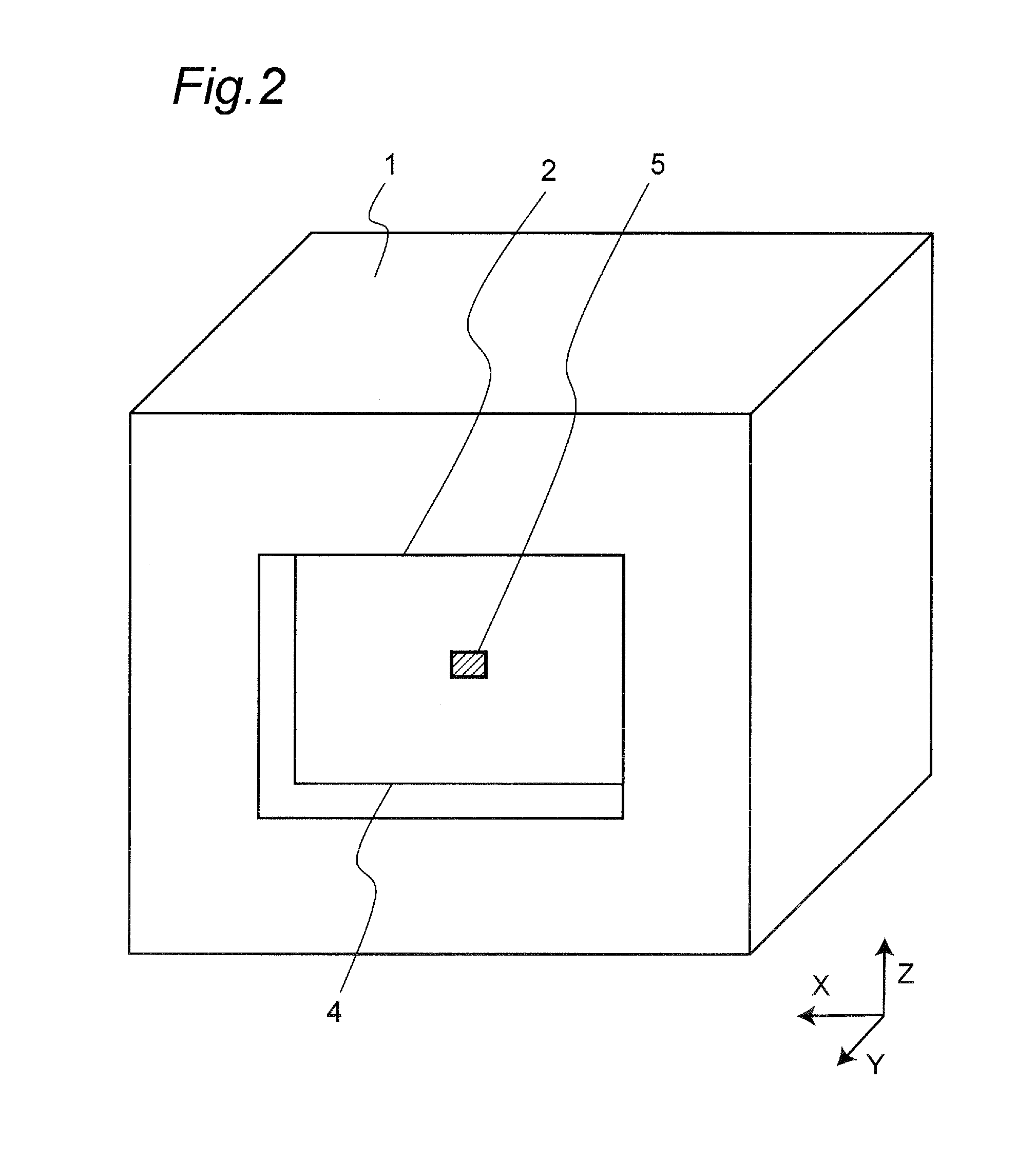

Electromagnetic wave filter apparatus without degrading radiation pattern of antenna

ActiveUS20100328186A1Prevent degradationEnsuring area coverageSimultaneous aerial operationsMagnetic/electric field screeningElectrical conductorAntenna radiation patterns

An electromagnetic wave filter apparatus includes: a shield conductor; a shield aperture provided in the shield conductor; a plurality of strip conductors, each of which is connected to the shield conductor at both ends thereof, and which divide the shield conductor into a plurality of apertures; and a plurality of stub conductors provided at intervals on each of the strip conductors. Each of the stub conductors prevents a current with a predetermined frequency from flowing through a corresponding strip conductor due to an electromagnetic wave with the predetermined frequency passing through the electromagnetic wave filter apparatus, and thus, the electromagnetic wave filter apparatus passes the electromagnetic wave with the predetermined frequency without exerting substantial influence on radiation of the electromagnetic wave with the predetermined frequency.

Owner:PANASONIC CORP

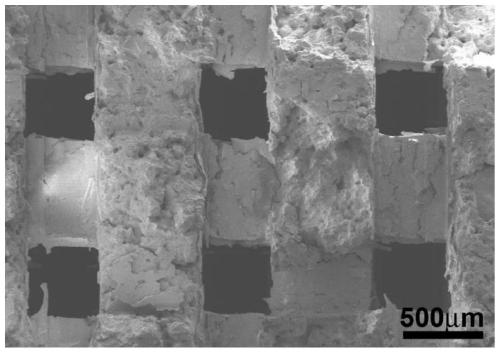

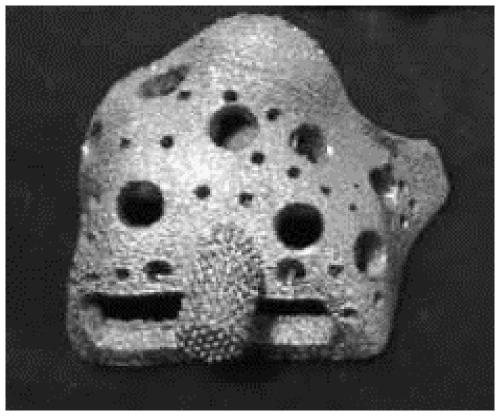

Porous calcium phosphate ceramics based on coating of calcium sulfate salt and preparation method of porous calcium phosphate ceramics

PendingCN110282998AGood osteoinductivityEasy accessTissue regenerationCeramicwareCalcium biphosphateSulfate

The invention discloses porous calcium phosphate ceramics based on coating of calcium sulfate salt. Calcium phosphate is taken as a substrate, andthe surface of the calcium phosphate is coated with the calcium sulfate salt to form a porous structure with arbitrary shapes; the hole types of holes in at least one dimension of directions are regular in the three-dimensional space directions in the porous structure, and the distances between the centers and edges of the holes are 50 to 2000 micrometers, and all the holes are interpenetrating. In addition, the invention further provides a preparation method of the porous ceramics. According to the designed porous ceramics, the quickly-degraded calcium sulfate salt is on the surface, and the slowly-degraded calcium phosphate are inside, so after the ceramics are implanted into a body, a gradient degradation processcan be formed, so that the porous ceramics are endowed with very high osteogenic activity, and the ceramics can maintain enough mechanical strength in a given period. Therefore, the designed porous ceramics have very high osteogenic activity, and the risk of rapid disintegration after implantation of the ceramics in the early and middle periods is also reduced.

Owner:陶合体科技(苏州)有限责任公司

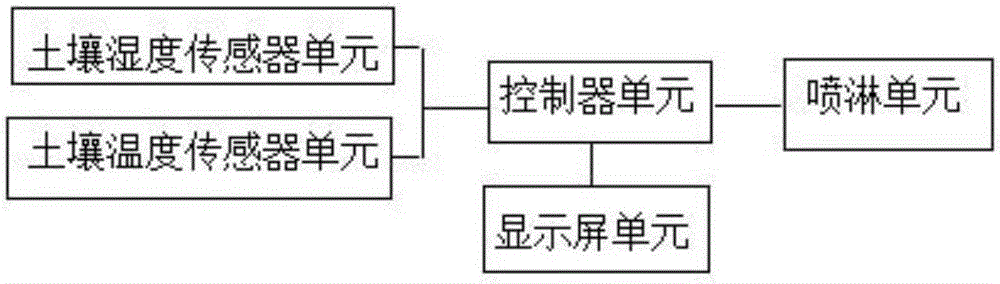

Household intelligentized automatic bonsai spraying device

InactiveCN105340699ATake advantage ofEnsure uniformitySelf-acting watering devicesPressurised distribution of liquid fertiliserEngineeringSoil temperature

The invention discloses a household intelligentized automatic bonsai spraying device. A soil humidity sensor unit and a soil temperature sensor unit are embedded in soil, the signal output end of the soil humidity sensor unit and the signal output end of the soil temperature sensor unit are connected with the signal input end of a controller unit, the signal output end of the controller unit is connected with the signal input end of a spraying unit, and the signal output end of the controller unit is connected with the signal input end of a display screen unit. The household intelligentized automatic bonsai spraying device can serve as an antecedent test body for researching a micro-irrigation technology and also can solve the problem that a family has no energy to carefully look after flowers and plants and loves the flowers but cannot keep the flowers alive when the family lives at a home.

Owner:YANCHENG INST OF IND TECH

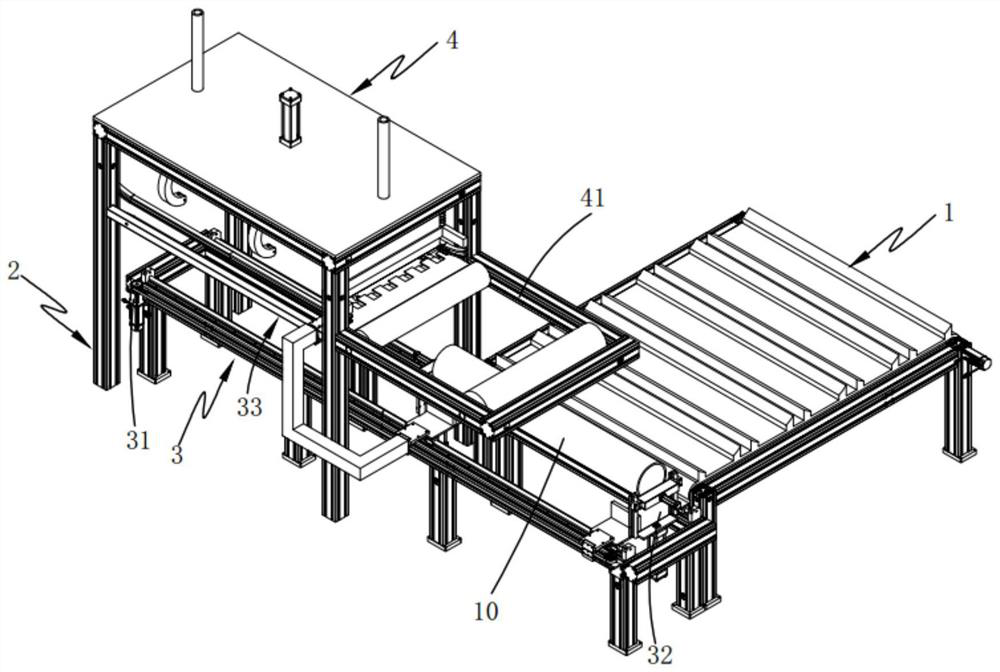

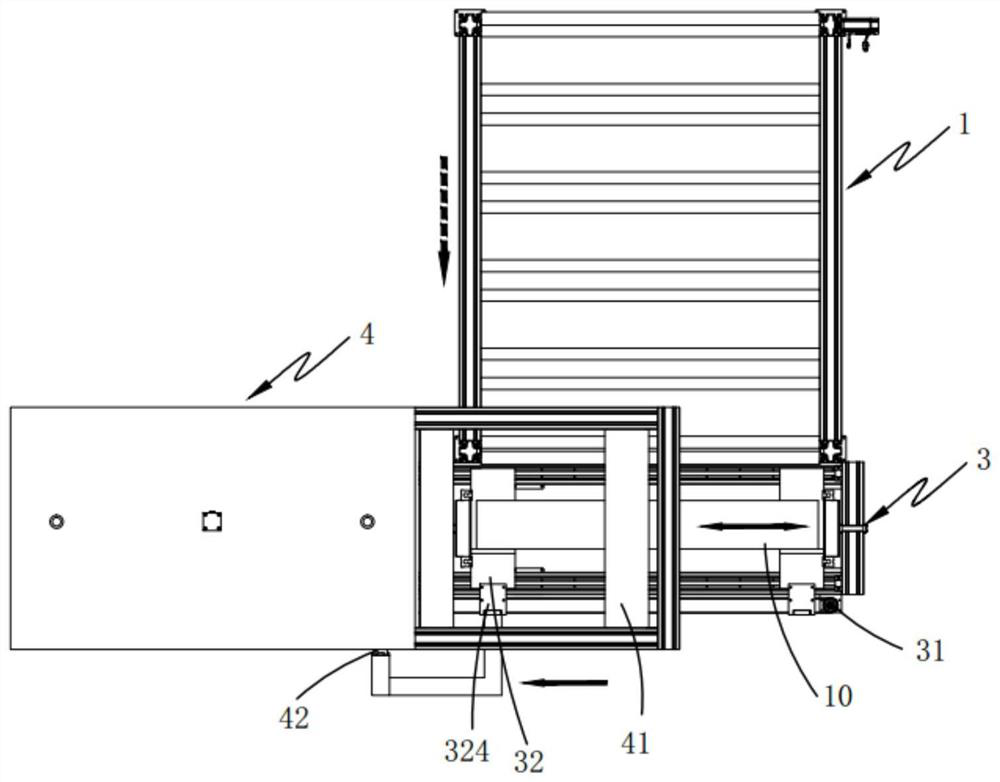

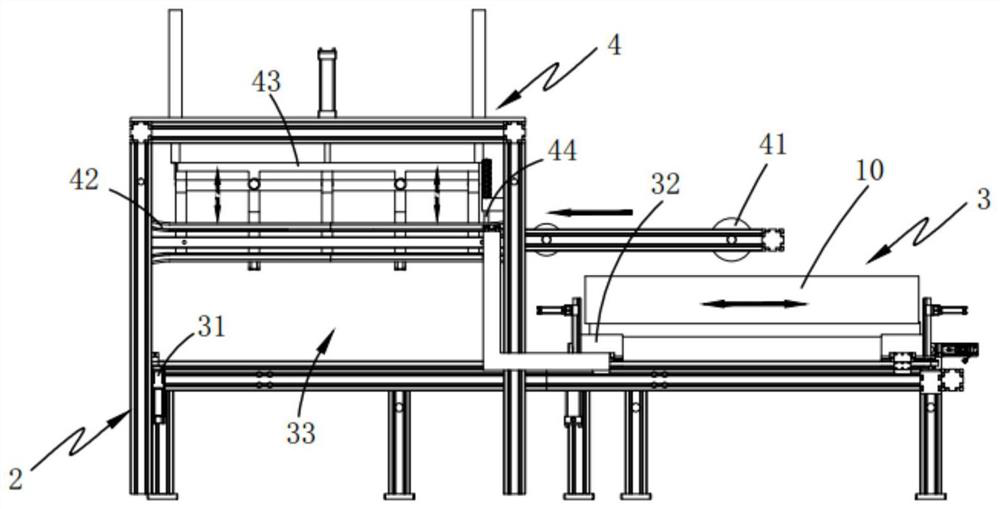

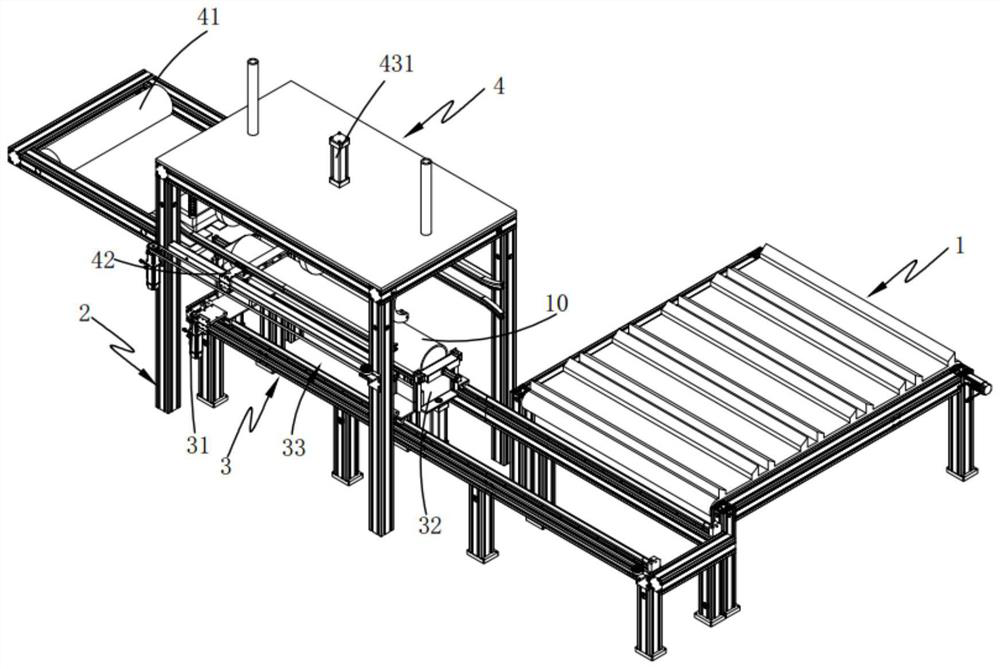

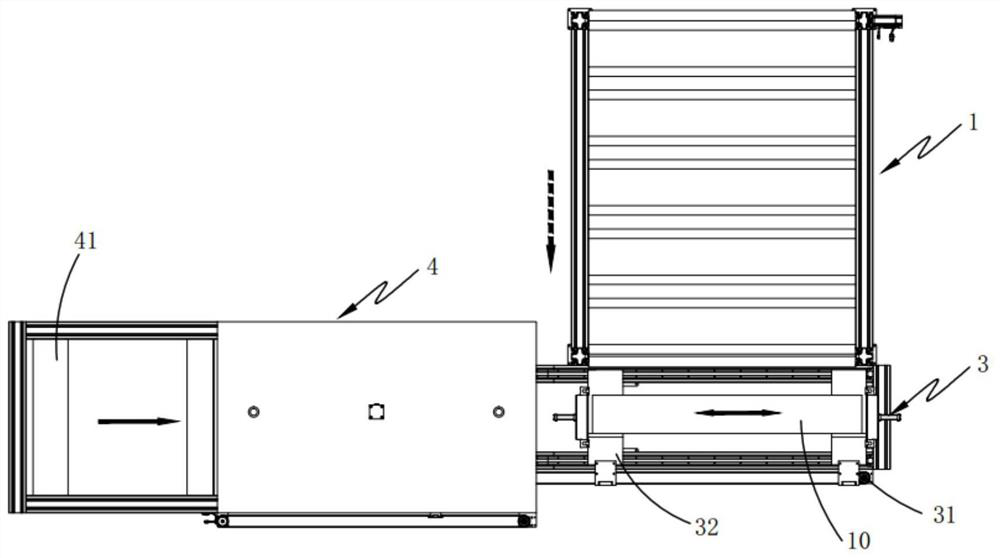

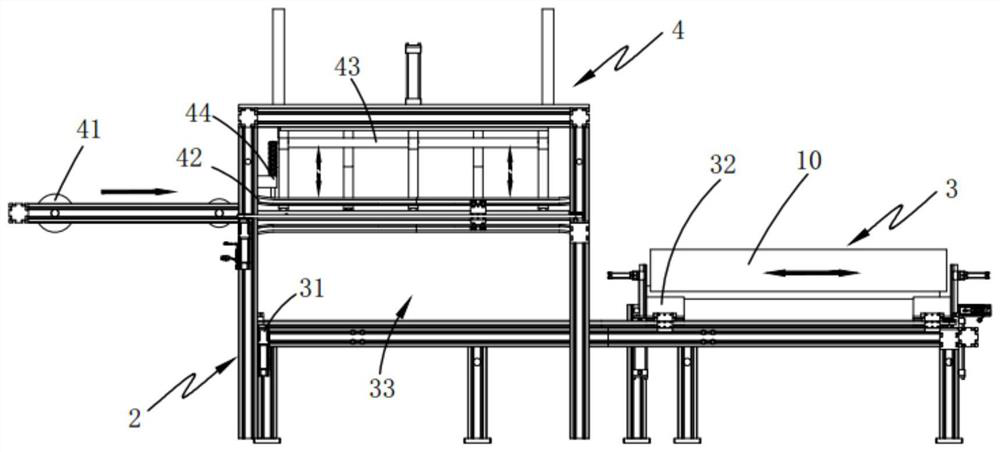

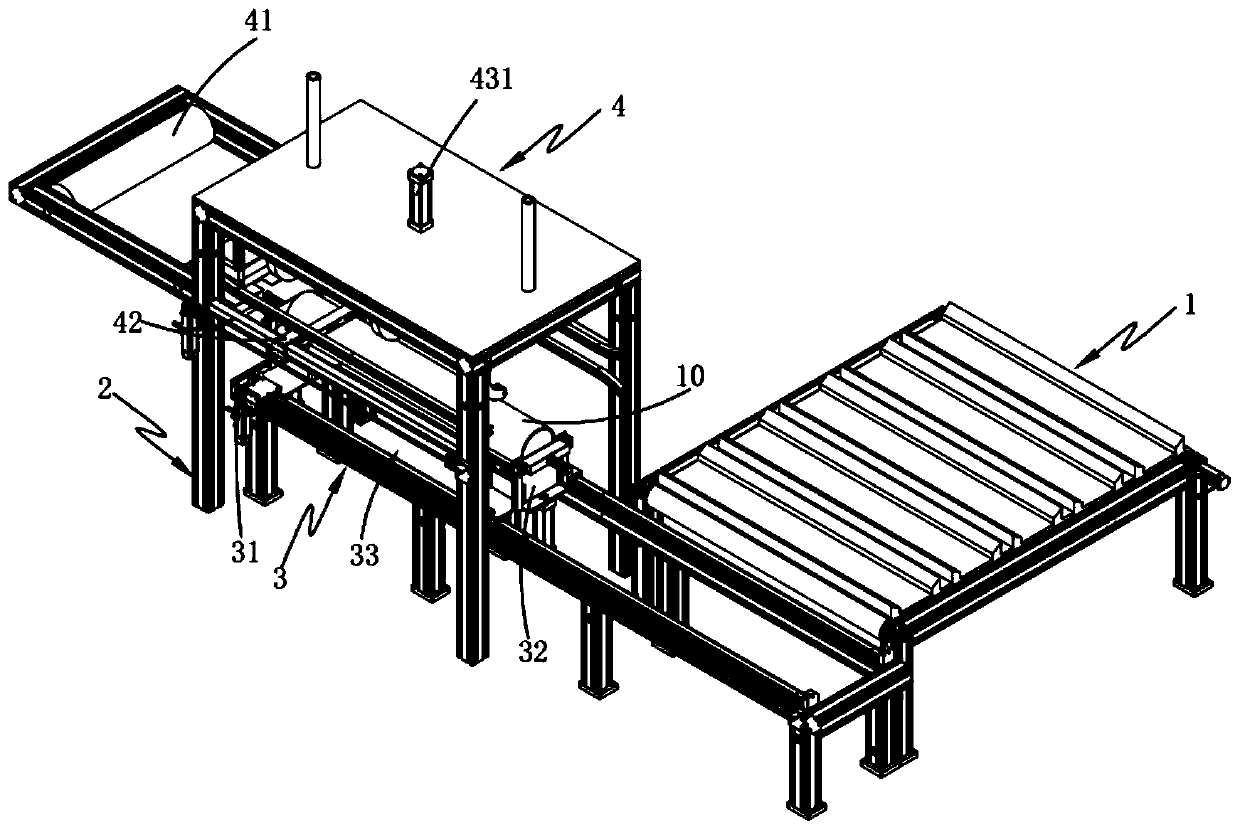

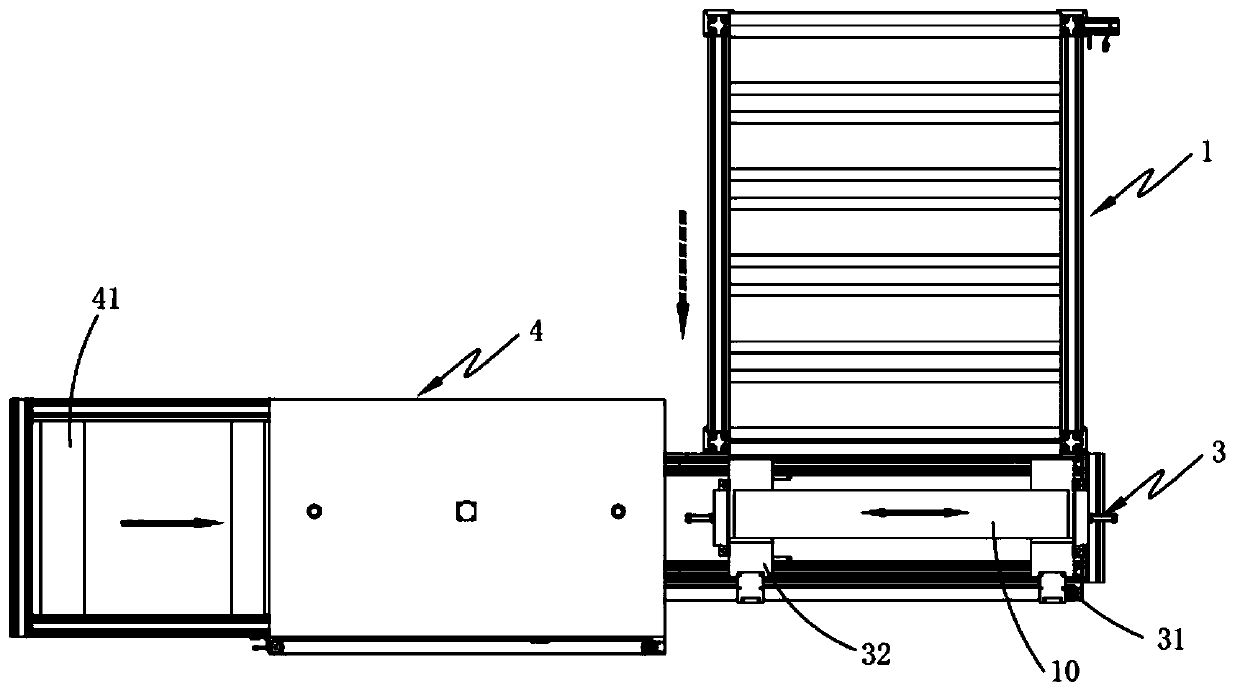

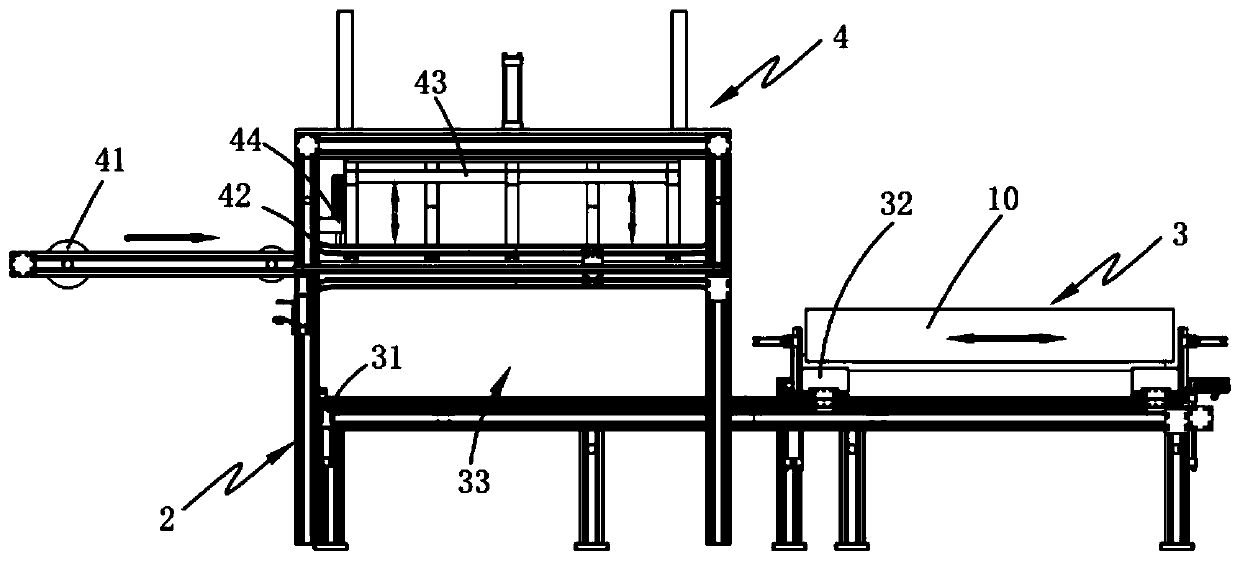

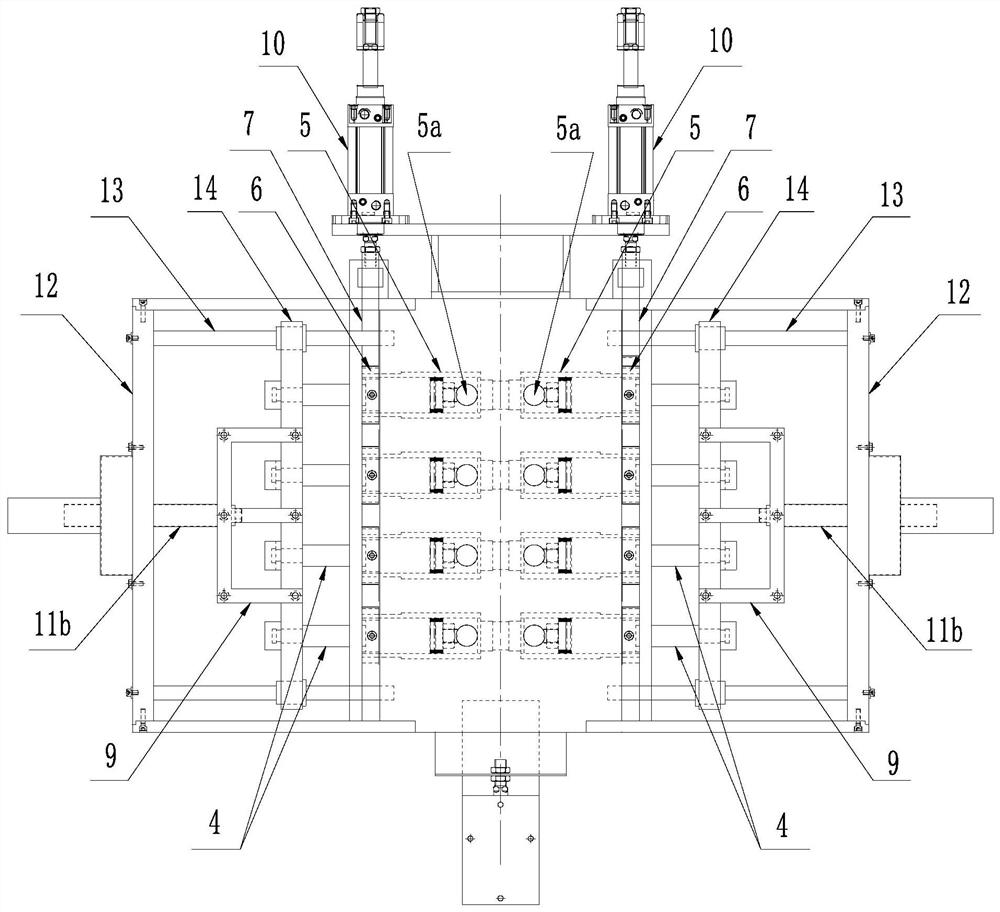

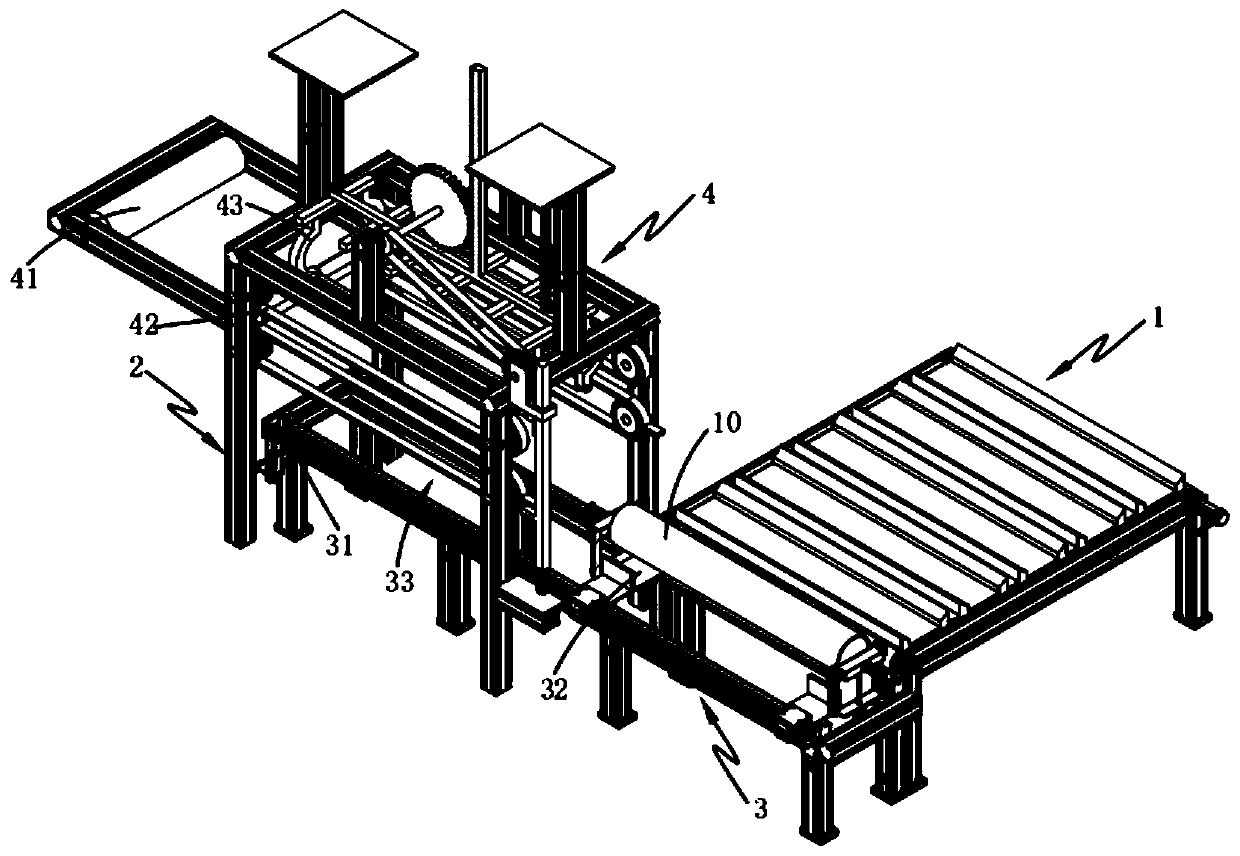

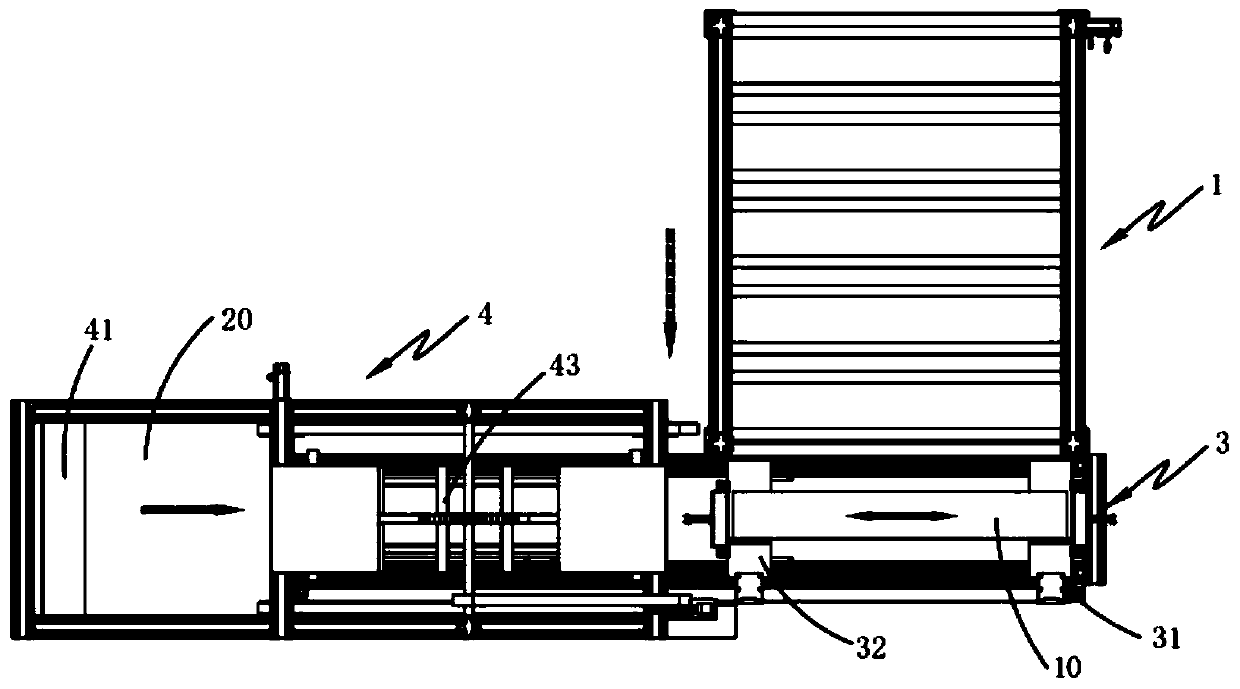

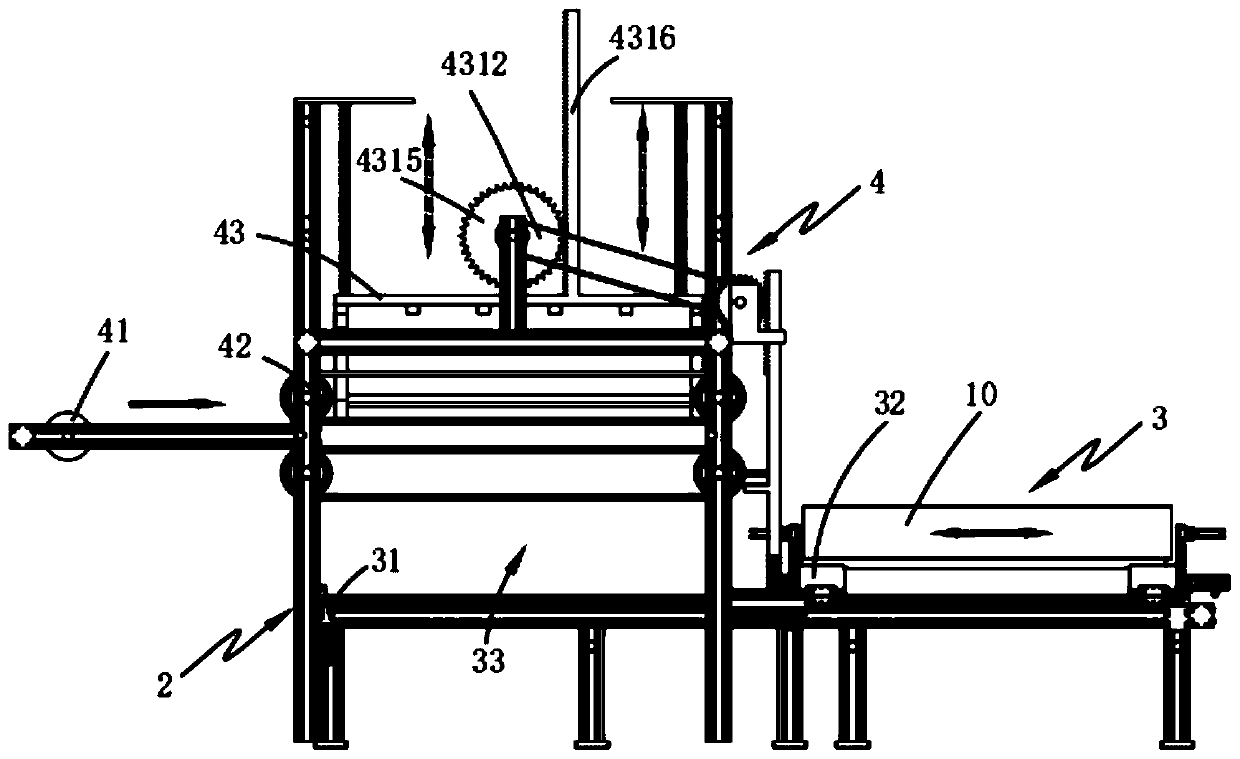

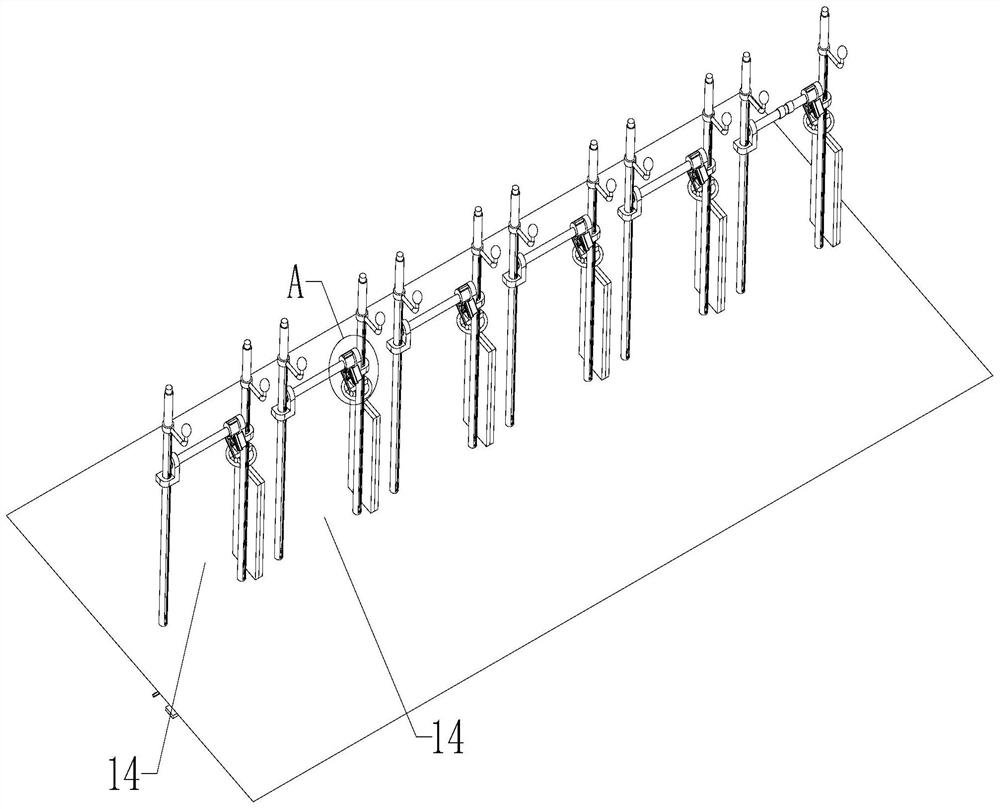

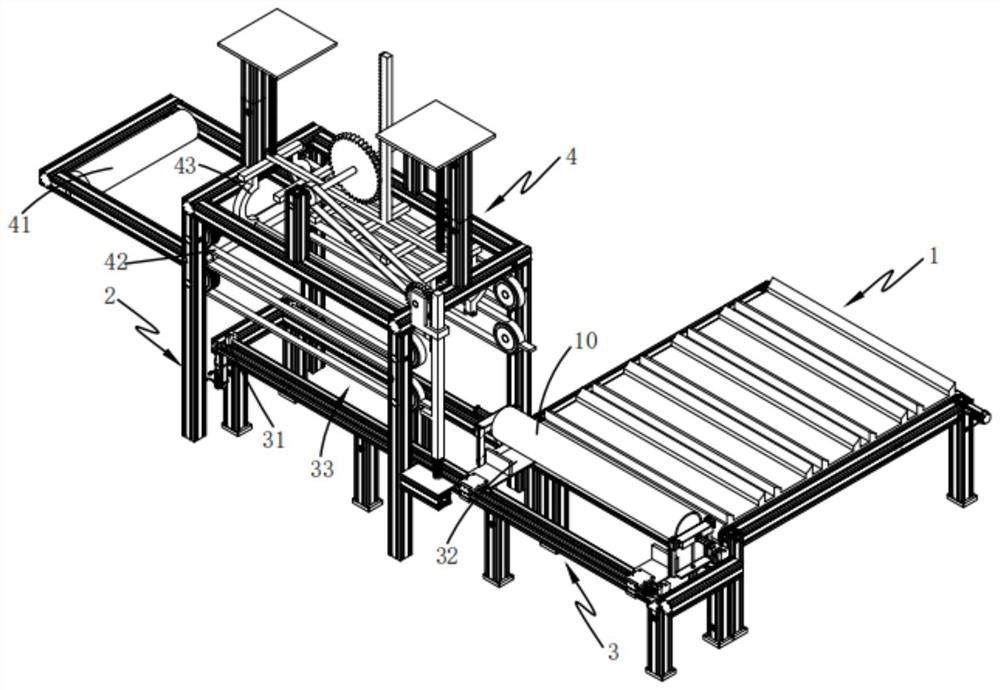

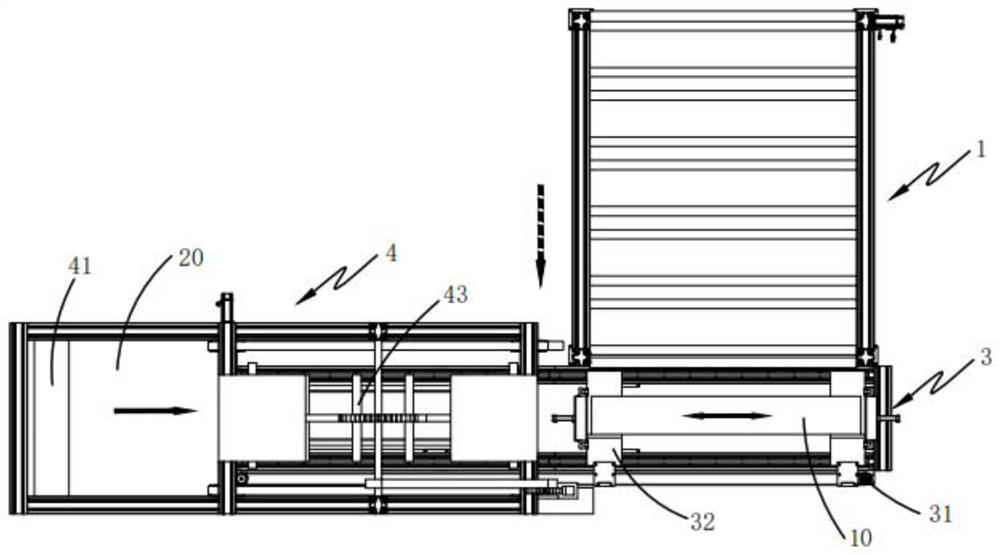

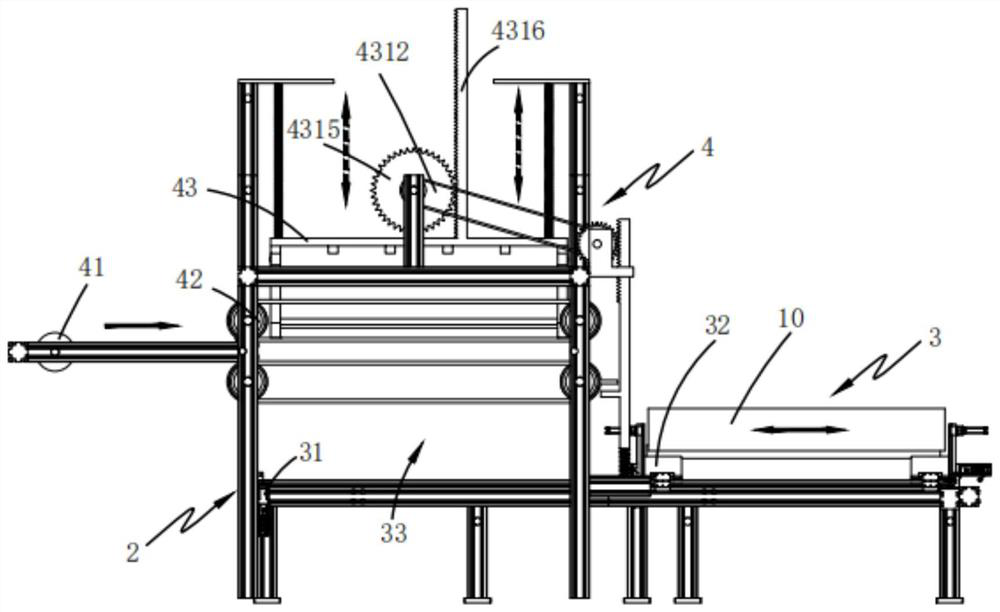

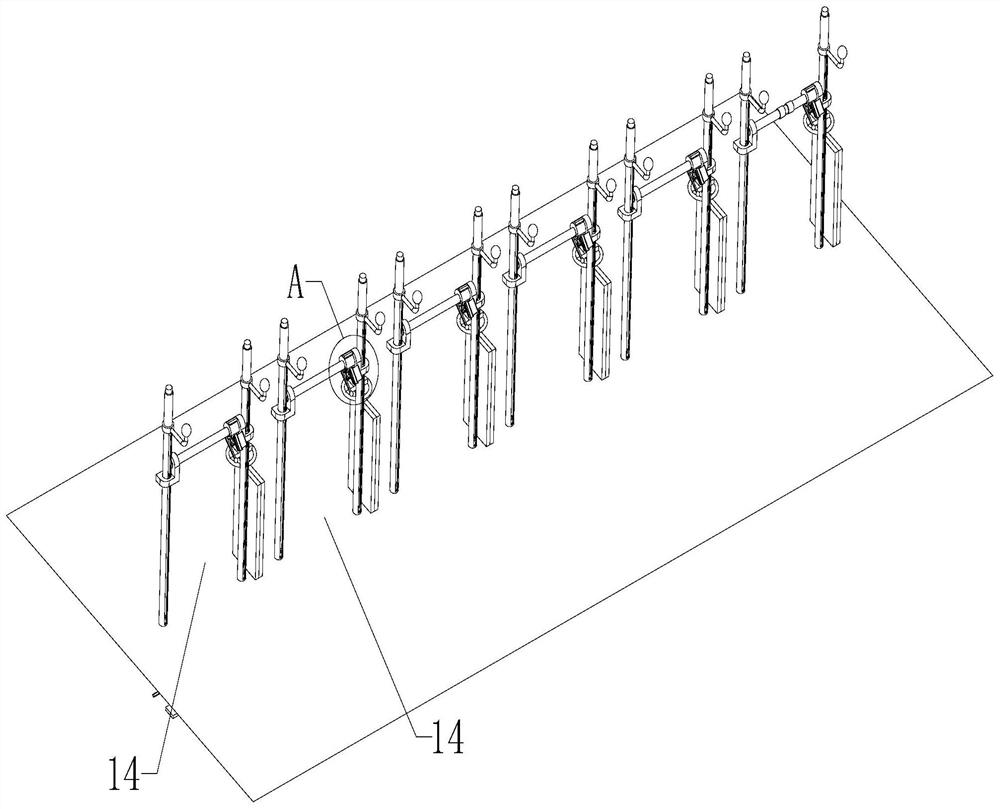

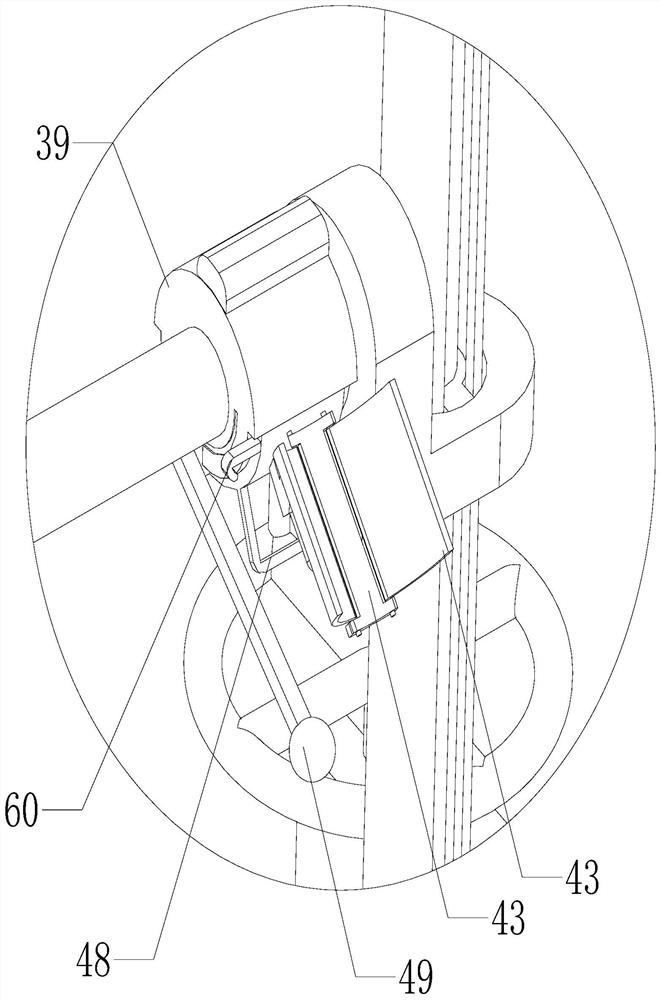

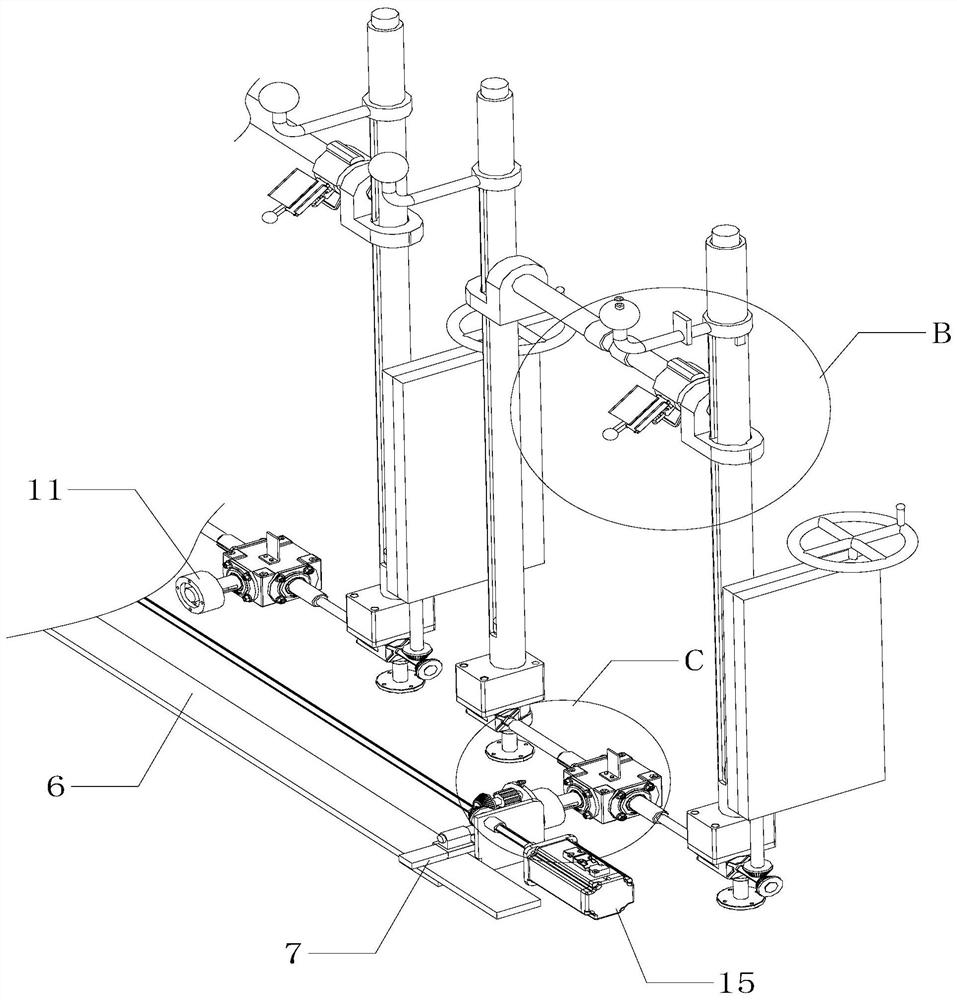

A post-processing automatic production line for road traffic signs

ActiveCN110002024BRealize automatic transportationImprove work efficiencyWrappingUnfolding thin materialsProduction lineRoad traffic

The invention provides a post processing automatic production line for a road traffic mark board. A feeding device, a rack, a mark rod limiting device and a cloth wrapping device are included. The mark rod limiting device is arranged on the rack, the feeding end of the mark rod limiting device is located on one side of the output end of the feeding device, and the mark rod limiting device comprises a feeding conveying assembly and an elevating limiting assembly. The cloth wrapping device is arranged above the wrapping area and comprises a cloth conveying assembly, a clamping cloth pulling assembly and a wrapping assembly. In the synchronous process that the mark rod limiting device conveys a mark rod to the position below the cloth wrapping device, the clamping cloth pulling assembly is driven to pull and pave the cloth to the position above the mark rod, the two ends of the cloth are glued during cloth pulling and paving, then, the wrapping assembly sequentially wraps the two ends ofthe cloth to the surface of the mark rod, the manual wrapping manner is replaced, and the work efficiency is greatly improved; and the technical problems that in the prior art, time and labor are wasted during manual cloth winding, and the cloth winding efficiency is low are solved.

Owner:HUZHOU COLLEGE

Normal-temperature special solid penetrating agent, ultra-thin overlay and construction method of ultra-thin overlay

ActiveCN113801574AImprove fatigue resistanceImprove crack resistanceIn situ pavingsPolyamide coatingsCrack resistanceOrganic solvent

The invention discloses a normal-temperature special solid penetrating agent, an ultrathin overlay and a construction method of the ultra-thin overlay. The normal-temperature special solid penetrating agent is a non-emulsified system solid penetrating agent, comprises an infiltration component and a cementing component, and is prepared through mixing, by weight, 100 parts of asphalt, 80-100 parts of heavy cycloalkane distillate oil, 3-5 parts of a styrene-isoprene block copolymer, 16-34 parts of polyamide resin, 3-5 parts of metal oxide, 18-30 parts of a penetrating agent, 0.1-1 part of a cross-linking agent and 100-200 parts of an organic solvent. The infiltration component can infiltrate into an original pavement by 3-4 cm depth, the performance of aged asphalt of the original pavement is recovered, the anti-fatigue characteristic and the crack resistance of a foundation layer are greatly improved, the defects of oil shortage, looseness and the like of the original pavement and the effect of sealing capillary cracks are effectively repaired, and the bonding effect between the original pavement and the ultra-thin overlay can be effectively enhanced through the bonding component, so layering and separation are not easy.

Owner:江苏瑞文戴尔交通科技有限公司

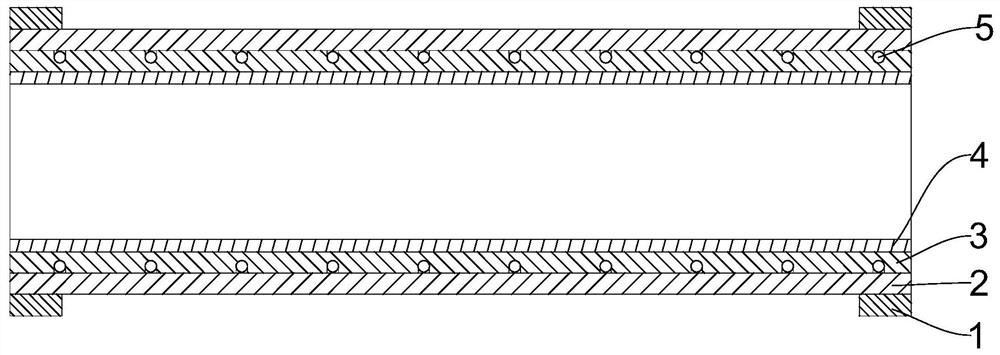

Automobile air inlet and outlet pipeline structure and coating process thereof

PendingCN112082006AImprove sound insulationImprove fire performanceCorrosion preventionPipe elementsCar drivingProcess engineering

The invention provides an automobile air inlet and outlet pipeline structure and a coating process thereof, and relates to the technical field of machining. The automobile air inlet and outlet pipeline structure comprises a pipe body and a coating structure, wherein the coating structure comprises a first coating layer and a second coating layer, the first coating layer is coated outside the pipebody, the second coating layer is tightly attached to the first coating layer, and the second coating layer is coated on the first coating layer. According to the automobile air inlet and outlet pipeline structure and the coating process thereof, the sound insulation effect of the air inlet and outlet pipeline can be enhanced, a good silencing effect is achieved, and noise pollution is prevented;and meanwhile, the process can also play a fireproof effect, and the situation that the safety of an automobile driver is influenced due to the fact that the automobile air inlet and outlet pipeline structure is combusted and spreads to the whole automobile is prevented.

Owner:李明辉

Double-sided melt impregnation equipment and method for continuous fiber reinforced adhesive tape

ActiveCN103802231BBalanced impregnation effectSpeed up the flowCoatingsPermeationFiber reinforcement

The invention discloses double-sided melting and impregnating equipment and a method for a continuous fiber-reinforcing adhesive tape. According to the equipment, a fiber pre-dispersion zone, a resin impregnation fiber zone and a fiber re-dispersion zone are arranged in a melting and impregnating equipment head; a pre-dispersion device is arranged in the pre-dispersion zone, and a double-sided distribution runner for distributing a resin melt is arranged in the resin impregnation fiber zone; in the fiber re-dispersion zone, a fiber channel is wavy, and re-dispersion devices are arranged on the upper side and the lower side of the fiber channel; an outlet at the tail end of the fiber channel is rectangular. The method comprises the following steps: firstly predispersing and preheating continuous long fibers, then entirely coating and impregnating through a double-sided distribution runner, and delivering out of the fiber channel after performing fiber redispersion treatment. According to the double-sided melting and impregnating equipment and the method, the impregnation effect of the resin melt to the continuous fiber in the adhesive tape can be balanced, the purposes of entire coating, permeation and impregnation can be achieved, the phenomenon that single-sided coating of the fibers is not tight can be avoided, long-time continuous stable production can be realized, and the output and quality of products can be both increased greatly.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

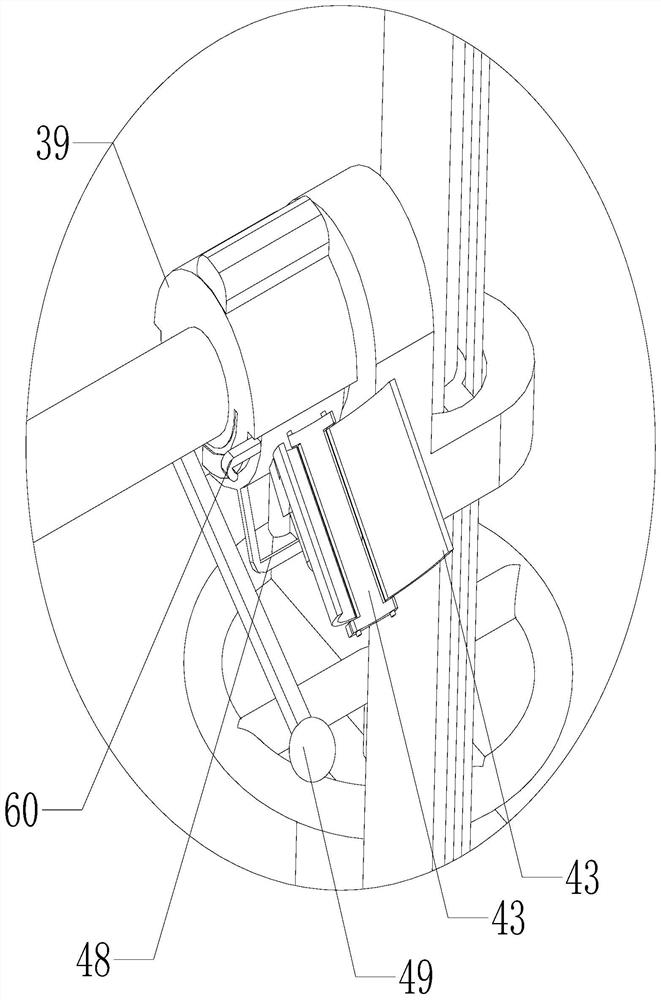

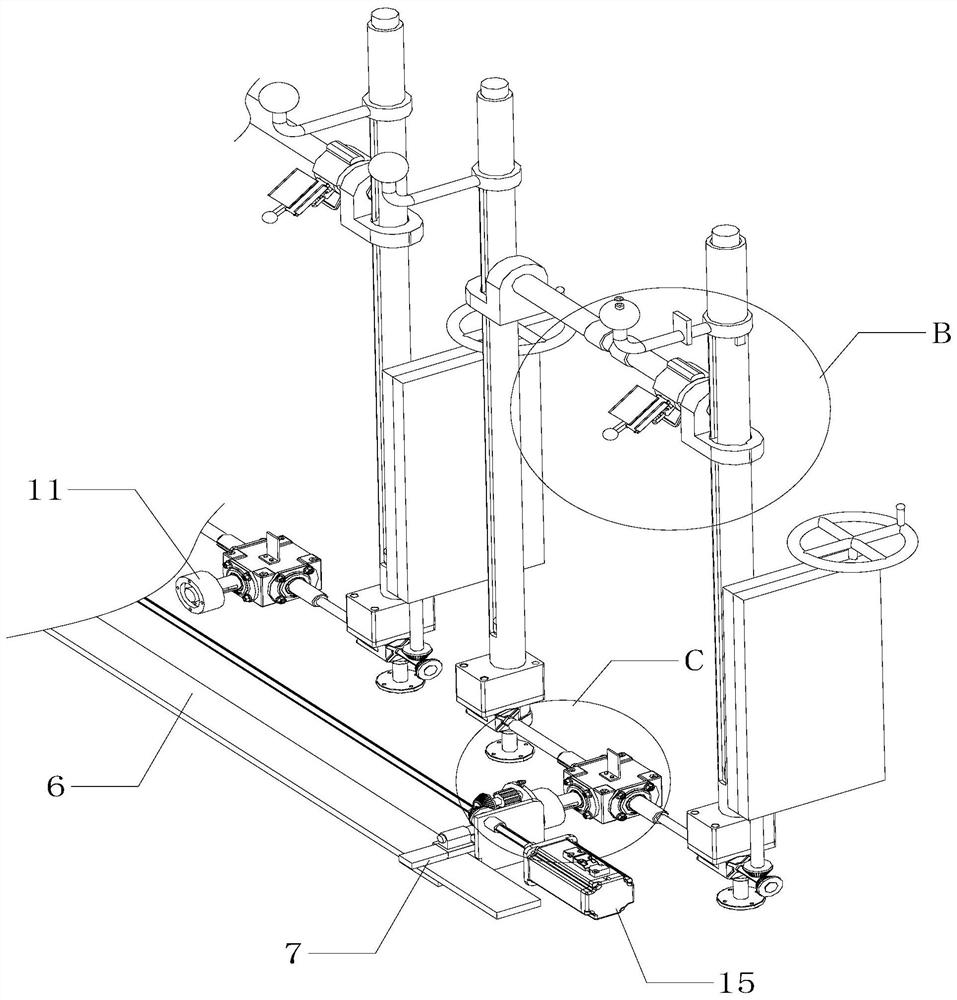

An automatic adhesion device for sign pole protection cloth for road traffic signs

ActiveCN109896075BRealize automatic transportationImprove work efficiencyPackagingMechanical engineeringRoad traffic

The invention provides automatic adhesion equipment for the marking rod protection cloth of a road traffic denoter. The automatic adhesion equipment comprises a feeding device, a machine frame, a making rod limiting device and a cloth adhesion device, the marking rod limiting device is arranged on the machine frame, the feeding end of the marking rod limiting device is located on one side of the output end of the feeding device, the marking rod limiting device comprises a feeding transporting assembly, and a lifting limiting assembly, the cloth adhesion device is arranged above a coating areaand comprises a cloth conveying assembly, a clamping and cloth pulling assembly, and an adhesion assembly, the marking rod limiting device transports the marking rod below the cloth adhesion device sothat the cloth is flatly paved in a cloth clamping and paving area above the marking rod under the rotary clamping of the clamping and cloth pulling assembly, the glue coating at the two ends of thecloth is achieved while cloth pulling and paving are achieved, sequential cladding and adhesion of the two ends of the cloth on the surface of the marking rod by the adhesion assembly are achieved, the original manual cladding manner is replaced, and the problem of the low cloth winding efficiency in the prior art is solved.

Owner:HUZHOU COLLEGE

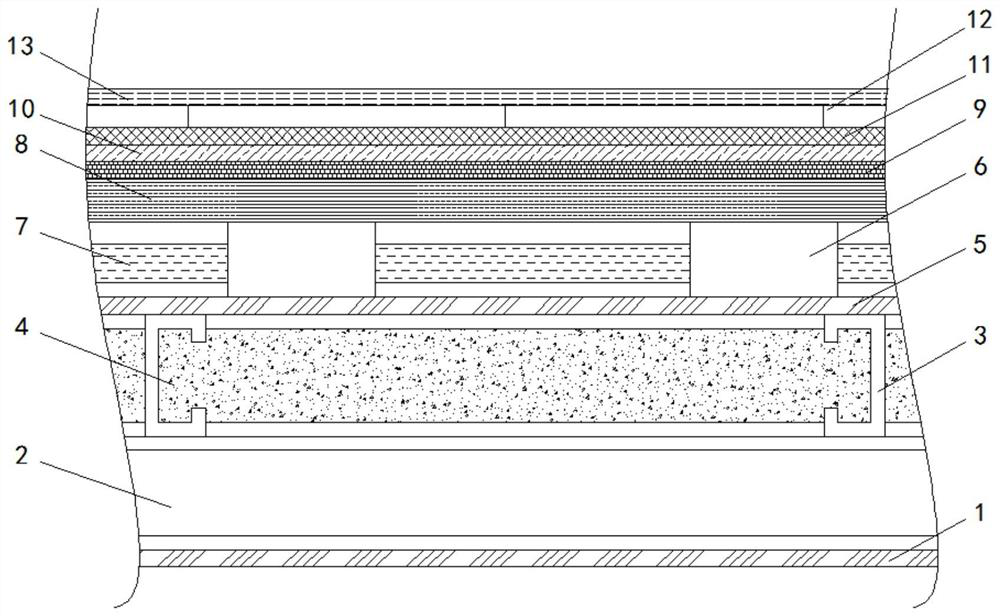

Heat-resistant and corrosion-resistant titanium-zinc plate

InactiveCN112012405AGood dispersionStable supportRoof covering using slabs/sheetsBuilding componentsInsulation layerTitanium

The invention relates to the technical field of titanium-zinc plates, and discloses a heat-resistant and corrosion-resistant titanium-zinc plate. The heat-resistant and corrosion-resistant titanium-zinc plate comprises a metal base plate. Supporting profile steel is fixedly connected to the top of the metal base plate, wiping strips are fixedly connected to the top of the supporting profile steel,a heat insulation layer is fixedly connected to the top of the supporting profile steel, and a sound absorption bottom plate is fixedly connected to the top of the heat insulation layer. According tothe heat-resistant and corrosion-resistant titanium-zinc plate, the supporting profile steel, the wiping strips and the heat insulation layer are arranged on the top of the metal base plate, and therefore the good supporting performance is provided for the whole structure through the transverse and vertical connection of the supporting profile steel and the wiping strips advantageously; the soundabsorption bottom plate, supporting strips, a sound absorption layer and an air isolation layer are arranged on the tops of the wiping strips, the sound absorption layer and the supporting strips arefixed in a penetrating and inserting mode, and therefore the sound absorption effect of the whole structure is improved conveniently. Meanwhile, the supporting strips ensure the stability of a soundabsorption structure, and the air isolation layer effectively avoids the phenomenon that due to the fact that the moisture enters the sound absorption structure, the sound absorption performance is reduced.

Owner:JIANGSU XINDING NEW MATERIAL CO LTD

Automatic adhesion equipment for marking rod protection cloth of road traffic denoter

ActiveCN109896075ARealize automatic transportationImprove work efficiencyPackagingAutomatic test equipmentEngineering

The invention provides automatic adhesion equipment for the marking rod protection cloth of a road traffic denoter. The automatic adhesion equipment comprises a feeding device, a machine frame, a making rod limiting device and a cloth adhesion device, the marking rod limiting device is arranged on the machine frame, the feeding end of the marking rod limiting device is located on one side of the output end of the feeding device, the marking rod limiting device comprises a feeding transporting assembly, and a lifting limiting assembly, the cloth adhesion device is arranged above a coating areaand comprises a cloth conveying assembly, a clamping and cloth pulling assembly, and an adhesion assembly, the marking rod limiting device transports the marking rod below the cloth adhesion device sothat the cloth is flatly paved in a cloth clamping and paving area above the marking rod under the rotary clamping of the clamping and cloth pulling assembly, the glue coating at the two ends of thecloth is achieved while cloth pulling and paving are achieved, sequential cladding and adhesion of the two ends of the cloth on the surface of the marking rod by the adhesion assembly are achieved, the original manual cladding manner is replaced, and the problem of the low cloth winding efficiency in the prior art is solved.

Owner:HUZHOU COLLEGE

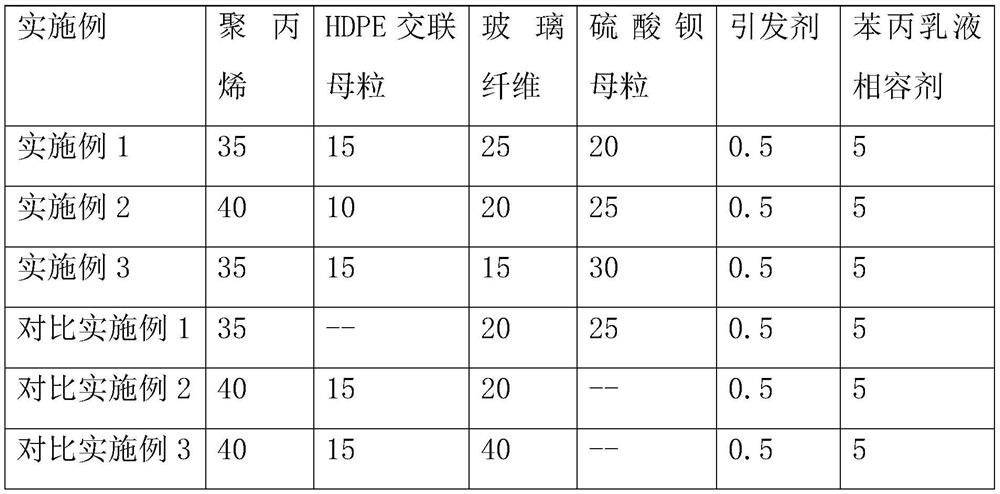

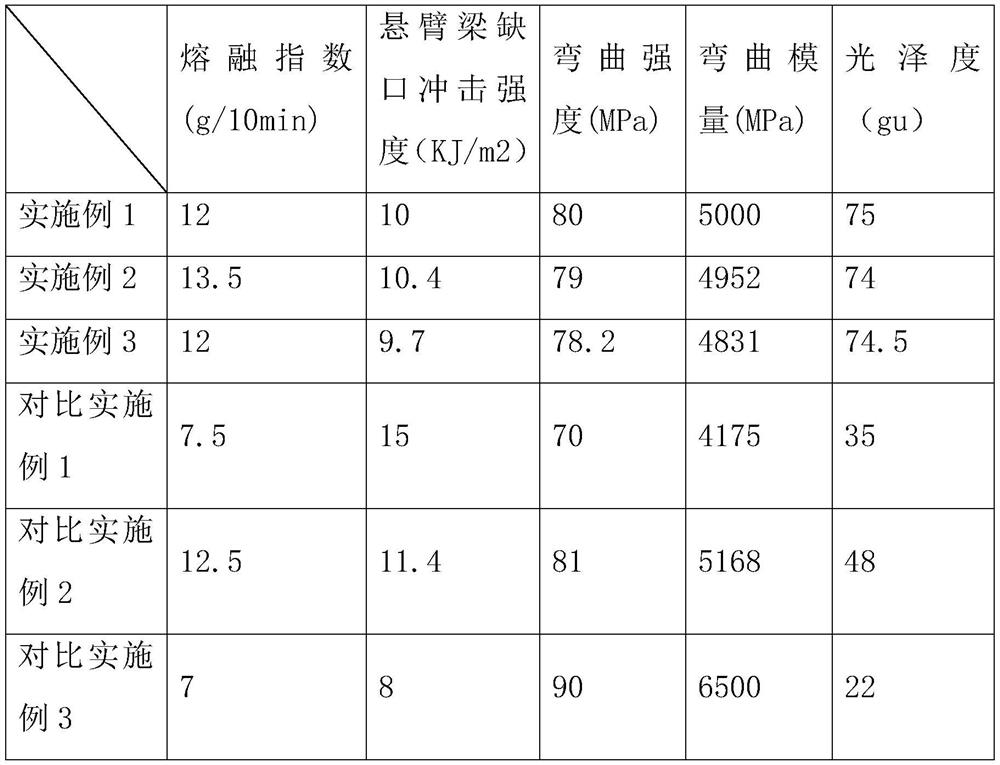

Styrene-acrylic emulsion grafted polypropylene composite material as well as preparation method and application thereof

The invention belongs to the field of high polymer materials, and particularly relates to a styrene-acrylic emulsion grafted polypropylene composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing polypropylene, polyethylene crosslinking master batch, glass fiber, barium sulfate master batch, an initiator, styrene-acrylic emulsion grafted polypropylene and a functional additive, melting and crosslinking at 190-230 DEG C, and extruding to obtain the polypropylene composite material. The styrene-acrylic emulsion grafted polypropylene with an amphiphilic structure is used as a compatilizer, the polypropylene, the polyethylene cross-linked master batch, the glass fiber, the barium sulfate master batch, the initiator, the styrene-acrylic emulsion grafted polypropylene and the functional additive are melted and cross-linked, and all the components cooperate with one another, so that the prepared composite material is good in mechanical property and high in mechanical property; the glossiness of a conventional PP material is improved, glass fibers are prevented from floating outwards, the reflection brightness of the surface of a part is enhanced, the surface of an injection molded part is attractive, and the PP material is applied to automobile lamp bases, lampshade shells and other products.

Owner:广州仕天材料科技有限公司

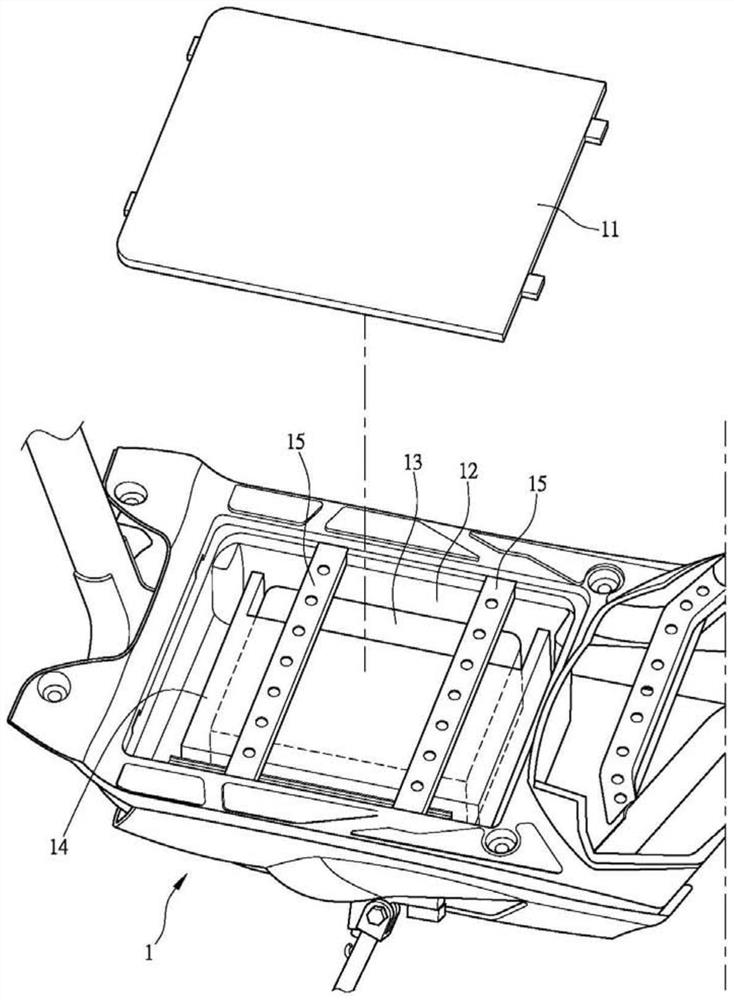

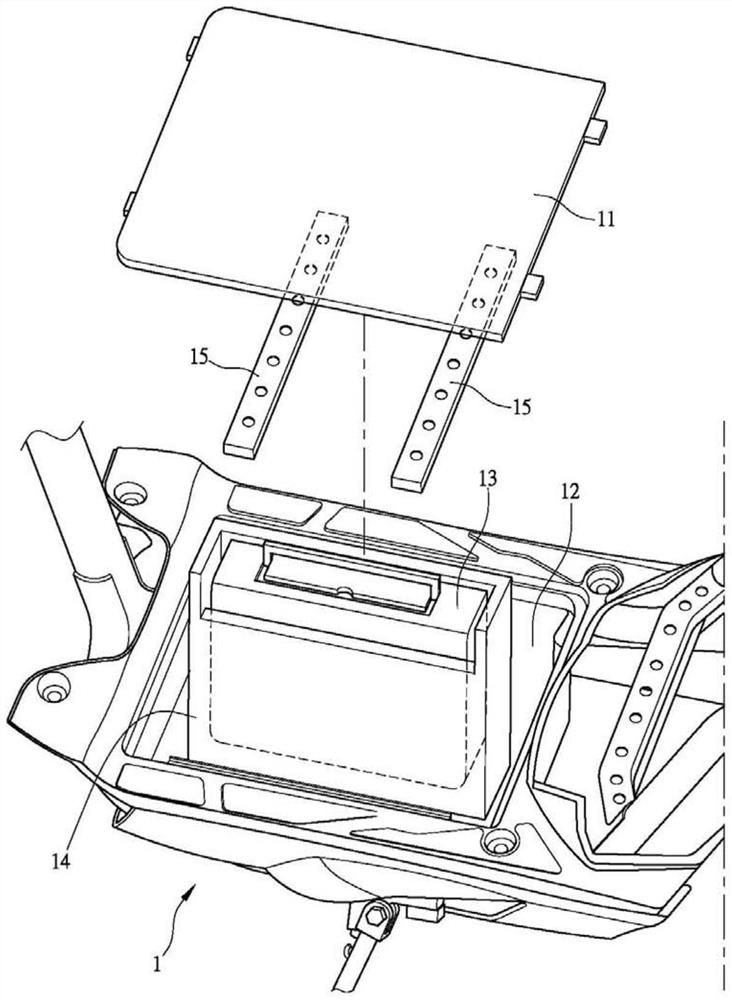

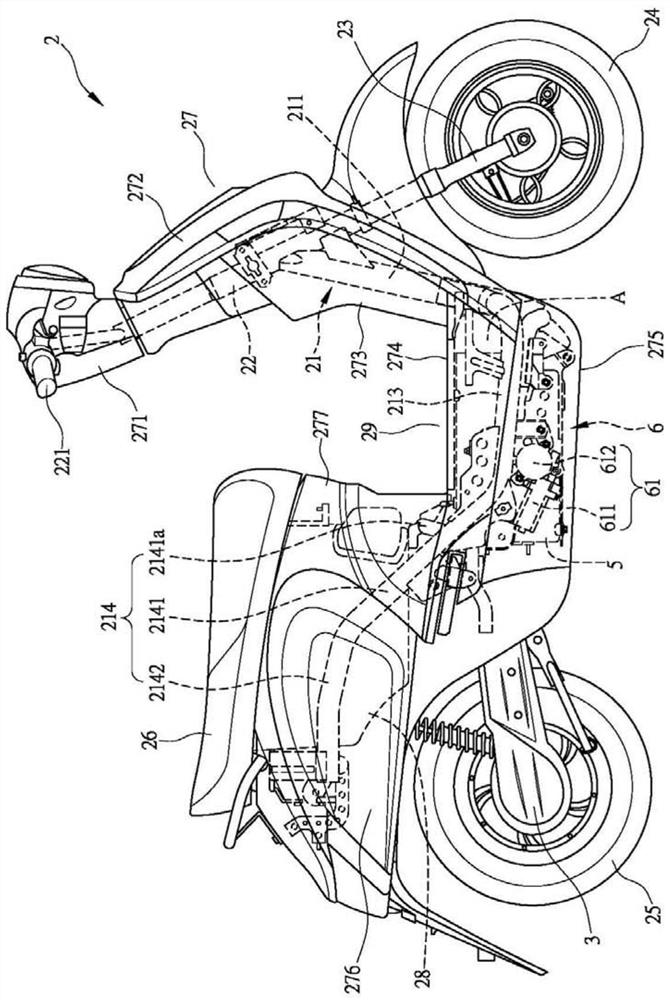

Protective cover for battery box of electric vehicle

ActiveCN110356498BStable storageWon't moveBattery isolationCell lids/coversVehicle frameElectric-vehicle battery

Owner:KYMCO

A kind of passivation method of nickel hydrazine nitrate

ActiveCN109293462BEasy to filterImprove securityExplosive working-up apparatusDistillationPhysical chemistry

Owner:DANCING FIREWORKS GROUP CO LTD

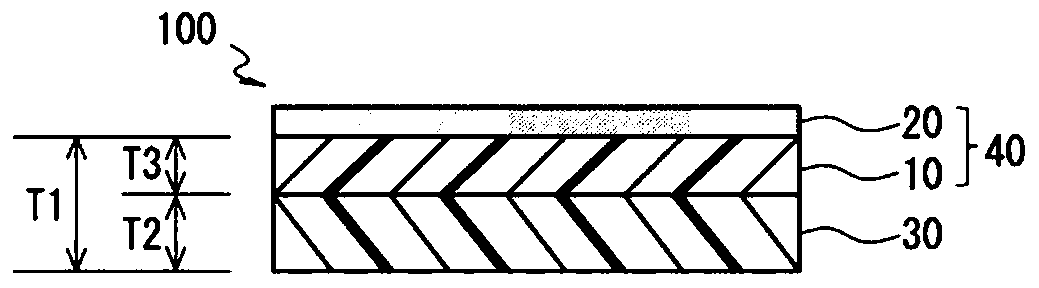

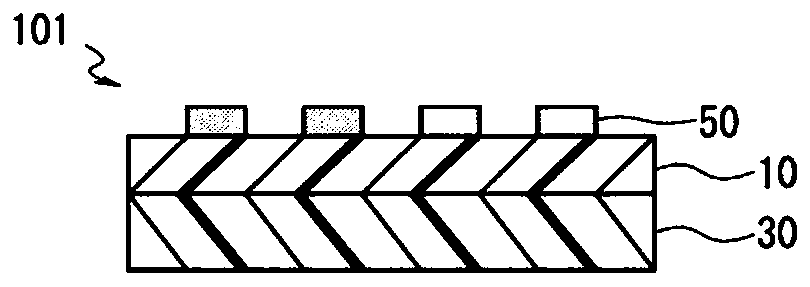

Metal-clad laminate, circuit board, multilayer circuit board, and method for producing same

PendingCN111132456AGuaranteed thicknessGood layer connectivityNon-macromolecular adhesive additivesPrinted circuit aspectsElectrical conductorHemt circuits

The invention provides a metal-clad laminate, a circuit board, a multilayer circuit board, and a method for producing the same. To provide a multilayer circuit board having an adhesive layer excellentin dimensional stability of a conductor circuit and capable of reducing transmission loss even in transmission of a high frequency signal. The circuit board 101 includes an insulating resin layer 10,a conductor circuit layer 10 laminated on one surface of the insulating resin layer 10, and an adhesive layer 30 laminated on the other surface of the insulating resin layer 50. The multilayer circuit board 200 is manufactured by disposing an adhesive layer 30 of a first circuit board 101 so as to face a conductor circuit layer 50 of an arbitrary circuit board 110 which is opposed to a conductorcircuit layer 50 of a 2 circuit board 101 and an adhesive layer 30 of a 2 circuit board 101 without an adhesive layer 30, and press-bonding them together.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

A kind of phase change thermoregulation paint and preparation method thereof

ActiveCN108948886BEnsure coverageImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesThermal dilatationMicrosphere

The invention discloses phase-change temperature regulation coating and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out atomization drying andthermal expansion treatment on a graphene oxide water solution to obtain a graphene microsphere with a mesoporous structure; and then fusing a phase-change material and sufficiently penetrating the phase change material into a cavity of the graphene microsphere, so as to obtain a phase-change microsphere with a core-shell structure. According to the phase-change temperature regulation coating, surplus phase-change material on the surface of the phase-change microsphere is removed through a filter pressing method, and the phase-change temperature regulation coating is obtained through adoptinga mechanical mixing method and uniformly mixing all components of the coating. The hollow graphene microsphere is used for covering the phase-change material so that leakage of the phase-change material in a utilization process is extremely reduced and the service life can be remarkably prolonged. The heat exchange between the environment and a coating layer can be effectively promoted through high heat conductivity of graphene and the heat of the coating layer can be stored and released. Furthermore, the graphene has high conductivity and antibacterial and far infrared emission properties, and the coating can obtain various new functions.

Owner:HANGZHOU GAOXI TECH CO LTD +1

Preparation method of medical porous titanium or titanium alloy material coated with tantalum coating

ActiveCN109261958BImprove bindingSolve the problem of poor bondingAdditive manufacturing apparatusTransportation and packagingTitanium alloyPorous titanium

The invention discloses a method for preparing a medical porous titanium or titanium alloy material coated with a tantalum coating on the surface. The method first adopts a 3D printing method to prepare a porous titanium skeleton or a porous titanium alloy skeleton, and then makes the porous titanium skeleton or porous titanium alloy After the skeleton is corroded, it is cleaned and dried, and then completely embedded in the ultrafine tantalum powder in the metal sheath, vacuum-sealed and then subjected to low-temperature diffusion sintering. Finally, the powder is removed after taking it out, and the medical porous titanium coated with tantalum coating is obtained. or titanium alloy material. The present invention coats tantalum on the surface of porous titanium skeleton or porous titanium alloy skeleton through powder embedding and low-temperature diffusion sintering to form a metallurgical bond, which greatly improves the bonding force between tantalum and the surface of porous titanium skeleton or porous titanium alloy skeleton, and solves the problem of The problem of poor bonding between the tantalum coating and the substrate overcomes the shortcomings of high cost and complicated procedures of the existing preparation methods.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Chocolate whole kernel mixed pouring head

The invention discloses a chocolate whole kernel mixing pouring head which comprises a shell, a hopper and a plunger mechanism, a pouring gate mechanism is arranged in the shell and comprises a pouring gate longitudinally arranged in the shell in a penetrating mode, and the upper end of the pouring gate is communicated with the hopper. The plunger mechanism comprises a plunger channel, a plunger and a plunger driving mechanism, the plunger channel is arranged in the shell and communicated with the pouring channel, the plunger is arranged in the plunger channel, and the plunger driving mechanism is connected with the plunger and drives the plunger to telescopically move along the plunger channel, and is characterized in that a spiral conveying mechanism is arranged in the hopper, and the pouring channel mechanism further comprises a blanking sleeve which is arranged in the plunger channel and sleeves the plunger; the front end of the blanking sleeve extends into the pouring channel and is communicated with the pouring channel through an opened side hole, the blanking sleeve driving mechanism is used for driving the blanking sleeve to rotate around the plunger, and the blanking sleeve is respectively communicated with the upper end and the lower end of the pouring channel by means of upward rotation and downward rotation of the side hole. The pouring device can smoothly and efficiently realize pouring of chocolate paste mixed with whole nuts, and is simple in structure and convenient to use.

Owner:苏州姑苏食品机械有限公司

Electromagnetic wave filter apparatus without degrading radiation pattern of antenna

ActiveUS8654028B2Reduced characteristicsEnsure coverageMagnetic/electric field screeningRadiating element housingsPower flowElectrical conductor

Owner:PANASONIC CORP

Traffic sign pole protection cloth automatic wrapping device

ActiveCN109956071ARealize automatic transportationImprove work efficiencyWrapping material feeding apparatusWrappingSign postingEngineering

The invention provides a traffic sign pole protection cloth automatic wrapping device, which comprises a feeding device, a rack, a sign pole limiting device, and a cloth wrapping device; the sign polelimiting device is arranged on the rack, and the feeding end of the sign pole limiting device is located on one side of the output end of the feeding device; the sign pole limiting device comprises afeeding conveying assembly and a lifting limiting assembly; the cloth wrapping device is arranged above a wrapped area, and the cloth wrapping device comprises a cloth conveying assembly, a rotary clamping assembly, and a wrapping assembly; the sign pole limiting device conveys a sign pole under the cloth wrapping device, the cloth is smoothly laid on the surface of the sign pole under rotary motion of the rotary clamping assembly, and then a wrapping treatment is synchronously conducted by the wrapping assembly; and integration of automatic transportation and wrapping of the sign post is realized, the original manual wrapping method is replaced, the work efficiency is greatly improved, and the technical problems that in the prior art manual cloth wrapping wastes time and effort, and cloth winding efficiency is low are solved.

Owner:HUZHOU COLLEGE

Warm-up training device for national sports

ActiveCN112933539ATo achieve the warm-up effectAchieve free switchingGymnastic exercisingSports equipmentStructural engineering

The invention relates to the technical field of sports equipment, and especially relates to a warm-up training device for national sports. The warm-up training device comprises a driving device and a plurality of warm-up training frames; each warm-up training frame comprises a warm-up pipe and two hand-operated lifters which are symmetrically arranged, the bottom ends of the lifters are input ends and are buried underground, lead screws on the lifters are provided with sliding pairs, and the two ends of the warm-up pipe are connected with the sliding pairs; one of the two lifters is provided with two input ends, one input end is connected with the input end of the other lifter through a gearbox, the other input end is provided with a manual transmission system, a first distance measuring sensor is arranged at the bottom of the sliding pair, the driving device is buried underground, and a color code sensor is arranged above the driving device; each gear box is provided with a detection plate; and an armrest is arranged at the upper portion of a guide pipe, and is provided with a stop and start button. A warm-up person can be supported to move more normatively when conducting warm-up exercises, and meanwhile the device supports more types of warm-up exercises.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Automatic wrapping equipment for traffic sign pole protection cloth

ActiveCN109956071BRealize automatic transportationImprove work efficiencyWrapping material feeding apparatusWrappingSign postingControl theory

The invention provides a traffic sign pole protection cloth automatic wrapping device, which comprises a feeding device, a rack, a sign pole limiting device, and a cloth wrapping device; the sign polelimiting device is arranged on the rack, and the feeding end of the sign pole limiting device is located on one side of the output end of the feeding device; the sign pole limiting device comprises afeeding conveying assembly and a lifting limiting assembly; the cloth wrapping device is arranged above a wrapped area, and the cloth wrapping device comprises a cloth conveying assembly, a rotary clamping assembly, and a wrapping assembly; the sign pole limiting device conveys a sign pole under the cloth wrapping device, the cloth is smoothly laid on the surface of the sign pole under rotary motion of the rotary clamping assembly, and then a wrapping treatment is synchronously conducted by the wrapping assembly; and integration of automatic transportation and wrapping of the sign post is realized, the original manual wrapping method is replaced, the work efficiency is greatly improved, and the technical problems that in the prior art manual cloth wrapping wastes time and effort, and cloth winding efficiency is low are solved.

Owner:HUZHOU COLLEGE

A warm-up training device for national sports

ActiveCN112933539BTo achieve the warm-up effectAchieve free switchingGymnastic exercisingSports equipmentGuide tube

The invention relates to the technical field of sports equipment, in particular to a warm-up training device for national sports, which includes a driving device and several warm-up training racks; The bottom end is the input end, which is buried in the ground. The screw on the elevator has a sliding pair, and the two ends of the warm-up tube are connected to the sliding pair; one of the two elevators has two input ends, and one of the input ends is connected to the other. The input end of the elevator is connected through a gearbox, and the other input end is equipped with a manual transmission system. The first distance measuring sensor is installed at the bottom of the sliding pair, the driving device is buried in the ground, and a color mark sensor is installed above it. A detection board is provided; a handrail is provided on the upper part of the guide tube, and stop and start buttons are provided on the handrail. The present invention can support warm-up participants to perform warm-up exercises in a more standardized manner, and at the same time support more types of warm-up exercises.

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com