Carbon-containing alumium nitride sintered compact, and ceramic substrate for use in apparatus for manufacturing and inspecting semiconductor

A technology for ceramic substrates and testing equipment, which is applied in the field of carbon-containing aluminum nitride sintered bodies and ceramic substrates, and can solve the problems of inaccurate temperature measurement, poor temperature control, and thick thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] (1) The following components were mixed, and the mixture was put into a mold to obtain a molded body: 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Corp., average particle diameter: 1.1 µm), 4 parts by weight of yttrium oxide (Y 2 o 3 , average particle diameter: 0.4 μm) and 8 parts by weight of an acrylic resin binder (manufactured by Kyoeisyha Chemical Co., Ltd., trade name: KC-600, acid value: 10KOHmg / g).

[0174] (2) The molded body was heated at 350° C. in a nitrogen atmosphere for 4 hours to thermally decompose the acrylic resin binder.

[0175] (3) At 1890°C and 150kg / cm 2 This molded body was hot-pressed under pressure for 3 hours to obtain an aluminum nitride sintered body.

[0176] Pulverize the sintered body, then heat the pulverized product at 500-800°C, and collect the generated CO x Gas, to determine the amount of carbon in the sintered body. The results of this measuring method confirmed that the amount of carbon contained i...

Embodiment 2

[0180] (1) The following components were mixed, and the mixture was put into a mold to obtain a molded body: 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Corp., average particle diameter: 1.1 µm) and 8 parts by weight of acrylic resin bonded Agent (manufactured by Kyoeisyha Chemical Co., Ltd., trade name: KC-600, acid value: 17KOHmg / g).

[0181] (2) The molded body was heated at 600° C. for 1 hour in a nitrogen atmosphere to thermally decompose the acrylic resin binder.

[0182] (3) At 1890°C and 150kg / cm 2 This molded body was hot-pressed under pressure for 3 hours to obtain an aluminum nitride sintered body.

[0183] The carbon content in the obtained aluminum nitride sintered body was 805 ppm. Its brightness N is 3.5.

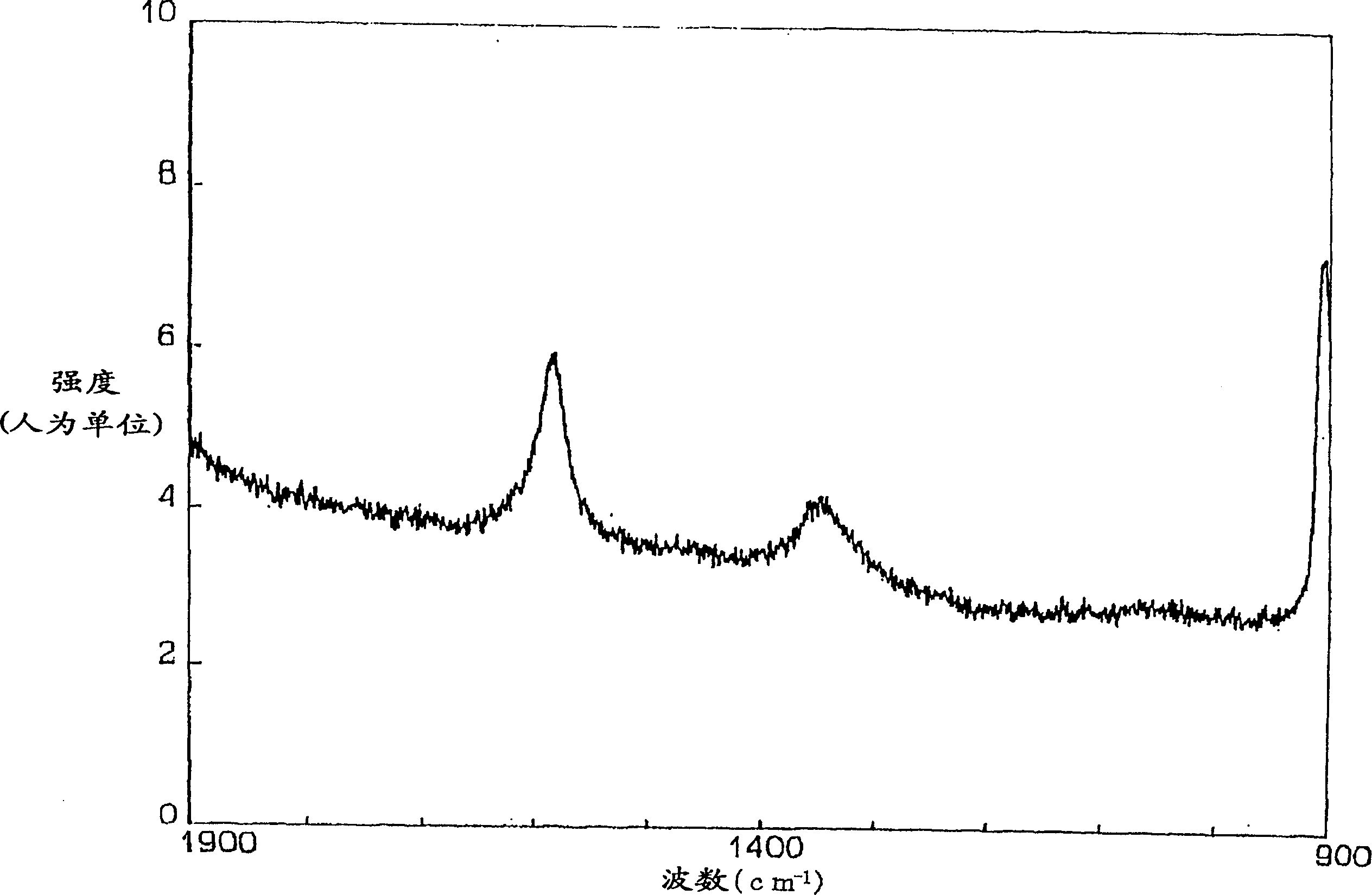

[0184] image 3 is a laser Raman spectrum showing the results of laser Raman spectroscopic analysis of carbon in the sintered body obtained in Example 2. The measurement conditions are the same as in Example 1.

[0185] Depe...

Embodiment 3

[0187] (1) The following components were mixed, and the mixture was put into a mold to obtain a molded body: 100 parts by weight of aluminum nitride powder (manufactured by Tokuyama Corp., average particle diameter: 1.1 µm), 4 parts by weight of yttrium oxide (Y 2 o 3 , average particle diameter: 0.4 μm) and 8 parts by weight of an acrylic resin binder (manufactured by Kyoeisyha Chemical Co., Ltd., trade name: KC-600, acid value: 10KOHmg / g).

[0188] (2) The molded body was heated at 350° C. in a nitrogen atmosphere for 4 hours to thermally decompose the acrylic resin binder.

[0189] (3) At 1750°C and 150kg / cm 2 This molded body was hot-pressed under pressure for 3 hours to obtain an aluminum nitride sintered body.

[0190] The carbon content in the obtained aluminum nitride sintered body was 800 ppm. Its brightness N is 3.5.

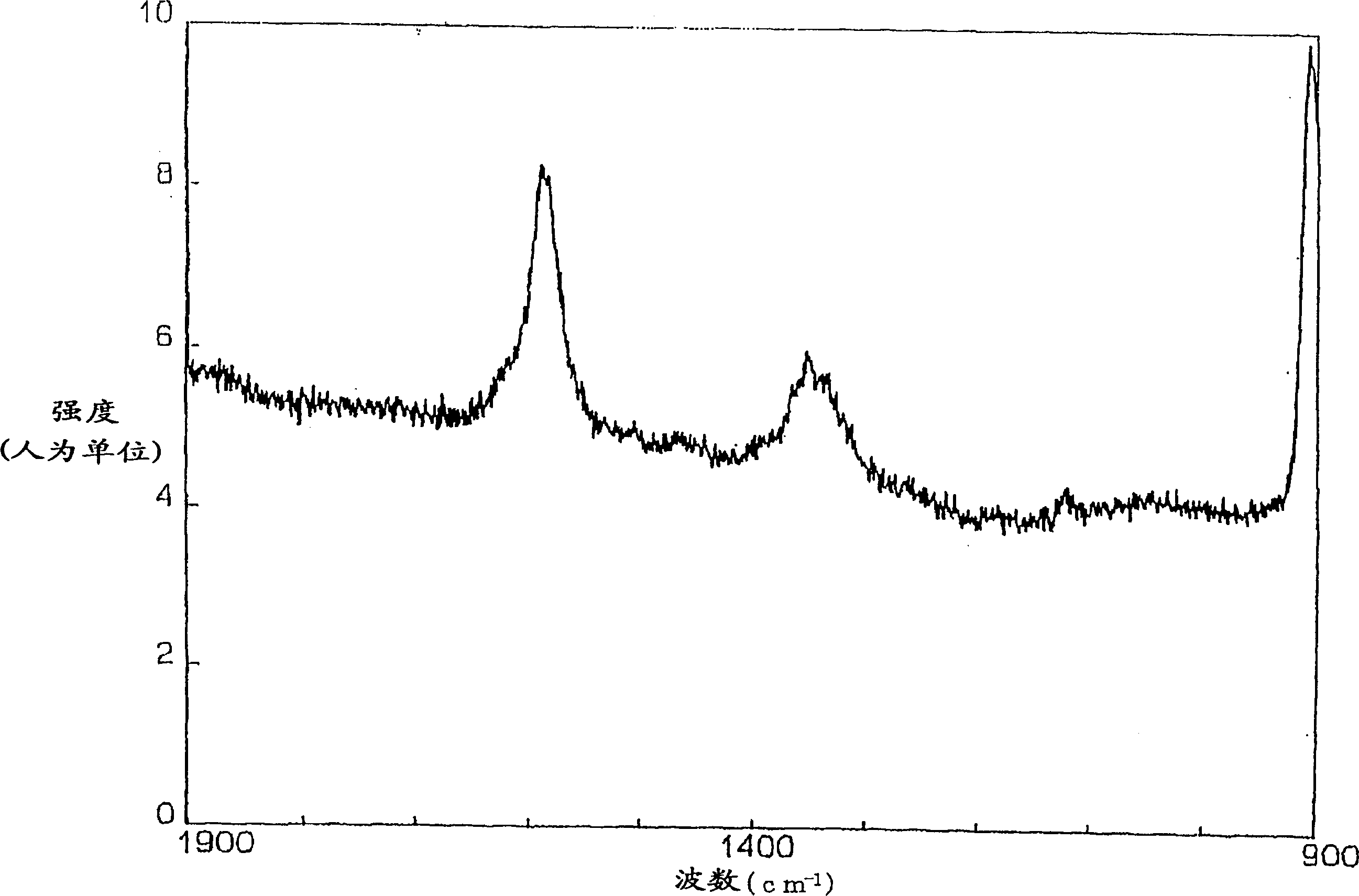

[0191] According to the laser Raman spectrum analysis of the carbon in the sintered body obtained in Example 3, the peak intensity ratio I(1580 / I(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com