Double-sided melt impregnation equipment and method for continuous fiber reinforced adhesive tape

A continuous fiber, melt impregnation technology, applied in the coating and other directions, can solve the problems such as the inability to ensure good infiltration of the fiber by the resin, uneven fiber dispersion in the prepreg tape, and decreased product quality stability, and achieve long-term continuous and stable production. , Impregnation effect is balanced, the effect of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

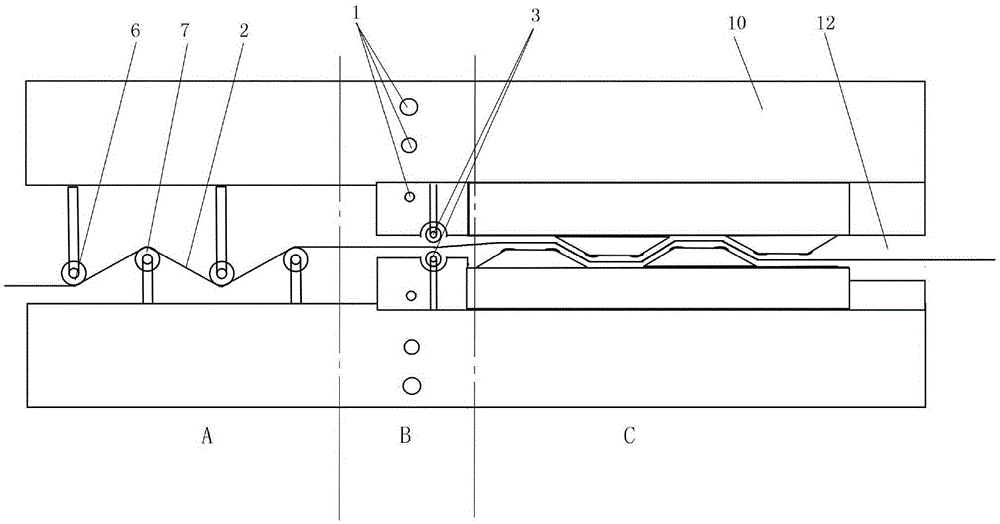

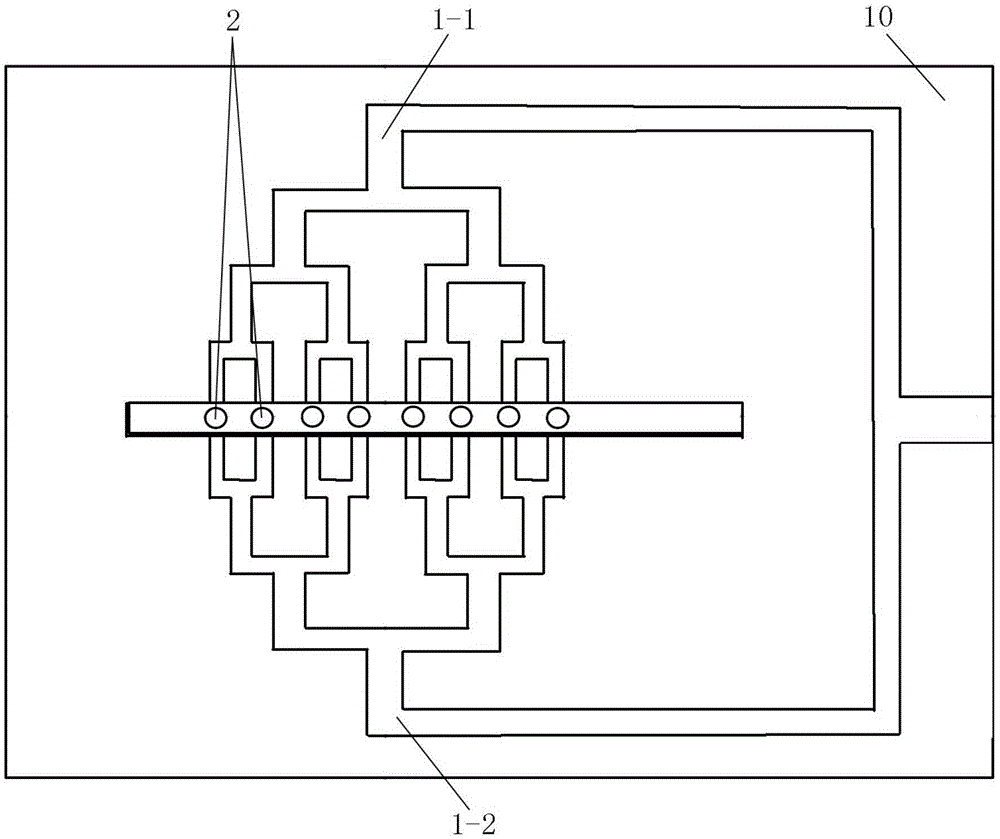

[0046] In this embodiment, a double-sided melt impregnation device for continuous fiber reinforced adhesive tape, such as figure 1 As shown, the melt impregnation head 10 is provided with a fiber channel 12 with a rectangular cross-section. The fiber channel includes a fiber pre-dispersion area A, a resin-impregnated fiber area B, and a fiber re-dispersion area C that are sequentially connected and continuously communicated; the fiber pre-dispersion area There is a pre-dispersion device in the middle, and a double-sided distribution flow channel 1 for resin melt distribution is set in the resin-impregnated fiber area; in the fiber re-dispersion area, the fiber channel is wavy, and the upper and lower sides of the fiber channel are equipped with re-dispersion devices ; The end outlet of the fiber channel is rectangular, and the adhesive tape 2 is placed in the fiber channel.

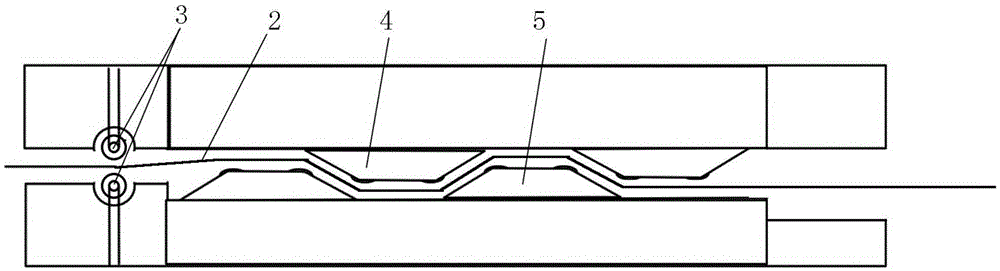

[0047] Among them, the redispersion device in the fiber redispersion zone such as image 3 As shown, ...

Embodiment 2

[0066] The double-sided melting impregnation equipment of a kind of continuous fiber reinforced adhesive tape of this embodiment, compares with embodiment 1, and its difference is: as Figure 4 As shown, in the fiber redispersion zone, the redispersion device includes an upper dispersing roller 8 and a lower dispersing roller 9, an upper dispersing roller is arranged above the fiber passage, a lower dispersing roller is arranged below the fiber passage, an upper dispersing roller and a lower dispersing roller Alternately distributed and arranged at equal intervals;

[0067] The upper dispersing roller and the lower dispersing roller have the same structure, both are smooth rollers with a square cross-section, the length of each side of the square is 5-60mm, and the corners of each square are rounded at 90-150°; each upper dispersing roller and lower dispersing roller There are electric heating rods inside the rollers, and the heating temperature is 60-400°C; between the adjace...

Embodiment 3

[0069] The double-sided melting impregnation equipment of a kind of continuous fiber reinforced adhesive tape of this embodiment, compares with embodiment 1, and its difference is: as Figure 5 As shown, in the fiber redispersion zone, the redispersing device includes an upper dispersing roller 8 and a lower dispersing block 5, an upper dispersing roller is arranged above the fiber channel, a lower dispersing block is provided below the fiber channel, and the upper dispersing roller and the lower dispersing block Alternately distributed and arranged at equal intervals, the fiber channel is wavy, the upper dispersing roller is placed in the trough, and the distance between the outer edge and the trough is 1-15mm;

[0070] Among them, the upper dispersing roller is a smooth roller with a square cross-section, the length of each side of the square is 5-60mm, and the corners of each square are rounded corners of 90-150°; each upper dispersing roller and the dispersing roller are eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com