Metal-clad laminate, circuit board, multilayer circuit board, and method for producing same

A technology of circuit substrates and laminated boards, applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, circuit substrate materials, etc., can solve the problems of high-frequency signal transmission application possibilities that have not been studied, and achieve high-density integration and durability Excellent thermal performance and good interlayer connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

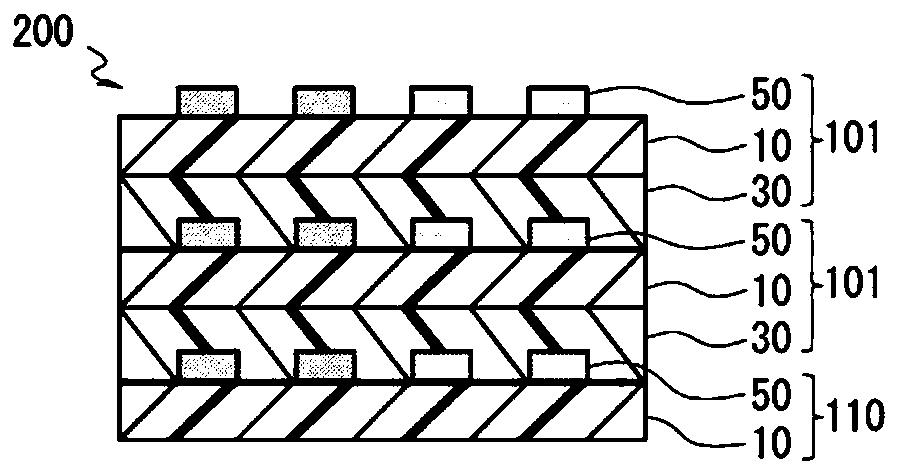

[0179] image 3 It is a cross-sectional view in the stacking direction showing the structure of the multilayer circuit board 200 according to the first embodiment of the present invention. The multilayer circuit board 200 of the first embodiment has a structure in which a plurality of circuit boards 101 and an arbitrary circuit board 110 are stacked in the same direction.

[0180] That is, since image 3 The upper side of the first circuit board 101 faces the lower side, and the adhesive layer 30 of the first circuit board 101 is in contact and laminated so as to cover the conductor circuit layer 50 of the second circuit board 101. Furthermore, the adhesive layer 30 of the second circuit board 101 The conductor circuit layer 50 of the arbitrary circuit board 110 which does not have the adhesive layer 30 may be contact|connected and laminated so that it may cover. Here, the structure or material of any circuit substrate 110 is not limited. For example, the conductive circuit layer...

no. 2 approach >

[0187] Figure 5 It is a cross-sectional view in the stacking direction showing the structure of the multilayer circuit board 201 according to the second embodiment of the present invention. In the multilayer circuit board 201 of the second embodiment, a structure in which a pair of circuit boards 101 are bonded such that these adhesive layers 30 face each other is set as one circuit board unit 102, and includes at least one The circuit board unit 102.

[0188] That is, since Figure 5 In the upper part facing downward, the first metal-clad laminate 100, the circuit board unit 102, and the second metal-clad laminate 100 (wherein the opposite direction to the first metal-clad laminate 100) are arranged in this order, and The circuit board unit 102 is sandwiched between the adhesive layers 30 of the two metal-clad laminates 100 and laminated. The adhesive layer 30 of the first metal-clad laminate 100 is laminated so as to be in contact with the conductor circuit layer 50 on the si...

Embodiment

[0195] Examples are shown below, and the features of the present invention will be described in more detail. However, the scope of the present invention is not limited to the examples. In addition, in the following examples, unless otherwise specified, various measurements and evaluations are based on the following.

[0196] [Measurement of dimensional change rate]

[0197] The measurement of the dimensional change rate is performed in the following procedure. First, a 150 mm square test piece was used to expose and develop the dry film resist at intervals of 100 mm, thereby forming a target for position measurement. In an environment with a temperature of 2322°C and a relative humidity of 5025%, the size before etching (normal) is measured, and thereafter, copper other than the target of the test piece is removed by etching (liquid temperature of 40°C or less, time within 10 minutes). After standing for 2424 hours in an environment with a temperature of 2322°C and a relative hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com