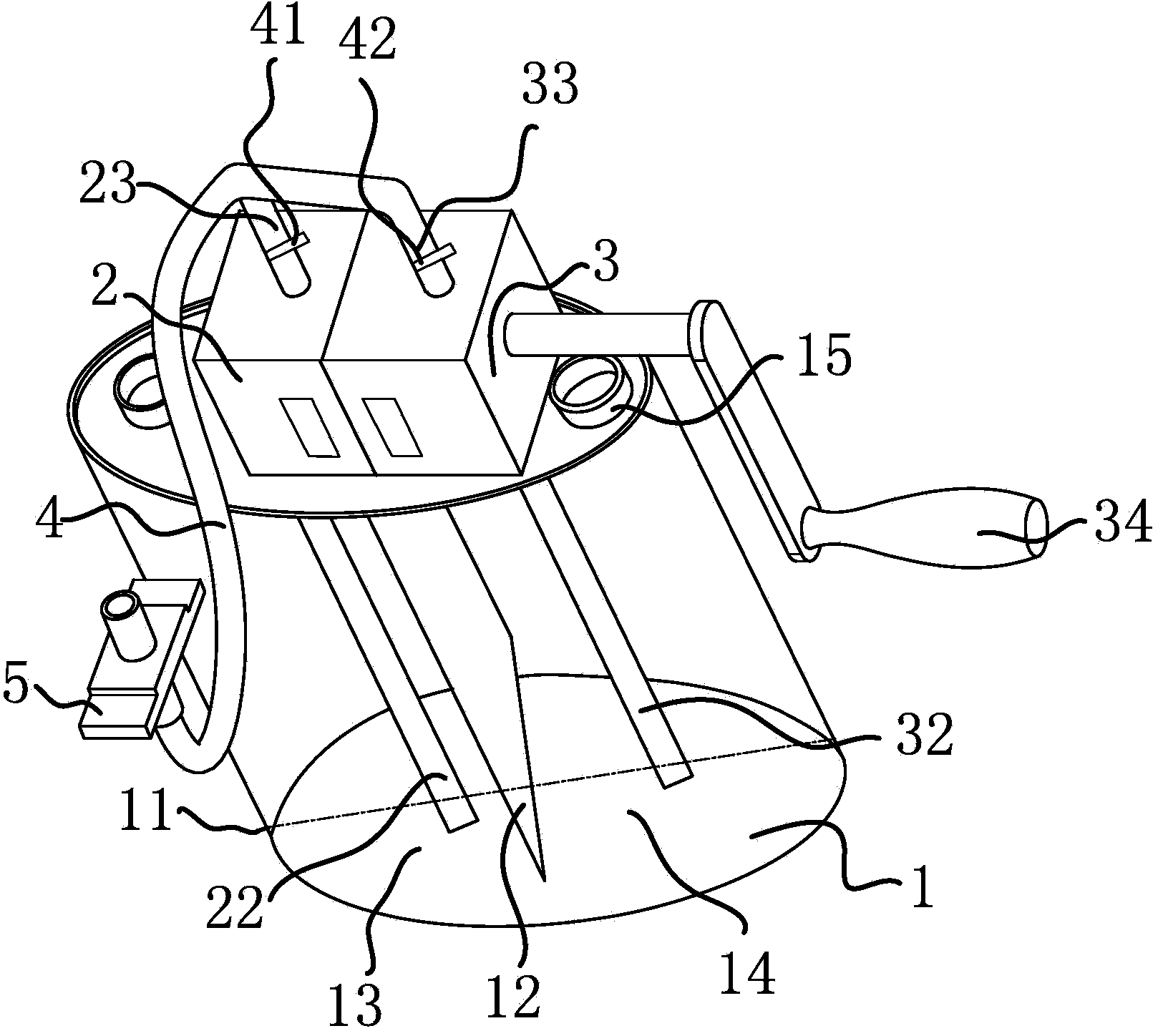

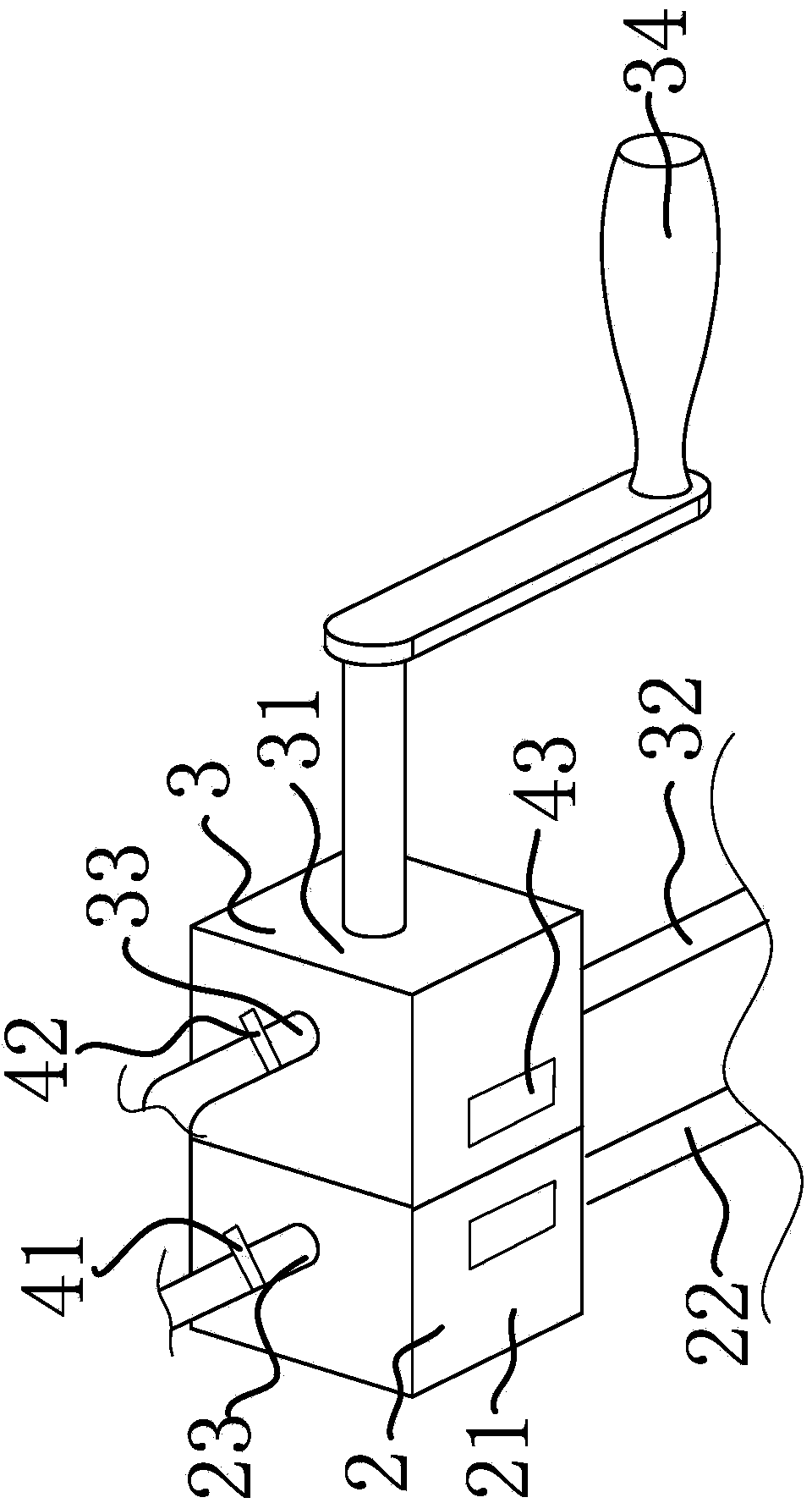

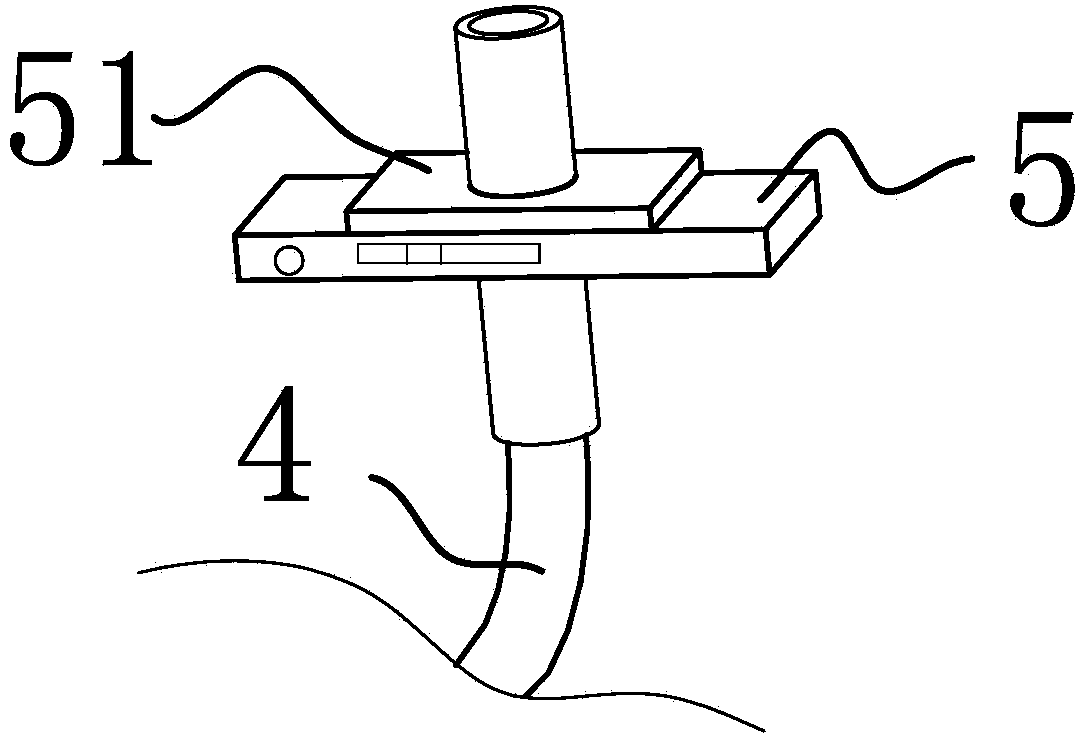

Automobile gearbox oiler

A technology of automobile gearbox and oiler, applied in the field of auto parts, can solve the problems of wasting resources, reducing the refueling rate, polluting the oiler, etc., and achieves the effects of preventing static electricity hazards, improving comprehensive performance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw materials were weighed according to the composition and parts by weight of the fuel tank inner surface coating in Example 1 in Table 1. Then first add epoxy resin and conductive filler with a particle size of 1-3 μm into the mixed solvent, stir evenly and then add melamine formaldehyde resin, toughening agent, curing agent and defoaming agent. After 25 minutes, start to paint the inner surface of the fuel tank, and paint 3 times with an interval of 20 hours between each painting, and the total thickness of the coating is 0.08mm.

Embodiment 2

[0043] The raw materials were weighed according to the composition and parts by weight of the fuel tank inner surface coating in Example 2 in Table 1. Then firstly add epoxy resin and conductive filler with a particle size of 5-8 μm into the mixed solvent, stir evenly and then add melamine formaldehyde resin, toughening agent, curing agent and defoaming agent. After 30 minutes, start to paint the fuel tank, and paint 4 times, with an interval of 24 hours between each painting, and the total thickness of the coating is 0.15mm.

Embodiment 3

[0045] The raw materials were weighed according to the composition and parts by weight of the fuel tank inner surface coating in Example 3 in Table 1. Then first add epoxy resin and conductive filler with a particle size of 1-6 μm into the mixed solvent, stir evenly and then add melamine formaldehyde resin, toughening agent, curing agent and defoaming agent. After 35 minutes, start to paint the fuel tank, and paint twice, with an interval of 22 hours between each painting, and the total thickness of the coating is 0.10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com