Lithium battery electrode tab cutting and dust removal device and lithium battery electrode tab cutting device

A technology of dust removal device and cutting equipment, applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems affecting the quality and risks of lithium batteries, and achieve the effect of preventing jitter, ensuring quality and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

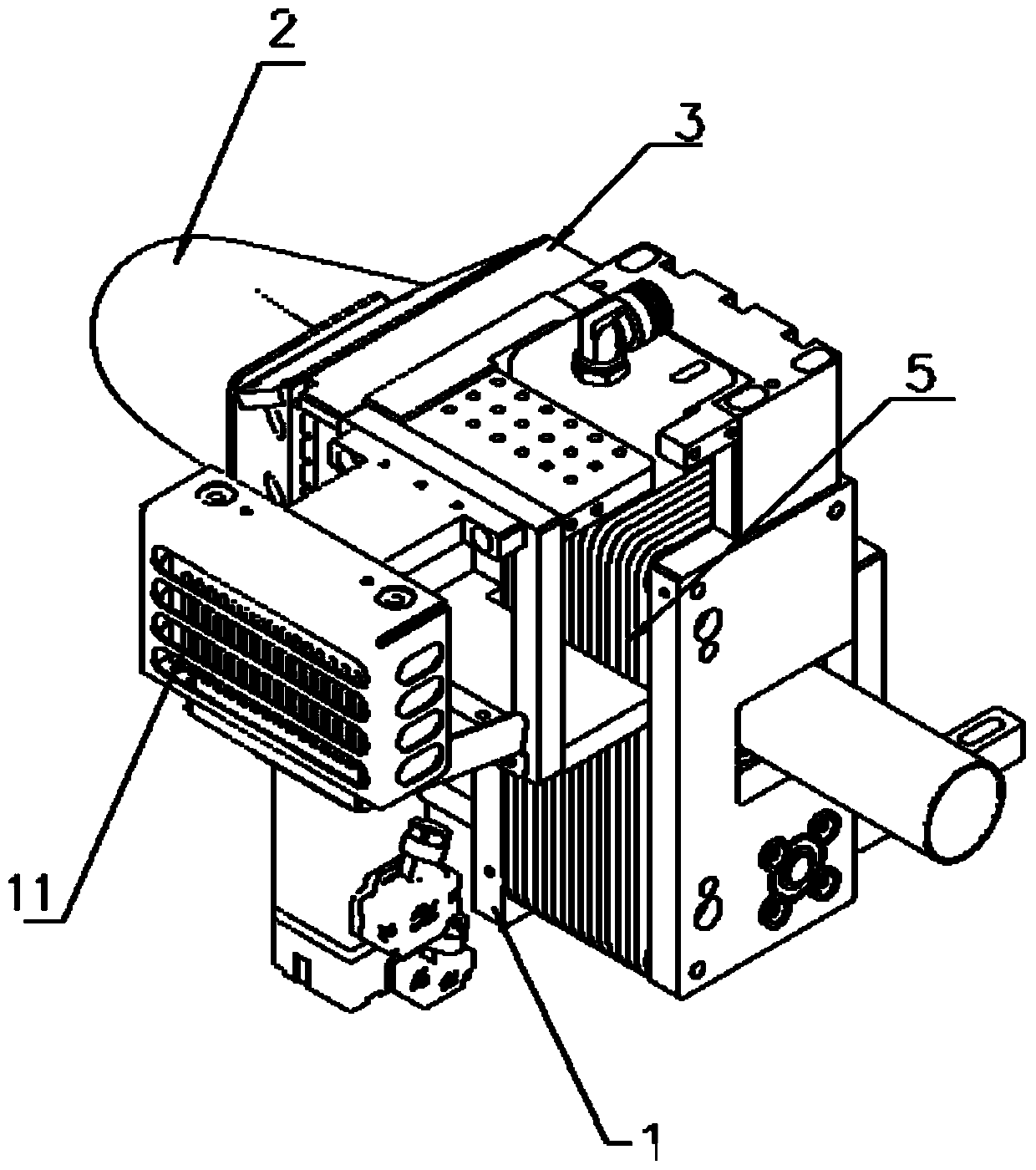

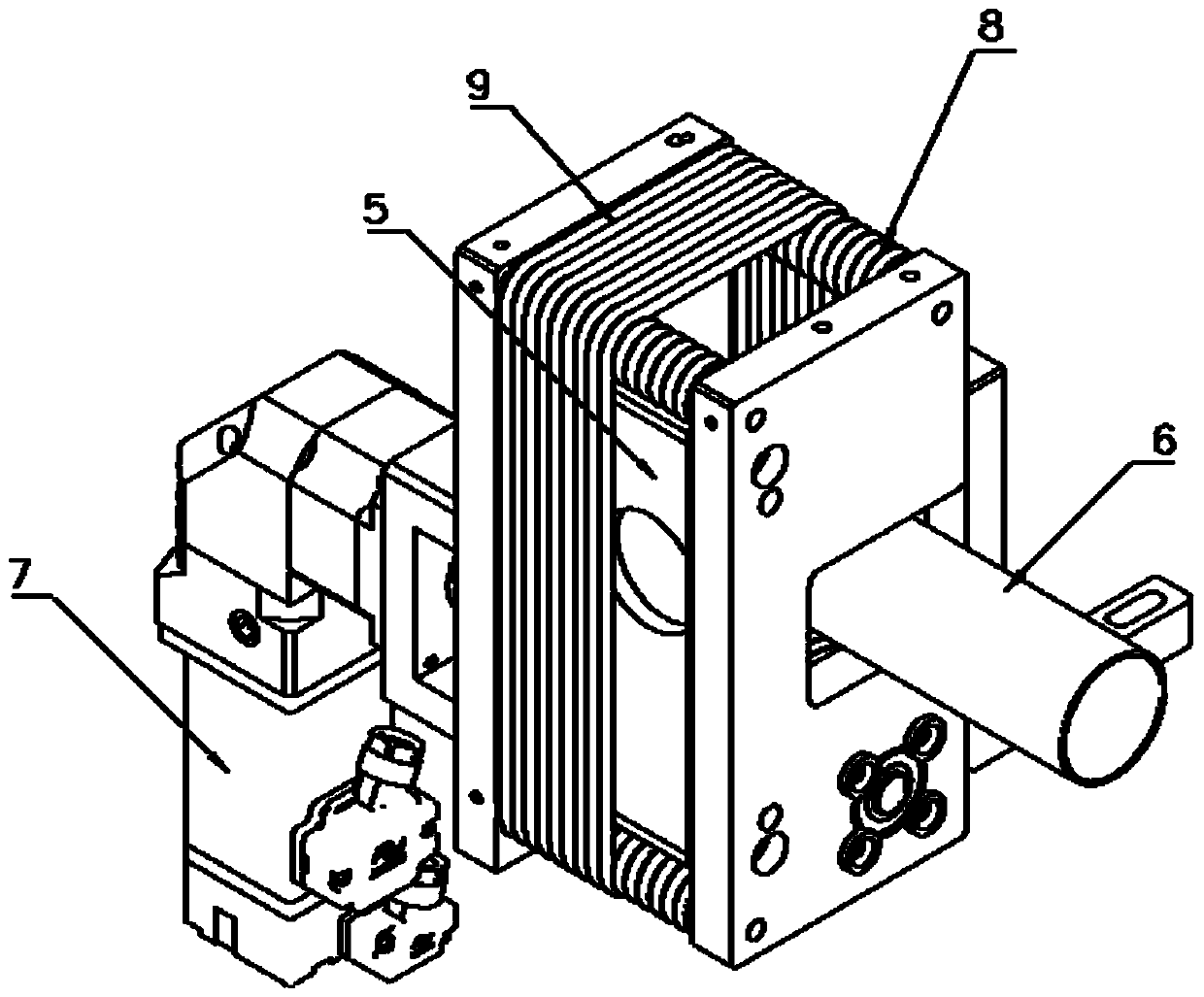

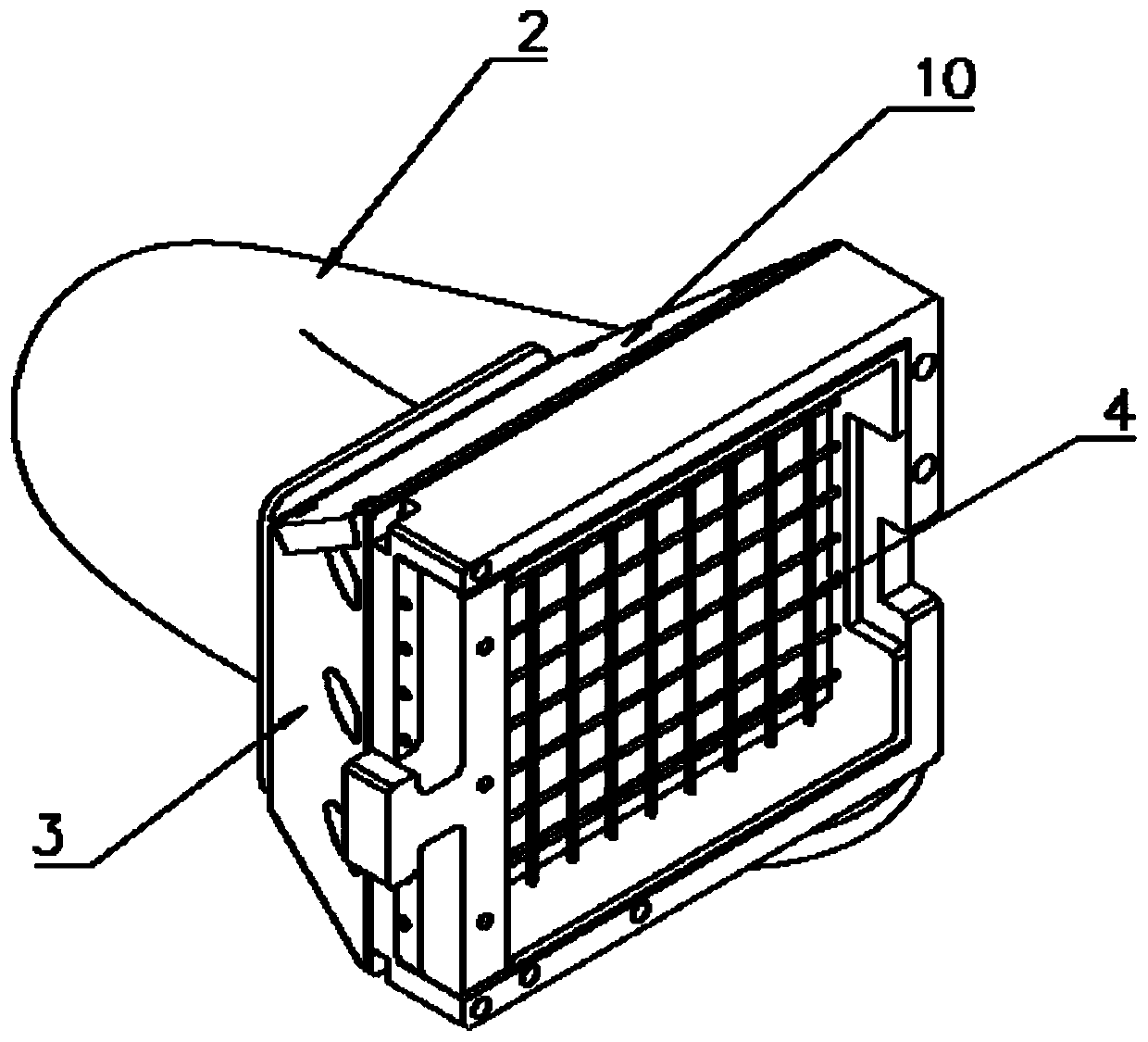

[0030] A lithium battery pole piece lug cutting dust removal device, such as Figure 1 to Figure 3 As shown, it includes a body 1, a dust removal pipe 2 and a suction fan. The body 1 is provided with a dust removal chamber 3, and the dust removal chamber 3 is provided with a filter screen on the side facing the processing area of the lithium battery pole piece lug cutting equipment. 4. The dust removal pipe 2 is arranged on the side of the dust removal cavity 3 opposite to the filter screen 4, and the dust removal pipe 2 is connected to the suction fan.

[0031] When the lithium battery tab tab cutting equipment is cutting, the dust removal chamber 3 sucks the dust generated during the tab cutting process into the dust removal chamber 3 through the suction force generated by the suction fan, and the dust removal chamber 3 is sealed and connected with the dust removal pipe 2 To prevent dust from leaking, the filter screen 4 provided on the dust removal chamber 3 can prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com