Packaging bag feeding, taking and supporting equipment and method

A technology for packaging bags and supplying bags, which is applied in the field of bag supplying, taking, and holding bag equipment, and packaging bag supplying, taking, and bagging equipment fields, can solve the problems of unsmooth suction of packaging bags, easy falling off of packaging bags, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

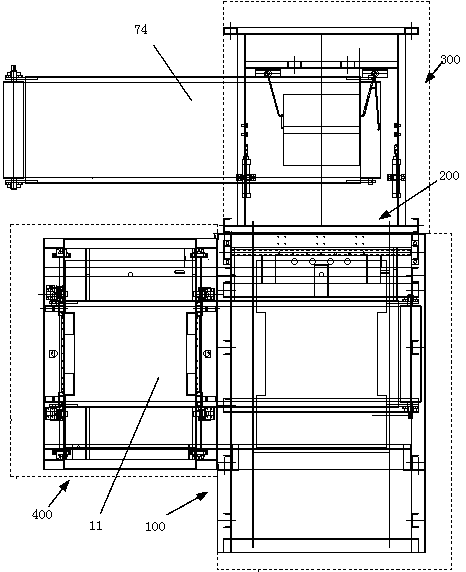

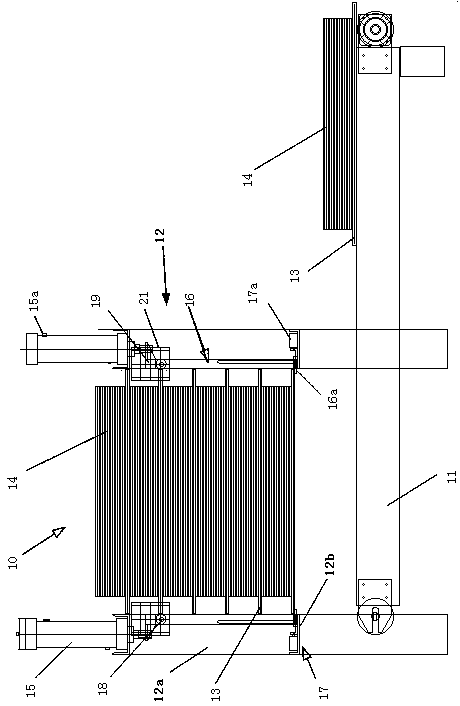

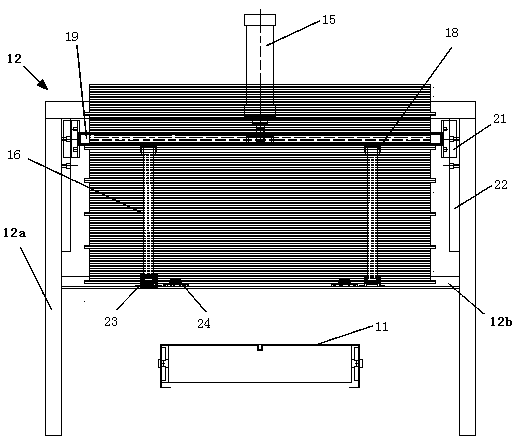

[0087] Below with reference to the accompanying drawings, the specific technical solutions of the present invention will be described. In the following description, the side of the conveyor belt away from the product conveyor belt will be regarded as the front of the equipment, and the conveying direction of the conveyor belt, that is, the X direction, will be regarded as the left-right direction, which is perpendicular to the left-right direction. The Y direction of the storage frame is described as the depth direction of the storage frame. The forward direction of the chain mechanism is regarded as the rear end or rear of the equipment, and the starting point side of the chain mechanism is regarded as the front of the equipment. In this state, the left side of the operator is the left side of the equipment, and the right side of the operator is the right or right side of the equipment.

[0088] The technical solution of the present invention is a packaging bag feeding, taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com