Precision machining tool and method for integral ribbed wallboard

A technology of precision machining and paneling, applied in metal processing equipment, metal processing machinery parts, workpieces, etc., can solve the problems of thickness, rib height deviation, and difficulty in guaranteeing machining accuracy deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

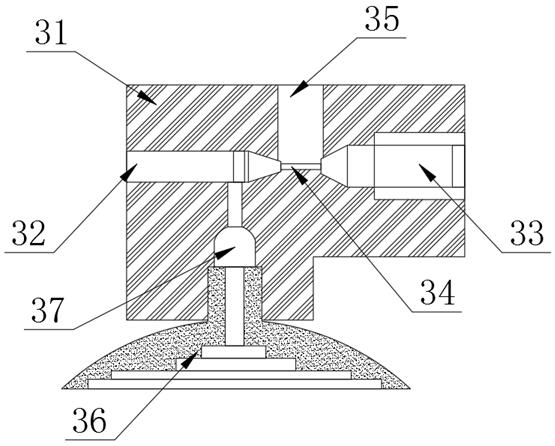

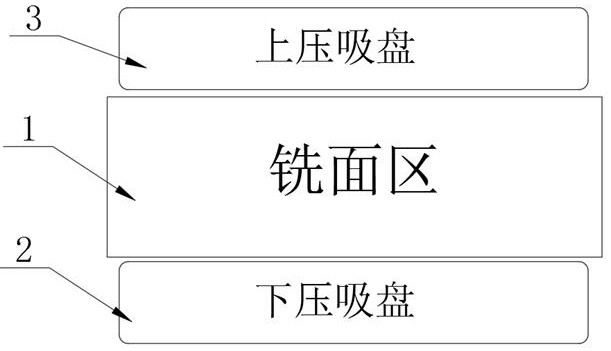

[0028] The invention provides a precision machining tool for an integral ribbed wallboard, which includes a milling area 1 and a vacuum storage tank 4, the two sides of the milling area 1 are respectively provided with a lower pressure suction cup 2 and an upper pressure suction cup 3, and the vacuum One side of the storage tank 4 is provided with a vacuum pump 5, and a pipeline is connected between the milling area 1, the lower pressure suction cup 2, the upper pressure suction cup 3 and the vacuum pump 5, and the vacuum storage tank 4. The pipelines between the suction cup 2, the upper pressure suction cup 3 and the vacuum storage tank 4 are set in two ways, one pipeline is connected with the lower pressure suction cup 2 and the upper pressure suction cup 3 respectively, the other pipeline is connected with the milling area 1, and the two pipelines are connected to each other. All are fixedly equipped with electromagnetic control valves 6, and the lower pressure suction cup 2...

Embodiment 2

[0036] The invention provides a precision machining tool for an integral ribbed wallboard, which includes a milling area 1 and a vacuum storage tank 4, the two sides of the milling area 1 are respectively provided with a lower pressure suction cup 2 and an upper pressure suction cup 3, and the vacuum One side of the storage tank 4 is provided with a vacuum pump 5, and a pipeline is connected between the milling area 1, the lower pressure suction cup 2, the upper pressure suction cup 3 and the vacuum pump 5, and the vacuum storage tank 4. The pipelines between the suction cup 2, the upper pressure suction cup 3 and the vacuum storage tank 4 are set in two ways, one pipeline is connected with the lower pressure suction cup 2 and the upper pressure suction cup 3 respectively, the other pipeline is connected with the milling area 1, and the two pipelines are connected to each other. All are fixedly equipped with electromagnetic control valves 6, and the lower pressure suction cup 2...

Embodiment 3

[0045] The invention provides a precision machining tool for an integral ribbed wallboard, which includes a milling area 1 and a vacuum storage tank 4, the two sides of the milling area 1 are respectively provided with a lower pressure suction cup 2 and an upper pressure suction cup 3, and the vacuum One side of the storage tank 4 is provided with a vacuum pump 5, and a pipeline is connected between the milling area 1, the lower pressure suction cup 2, the upper pressure suction cup 3 and the vacuum pump 5, and the vacuum storage tank 4. The pipelines between the suction cup 2, the upper pressure suction cup 3 and the vacuum storage tank 4 are set in two ways, one pipeline is connected with the lower pressure suction cup 2 and the upper pressure suction cup 3 respectively, the other pipeline is connected with the milling area 1, and the two pipelines are connected to each other. All are fixedly equipped with electromagnetic control valves 6, and the lower pressure suction cup 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com