Biodegradable plastic master batch

A technology for biodegradable plastics and masterbatches, which is applied in the field of degradable plastic raw materials, can solve the problems of poor use effect and cannot be double-degraded, and achieves the effects of low production cost, good mechanical properties and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

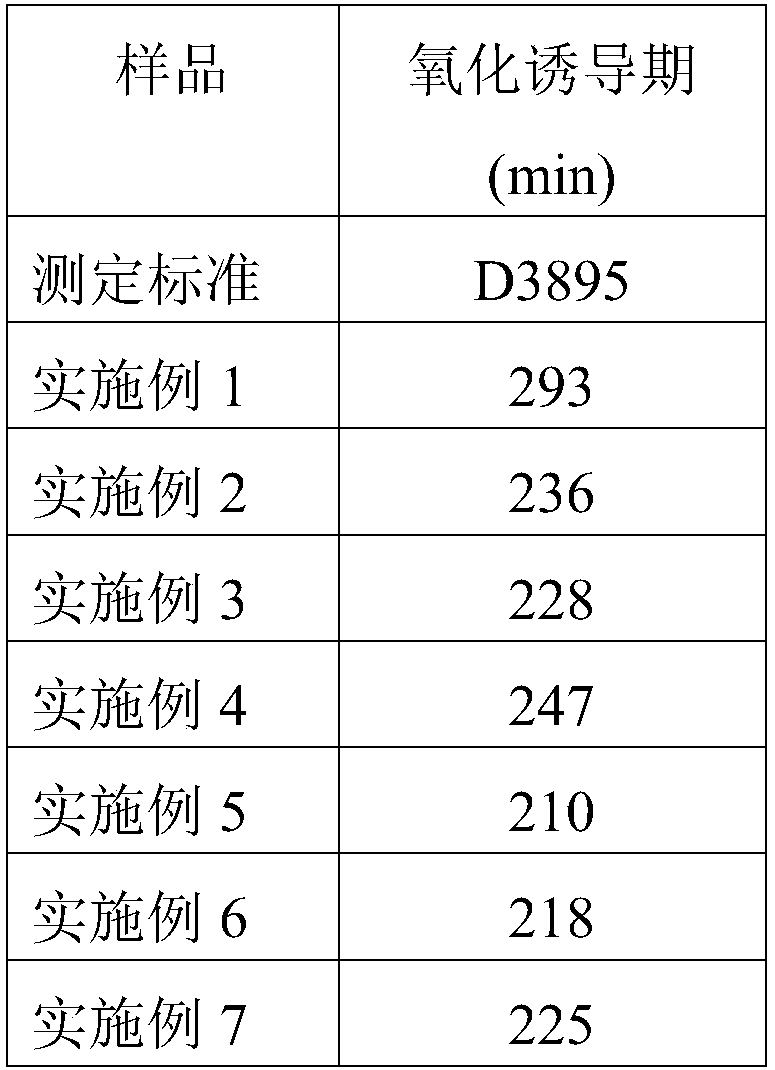

Examples

Embodiment 1

[0026] Biodegradable plastic masterbatch raw materials (parts by weight): 30 parts of low-density polyethylene, 30 parts of bentonite, 10 parts of chlorinated paraffin, 1.5 parts of epoxy butyl stearate, tetraisopropyl di(dioctyl phosphite) 0.2 parts of titanate, 0.6 parts of dispersant, and 1.5 parts of antioxidant.

[0027] The dispersant is obtained by uniformly stirring and mixing calcium arachidate, zinc stearate and zinc myristate in a mass ratio of 1:1:1.

[0028] The antioxidant is obtained by uniformly stirring and mixing 2,6-di-tert-butyl-p-cresol, tert-butylhydroquinone and ethoxyquinoline at a mass ratio of 1:1:1.

[0029] Preparation of biodegradable plastic masterbatch:

[0030] (1) take each component according to weight ratio;

[0031] (2) Add low-density polyethylene, bentonite, chlorinated paraffin, epoxy butyl stearate, tetraisopropyl bis(dioctyl phosphite) titanate, dispersant, and antioxidant into the high-speed mixer Mixing, the mixing speed is 86 rpm,...

Embodiment 2

[0034] It is basically the same as Example 1, except that the dispersant is obtained by stirring and mixing zinc stearate and zinc myristate at a mass ratio of 1:1. Obtain the biodegradable plastic masterbatch of embodiment 2.

Embodiment 3

[0036] It is basically the same as Example 1, except that the dispersant is obtained by stirring and mixing evenly calcium arachidic acid and zinc myristate at a mass ratio of 1:1. Obtain the biodegradable plastic masterbatch of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com