Industrial production method for trioctyl phosphate

A technology of trioctyl phosphate and octanol, applied in chemical instruments and methods, organic chemistry, chlorine/hydrogen chloride, etc., can solve problems such as inconvenience in industrial production, safety risks, inconvenient storage, etc., to reduce the degree of emulsification, increase the Product purity, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and drawings, but it is not intended to further limit the present invention.

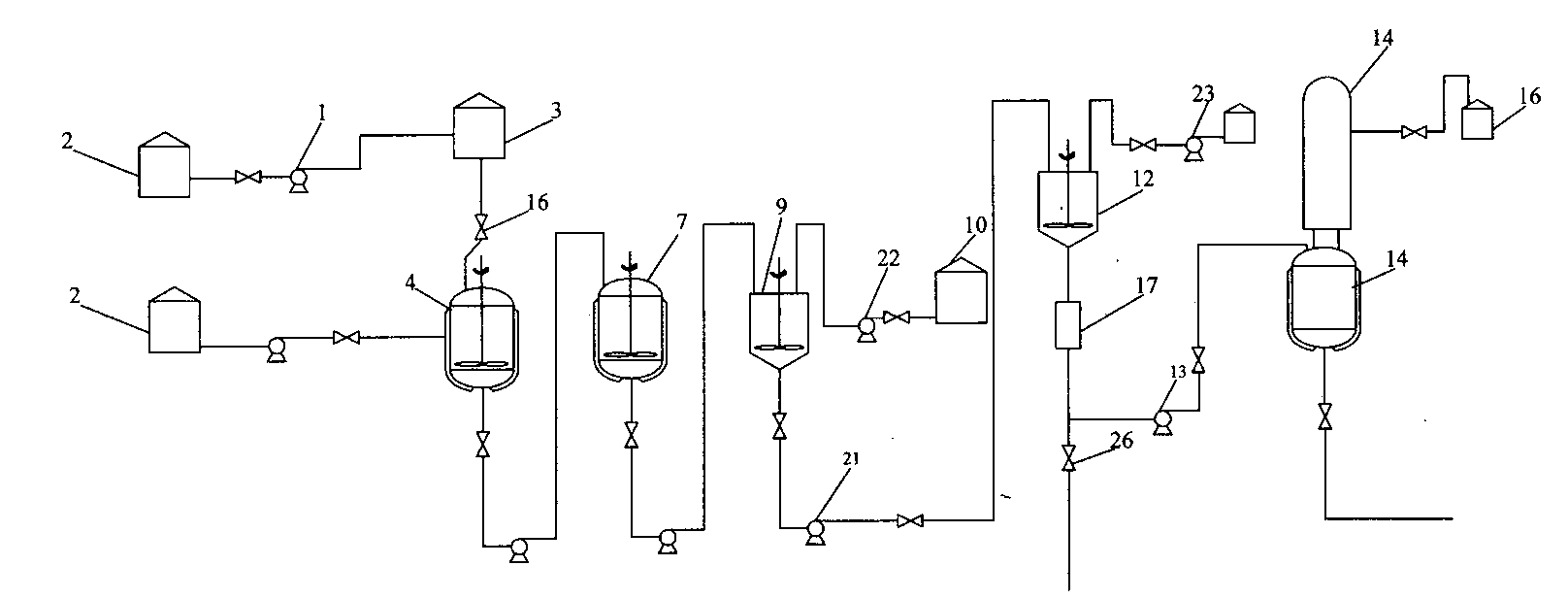

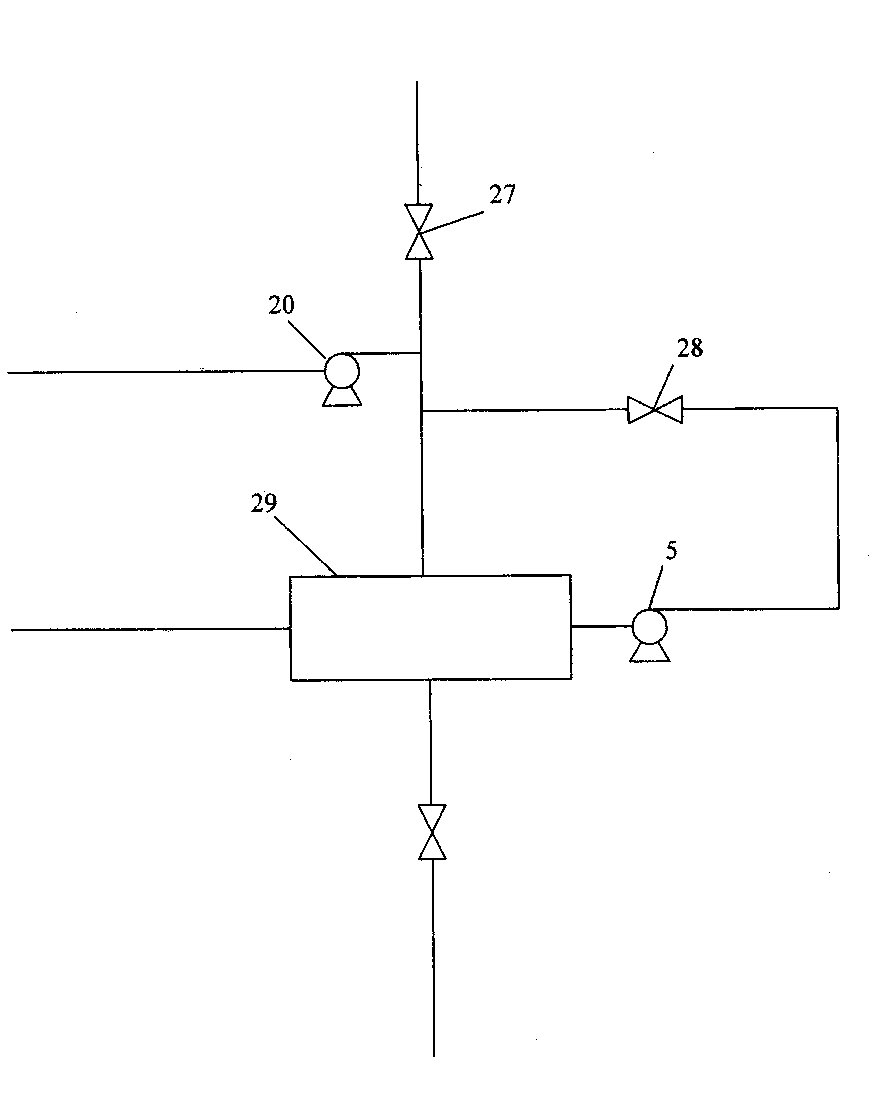

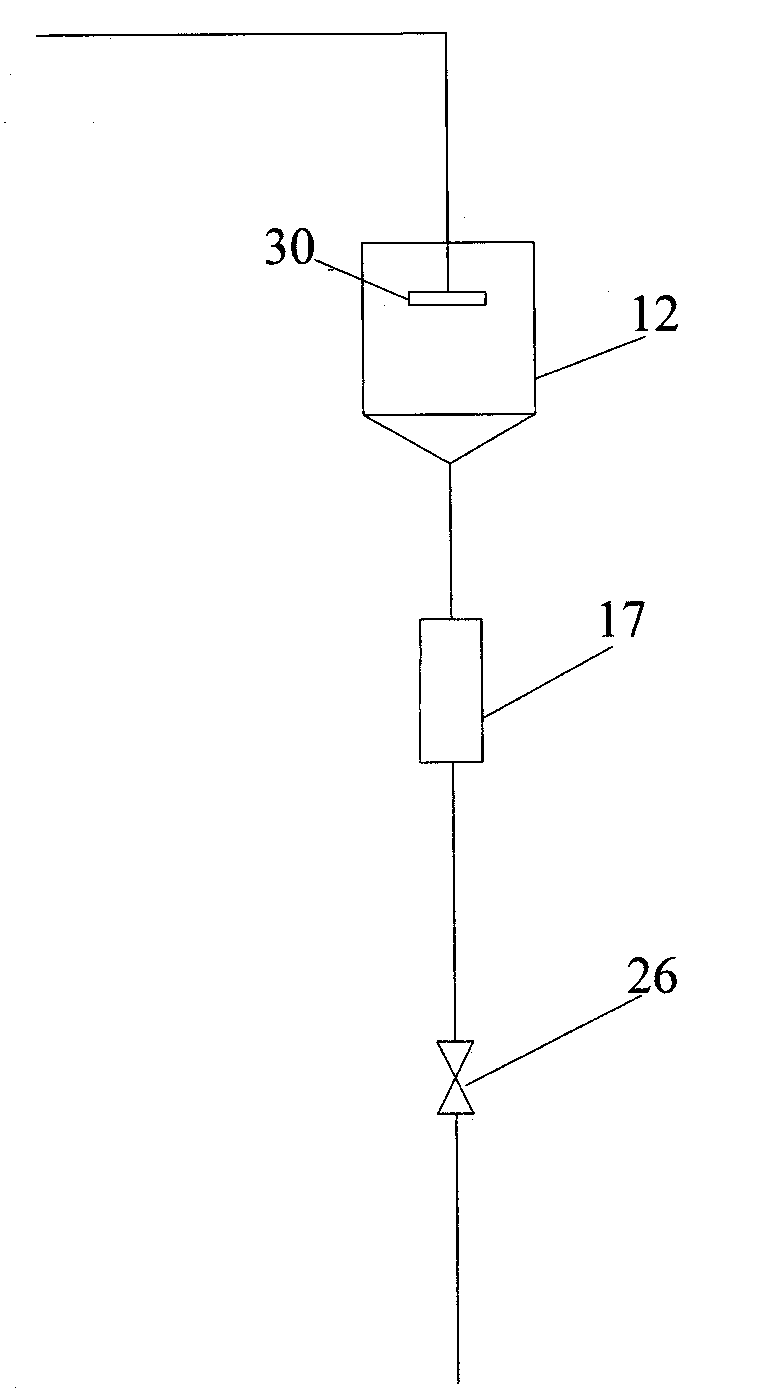

[0027] As attached to the manual figure 1 As shown, the industrial production process of trioctyl phosphate of the present invention mainly consists of centrifugal pump 1, octanol storage tank 2, octanol metering tank 3, mixing kettle 4, frozen brine pump 5, frozen brine device 6, esterification kettle 7, steam pipeline 8, neutralization kettle 9), alkali water tank 10, hydrogen chloride recovery device 11, washing device 12, vacuum pump 13, rectification kettle 14, condenser 15, alcohol-water separator 16, lens 17, etc.

[0028] Wherein, the centrifugal pump 1 draws octanol from the octanol storage tank 2 into the octanol metering tank 3, opens the valve 18, and adds the octanol in the octanol metering tank 3 to the mixing tank 4. The frozen brine in the frozen brine device 6 enters the jacket of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com