High-temperature-resistance and antioxidant infrared low-emissivity composite film and preparation method thereof

A composite film, low emissivity technology, applied in the field of infrared stealth, to achieve the effects of high melting point, simple film production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

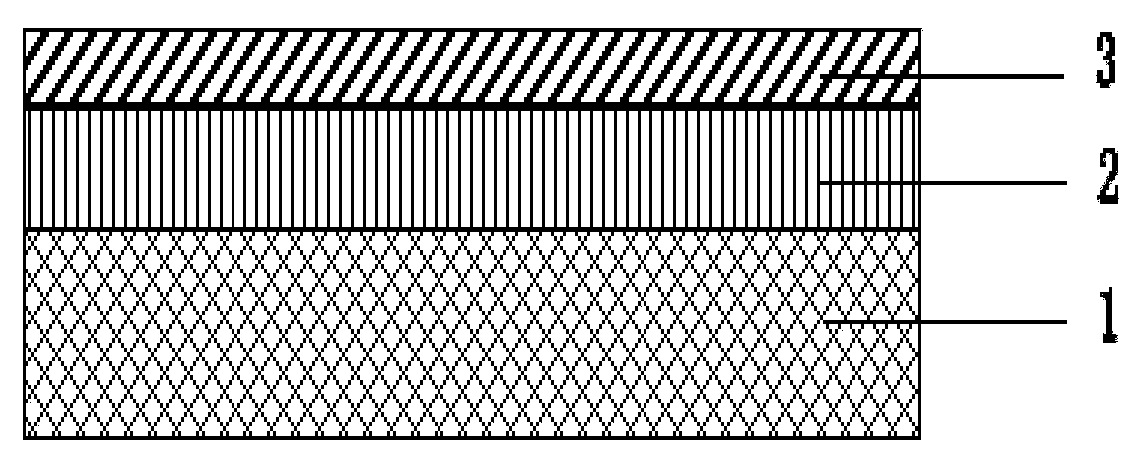

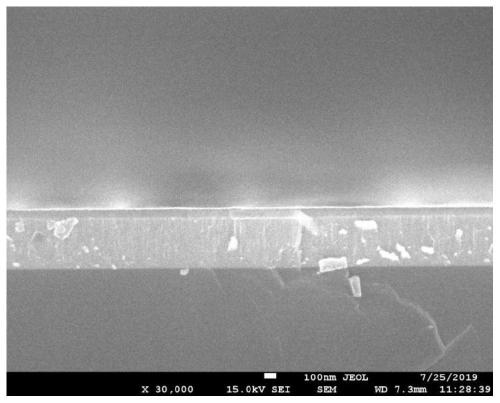

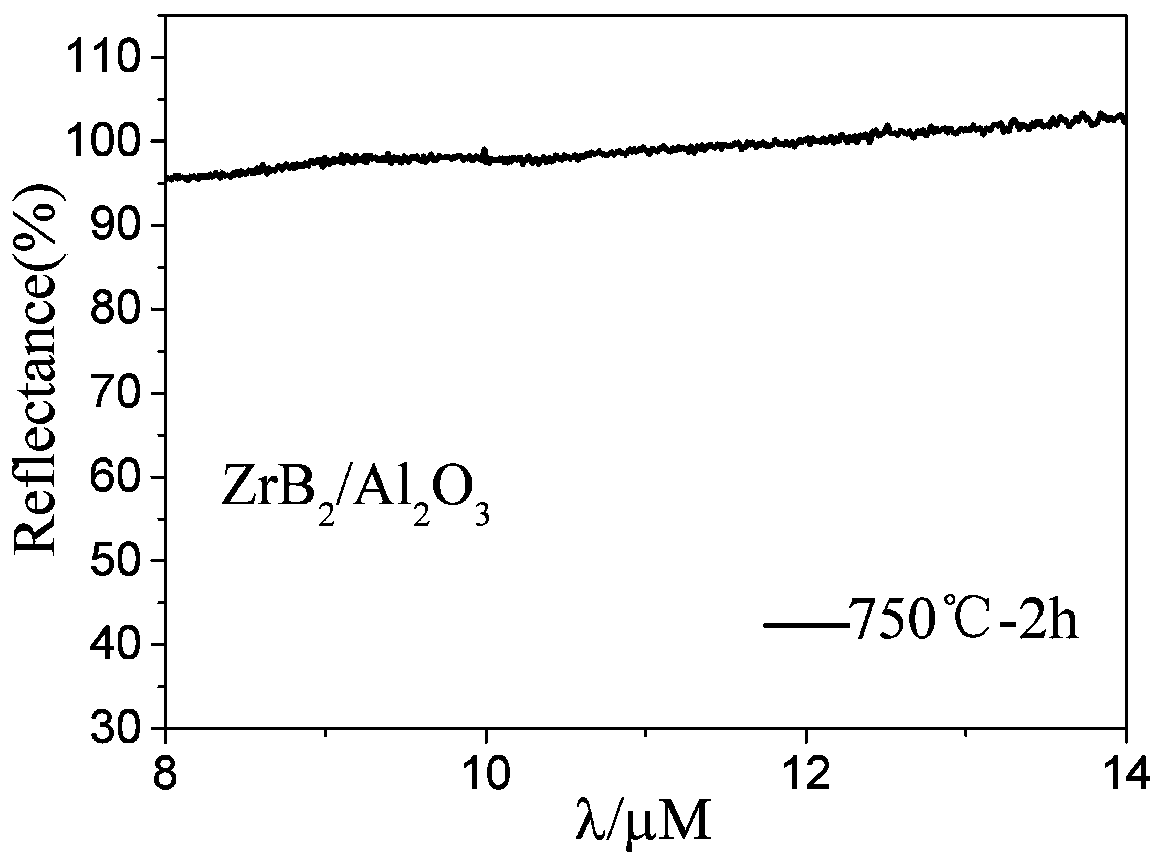

[0019] Embodiment: A high temperature resistant, anti-oxidation infrared low emissivity composite film is a multi-functional layer superimposed structure, which successively includes a low emissivity functional layer 2, an oxidation protection film 3, and 1 is the surface of the target object; each layer Among them, mechanical bonding is the main bonding method, and the low-emissivity functional layer 2 is ZrB 2 Thin film, oxide protection film 3 is Al 2 o 3 film. The infrared low emissivity composite thin film of this embodiment is deposited on the Si substrate (1).

[0020] In the embodiment, the thickness of the low-emissivity functional layer is 400 nm, and the thickness of the oxidation protection film is 70 nm. The low-emissivity functional layer thickness is prepared by DC magnetron sputtering method, and the target material used is ZrB 2 Target (purity 99.99%), the oxidation protection film adopts radio frequency magnetron sputtering method to prepare, and used tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com