Method for producing Ni-Al bimetal composite material solid core wire material

A composite material and bimetal technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of large difference in specific gravity of nickel-aluminum two-phase elements, difficulty in metallurgical melting, and influence on coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

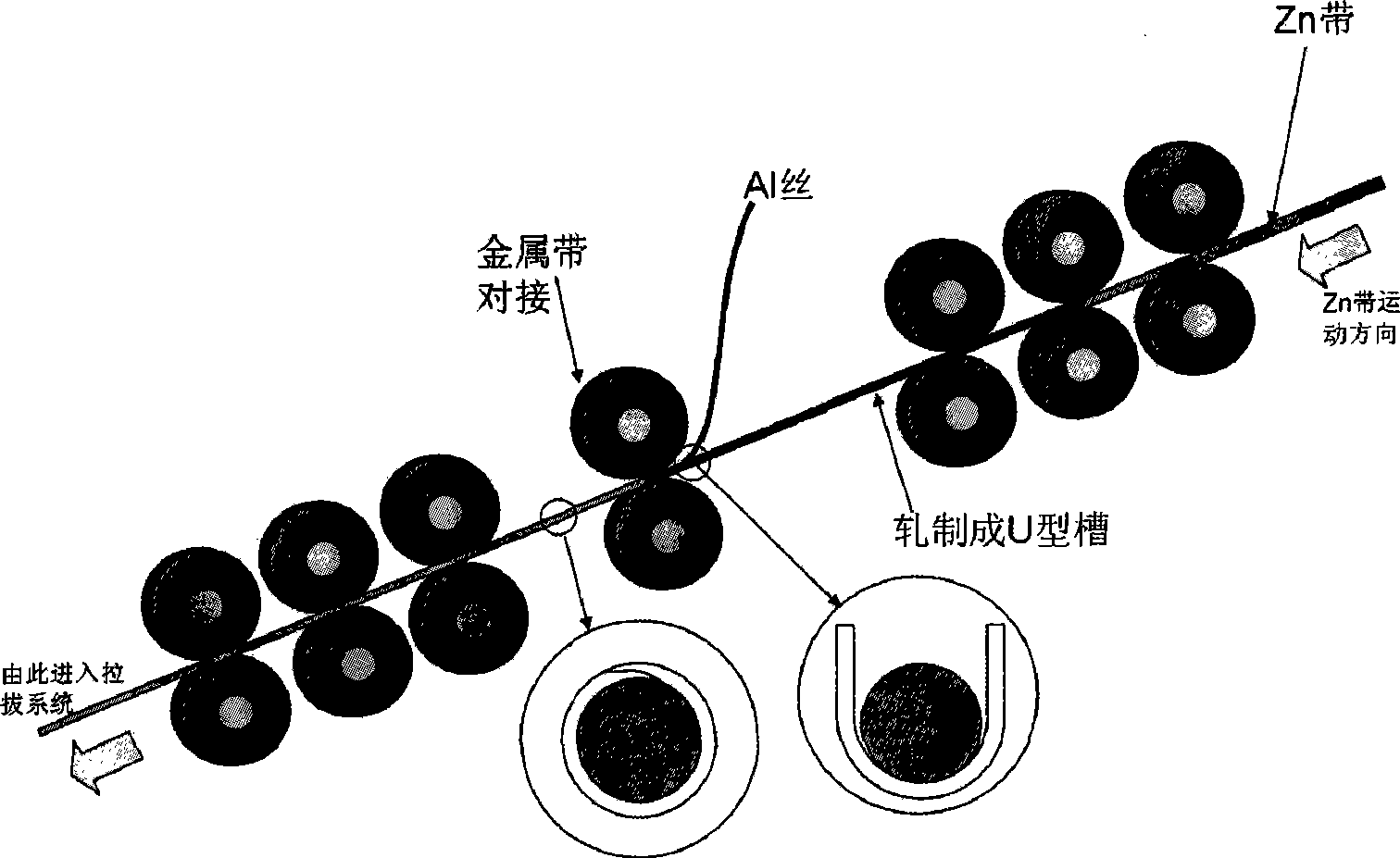

Embodiment 1

[0016] The nickel-aluminum-alloy strip of outer cladding selects the Ni alloy strip of 10 * 0.4 (width 10mm, thickness 0.4mm) for use, according to the present invention it is rolled into " U " shape. Before the "U"-shaped skin enters the butt roll, the φ1.0mm solid nickel wire is fed into the "U" groove. After passing the butt roll, the U-shaped groove closes, and the filling rate is 95%. Then perform multi-channel drawing and diameter reduction, and finally form a φ2.0mm bimetallic composite wire. The characteristic of the nickel-aluminum composite wire is that the aluminum content is 5% (mass fraction).

Embodiment 2

[0018] The outer wrapping strip selects the Ni strip of 10 * 0.4 (width 10mm, thickness 0.4mm) for use, according to the present invention the nickel strip is rolled into " U " shape. Before the "U"-shaped skin enters the butt roll, the φ1.0mm solid nickel wire is fed into the "U" groove. After passing through the butt roll, the U-shaped groove closes, and the filling rate is 75%. Then perform multi-channel drawing and diameter reduction, and finally form a φ2.0mm bimetallic composite wire. The characteristic of the nickel-aluminum composite wire is that the aluminum content is 22% (mass fraction).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com