Bone-like hierarchical pore ceramic-based photo-thermal storage material and preparation method thereof

A technology for storing materials and graded pores, applied in ceramic products, materials for heat exchange, chemical instruments and methods, etc., can solve the problems of reduced heat transfer efficiency, low final efficiency, heat loss, etc., to improve the spectral absorption rate, spectral The effect of improving the absorption rate and improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

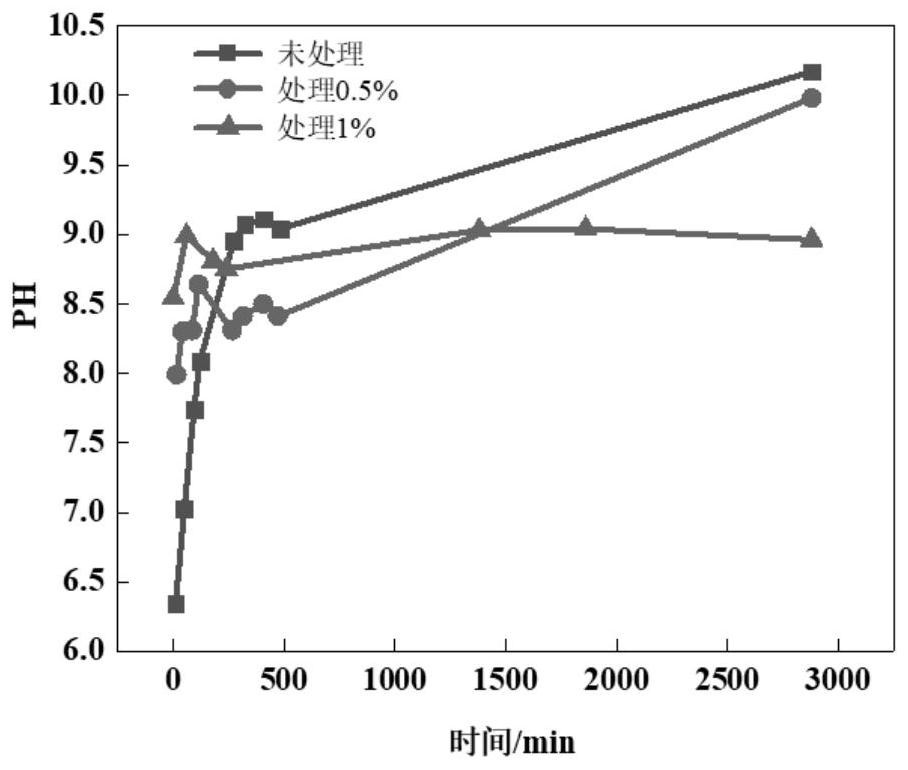

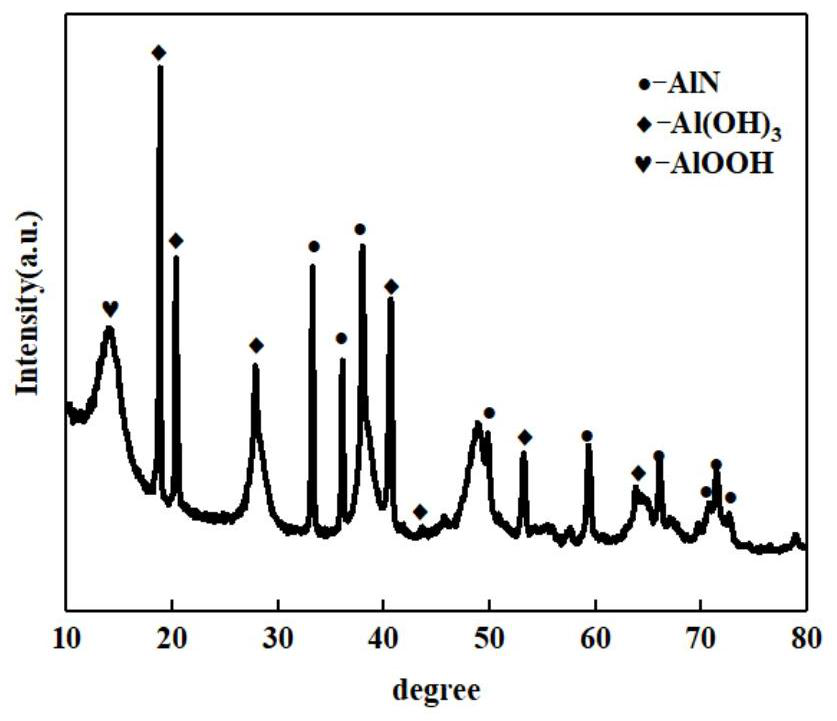

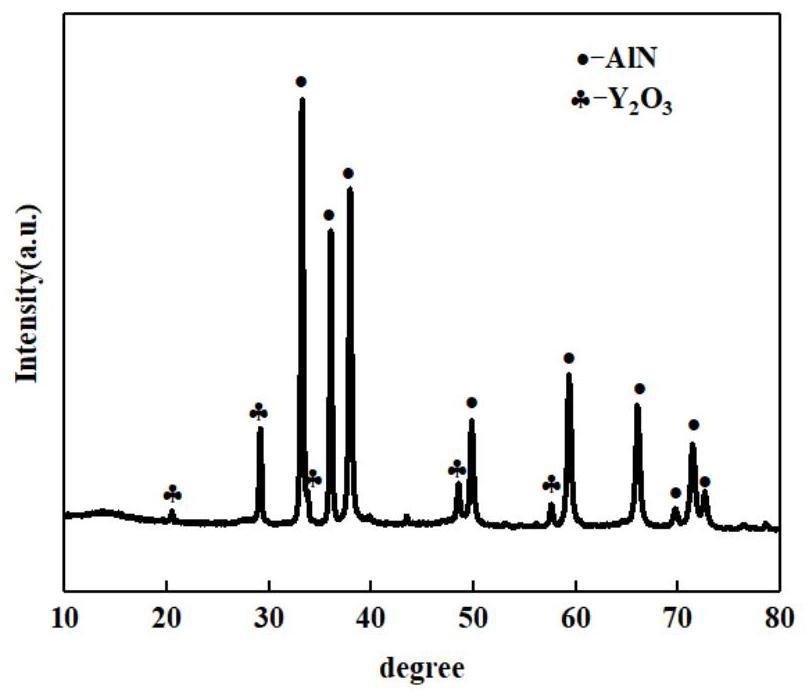

[0047] Take 1μm aluminum nitride powder, yttrium oxide, and absolute ethanol with a mass ratio of 100:3:75, respectively 35g, 1.05g, and 26.25g, and place them in a ball mill at a speed of 270rpm, and ball mill for half an hour; then add 0.2wt % ethanol dispersant polyacrylic acid, continue to ball mill at 270rpm for half an hour; then add 1wt% polyurethane and mill at 270rpm for half an hour; finally add tetraethylenepentamine and mechanically stir to make it react with polyurethane to form a water-resistant film wrapped in on aluminum nitride powder.

[0048]Then put it into an oven and dry it to make a hydration-resistant aluminum nitride powder. Take the treated aluminum nitride powder and water with a mass ratio of 73%, and weigh 0.3wt% of Ib-104 (as a gelling agent, dispersant) to mix with it and place it in a ball mill to mill half of it at 270rpm Hour.

[0049] Take out the ball-milled slurry, weigh 0.65wt% foaming agent (triethanolamine lauryl sulfate) of the taken ...

Embodiment 2

[0054] Take 2μm aluminum nitride powder, yttrium oxide, and absolute ethanol with a mass ratio of 100:3:75, respectively 35g, 1.05g, and 26.25g, and place them in a ball mill at a speed of 270rpm, and ball mill for half an hour; then add 0.2wt % ethanol dispersant polyacrylic acid, continue ball milling at 270rpm for half an hour; then add 1wt% polyurethane and mill at 270rpm for half an hour.

[0055] Finally, tetraethylenepentamine is added for mechanical stirring to make it react with polyurethane to form a water-resistant film wrapped on the aluminum nitride powder. Then put it into an oven and dry it to make a hydration-resistant aluminum nitride powder. Take the treated aluminum nitride powder and water with a mass ratio of 73%, and weigh 0.3wt% of Ib-104 (as a gelling agent, dispersant) to mix with it and place it in a ball mill to mill half of it at 270rpm Hour. Take out the ball-milled slurry, weigh 0.65wt% foaming agent (triethanolamine lauryl sulfate) of the taken...

Embodiment 3

[0058] Take 1μm silicon carbide powder, yttrium oxide, and absolute ethanol with a mass ratio of 100:3:75, respectively 35g, 1.05g, and 26.25g, and place them in a ball mill at a speed of 270rpm, and weigh the silicon carbide with a mass ratio of 70%. Powder and water, and weigh 0.3wt% of Ib-104 (as a gelling agent, dispersant) and mix it in a ball mill at 270rpm for half an hour. Take out the ball-milled slurry, weigh 0.65wt% foaming agent (triethanolamine lauryl sulfate) of the taken out slurry, pour it into the slurry, and mechanically stir at 700rpm to foam for half an hour. Pour the porous slurry after foaming into the mold, take it out from the mold after it is formed, dry it naturally for two days, place it in the air atmosphere of a muffle furnace and heat it to 650°C at a heating rate of 1°C / min. -104 all removed. Afterwards, the skeleton green body is placed in a nitrogen atmosphere of a hot-press furnace and heated to 1950°C for sintering for 4 hours to obtain a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com