Method for preparing mixture containing natural vitamin P from sea-buckthorn

A technology of natural vitamins and mixtures, which is applied to medical preparations containing active ingredients, drug combinations, and pharmaceutical formulas. It can solve problems such as high cost, easy oxidation of products, and low yield, and achieve high yield of biologically active substances. The effect of promoting human body absorption and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

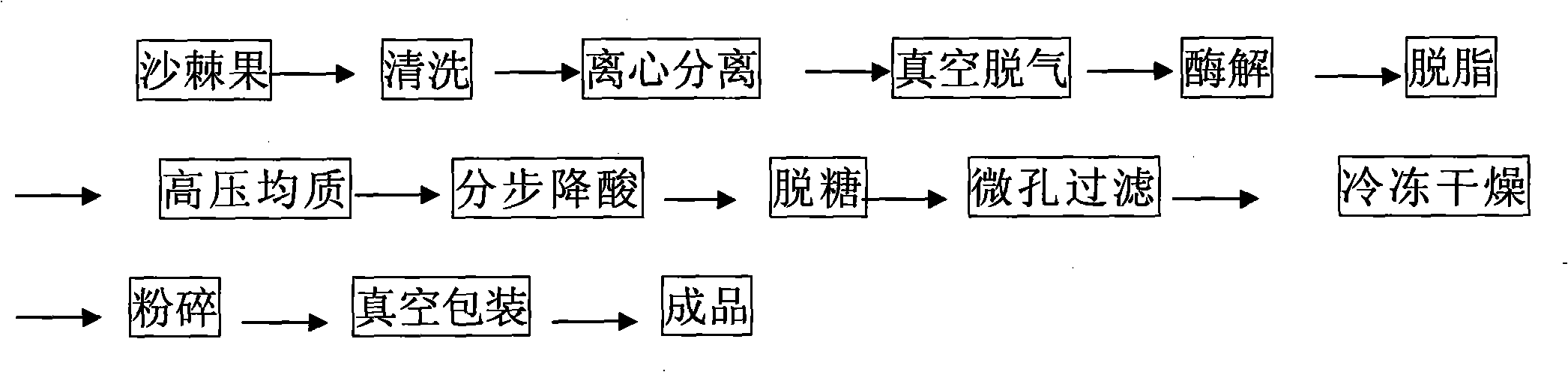

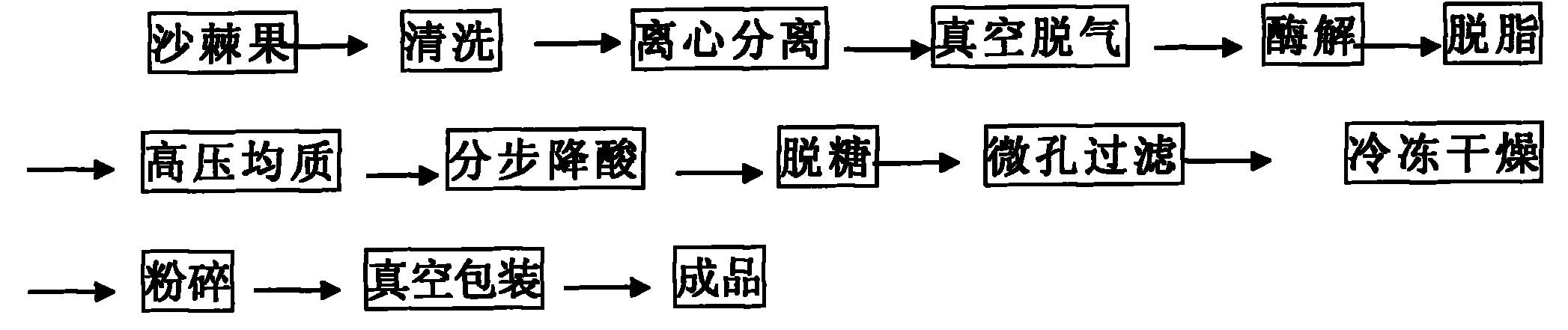

Method used

Image

Examples

Embodiment 1

[0020] (1) Juice extraction: Seabuckthorn fruit was washed and centrifuged at a speed of 3500 rpm for 10 minutes to obtain seabuckthorn juice;

[0021] (2) Degassing: take 100 kg of seabuckthorn juice obtained above and degas it under the condition of vacuum degree of 5.13 Pa and temperature of 43° C. until there is no obvious bubble under the stirring state;

[0022] (3) Enzymolysis: add 95% sodium hydroxide solution to the degassed seabuckthorn juice to adjust the pH to 3, and add pectinase in the membrane separation type enzymolysis reactor at an amount of 2 g / liter for enzymolysis 6 Hour;

[0023] (4) Degreasing: the seabuckthorn juice after enzymolysis is passed into a disc type degreasing machine for degreasing, and its content is controlled at 0.2%;

[0024] (5) Homogenization: The degreased seabuckthorn juice is homogenized twice with a high-pressure homogenizer at a temperature of 26 ° C. The first time is to homogenize under a pressure of 14 MPa for 3 hours, and the...

Embodiment 2

[0032] (1) Juice extraction: Seabuckthorn fruit was washed and centrifuged at a speed of 4000 rpm for 5 minutes to obtain seabuckthorn juice;

[0033] (2) Degassing: take 100 kg of seabuckthorn juice obtained above and degas it under the condition of vacuum degree of 5.33 Pa and temperature of 41°C until there is no obvious bubble under stirring state;

[0034] (3) Enzymolysis: add 95% sodium hydroxide solution to the degassed seabuckthorn juice to adjust the pH to 4, and add pectinase in the membrane separation type enzymolysis reactor at an amount of 4 g / liter for enzymolysis 2 Hour;

[0035] (4) degreasing: the seabuckthorn juice after enzymolysis is passed into a disc type degreasing machine for degreasing, and its content is controlled at 0.5%;

[0036] (5) Homogenization: The degreased seabuckthorn juice is homogenized twice with a high-pressure homogenizer at a temperature of 40°C. The first time it is homogenized under a pressure of 16.4 MPa for 5 hours, and the secon...

Embodiment 3

[0044] (1) Juice extraction: Seabuckthorn fruit was washed and centrifuged at a speed of 4500 rpm for 8 minutes to obtain seabuckthorn juice;

[0045] (2) Degassing: take 100 kg of seabuckthorn juice obtained above and degas it under the condition of 5.2 Pa in vacuum and 42° C. until the stirring state has no obvious bubbles;

[0046] (3) Enzymolysis: add 95% sodium hydroxide solution to the degassed seabuckthorn juice to adjust the pH to 3.5, and add pectinase in an amount of 3 g / liter to the membrane separation type enzymolysis reactor for enzymolysis 4 Hour;

[0047] (4) Degreasing: the seabuckthorn juice after enzymolysis is passed into a disc type degreasing machine for degreasing, and its content is controlled at 0.35%;

[0048] (5) Homogenization: The degreased seabuckthorn juice is homogenized twice with a high-pressure homogenizer at a temperature of 35°C. The first time is to homogenize under a pressure of 15 MPa for 4 hours, and the second time is to homogenize at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com