Burner used for gasifier

A gasification furnace and gasification agent channel technology, applied in the direction of granular/powdered fuel gasification, injection device, liquid injection device, etc., can solve the problem of increasing the complexity, danger, and poor cooling effect of the gasification furnace operation program , increase operating time and other issues, to avoid dew point corrosion and high temperature creep conditions, facilitate production and installation, and avoid high temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

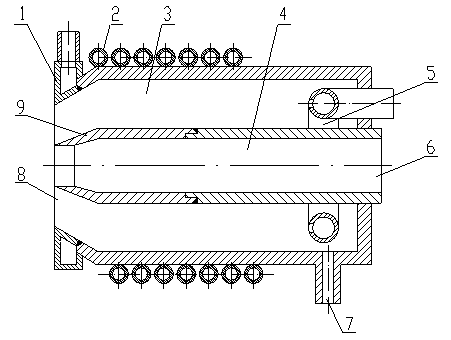

[0069] See figure 1 : A burner for a gasifier. The burner includes a fuel channel 4 coaxial with the gasification agent channel 3 and directly sleeved inside the gasification agent channel 3, the input end of the fuel channel 4 is a fuel input port 6, and the outlet end of the fuel channel 4 is fixedly connected with a burner Nozzle 9, the input end of the gasification agent channel 3 is the gasification agent input port 7, the outlet end of the gasification agent channel 3 is the air injection port 8, and the outside of the gasification agent channel 3 is provided with a cooling water jacket 10 or a cooling water pan Tube 2. In this embodiment, a cooling water coil 2 is arranged outside the gasification agent passage 3, and a jacket 1 on the front face of the burner is arranged on the top of the burner.

[0070] There is a through hole in the center of the jacket 1 on the front face of the burner, which exposes the gas injection port 8 at the front end of the burner gasific...

Embodiment 2

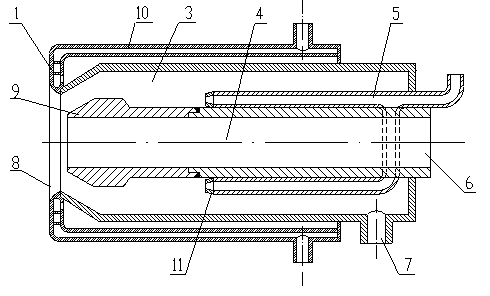

[0077] See figure 2 : a cooling water jacket 10 is arranged outside the gasifying agent channel 3 . The cooling pipe 5 is connected in parallel by at least two straight pipes and installed in the gasification agent passage 3, wherein the coolant input port of the cooling pipe 5 is located outside the gasification agent passage 3, and the coolant output port is configured as a nozzle 11 , and located in the gasification agent channel 3. When the cooling water atomized by the nozzle 11 is sprayed to the burner fuel channel 4 and the burner nozzle 9 at its front end, it is blocked by the tapered inner wall of the gas injection port 8 of the gasification agent channel 3 to form a turbulent water ring. Coated on the 9 parts of the nozzle of the burner, and sprayed onto the jacket 1 part of the front face of the burner, and finally sprayed into the furnace and converted into water vapor by the high temperature in the furnace. All the other are the same as the first embodiment.

Embodiment 3

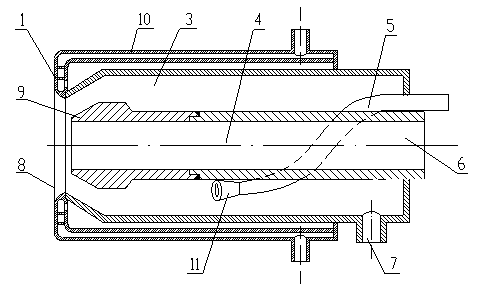

[0079] See image 3 : a cooling water jacket 10 is arranged outside the gasifying agent channel 3 . The cooling pipe 5 is a spiral pipe wound on the outer peripheral wall of the fuel passage 4 . The cooling water input port of the spiral cooling pipe 5 is located outside the gasification agent channel 3, and the coolant output port is structured as a nozzle 11 and is located in the gasification agent channel 3. When the atomized cooling water is sprayed into the burner fuel channel 4 When the burner nozzle 9 at the front end is blocked by the conical inner wall of the gas injection port 8 of the gasification agent channel 3, a turbulent water ring is formed, which covers the burner nozzle and sprays to the jacket of the front face of the burner , and finally sprayed into the furnace and converted into water vapor by the high temperature in the furnace. All the other are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com