Ceramic-based high-thermal-conductivity composite phase-change heat storage material and preparation method thereof

A technology of composite phase change and heat storage materials, which is applied in the field of ceramic-based high thermal conductivity composite phase change heat storage materials and preparation, can solve the problems of expensive nano-scale adsorption materials, high graphite packaging technology, and potential safety hazards, etc. The effect of low expansion rate, uniform distribution and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another aspect of the present invention also provides a preparation method of a ceramic-based high thermal conductivity composite phase change heat storage material, including:

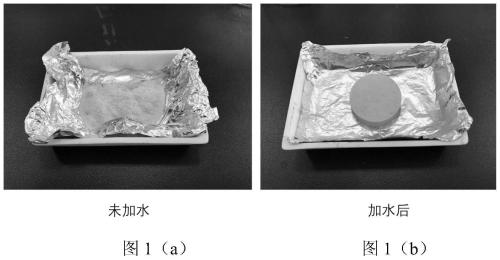

[0039] (1) Weigh the inorganic salt and aluminum nitride according to the proportion of the formula, stir evenly, add water and mix them, and form them to prepare the precursor of the composite phase change heat storage material;

[0040] (2) The precursor prepared in step (1) is sealed and packaged, and placed in a blast drying oven for low-temperature reaction to prepare a green body;

[0041] (3) The green body prepared in step (2) is placed in a muffle furnace, the temperature is raised by program, and heated and sintered to obtain a ceramic-based high thermal conductivity composite phase-change heat storage material.

[0042] Further, the raw materials of the formula are: 50%-70% of inorganic salt, 20-50% of aluminum nitride, and 5%-15% of water according to mass percentage.

[0043] Furt...

Embodiment 1

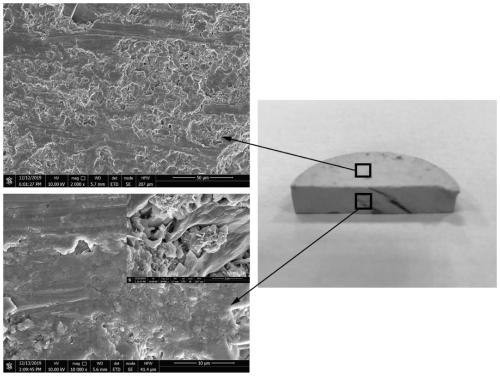

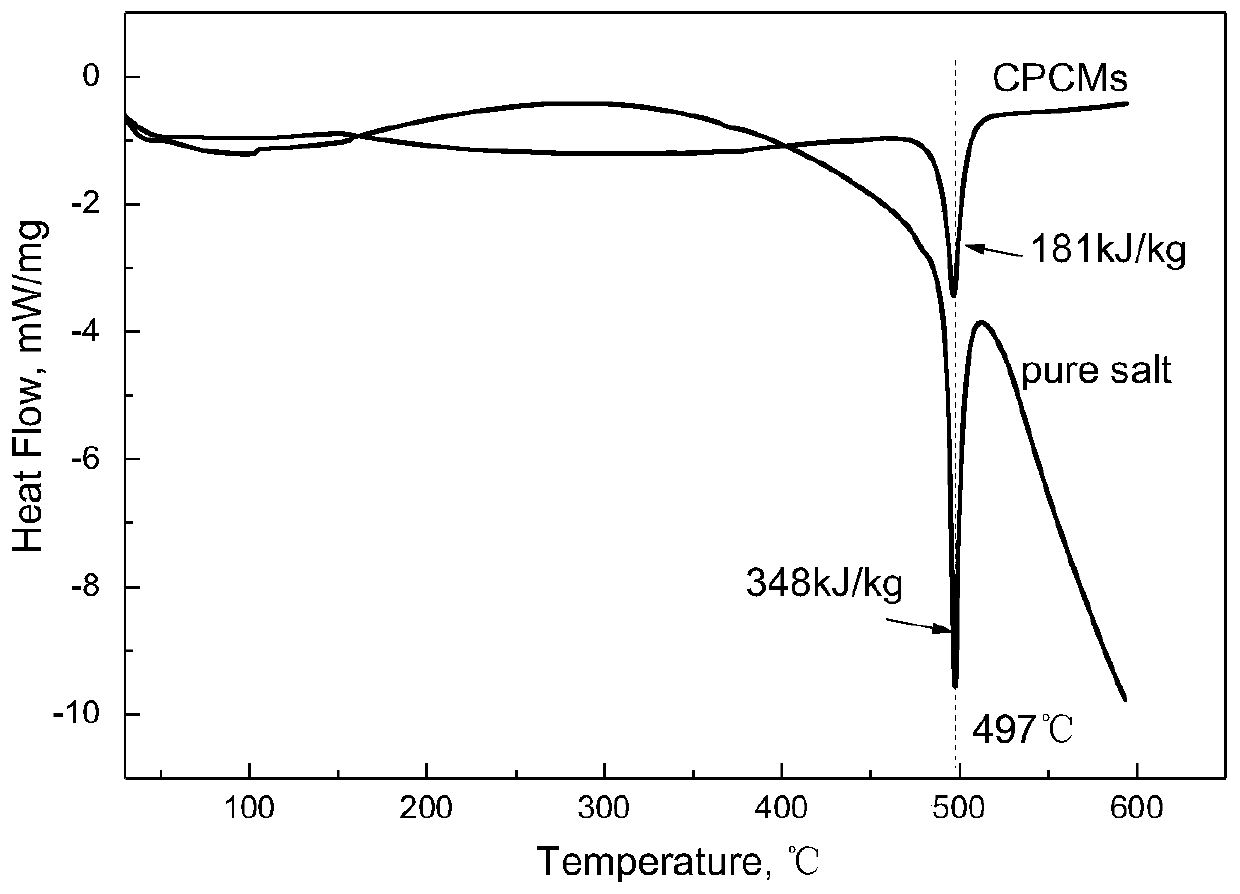

[0050] A ceramic-based high thermal conductivity composite phase change heat storage material, the preparation process is: weigh 2.6g Li 2 CO 3 , 3.4gNa 2 CO 3 1. Put 4g of AlN powder into the powder machine and stir evenly, then take 1g of water and add it into the powder machine and mix well. The obtained mixed powder was pressed into shape with a press, the pressure was 30 MPa, and the holding time was 3 minutes to obtain the precursor. The precursor was sealed and packaged and placed in a blast oven for low-temperature reaction, the set temperature was 70°C, and the reaction time was 16 hours. Transfer the obtained green body to a ceramic boat, place it in a muffle furnace, raise the temperature to 105°C at a heating rate of 5°C / min, and keep it for 1 hour; then raise it to 300°C at a heating rate of 10°C / min, and hold it for 1.5 h; finally, the temperature was raised to 550°C at a heating rate of 5°C / min, and kept for 2 hours; cooled to room temperature with the furna...

Embodiment 2

[0055] A ceramic-based high thermal conductivity composite phase change heat storage material, the preparation process is: weigh 2.6g Li 2CO 3 , 3.4gNa 2 CO 3 1. Put 3g of AlN powder into the powder machine and stir evenly, then take 1g of water and add it into the powder machine and stir evenly. The obtained mixed powder was pressed into shape with a press, the pressure was 30 MPa, and the holding time was 3 minutes to obtain the precursor. The precursor was sealed and packaged and placed in a blast oven for low-temperature reaction. The set temperature was 60°C, and the reaction time was 16 hours. Transfer the obtained green body to a ceramic boat, place it in a muffle furnace, raise the temperature to 105°C at a heating rate of 5°C / min, and keep it for 1 hour; then raise it to 300°C at a heating rate of 10°C / min, and hold it for 1.5 h; finally, the temperature was raised to 550°C at a heating rate of 5°C / min, and kept for 2 hours; cooled to room temperature with the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com