Preparation method of coating composition

A composition and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

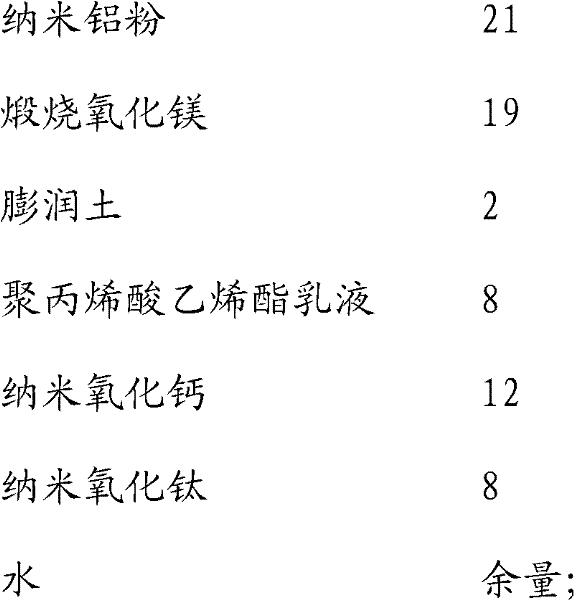

Embodiment 1

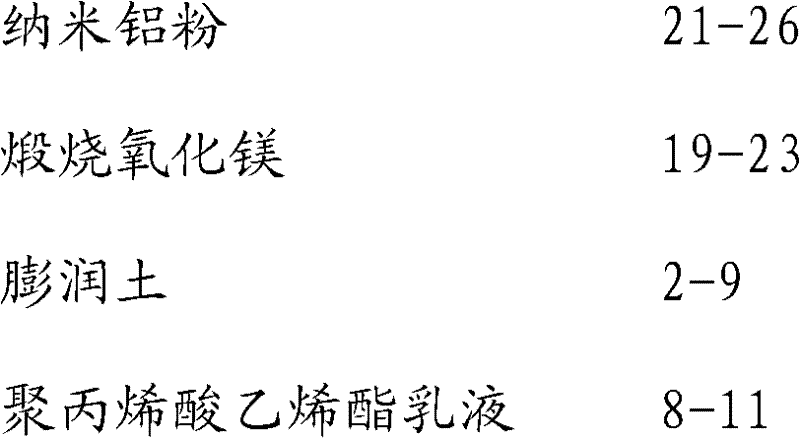

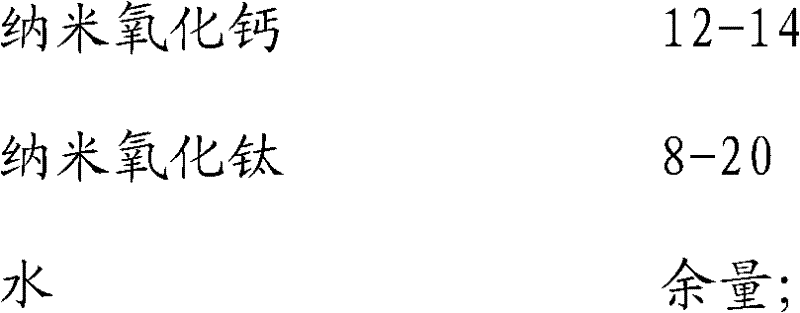

[0017] A kind of preparation method of coating composition, coating component is made of following weight components:

[0018]

[0019] Its preparation method specifically comprises the following steps:

[0020] Take polyvinyl acrylate emulsion and part of water according to the formula and add it to the container, heat it in microwave to 35°C, keep the temperature constant, then add nano-aluminum powder, calcined magnesia, bentonite, nano-calcium oxide and nano-titanium oxide in sequence under ultrasonic , sonicate for 20min, the frequency is 200HZ, the power is 650W, then add the remaining part of water, and stir for 25min under mechanical stirring, the stirring speed is 1100r / min.

[0021] Apply the above paint on A3 steel, investigate the high temperature resistance performance at 1800 degrees Celsius and test its corrosion resistance effect in 3% NaCl solution, the results are as follows:

[0022] Antiseptic effect (3% NaCl solution, test period 1 year)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com