Coating composition

A composition and coating technology, which is applied in the field of corrosion resistance, corrosion resistance, and certain temperature resistance coatings, and can solve problems such as complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

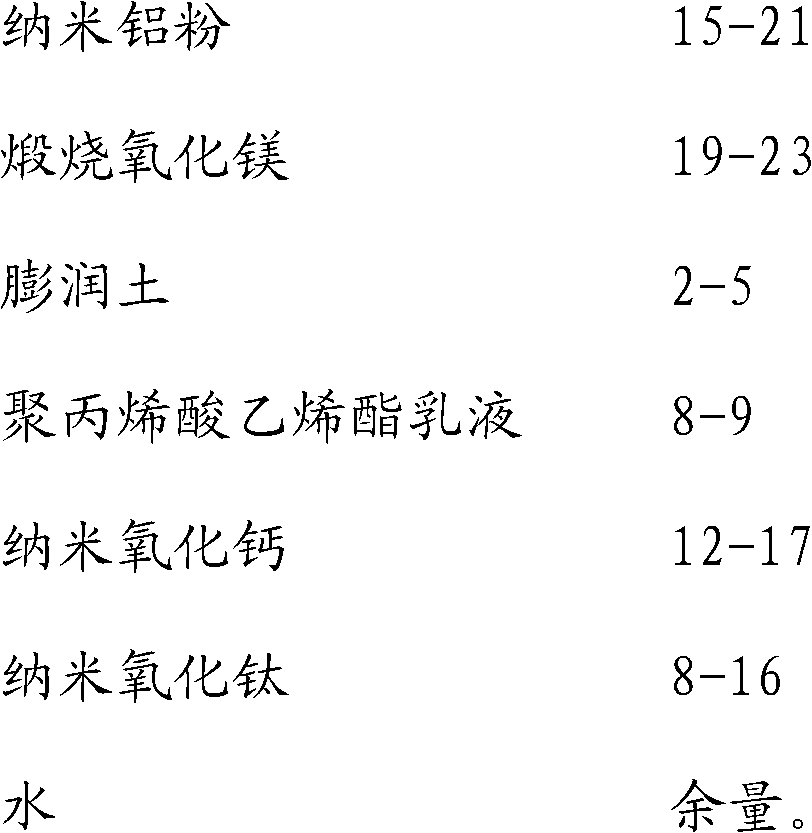

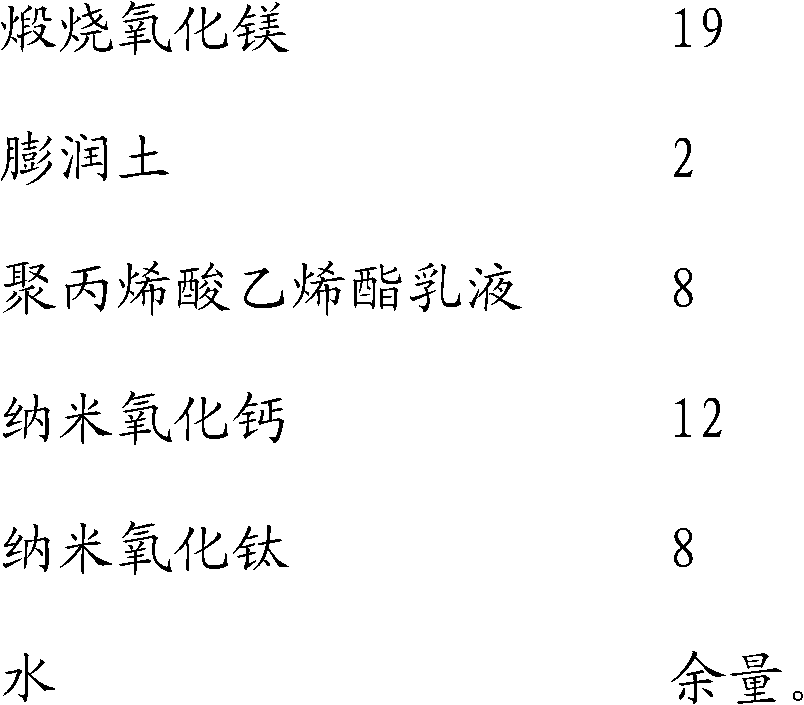

Embodiment 1

[0016] Prepare the coating as follows

[0017]

[0018] Apply the above paint on A3 steel, investigate the high temperature resistance performance at 1500 degrees Celsius and test its corrosion resistance effect in 3% NaCl solution, the results are as follows:

[0019]

[0020] The coating of the present invention has outstanding anti-corrosion performance, and also has high-temperature resistance, high-temperature resistance and corrosion resistance at the same time, multi-components have achieved a synergistic effect, and the effect played by any single component is greater, and the application surface is wider. widely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com