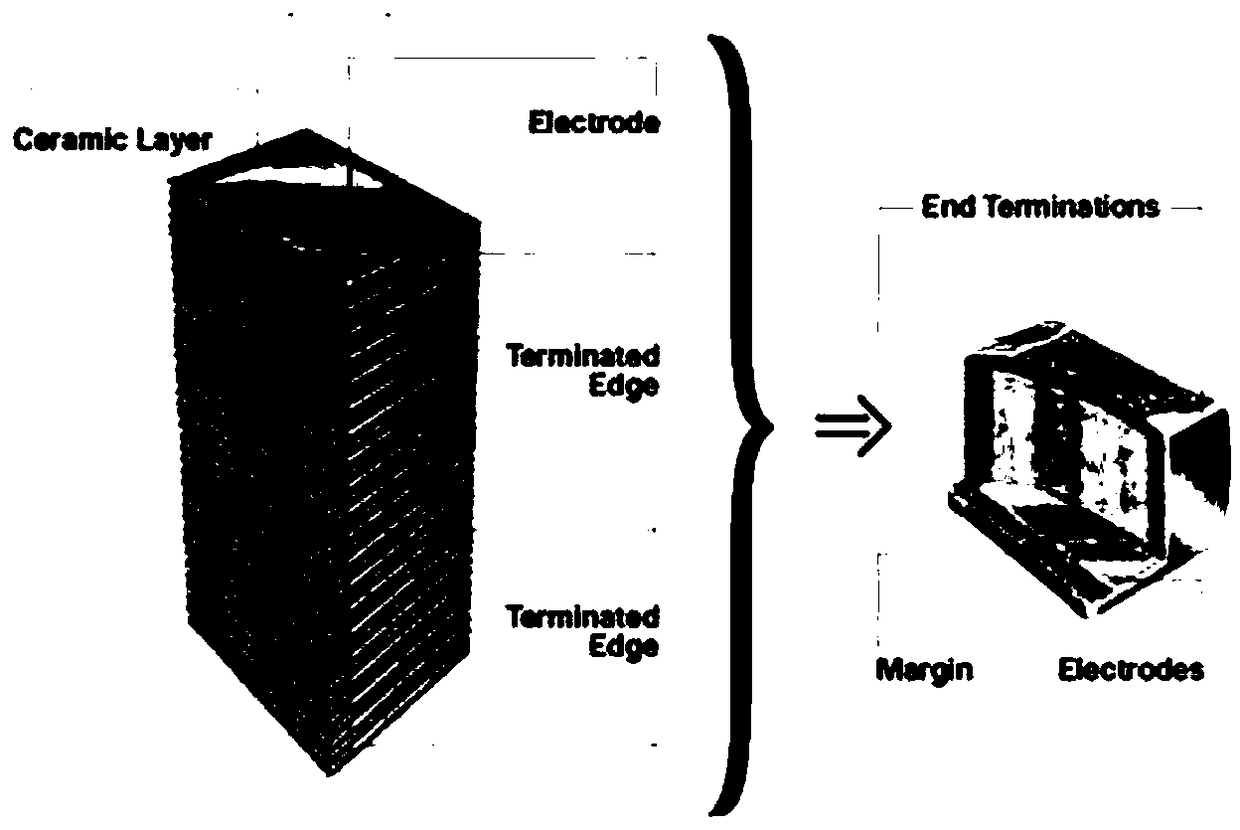

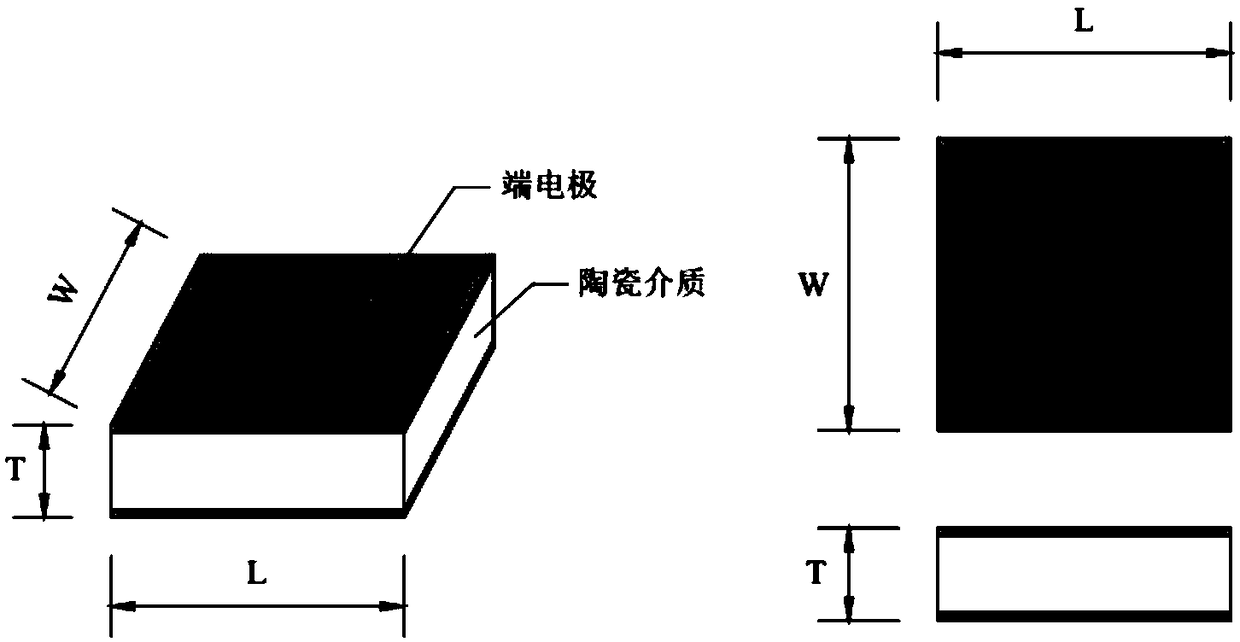

Chip-type through-hole gold electrode chip capacitor and preparation method thereof

An electrode chip and capacitor technology, applied in the direction of multilayer capacitors, fixed capacitor dielectrics, fixed capacitor terminals, etc., can solve the problems of limited microwave circuit application, low internal inductance, high insulation resistance, and avoid mutual diffusion problems and parasitic inductance. Small, high solderability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

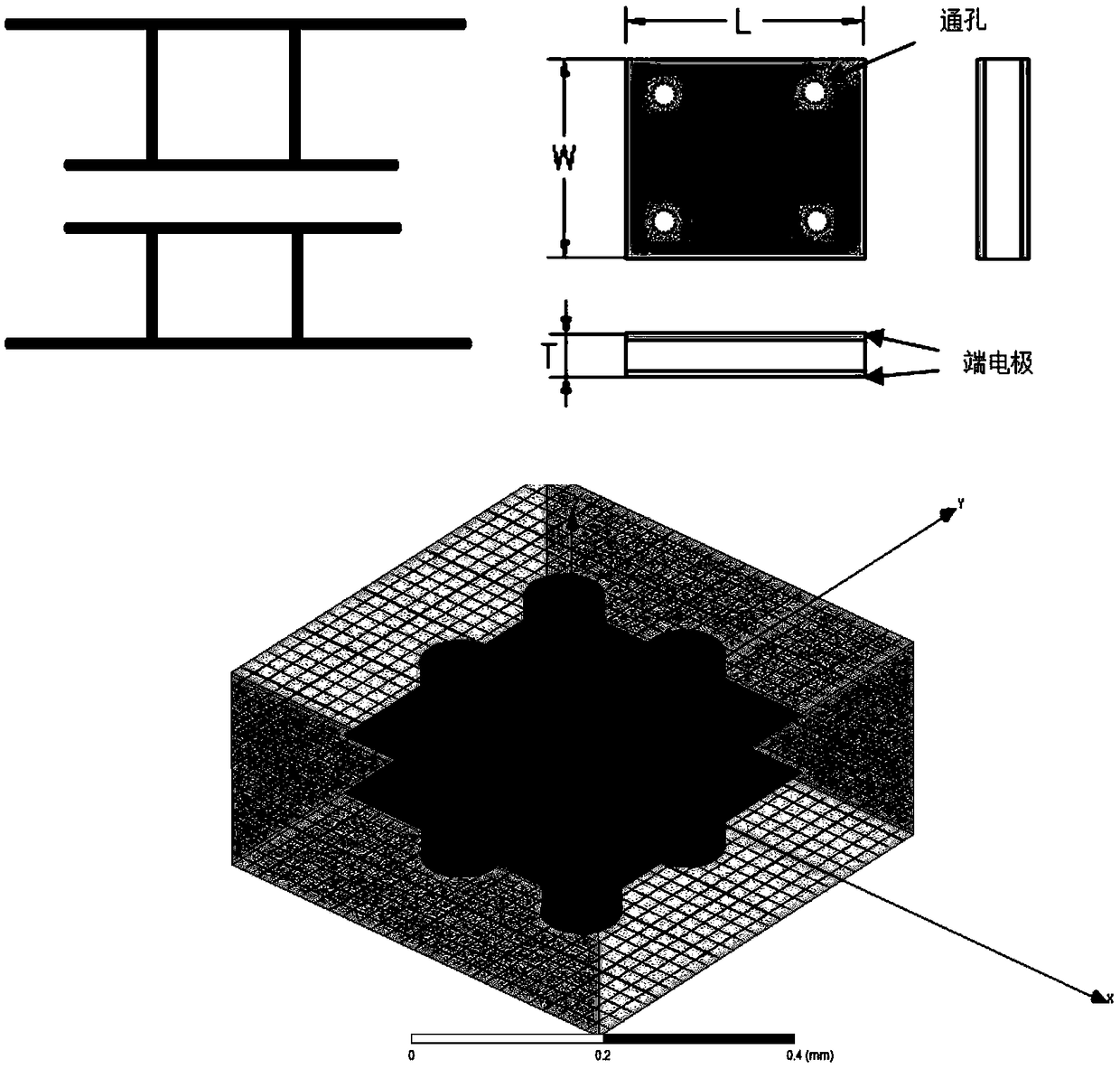

[0040] 1) Preparation of Through-hole Chip Gold Electrode Chip Capacitor Products

[0041] Weigh 3000g according to the following raw material proportions, including barium titanate (BaTiO3) 2700g-2960g, niobium pentoxide (Nb2O5) 10g-45g, neodymium oxide (Nd2O3) 15g-30g, calcium carbonate (CaCO3) 20g-25g, Silicon (SiO2) 3g-4.5g, manganese carbonate (MnCO3) 3g, zinc oxide (ZnO) 2g-5g, boric acid (H2BO3) 10g-50g, zinc borosilicate glass (by mass percentage, ZnO: 65%; B 2 o 3 : 25%; SiO 2 : 10%) 20g ~ 100g. The purity of the above raw materials are analytically pure. After the above powders are weighed separately, they are sand-milled and mixed, dried and placed in a high-temperature box furnace for pre-firing treatment, sprayed and pulverized to make ceramic medium porcelain materials, and then prepared by batching, casting, and cutting into a porcelain diaphragm.

[0042] Taking the product design of CT0505052X101M3X as an example, first prepare the special through-hole st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com