A kind of multilayer gold electrode chip capacitor and its preparation method

A technology of electrode chips and multi-layer chips, which is applied in the field of capacitors to achieve the effects of reducing installation space, avoiding high temperature oxidation, and avoiding silver migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

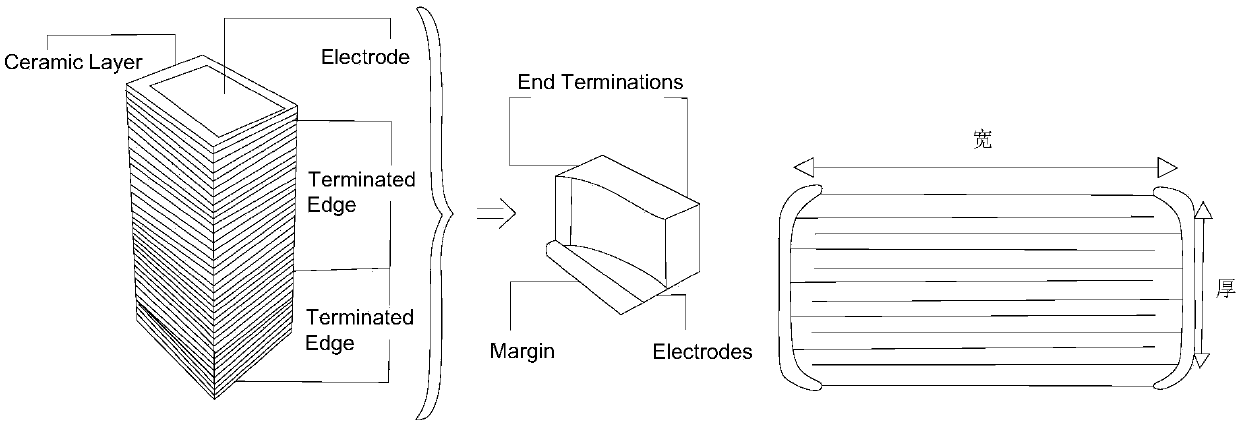

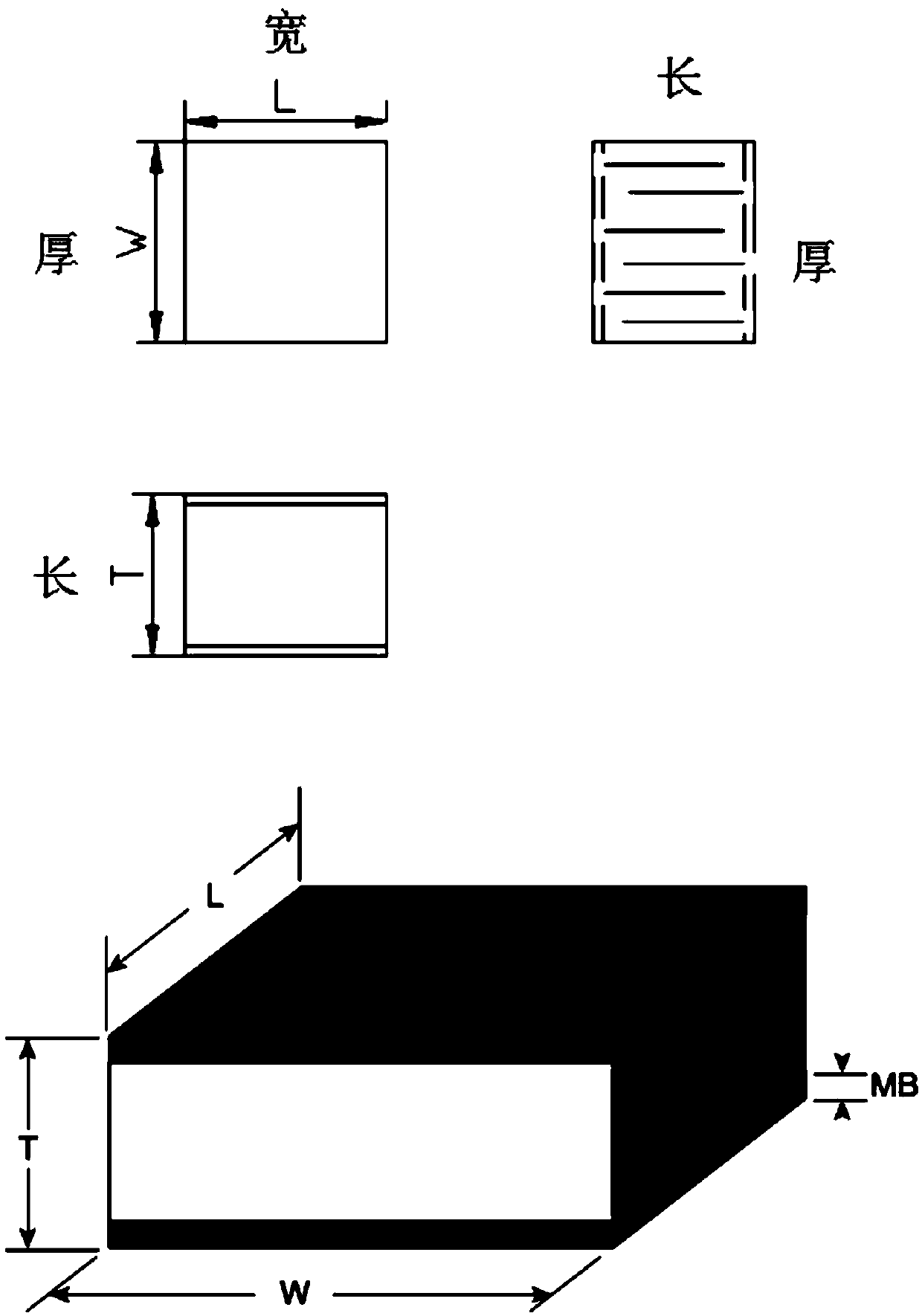

[0024] refer to Figure 1 to Figure 5 , a method for preparing a chip multilayer gold electrode chip capacitor, comprising:

[0025] Prepare ceramic medium porcelain powder with various raw materials, and then make ceramic medium porcelain powder into green porcelain diaphragm;

[0026] Make internal electrodes made of gold on the green ceramic diaphragm;

[0027] The terminal electrode is prepared by thin film sputtering process;

[0028] Among them, various raw materials are counted in parts by weight, including: 90-110 parts of BaTiO 3 , 0.3-2 parts of Nb 2 o 5 , 0.3~1.5 parts of Nd 2 o 3 , 0.5-1 part of CaCO 3 , 0.1 to 0.5 parts of SiO 2 , 0.1 to 0.5 parts of MnCO 3 , 0.1 to 0.5 parts of ZnO, 0.3 to 2 parts of H 2 BO 3 And 0.5~4 parts of ZnO-B 2 o 3 -SiO 2 Glass.

[0029] In the embodiment of the present invention, a variety of raw materials are used to prepare ceramic medium porcelain powder, and then the ceramic medium porcelain powder is made into a green...

Embodiment 1

[0045] This embodiment provides a chip capacitor with multilayer gold electrodes, which is prepared by the following method:

[0046] The ground and dispersed slurry formed by sand grinding and mixing various raw materials is spray-dried, and the dried mixture is pre-fired at a temperature of 500 °C and kept for 1.5 hours to obtain ceramic medium porcelain powder, and then the ceramic Dielectric porcelain powder, absolute ethanol, dispersant, defoamer and PVB are used to make a slurry, and the slurry is sequentially passed through a casting machine and a cutting machine to obtain a 4-inch green ceramic diaphragm;

[0047] Among them, various raw materials are counted in parts by weight, including: 90 parts of BaTiO 3 , 0.3 part Nb 2 o 5 , 0.3 Nd 2 o 3 , 0.5 parts of CaCO 3 , 0.1 part of SiO 2 , 0.1 part of MnCO 3 , 0.5 parts of ZnO, 0.3 parts of H 2 BO 3 and 0.4 parts of ZnO-B 2 o 3 -SiO 2 Glass. ZnO-B 2 o 3 -SiO 2 The glass is made by adding 70wt% ZnO, 25wt% B...

Embodiment 2

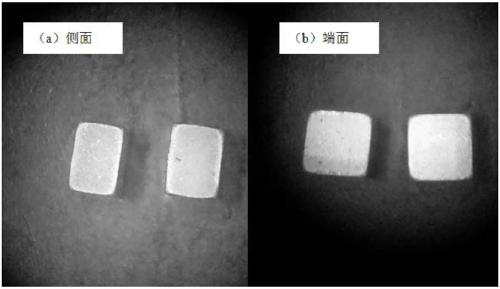

[0052] refer to image 3 , this embodiment provides a chip capacitor with multilayer gold electrodes, which is prepared by the following method. The difference between this method and the method provided in Example 1 is:

[0053] The ground and dispersed slurry formed by sand grinding and mixing various raw materials is spray-dried, and the dried mixture is pre-fired at a temperature of 700°C and kept for 2 hours to obtain ceramic medium porcelain powder, and then the ceramic Dielectric porcelain powder, toluene, dispersant, defoamer and PVB are used to make a slurry, and the slurry is passed through a casting machine and a cutting machine in sequence to obtain a 6-inch green ceramic diaphragm;

[0054] Among them, various raw materials are counted in parts by weight, including: 100 parts of BaTiO 3 , 1 Nb 2 o 5 , 1 Nd 2 o 3 , 0.7 parts of CaCO 3 , 0.3 parts of SiO 2 , 0.4 parts of MnCO 3 , 0.3 parts of ZnO, 1 part of H 2 BO 3 and 2 parts of ZnO-B 2 o 3 -SiO 2 Gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com