Processing and fresh-keeping method for high-quality wet dough

A technology for raw wet noodles and formula, applied in the field of noodle product processing, can solve the problems of short storage shelf life of raw wet noodles, reduced sensory quality of raw wet noodles, and high activity of polyphenol oxidase, and achieves reduction of initial bacterial content and excellent quality. Taste, interaction-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Formula: 100kg of wheat flour, 1.5kg of edible salt, 0.24g of sodium lactate, 1kg of monosodium fumarate, 0.15kg of propylene glycol, 3kg of sorbitol solution, 2.4g of compound phosphate, 40kg of slightly acidic electrolyzed water.

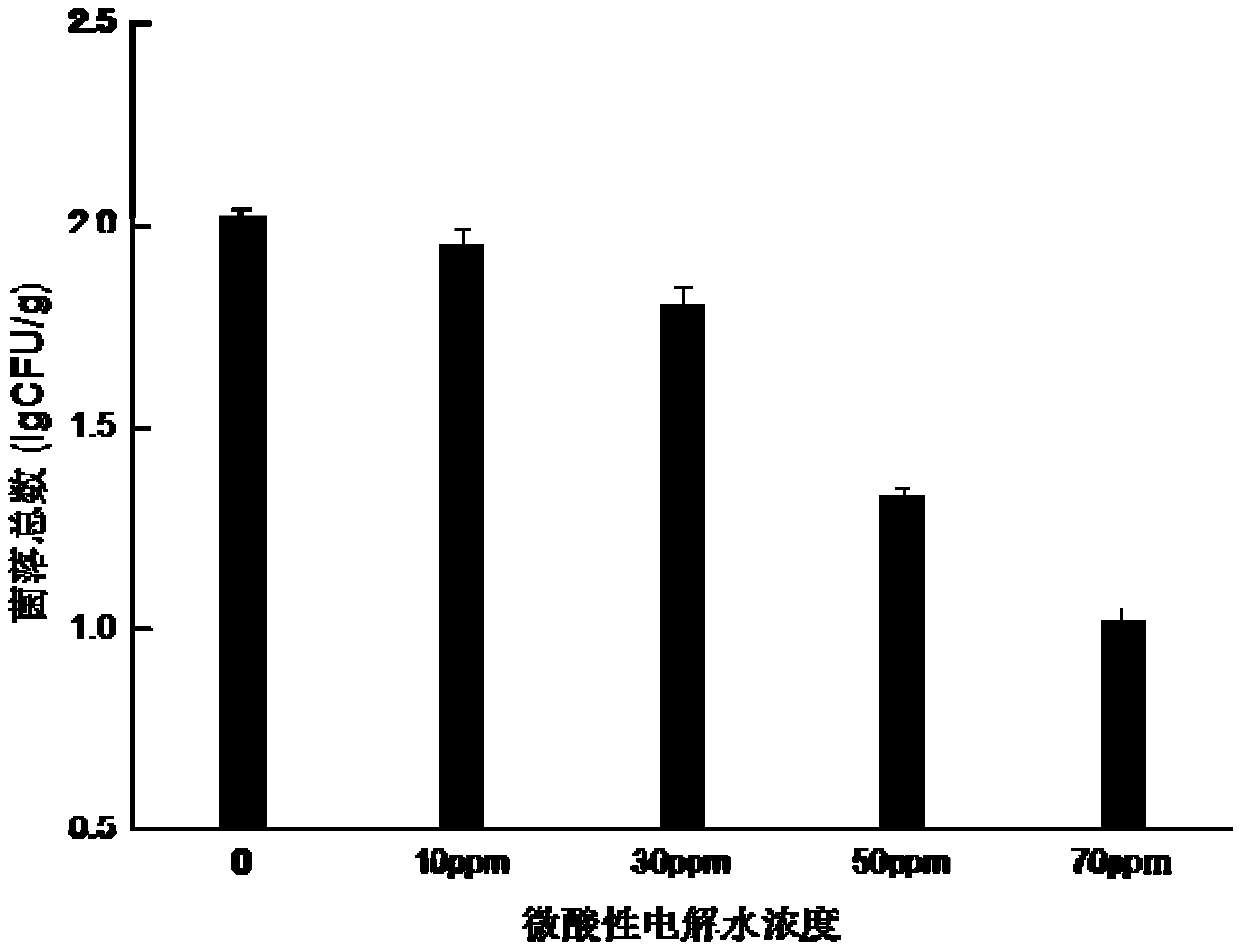

[0044] (1) Vacuum kneading: Add 100kg of high-quality wheat flour into the vacuum kneading machine, add 27kg of 70ppm slightly acidic electrolyzed water required in the mixing mixer, start the stirring device, and then slowly add 1kg of fuma weighed according to the formula requirements Sodium monosodium acid, 0.24g sodium lactate, 0.15kg propylene glycol, 3kg sorbitol solution, 2.4g compound phosphate, 1.5kg edible salt, then add the remaining 13kg70ppm slightly acidic electrolyzed water, stir well and then pump into the vacuum dough kneading machine ; Start the vacuum dough kneading machine, and knead the dough under the condition of a vacuum degree of -0.08Mpa, the kneading time is 5min, and the kneading temperature is 15°C, and the flour...

Embodiment 2

[0054] Formula: 100kg of wheat flour, 1.5kg of edible salt, 0.8kg of monosodium fumarate, 0.04g of sodium lactate, 0.15kg of propylene glycol, 3kg of sorbitol solution, 0.4g of compound phosphate, 33kg of slightly acidic electrolyzed water.

[0055] With reference to Example 1, the formula was replaced by the above formula, and other conditions remained unchanged, and raw wet noodles were prepared.

Embodiment 3

[0057] Formula: 100kg wheat flour, 0.5kg edible salt, 0.5kg monosodium fumarate, 0.12g sodium lactate, 0.05kg propylene glycol, 1.5kg sorbitol solution, 1.2g compound phosphate, 38kg slightly acidic electrolyzed water.

[0058] With reference to Example 1, the formula was replaced by the above formula, and other conditions remained unchanged, and raw wet noodles were prepared.

[0059] The performance test was carried out on the raw and wet noodles obtained in Examples 1-3, and the results are shown in Table 1.

[0060] The quality of table 1 embodiment 1-3 gained raw wet noodle

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com