Candied mango and preparation method thereof

A technology for preserved mango and mango, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of perishable and deteriorated fresh fruit, short storage time of mango, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

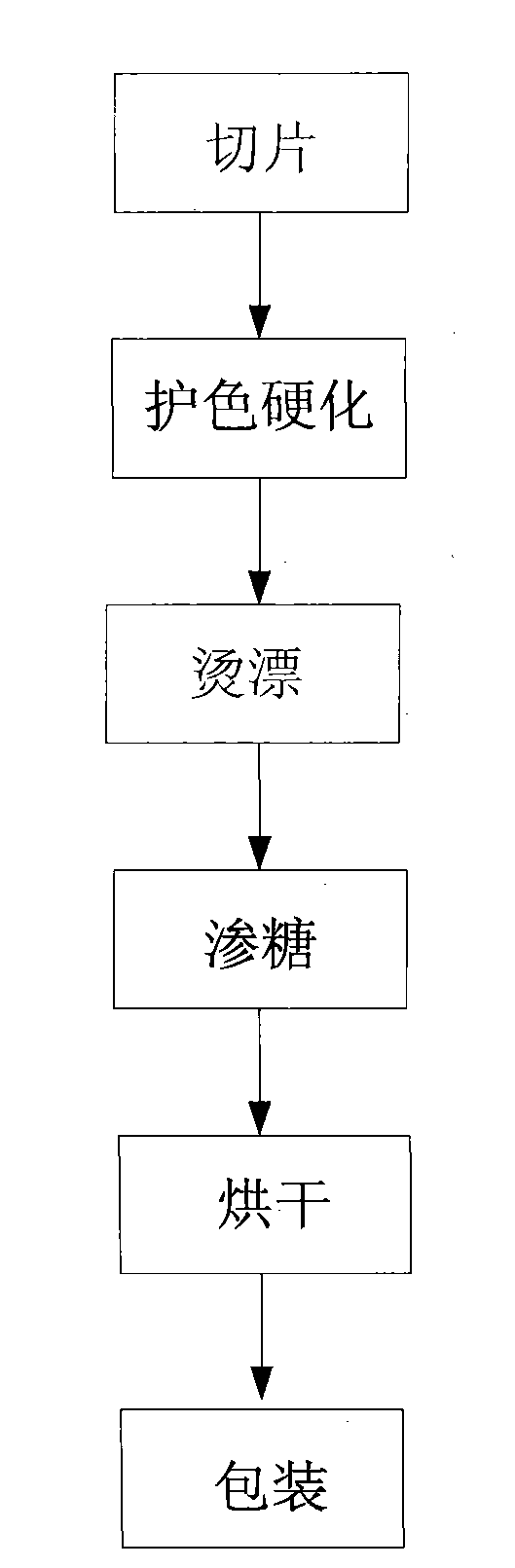

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of preserved mango, which comprises the following operations: (1) slicing: cutting the cleaned, peeled and pitted mango into mango slices with a thickness of 6-8mm; (2) color protection and hardening: Soak the mango slices in a solution containing a color-protecting agent and a hardening agent for 8-16 hours; (3) blanching: heat the mango slices that have completed the color-protecting and hardening at 90-100°C for 3-5 minutes; (4) infiltrate Sugar: Cool the blanched mango slices to 30-40°C and soak them for 48-72 hours in a sugar solution with a mass fraction of 35%-50% sweetener; Drain the sugar solution on the surface of the mango slices and dry them at 45-60°C for 5-7 hours, then dry them at 80-85°C for 2-3 hours; (6) Packing: pack the dried mango slices after shaping .

[0026] In order to prepare preserved mangoes, first select fresh mangoes that are free from mildew and deterioration, pests and diseases, and agricultur...

Embodiment 1

[0035]Select fully ripe fresh mangoes, pick out the rot, deterioration and sundries remaining in the mangoes, clean the residual dirt such as mud and sand on the mangoes, and then peel them. Cut the peeled mango in half and remove the core. Afterwards, the pitted pulp is cut into 6-8mm thick mango slices, and the length of the mango slices is generally cut into 7-10cm. Soak the mango slices in a solution with a mass fraction of 0.3‰ of sodium chloride, 0.2‰ of sodium metabisulfite and 0.5‰ of calcium chloride for 16 hours to protect and harden the mango slices. After the color protection and hardening are completed, place the mango slices in a jacketed pot and heat for 3-5 minutes at a temperature of 90-100°C. The heated mango slices were cooled to 30°C, and then soaked in a sugar solution with a mass fraction of 35% sweetener for 72 hours to further increase the sugar content in the mango slices, wherein the sweetener used was white sugar. After soaking for 72 hours, take o...

Embodiment 2

[0037] Select fresh mangoes with a ripeness of nine, pick out the rot, deterioration and sundries remaining in the mangoes, clean the remaining dirt such as mud and sand on the mangoes, and then peel them. Cut the peeled mango in half and remove the core. Afterwards, the pitted pulp is cut into 6-8mm thick mango slices, and the length of the mango slices is generally cut into 7-10cm. Soak the mango slices in a solution with a mass fraction of 0.4‰ of sodium chloride, 0.3‰ of sodium metabisulfite, and 0.4‰ of calcium chloride for 12 hours to protect the color and harden the mango slices. After the color protection and hardening are completed, place the mango slices in a jacketed pot and heat for 3-5 minutes at a temperature of 90-100°C. Cool the heated mango slices to 35°C, and then soak them in a sugar solution with a mass fraction of 40% sweetener for 60 hours to further increase the sugar content in the mango slices, wherein the sweetener used is fructose syrup . After so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com