Production process for family laver puff pastry

A production process, seaweed technology, applied in the direction of dough processing, baking, baked food, etc., can solve the problems of single product sales channels, single product form, etc., and achieve the effect of good taste, rich nutrition, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

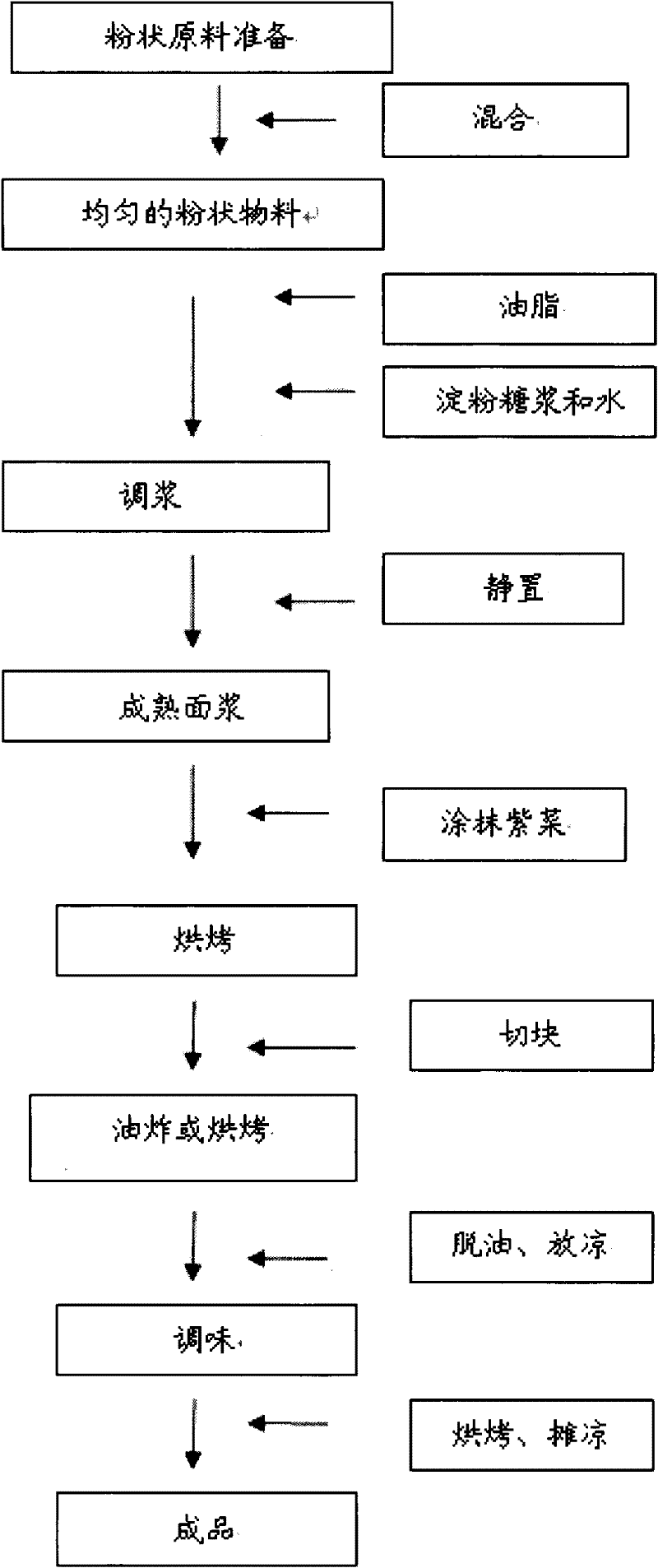

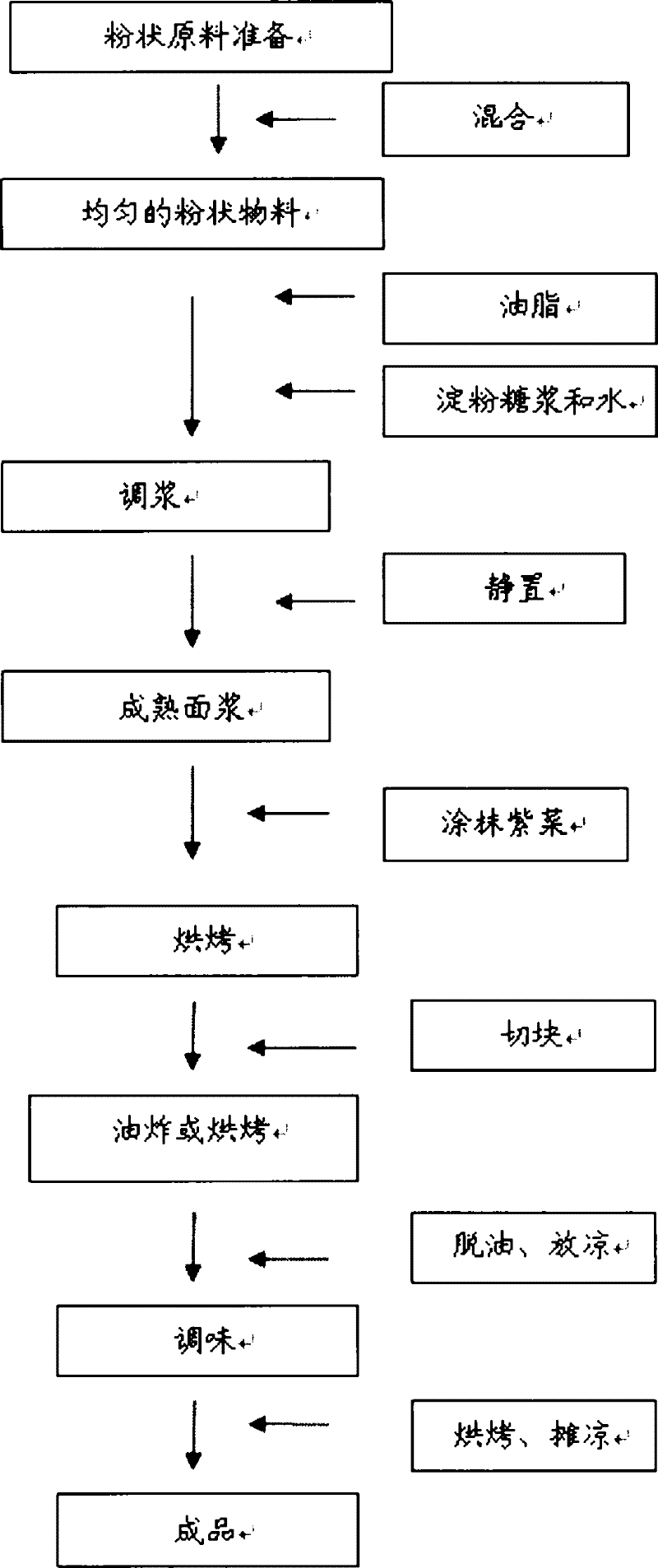

Method used

Image

Examples

Embodiment Construction

[0012] The first is the selection of seaweed raw materials, mainly dry laver flakes, dry laver fragments; ingredients, in the preparation process of noodle paste, the content ratio of raw materials is: low-gluten wheat flour 0.1-2%, wheat starch 0.1-10% , corn starch 1-30%, potato starch 0.1-10%, protein powder 0.1-5%, baking powder 1-5%, starch syrup 0.1-10%, salt 0.1-3%, corn germ oil, rice bran oil, Soybean oil or peanut oil, etc. 2-10%; powdery material mixed powder, low-gluten wheat flour, wheat starch, corn starch and other solid powders are mixed evenly first; mixed with oil, flour is first mixed with vegetable oil, and vegetable oil is mixed with flour evenly ; Slurry mixing, the flour mixed evenly with vegetable oil, water, and starch syrup are adjusted to make a dough slurry, and placed at 0-40°C for 10-100 minutes; Smearing, the flour slurry is applied to the surface of dried seaweed with a thickness of 3-5 mm; baked Bake, bake the seaweed after smearing the batter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com